What is a panel bender, and what are its applications?

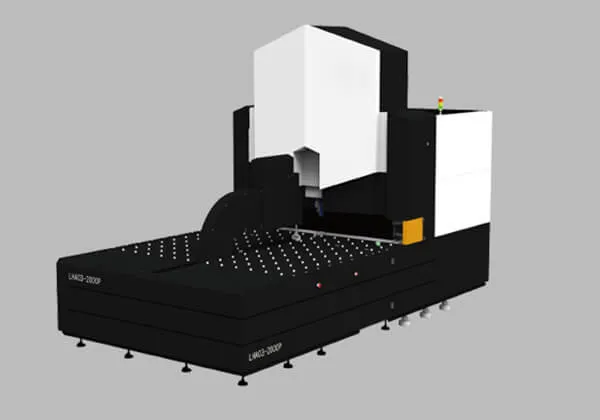

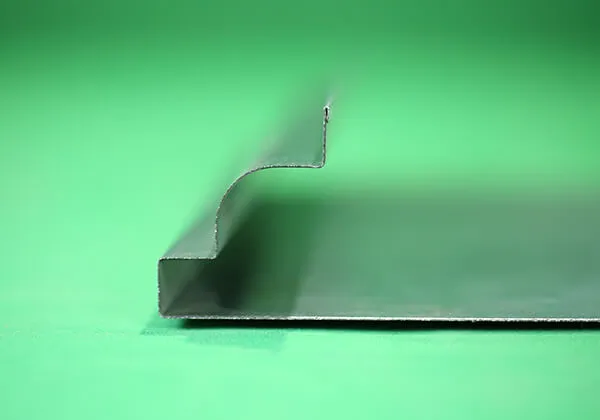

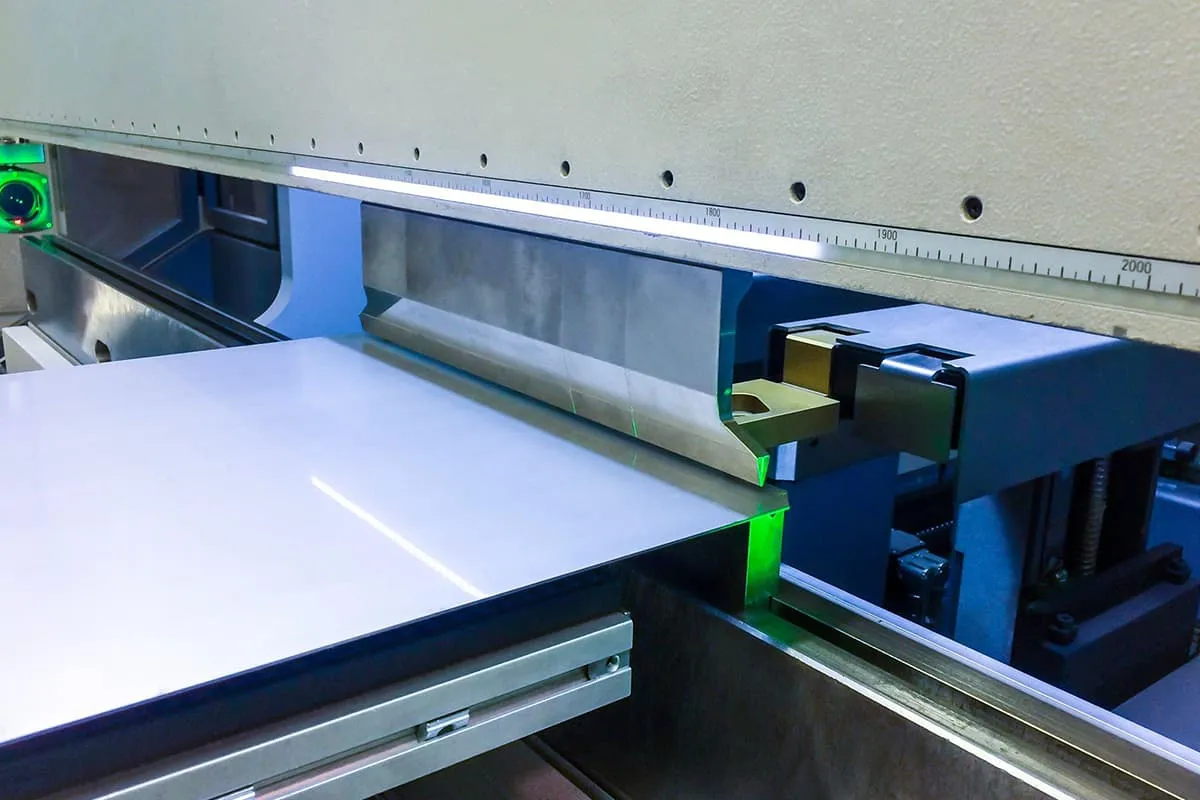

A panel bender is a machine tool used for bending and forming metal sheets. It can perform precise bending operations on metal sheets of various thicknesses and materials. Panel benders are widely used in the manufacturing of metal enclosures for industries such as machine casings, elevators, home appliances, and advertising. Using a panel bender can significantly improve production efficiency, product accuracy, and reduce labor costs.

What are the advantages of a panel bender compared to traditional bending machines?

Compared to traditional bending machines, panel benders offer the following advantages:

- Higher degree of automation, making operation more convenient

- Quicker and easier die changeovers, resulting in higher production efficiency

- Higher bending precision and more consistent product quality

- Ability to process larger sizes and more complex workpiece shapes

- Wider range of die types available, making it suitable for more applications

What are the bending length and thickness ranges of a panel bender?

The processing capabilities of panel benders vary depending on the specific model. Generally, the bending length can range from 200 to 4000mm, and the bending thickness can range from 0.4 to 3mm. We can recommend a suitable model based on the customer's specific requirements.

How is the quality and after-sales service of your company's panel benders?

We have many years of experience in manufacturing panel benders, and our product quality and stability are industry-leading. Before leaving the factory, each machine undergoes rigorous quality inspections and long-term testing to ensure exceptional performance. We provide a one-year warranty for the entire machine, during which we offer free on-site repairs and parts replacement. After the warranty period, we also provide lifetime maintenance services and after-sales technical support. Customer satisfaction is our service tenet.