Imagine a material that combines remarkable durability with impressive resistance to corrosion, all while maintaining a sleek and polished appearance. This is the essence of 3Cr14 stainless steel, a versatile alloy that plays a crucial role in various industries. But what exactly makes 3Cr14 stainless steel so special? By delving into its chemical composition and examining its physical and mechanical properties, we can uncover the secrets behind its widespread use. From kitchen appliances and cutlery to industrial applications, this alloy’s unique characteristics make it an invaluable asset. Join us as we explore the intricate details of 3Cr14 stainless steel and discover why it stands out in the world of metallurgy. What properties make it ideal for manufacturing, and how does it compare to other stainless steels? Read on to find out.

Overview

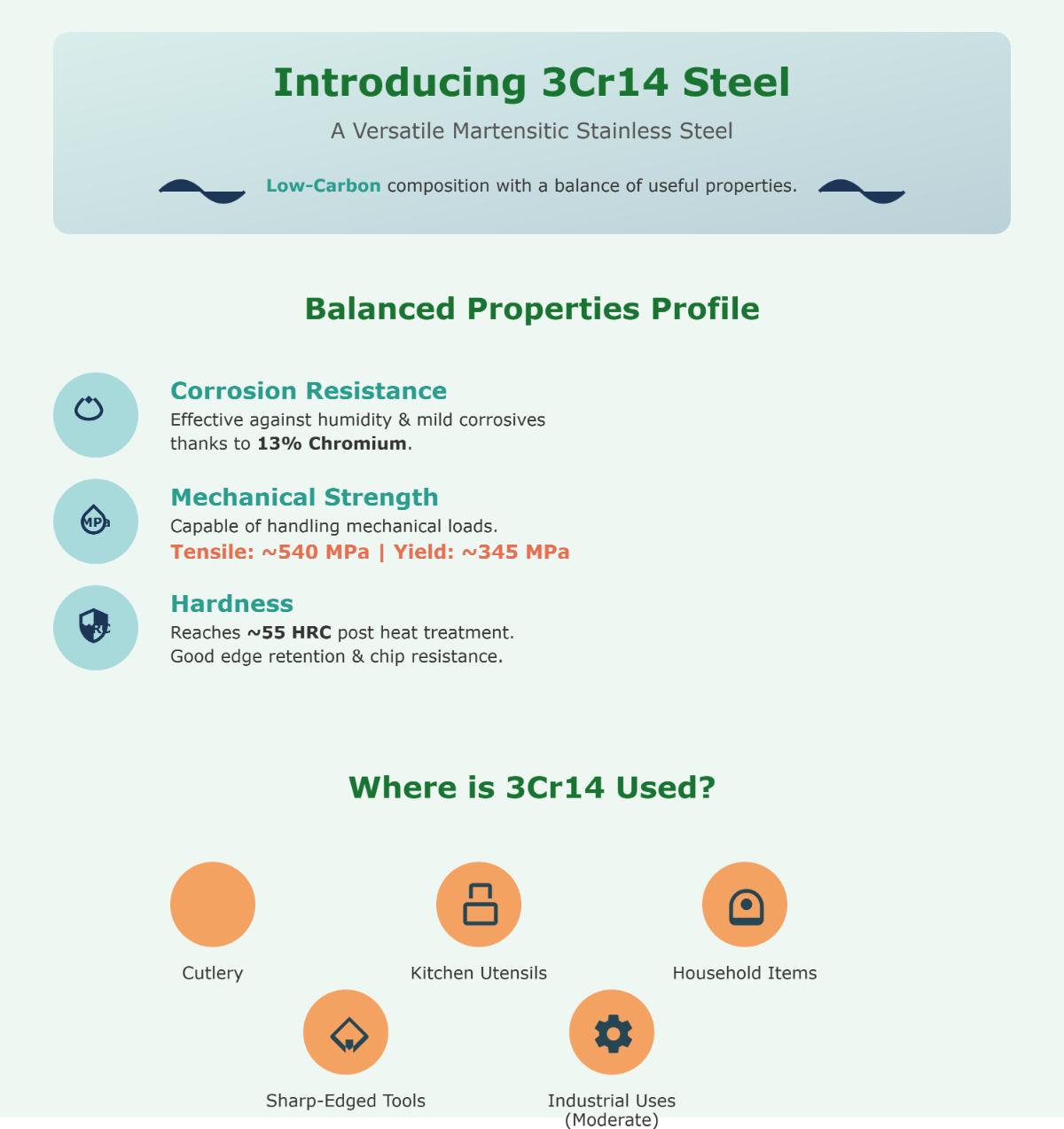

Introduction to 3Cr14 Stainless Steel

3Cr14 stainless steel is a type of martensitic stainless steel with low carbon content, offering a great mix of corrosion resistance, hardness, and strength. This material is widely used in various industrial and consumer applications due to its versatile properties. It belongs to the 420-grade series of martensitic stainless steels, which are characterized by moderate corrosion resistance and hardness.

Key Characteristics

Containing approximately 13% chromium for corrosion resistance, 0.35% carbon for hardness and strength, and about 1% molybdenum to enhance strength and reduce brittleness, 3Cr14 stainless steel is suitable for demanding applications.

Applications and Uses

3Cr14 stainless steel finds applications across a broad spectrum of industries due to its balanced properties. Some common uses include:

- Cutlery and Kitchen Utensils: Its sharp edge retention and corrosion resistance make it perfect for knives, scissors, and other cutting tools.

- Household Items: The material’s durability and resistance to rust make it suitable for various appliances and tools used in domestic environments.

- Industrial Tools: It is employed in the manufacturing of blades, scissors, and components for heavy machinery where moderate toughness and wear resistance are required.

Composition and Properties

3Cr14 stainless steel’s carefully designed composition offers beneficial mechanical and physical properties for various applications. The primary elements include chromium, carbon, and molybdenum, with additional trace elements that may be present. The material exhibits good corrosion resistance, can be hardened to about 55 HRC, and maintains moderate flexibility, making it less brittle compared to higher-carbon steels.

Advantages of 3Cr14 Stainless Steel

- Corrosion Resistance: The chromium content grants the material the ability to withstand rust and corrosion, making it suitable for environments where moisture and oxidation are concerns.

- Hardness and Strength: Through heat treatment, 3Cr14 stainless steel can achieve a good balance of hardness and wear resistance, essential for cutting tools and other applications requiring durability.

- Versatility: Its balanced properties make 3Cr14 stainless steel a reliable and cost-effective choice for both industrial and consumer products.

Chemical Composition of 3Cr14 Stainless Steel

3Cr14 stainless steel is a type of martensitic stainless steel known for its hardness, strength, and corrosion resistance. The chemical composition of 3Cr14 stainless steel is a critical factor that determines its properties and suitability for various applications. Below is a detailed breakdown of the primary elements that make up this alloy:

Carbon (C)

Carbon is present in 3Cr14 stainless steel at approximately 0.35%. This element is crucial for enhancing the hardness and strength of the steel through the formation of carbides. The carbon content allows the material to achieve a high level of hardness after heat treatment, making it ideal for applications requiring wear resistance and edge retention.

Chromium (Cr)

Chromium is the principal alloying element in 3Cr14 stainless steel, comprising about 13% of its composition. Chromium is essential for providing corrosion resistance by forming a passive oxide layer on the surface of the steel, which protects it from rust and oxidation. This element also contributes to the material’s hardness and tensile strength, making it robust and durable.

In addition to Chromium’s crucial role, other elements like Manganese and Silicon further contribute to the steel’s overall properties. Manganese enhances the steel’s toughness and wear resistance, while Silicon improves its strength and helps in deoxidizing the steel during its production process.

Manganese (Mn)

Manganese, present at about 1%, acts as a deoxidizer and improves the steel’s toughness and strength. It enhances the material’s hardness and wear resistance, making it more durable and suitable for various industrial applications.

Silicon (Si)

Silicon, usually around 1%, serves as a deoxidizer and enhances the strength and hardness of the steel. It also helps resist oxidation at high temperatures, ensuring the material maintains its integrity in various environments.

Phosphorus (P) and Sulfur (S)

Phosphorus and Sulfur are kept to a minimum in 3Cr14 stainless steel, usually less than 0.04% and 0.03%, respectively. While these elements can increase strength and machinability, they can also make the steel more brittle. Controlling their content ensures the material maintains good toughness and ductility.

The specific combination of elements in 3Cr14 stainless steel gives it a unique set of properties that make it suitable for various applications. The balanced chemical composition ensures that the material can be heat-treated to achieve high hardness levels while maintaining good corrosion resistance and mechanical strength. The presence of chromium, carbon, and molybdenum, in particular, allows 3Cr14 stainless steel to perform well in environments where both wear resistance and corrosion resistance are critical.

Physical and Mechanical Properties of 3Cr14 Stainless Steel

Physical Properties

Density

3Cr14 stainless steel has a density of approximately 7.75 g/cm³, which is about the same as other common stainless steels. This density contributes to its strength and durability, making it a reliable choice for various applications.

Melting Point

With a melting point around 1450°C (2642°F), 3Cr14 stainless steel can withstand high temperatures without losing its structural integrity. This makes it suitable for applications that involve significant heat exposure.

Thermal Conductivity

The thermal conductivity of 3Cr14 stainless steel is about 25 W/m·K. This means it can conduct heat moderately well, which is useful in situations where heat dissipation is necessary, such as in certain industrial processes.

Mechanical Properties

Tensile Strength

3Cr14 stainless steel boasts a tensile strength of approximately 540 MPa. This high tensile strength indicates its ability to endure substantial stress when being stretched or pulled, making it ideal for load-bearing applications.

Hardness

When properly heat-treated, 3Cr14 stainless steel can achieve a hardness level of around 55 HRC on the Rockwell Hardness scale. The HRC scale measures the material’s resistance to indentation; a higher number means greater hardness. This level of hardness allows 3Cr14 to maintain sharp edges and resist wear, making it perfect for cutting tools and blades.

Ductility

3Cr14 stainless steel has moderate ductility, meaning it can deform under tensile stress without breaking. This is essential for applications requiring the material to be shaped or machined into specific forms.

Corrosion Resistance

Thanks to its chromium content, 3Cr14 stainless steel excels in corrosion resistance. The 13% chromium forms a protective oxide layer on the surface, preventing rust and oxidation. This makes it highly suitable for environments with high moisture levels, such as kitchen utensils and household appliances.

Comparison with Other Materials

3Cr14 stainless steel stands out when compared to other materials used in similar applications:

- Compared to carbon steel: 3Cr14 offers superior corrosion resistance and hardness, making it more suitable for environments where rust is a concern.

- Compared to austenitic stainless steels: While austenitic steels like 304 stainless steel provide higher corrosion resistance, 3Cr14 excels in hardness and edge retention, making it preferable for cutting tools.

- Compared to other martensitic stainless steels: The specific composition of 3Cr14, including its chromium and molybdenum content, offers a balanced combination of hardness, toughness, and corrosion resistance, making it versatile for various applications.

The physical and mechanical properties of 3Cr14 stainless steel, such as density, melting point, thermal conductivity, tensile strength, hardness, ductility, and corrosion resistance, make it a highly valuable material for numerous industrial and consumer applications.

3Cr14 Stainless Steel Uses and Industrial Applications

Overview of Common Applications

3Cr14 stainless steel is widely used due to its excellent balance of hardness, corrosion resistance, and affordability. Its versatility makes it an ideal choice for both consumer products and industrial components.

Manufacturing Processes

Techniques Used in Forming and Shaping

3Cr14 stainless steel can be processed using various techniques to achieve the desired shapes and forms, making it suitable for different applications. Some common manufacturing processes include:

- Forging: This technique involves shaping the steel by applying compressive forces, enhancing its strength and durability. Forging is often used to produce high-strength components such as blades and machinery parts.

- Machining: Due to its moderate hardness, 3Cr14 stainless steel can be machined using conventional methods, including turning, milling, and drilling, which are essential for creating precise components.

- Heat Treatment: Proper heat treatment is crucial for achieving the desired hardness and mechanical properties. The steel undergoes processes such as quenching and tempering to enhance its wear resistance and toughness.

- Welding: Welding 3Cr14 stainless steel can be challenging due to its carbon content, but techniques like TIG welding can effectively join components.

Specific Use Cases

Kitchen Appliances

3Cr14 stainless steel is commonly used in the production of kitchen appliances due to its corrosion resistance and durability. Some typical applications include:

- Cutlery: Knives, forks, and spoons made from 3Cr14 stainless steel maintain sharp edges and resist rust, making them ideal for everyday use.

- Cookware: Pots, pans, and other cooking utensils benefit from the material’s ability to withstand high temperatures and resist corrosion.

- Kitchen Tools: Scissors, peelers, and other kitchen tools made from 3Cr14 stainless steel offer longevity and maintain their functionality over time.

Cutlery

The high hardness and edge retention of 3Cr14 stainless steel make it an excellent choice for cutlery, as it can be sharpened to a fine edge and resists wear. Key attributes include:

- Sharpness: The material can be sharpened to a fine edge, which is essential for cutting tools such as knives and scissors.

- Durability: The steel’s resistance to wear and corrosion ensures that cutlery items remain functional and aesthetically pleasing for extended periods.

- Ease of Maintenance: Cutlery made from 3Cr14 stainless steel is easy to clean and maintain, making it convenient for both household and professional use.

Other Industrial Applications

Beyond household items and cutlery, 3Cr14 stainless steel is ideal for various industrial uses, including heavy machinery components, fasteners, and cutting tools, due to its strength and durability. Some notable uses include:

- Heavy Machinery Components: The strength and wear resistance of 3Cr14 stainless steel make it ideal for parts subjected to high stress and wear, such as gears, shafts, and bearings.

- Fasteners and Hardware: Bolts, screws, and rivets made from 3Cr14 stainless steel offer excellent corrosion resistance and mechanical strength, making them reliable for construction and machinery assembly.

- Blades and Cutting Tools: Industrial blades and cutting tools benefit from the material’s ability to maintain a sharp edge and resist wear, essential for efficient and precise cutting operations.

Case Studies of Industrial Applications

Example 1: Food Processing Equipment

In the food processing industry, 3Cr14 stainless steel is used to manufacture various equipment components, such as blades and cutting surfaces. Its corrosion resistance ensures that the equipment remains hygienic and free from rust, while its hardness allows for efficient and precise cutting of food products.

Example 2: Automotive Parts

3Cr14 stainless steel is employed in the automotive industry for producing components such as valve parts and pump shafts. The material’s strength and wear resistance ensure that these parts can withstand the harsh operating conditions within an engine, contributing to the vehicle’s overall durability and performance.

Comparisons with Other Stainless Steels

Comparison of Chemical Composition

Understanding the chemical composition of different stainless steels is essential for identifying their unique properties and applications. Here, we compare the chemical makeup of 3Cr14 stainless steel with other commonly used stainless steels.

3Cr14 Stainless Steel

- Chromium (Cr): 13%

- Carbon (C): 0.35%

- Molybdenum (Mo): 1%

- Other Elements: Small amounts of manganese, silicon, phosphorus, and sulfur

304 Stainless Steel

- Chromium (Cr): 18%

- Nickel (Ni): 8-10%

- Carbon (C): Low carbon content

- Other Elements: Small amounts of manganese and silicon

316 Stainless Steel

- Chromium (Cr): 16.5-18.5%

- Nickel (Ni): 10-13%

- Molybdenum (Mo): 2-3%

- Other Elements: Small amounts of manganese and silicon

309/310 Stainless Steel

- Chromium (Cr): 22-25%

- Nickel (Ni): 19-22%

- Other Elements: Small amounts of manganese and silicon

Comparison of Physical and Mechanical Properties

The physical and mechanical properties of stainless steels vary significantly based on their composition, affecting their suitability for different applications.

Tensile Strength

Tensile strength is a crucial factor in determining the durability and load-bearing capacity of stainless steel.

- 3Cr14 Stainless Steel: Approximately 540 MPa

- 304 Stainless Steel: 515-750 MPa

- 316 Stainless Steel: 515-750 MPa

- 309/310 Stainless Steel: Similar to 304 and 316

Hardness

Hardness affects the wear resistance and ability of stainless steel to maintain sharp edges.

- 3Cr14 Stainless Steel: Can achieve around 55 HRC through heat treatment

- 304 Stainless Steel: Generally lower hardness, suitable for applications requiring good formability

- 316 Stainless Steel: Moderate hardness, enhanced corrosion resistance due to molybdenum

- 309/310 Stainless Steel: High heat resistance, moderate hardness

Corrosion Resistance

Corrosion resistance determines the suitability of stainless steel for various environments, particularly those involving moisture or corrosive substances.

- 3Cr14 Stainless Steel: Moderate corrosion resistance, suitable for applications where sharp edges and wear resistance are crucial

- 304 Stainless Steel: Excellent general corrosion resistance, widely used in kitchenware and architectural applications

- 316 Stainless Steel: Superior corrosion resistance, particularly in marine environments due to molybdenum

- 309/310 Stainless Steel: Excellent high-temperature oxidation resistance, suitable for furnace components and heat exchangers

Comparison of Uses

Different stainless steels are chosen based on their specific properties, making them suitable for various applications.

3Cr14 Stainless Steel

- Primary Uses: Kitchen utensils, cutlery, sharp-edged tools

- Strengths: High hardness, good edge retention, moderate corrosion resistance

- Specific Examples: Chef’s knives, hunting knives, and precision cutting tools

304 Stainless Steel

- Primary Uses: Kitchen utensils, cookware, architectural features

- Strengths: Excellent corrosion resistance, good formability

- Specific Examples: Sinks, pots and pans, and outdoor sculptures

316 Stainless Steel

- Primary Uses: Marine hardware, chemical processing equipment, medical implants

- Strengths: Superior corrosion resistance, especially in chloride environments

- Specific Examples: Boat fittings, chemical tanks, and surgical instruments

309/310 Stainless Steel

- Primary Uses: Furnace components, heat exchangers, petrochemical equipment

- Strengths: High heat resistance, ability to maintain mechanical properties at elevated temperatures

- Specific Examples: Furnace linings, heat exchanger tubing, and refinery equipment

The comparison of 3Cr14 stainless steel with other stainless steels highlights its unique combination of hardness, edge retention, and moderate corrosion resistance, making it ideal for sharp-edged tools and kitchen utensils. In contrast, other stainless steels like 304 and 316 are preferred for their superior corrosion resistance and versatility in various environments, while 309/310 are chosen for applications requiring high-temperature stability.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the properties and applications of 3Cr14 stainless steel?

3Cr14 stainless steel is a low-carbon martensitic stainless steel. It offers a balanced combination of properties, including good corrosion resistance due to its 13% chromium content, making it suitable for humid or mildly corrosive environments. With a tensile strength of approximately 540 MPa and yield strength around 345 MPa, it can endure mechanical stresses. After heat treatment, it can reach a hardness of near 55 HRC, providing a good balance between sharpness retention and resistance to chipping. Applications include cutlery, kitchen utensils, household items, sharp – edged tools, and some industrial uses where moderate corrosion resistance and strength are required.

How is 3Cr14 stainless steel used in manufacturing?

3Cr14 stainless steel is extensively utilized in manufacturing due to its balanced properties of corrosion resistance, hardness, and machinability. It is predominantly used in the production of cutlery and kitchen utensils, where its ability to be heat treated to a high hardness ensures durability and sharp edges. This makes it ideal for knives, scissors, and other kitchen tools.

Additionally, 3Cr14 stainless steel is favored for household and utility items because it resists rust and can be easily machined. This includes everyday objects and general-purpose tools that require moderate wear resistance and durability. In the industrial sector, it is used for precision components and tools, such as blades, surgical instruments, and automotive parts, where precise machining and moderate toughness are essential.

The steel’s properties also make it suitable for manufacturing blades and razors, particularly in applications where corrosion resistance is prioritized over maximum hardness, such as in eyebrow razors and certain marine applications.

What makes 3Cr14 stainless steel suitable for cutlery?

3Cr14 stainless steel is particularly suitable for cutlery due to its balanced composition and properties. It contains approximately 13% chromium, which provides significant corrosion resistance by forming a protective oxide layer on the surface. This characteristic is essential for cutlery as it ensures durability and longevity, even when exposed to moisture and acidic substances from food. Additionally, the presence of about 0.35% carbon in 3Cr14 stainless steel contributes to its hardness and strength, which are critical for maintaining sharp edges over time. This steel can be heat-treated to achieve a hardness of around 55 HRC, making it ideal for sharp-edged tools like knives and scissors. The inclusion of 1% molybdenum further enhances corrosion resistance and reduces brittleness. Moreover, the martensitic structure of 3Cr14 allows for good machinability, facilitating the production of complex shapes required for various cutlery designs.

How does 3Cr14 stainless steel compare to other stainless steels?

3Cr14 stainless steel is a low-carbon martensitic stainless steel characterized by its high hardness and good corrosion resistance, making it suitable for applications that require sharp edges and durability, such as cutlery and kitchen utensils. When compared to other stainless steels, 3Cr14 stands out for its specific composition and properties:

- Composition: 3Cr14 contains approximately 13% chromium, 0.35% carbon, and 1% molybdenum. The inclusion of molybdenum enhances its strength and reduces brittleness, which is crucial for applications requiring high durability.

- Properties: 3Cr14 offers a tensile strength around 540 MPa and a yield strength about 345 MPa. Its hardness can be elevated to around 55HRC through heat treatment, making it ideal for sharp tools and blades.

- Uses: This steel is commonly used in the production of kitchen utensils, cutlery, and other sharp-edged tools due to its hardness and corrosion resistance.

In comparison:

- 314 Stainless Steel is optimal for high-temperature applications due to its high oxidation resistance, thanks to its higher chromium (23-26%) and nickel (19-22%) content.

- 304 Stainless Steel is widely used in various industries for its excellent corrosion resistance and versatility, containing 18-20% chromium and 8-12% nickel.

While 3Cr14 is preferred for applications requiring high hardness and edge retention, 314 and 304 stainless steels are chosen for their superior corrosion resistance and performance in different environments.

What are the corrosion resistance capabilities of 3Cr14 stainless steel?

3Cr14 stainless steel is a martensitic stainless steel renowned for its high corrosion resistance. This is primarily due to its composition, which includes approximately 13% chromium, 0.35% carbon, and 1% molybdenum. The chromium content helps form a passive layer on the steel’s surface, protecting it from oxidation and corrosion. The addition of molybdenum further enhances its resistance to pitting and crevice corrosion, making it suitable for applications in harsh environments.

3Cr14 stainless steel performs well in general corrosion scenarios and offers excellent protection against rust and environmental degradation. Its resistance capabilities are particularly beneficial in industrial applications such as kitchen utensils, cutlery, and tools, where both strength and corrosion resistance are crucial. Compared to other stainless steels like 3Cr13 and 304, 3Cr14 provides better strength and corrosion resistance, especially in environments that require durability against specific corrosive agents.