When it comes to selecting the perfect steel for your project, understanding the subtle yet significant differences between various grades is crucial. Enter 4110 and 4116 steel—two popular choices renowned for their unique properties and diverse applications. But what exactly sets them apart? Is one better suited for corrosion resistance, or does one boast superior hardness? This article dives deep into the intricacies of these two steel types, comparing their chemical composition, mechanical properties, and real-world performance. By the end, you’ll have a clear understanding of which steel is the better fit for your specific needs and applications. So, which steel will come out on top? Let’s find out.

Overview of 4110 Steel

1.4110 steel, also known as EN X55CrMo14, is a type of stainless steel with high chromium content, which provides excellent corrosion resistance and hardness. The chemical composition of 1.4110 steel includes:

- Carbon (C): 0.48-0.60%

- Chromium (Cr): 13.0-15.0%

- Molybdenum (Mo): 0.50-0.80%

- Manganese (Mn): Maximum 1.0%

- Silicon (Si): Maximum 1.0%

- Phosphorus (P): Maximum 0.04%

- Sulfur (S): Maximum 0.03%

These elements work together to provide a balance of hardness, durability, and corrosion resistance, making 1.4110 steel highly suitable for demanding applications.

Mechanical Properties

1.4110 steel has significant mechanical properties, making it a preferred material in various industries, such as:

- Young’s Modulus: ~190 GPa (28 x 10^6 psi) for stiffness.

- Elongation at Break: 11% to 14% for ductility.

- Fatigue Strength: 250 to 730 MPa (36 to 110 ksi) for cyclic loading resistance.

These properties ensure that 1.4110 steel can maintain structural integrity under stress and resist deformation.

Common Applications

Thanks to its superior corrosion resistance and hardness, 1.4110 steel is widely used in applications that require high durability and performance, such as:

- Cutlery: Its ability to maintain a sharp edge and resist wear makes it ideal for premium knives and kitchen tools.

- Tools: The hardness and toughness of 1.4110 steel make it suitable for various hand tools and industrial equipment.

- Medical Instruments: Its biocompatibility and corrosion resistance are advantageous for surgical tools and medical devices.

Advantages and Disadvantages

While 1.4110 steel offers high corrosion resistance, hardness, and durability, it has some drawbacks: Machinability can be challenging due to its hardness, higher costs may impact budget-sensitive projects, and it may lack the flexibility needed for certain applications.

Overview of 4116 Steel

4116 steel, also called X50CrMoV15, is a type of martensitic stainless steel known for its balanced mechanical properties. The chemical composition includes approximately 0.5% carbon, 15% chromium, 1% molybdenum, 0.5% vanadium, and trace amounts of silicon and manganese. These elements contribute to its high corrosion resistance, hardness, toughness, and edge retention, with chromium significantly enhancing its ability to resist moisture and acidic substances.

Mechanical Properties

Hardness and Wear Resistance

4116 steel has a Rockwell hardness rating of 55-57 HRC, providing a good balance between hardness and ease of sharpening. The addition of vanadium and molybdenum enhances wear resistance and edge retention, which, combined with proper heat treatment, ensures long-term performance and reliability. This makes the steel ideal for applications where maintaining a sharp edge is crucial.

Toughness and Durability

One of the standout features of 4116 steel is its toughness and durability. Its balanced composition allows it to withstand rigorous use, making it suitable for professional applications such as high-end kitchen cutlery and surgical instruments. Proper heat treatment further maximizes its mechanical properties, ensuring long-term performance and reliability.

Common Applications

Because of its balanced properties, 4116 steel is used in many different applications:

- Kitchen Cutlery: Its ability to maintain a sharp edge and resist corrosion makes it a preferred choice for high-end knives and kitchen tools.

- Surgical Instruments: The steel’s biocompatibility and corrosion resistance are advantageous for medical devices and surgical tools.

- Tactical Knives: Its toughness and durability make it suitable for tactical and outdoor knives.

Advantages and Disadvantages

Advantages

- Corrosion Resistance: The high chromium content provides excellent protection against rust and corrosion, making 4116 steel ideal for use in moist or acidic environments.

- Balanced Hardness: With a Rockwell hardness rating of 55-57 HRC, 4116 steel offers a good balance between hardness and ease of sharpening.

- Versatility: The steel’s properties make it suitable for a wide range of applications, from kitchen cutlery to surgical instruments and tactical knives.

- Edge Retention: The presence of vanadium improves edge retention, ensuring the steel maintains a sharp edge over time.

Disadvantages

- Frequent Sharpening: Compared to harder steels like D2, 4116 steel may require more frequent sharpening to maintain its edge.

- Long-Term Durability: Although 4116 steel is durable, it might not last as long as higher-end steels like 440C.

Processing and Heat Treatment

Forging 4116 steel needs precise temperature control, usually between 1100°C and 800°C, followed by rapid cooling. Proper heat treatment is crucial to maximize its hardness and performance characteristics. The steel’s composition allows for effective hardening, ensuring optimal mechanical properties for demanding applications.

Stainless Steel Basics

Stainless steel is an alloy made primarily of iron, with at least 10.5% chromium, which forms a protective oxide layer that gives it excellent corrosion resistance. The chromium in stainless steel reacts with oxygen to form a thin, stable layer of chromium oxide, which prevents further corrosion and protects the metal’s internal structure. The addition of other elements such as nickel, molybdenum, and vanadium can further enhance properties like hardness, toughness, and resistance to various forms of wear and corrosion.

One of the hallmark properties of stainless steel is its ability to resist corrosion. This makes stainless steel highly suitable for environments where exposure to moisture and corrosive substances is common. Stainless steel can be heat-treated to enhance its hardness and strength. These properties can vary widely among different grades of stainless steel, making it a versatile material for various applications.

Stainless steel is classified into several types based on its microstructure: austenitic (known for excellent corrosion resistance and weldability), ferritic (magnetic and resistant to stress corrosion cracking), martensitic (can be hardened by heat treatment), and duplex (high strength and excellent resistance to chloride stress corrosion cracking). Each type has distinct characteristics and uses.

Austenitic stainless steels, such as grades 304 and 316, are non-magnetic and are widely used in kitchen appliances, food processing equipment, and chemical containers. Ferritic stainless steels are typically used in automotive applications, industrial equipment, and some kitchen utensils due to their good resistance to stress corrosion cracking. Martensitic stainless steels, including grades 410 and 420, offer high strength and moderate corrosion resistance, making them suitable for cutlery, surgical instruments, and some industrial applications. Duplex stainless steels are used in chemical processing, oil and gas industries, and marine environments due to their high strength and excellent resistance to chloride stress corrosion cracking.

Both 4110 and 4116 stainless steels belong to the martensitic family, known for their ability to be heat-treated to high hardness levels. 4110 steel contains about 14% chromium and 1% molybdenum, offering a good balance of corrosion resistance and toughness. 4116 steel has a similar composition but includes more molybdenum and vanadium, improving hardness, wear resistance, and edge retention.

The unique properties of 4110 and 4116 stainless steels make them ideal for specific uses. 4110 steel is commonly used in food processing tools and applications requiring toughness and moderate hardness. 4116 steel is ideal for high-performance kitchen knives, medical tools, and environments where higher corrosion resistance and edge retention are essential. Understanding the basics of stainless steel and its various types can help in selecting the right material for specific applications, ensuring optimal performance and longevity.

Detailed Comparison: 4110 vs 4116 Steel

The chemical composition of 4110 and 4116 steel plays a crucial role in determining their properties and applications.

Chemical Composition

- 4110 Steel Composition:

- Carbon (C): 0.48-0.60%

- Chromium (Cr): 13.0-15.0%

- Molybdenum (Mo): 0.50-0.80%

- Manganese (Mn): Maximum 1.0%

- Silicon (Si): Maximum 1.0%

- Phosphorus (P): Maximum 0.04%

- Sulfur (S): Maximum 0.03%

- 4116 Steel Composition:

- Carbon (C): ~0.5%

- Chromium (Cr): 14-15%

- Molybdenum (Mo): ~1%

- Vanadium (V): ~0.5%

- Silicon (Si): Trace amounts

- Manganese (Mn): Trace amounts

Mechanical Properties

Both steels exhibit significant hardness, with slight differences: 4110 Steel offers a Rockwell hardness of approximately 56-58 HRC, providing good edge retention and durability. 4116 Steel features a Rockwell hardness of 55-57 HRC, balancing hardness with ease of sharpening. Additionally, 4110 Steel is known for higher tensile strength, typically around 730 MPa, making it suitable for tools and applications where strength is paramount. 4116 Steel has slightly lower tensile strength, yet it is sufficient for cutlery and surgical instruments, providing durability without excessive brittleness.

Flexibility indicates how well the steel can withstand deformation. 4110 Steel has moderate flexibility with elongation at break between 11% to 14%, allowing it to resist fractures under strain. 4116 Steel shows comparable flexibility, making it suitable for applications requiring a balance between toughness and rigidity.

Corrosion and wear resistance are crucial for steels used in environments exposed to moisture and chemicals. 4110 Steel’s high chromium content provides excellent corrosion resistance, making it suitable for food processing and medical tools. It also offers good wear resistance, suitable for tools and industrial applications. 4116 Steel has enhanced corrosion resistance due to higher chromium and molybdenum content, ideal for kitchen cutlery and surgical instruments. Its addition of vanadium provides superior edge retention and durability in demanding applications like tactical knives.

Comparison Table

| Property | 4110 Steel | 4116 Steel |

|---|---|---|

| Carbon Content | 0.48-0.60% | ~0.5% |

| Chromium Content | 13-15% | 14-15% |

| Molybdenum Content | 0.50-0.80% | ~1% |

| Vanadium Content | None | ~0.5% |

| Hardness (HRC) | 56-58 | 55-57 |

| Tensile Strength | ~730 MPa | Slightly lower |

| Corrosion Resistance | High | Very high |

| Wear Resistance | Good | Higher |

Durability in Various Applications

The durability of these steels in various applications highlights their strengths:

- 4110 Steel: Durable in high-stress applications like industrial machinery and heavy-duty tools, maintaining performance under rigorous conditions.

- 4116 Steel: Robust in environments requiring frequent edge maintenance and corrosion resistance, such as kitchen cutlery and medical tools.

Application Areas

Knife Production

Performance of 4110 vs 4116 in Blade Making

In knife production, both 4110 and 4116 steels are popular choices, each offering specific advantages for different applications:

- Edge Retention: 4116 steel, known for its superior edge retention due to higher molybdenum and added vanadium, is popular for high-end kitchen knives where sharpness is crucial. In contrast, 4110 steel offers good edge retention but doesn’t last as long with extended use.

- Corrosion Resistance: Both steels have high chromium content, providing excellent corrosion resistance. However, 4116 steel’s enhanced composition with additional molybdenum makes it more resistant to rust and staining, making it preferable for kitchen environments where exposure to moisture is frequent.

- Ease of Sharpening: 4110 steel is easier to sharpen compared to 4116 steel. This can be beneficial for users who frequently need to maintain their knives, such as chefs or outdoor enthusiasts.

Industrial Applications

Suitability for Machinery and Tools

In industrial applications, the choice between 4110 and 4116 steel depends on the specific requirements of the tools and machinery:

- Durability and Toughness: 4110 steel offers excellent durability and toughness, making it suitable for heavy-duty tools and industrial machinery that undergo significant stress and wear. Its ability to stay strong under tough conditions is a major benefit.

- Corrosion and Wear Resistance: With higher molybdenum content, 4116 steel offers better wear resistance and corrosion protection, making it ideal for tools and machinery in harsh environments. This includes applications in the food processing industry, where hygiene and resistance to corrosive substances are critical.

- Cost-Effectiveness: For cost-sensitive industrial applications, 4110 steel can be a more economical choice. It provides a good balance of properties at a lower cost, making it suitable for general-purpose tools and equipment.

Medical Instruments

Applications in Surgical Tools

4116 steel’s origins in medical-grade applications highlight its suitability for surgical instruments:

- Biocompatibility: The steel’s high corrosion resistance and biocompatibility make it an excellent choice for medical instruments that must remain sterile and free from rust. This includes surgical scalpels, forceps, and other precision tools.

- Edge Retention and Sharpness: The enhanced edge retention of 4116 steel ensures that surgical instruments remain sharp and effective during procedures, reducing the need for frequent re-sharpening and ensuring consistent performance.

Outdoor and Utility Knives

Performance in Field Conditions

For outdoor and utility knives, the performance characteristics of 4110 and 4116 steel are crucial:

- Toughness and Flexibility: 4110 steel’s toughness and moderate flexibility make it suitable for outdoor knives that need to withstand rough use and potential impacts. Its ability to resist chipping and cracking under stress is beneficial for survival and camping knives.

- Ease of Maintenance: 4116 steel’s superior corrosion resistance makes it ideal for outdoor knives used in wet or humid environments. Its edge retention and durability ensure reliable performance over time, even with less frequent maintenance.

- Sharpening Frequency: While 4116 steel offers better long-term edge retention, 4110 steel’s ease of sharpening makes it a practical choice for users who need to quickly restore their knife’s edge in the field.

Food Preparation Tools

Application in Kitchen and Food Processing

Both 4110 and 4116 steels are used in food preparation tools, but their specific properties cater to different needs:

- Stainless Steel Cutlery: 4116 steel is often preferred for high-end kitchen knives and cutlery due to its excellent edge retention, corrosion resistance, and durability. It ensures that knives remain sharp and free from rust, even with frequent exposure to acidic foods and moisture.

- Budget Kitchen Tools: 4110 steel, while still providing good corrosion resistance and edge retention, is more commonly used in budget-friendly kitchen tools. Its cost-effectiveness makes it a suitable choice for mass-produced kitchen knives and utensils.

Real-World Examples and Comparative Testing

When comparing 4110 and 4116 stainless steel, the differences in their compositions, though subtle, significantly impact their performance. Both are primarily iron alloys with chromium and molybdenum additions that enhance corrosion resistance and strength, but 4116 steel includes slightly higher amounts of molybdenum and vanadium, which are crucial for increasing hardness, wear resistance, and edge retention.

| Element | 4110 Steel | 4116 Steel |

|---|---|---|

| Carbon (C) | ~0.50% | 0.45-0.55% |

| Chromium (Cr) | ~14% | 14.0-15.0% |

| Molybdenum (Mo) | ~0.4% | 0.50-0.80% |

| Vanadium (V) | Trace | 0.10-0.20% |

Hardness and Edge Retention

4116 steel typically achieves a hardness of 55-57 HRC, offering a good balance between toughness and edge retention, making it suitable for a variety of cutting tasks. In contrast, 4110 steel, while similar, tends to have slightly less wear resistance and edge retention due to its lower molybdenum and vanadium content. Users and testers have reported that 4116’s edge retention can be comparable to 440C stainless steel, a higher-end steel known for good hardness but less corrosion resistance.

Corrosion Resistance and Practical Usage

Both steels offer excellent corrosion resistance due to their chromium content, but 4116 provides slightly better resistance in wet or humid environments. This makes 4116 a popular choice for kitchen knives and food preparation tools, as well as outdoor knives where rust resistance and ease of sharpening are highly valued. 4110 steel also provides good corrosion resistance but is less commonly used in environments that demand enhanced edge retention and toughness.

Real-World Testing and User Feedback

Practical tests by outdoor gear reviewers have found 4116 knives to be comparable to or better than several common steels used in knives, such as 420HC and 440C, in terms of edge retention and cutting performance. Users report that knives made with 4116 steel can be easily sharpened with basic tools and maintain their sharpness well, making them ideal for field use where frequent edge maintenance might be necessary.

Empirical testing shows that 4116 steel holds up well under typical cutting tasks without chipping, breaking, or rolling edges—common failure modes in knives. On the other hand, 4110 steel knives are less frequently discussed in terms of performance but are considered serviceable for applications that demand less wear resistance.

Heat Treatment and Processing

Both 4110 and 4116 steels respond well to heat treatment, which is crucial for maximizing their mechanical properties. 4116’s composition allows for relatively straightforward processing and heat treatment, resulting in a tough, durable blade suitable for everyday use and professional applications. Proper heat treatment enhances 4116’s hardness and edge retention without compromising its corrosion resistance. 4110 steel, with its simpler alloy balance, is also easy to process but may not reach the same peak hardness or edge performance as 4116.

Comparative Analysis of 4110 vs 4116 Steel

| Feature | 4110 Stainless Steel | 4116 Stainless Steel |

|---|---|---|

| Composition | Slightly lower Mo, no V | Slightly higher Mo, contains V |

| Hardness (HRC) | Moderate, slightly lower | Typically 55-57 HRC, higher |

| Edge Retention | Good but less than 4116 | Comparable to 440C, better wear resistance |

| Corrosion Resistance | Good | Slightly better due to Mo and V |

| Ease of Sharpening | Easy to sharpen | Easy to sharpen |

| Real-World Performance | Suitable for less demanding tasks | Well-suited for kitchen and outdoor knives with good edge retention |

| Typical Applications | General-purpose knives | Food prep, outdoor, medical tools |

While both 4110 and 4116 stainless steels are closely related, 4116 offers enhanced performance in terms of hardness, edge retention, and corrosion resistance due to its increased molybdenum and vanadium content. Real-world comparative testing shows that 4116 steel knives perform reliably against popular mid-range steels, making it a preferred choice for knives requiring a good balance of durability, corrosion resistance, and ease of maintenance. 4110 steel remains a solid, cost-effective option for applications with less demanding requirements.

Cost-Benefit Analysis

Composition and Performance

EN 1.4110 and EN 1.4116 stainless steels are both iron alloys commonly used in various applications, such as cutlery and industrial tools. Despite their similarities in composition, they exhibit distinct differences in performance, influencing their cost-benefit analysis.

EN 1.4110 Stainless Steel

EN 1.4110 stainless steel is characterized by its balanced composition, which offers good corrosion resistance and mechanical properties. Its composition includes approximately 0.48-0.60% carbon, 13-15% chromium, and 0.50-0.80% molybdenum. These elements contribute to its overall strength and durability, although specific performance details compared to 4116 are less documented.

EN 1.4116 Stainless Steel

EN 1.4116 stainless steel has a slightly higher molybdenum content compared to 4110, which enhances its corrosion resistance. It includes 0.45-0.55% carbon, 14-15% chromium, and approximately 1% molybdenum, alongside trace amounts of vanadium. This composition results in better strength and edge retention, often favorably compared to other stainless steels like 440C regarding corrosion resistance and price.

Hardness and Wear Resistance

EN 1.4116 Stainless Steel

EN 1.4116 typically achieves a Rockwell hardness rating of 55-57 HRC, making it suitable for various cutting tasks without significant risk of chipping or breaking, while offering good edge retention.

EN 1.4110 Stainless Steel

The specific hardness ratings for 4110 are not commonly detailed, but given its similar composition to 4116, it likely exhibits comparable hardness properties.

Corrosion Resistance

EN 1.4116 Stainless Steel

With its 15% chromium content, EN 1.4116 provides excellent corrosion resistance, making it ideal for use in humid or wet conditions. This is a significant advantage in applications where rust resistance is crucial.

EN 1.4110 Stainless Steel

EN 1.4110 also offers good corrosion resistance, but the slightly lower molybdenum content may result in marginally less effective protection compared to 4116.

Cost Considerations

EN 1.4116 Stainless Steel

EN 1.4116 is known for its affordability and balance between performance and cost, making it a popular choice for knives due to its ease of sharpening and corrosion resistance. It is generally more economical than high-end stainless steels like 440C.

EN 1.4110 Stainless Steel

Specific pricing data for EN 1.4110 is not readily available, but it is assumed to be comparable to 4116, with both being relatively affordable options for stainless steel applications.

Performance in Practical Use

EN 1.4116 Stainless Steel

EN 1.4116 is praised for being easy to sharpen and maintaining a good edge, making it ideal for users who want knives that can be easily maintained with basic tools. Recent tests have shown it to perform well in tasks such as rope cutting, often comparable to other steels like 420HC and 12C27.

EN 1.4110 Stainless Steel

While EN 1.4110 shares similar composition, specific performance data is less discussed, suggesting that 4116 may have a slight edge in terms of documented performance and user preference.

Comparative Analysis

Both EN 1.4110 and EN 1.4116 stainless steels offer good mechanical properties and corrosion resistance, making them suitable for various applications. However, 4116 is more commonly discussed for its balance of performance, ease of sharpening, and affordability. The slightly higher molybdenum content in 4116 may provide a slight advantage in corrosion resistance, but overall, both steels are cost-effective options depending on specific needs. For users prioritizing ease of maintenance and cost, 4116 appears to be a preferred choice.

Sustainability and Performance Trends

The sustainability of 4110 and 4116 steels largely depends on their compositions. Both steels are iron alloys with chromium and molybdenum as key elements, but 4116 includes additional vanadium, which enhances certain performance characteristics.

Material Longevity

Both 4110 and 4116 steels are known for their durability and long service life. Their high chromium content ensures excellent corrosion resistance, reducing the need for frequent replacements and contributing to sustainability by minimizing waste. The longevity of these materials is crucial in applications where long-term performance is essential, such as in kitchen knives and industrial tools.

Recyclability

Stainless steels, including 4110 and 4116, are fully recyclable. This recyclability is a critical aspect of their sustainability profile. The extra vanadium in 4116 doesn’t affect its recyclability but improves performance, making products last longer and reducing environmental impact.

Performance Trends

Corrosion Resistance

Corrosion resistance is a key performance indicator for both 4110 and 4116 steels. The high chromium content in both steels provides excellent resistance to rust and corrosion, making them suitable for use in environments exposed to moisture and chemicals. However, the higher molybdenum content in 4116 steel offers slightly better corrosion resistance, which is particularly beneficial in kitchen and food preparation tools where hygiene is paramount.

Wear Resistance and Edge Retention

Wear resistance and edge retention are crucial for knives and industrial tools, and the vanadium in 4116 steel enhances these properties, making it ideal for high-performance applications. This improvement means that tools and knives made from 4116 steel can maintain their sharpness and effectiveness over longer periods, reducing the need for frequent sharpening and replacement.

Ease of Processing

How these steels are processed and heat-treated affects their sustainability. 4116 steel is noted for its straightforward processing and heat treatment, which can lead to lower energy consumption during manufacturing cycles. Efficient processing not only reduces costs but also minimizes the environmental footprint of production, making 4116 an attractive option from a sustainability perspective.

Environmental Impact

Producing and using 4110 and 4116 steels impacts the environment. Key factors include resource extraction, energy use, and emissions. Both steels benefit from being part of the stainless steel family, which is known for its lower environmental impact compared to other materials. The enhanced properties of 4116, such as better wear resistance and corrosion resistance, contribute to longer product life cycles, which is beneficial for the environment as it reduces the frequency of replacements and the associated resource consumption.

Innovations and Future Trends

The future trends in the development and use of 4110 and 4116 steels are likely to focus on further enhancing their performance and sustainability. Advances in alloying techniques and heat treatment processes could lead to even better wear resistance, corrosion resistance, and overall durability. Additionally, innovations in recycling processes and the use of renewable energy in production can further reduce the environmental impact of these steels.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the differences between 4110 and 4116 steel?

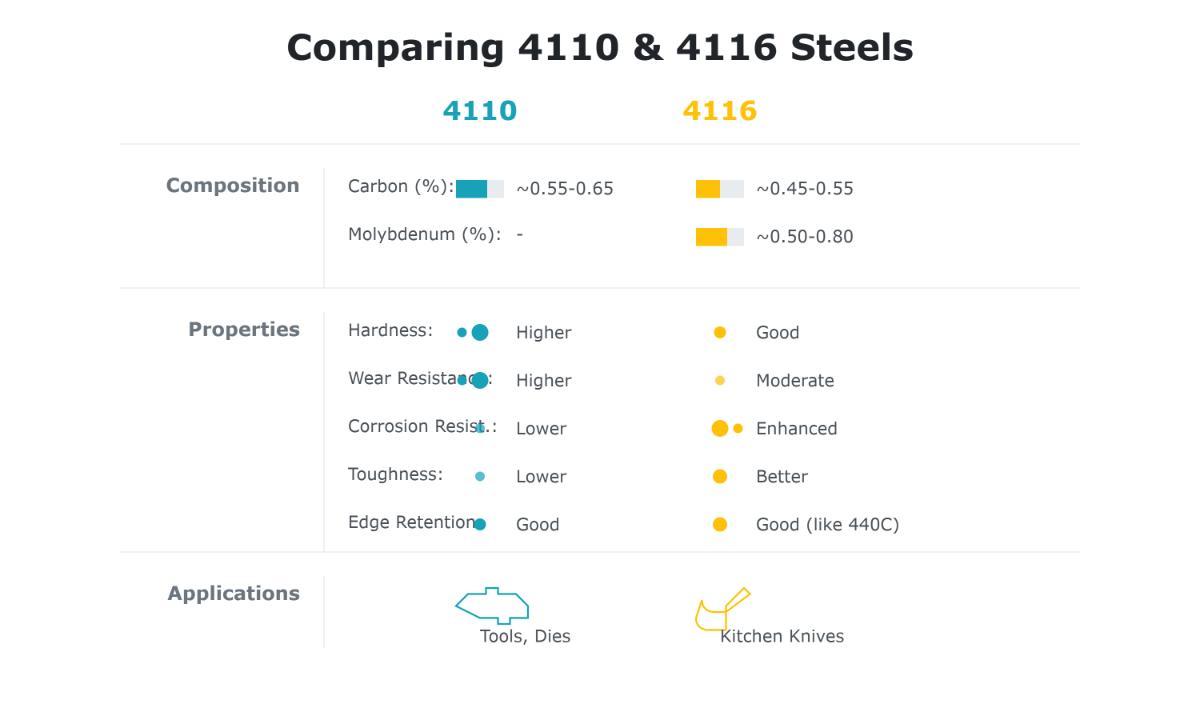

4110 and 4116 steels are both stainless tool steels with distinct differences mainly in their chemical compositions, which affect their properties and applications.

4110 steel typically has a higher carbon content (approximately 0.55% – 0.65%) compared to 4116 steel (approximately 0.45% – 0.55%), which allows 4110 to achieve greater hardness and wear resistance. This makes 4110 steel suitable for high-wear applications like tool and die making. However, its corrosion resistance is not as high as 4116 steel.

4116 steel contains a higher molybdenum content (around 0.50% – 0.80%), enhancing its corrosion resistance significantly. This makes 4116 steel ideal for applications in environments prone to moisture and acids, such as kitchen knives and food preparation tools. Additionally, 4116 steel balances hardness with better toughness, providing good edge retention comparable to 440C stainless steel.

Which steel is better for corrosion resistance?

4116 steel offers better corrosion resistance compared to 4110 steel, primarily due to its higher molybdenum content (approximately 0.5–0.8%). Molybdenum enhances resistance to pitting and crevice corrosion, making 4116 more effective in wet, acidic, or harsh environments. While both steels contain similar chromium levels (around 13–15%), this slight increase in alloying elements like molybdenum and vanadium in 4116 gives it superior protection against rust and degradation, particularly relevant in applications such as kitchen knives and medical tools. In contrast, 4110, with somewhat lower molybdenum content, still provides decent corrosion resistance but is generally less robust in demanding settings. Therefore, for applications where corrosion resistance is a priority, 4116 is the preferred choice.

How does the hardness of 4110 compare to 4116?

The hardness of 4110 steel is generally not as well-documented as that of 4116 steel. 4116 steel typically exhibits a Rockwell hardness rating of 55-58 HRC, which provides a good balance between hardness and toughness. This makes 4116 steel suitable for applications requiring good edge retention and corrosion resistance, such as kitchen knives.

On the other hand, while specific hardness values for 4110 steel are less commonly detailed, it is known to offer a balance of corrosion resistance and mechanical strength similar to 4116. The main difference between the two steels lies in their alloy composition, particularly the molybdenum content, which slightly influences their mechanical properties. Therefore, while 4116 steel’s hardness is well-documented, 4110 steel can be expected to have comparable but slightly varied hardness characteristics due to its composition.

What applications are best suited for 4110 steel?

4110 steel, also known as DIN 1.4110, is a martensitic stainless steel that excels in applications requiring a balance of hardness and corrosion resistance. Its primary applications include high-end cutlery, kitchen knives, and surgical instruments due to its excellent mechanical properties and resistance to corrosion. The high chromium content in 4110 steel contributes to its durability and ability to maintain a sharp edge, making it particularly valued for producing durable, sharp knives. Additionally, its corrosion resistance and durability make it suitable for surgical instruments and other medical tools. Beyond cutlery and medical tools, 4110 steel is also used in various precision tools where its reliability and versatility are advantageous.

What applications are best suited for 4116 steel?

4116 steel, also known as X50CrMoV15, is best suited for applications requiring a balance of hardness, toughness, corrosion resistance, and edge retention. This makes it particularly ideal for high-end kitchenware and cutlery, where its ability to maintain a sharp edge and resist corrosion from frequent exposure to water and acidic substances is essential. Additionally, its durability and resistance to wear and corrosion make it a preferred material for surgical instruments, ensuring reliability and longevity in medical environments. 4116 steel is also used in pocket knives, hunting knives, and other outdoor tools, where its toughness and ability to withstand harsh conditions are highly valued. Moreover, it finds applications in various engineering components where strength and resistance to pitting corrosion are crucial. Overall, 4116 steel’s versatility and performance characteristics make it a top choice for both consumer and professional-grade tools and instruments.

Is there a significant difference in cost between 4110 and 4116 steel?

There is no significant difference in cost between 4110 and 4116 steel. Both steels have similar alloy compositions and manufacturing processes, leading to comparable production costs. While 4116 steel contains slightly higher amounts of molybdenum and vanadium, enhancing its corrosion resistance and edge retention, these variations do not substantially increase the raw material costs. Market data shows that knives made from 4116 steel are priced affordably, typically in the $40 to $60 range, reflecting its cost-effective production. Consequently, products made from 4110 steel are expected to be in a similar price range. Therefore, the choice between 4110 and 4116 steel should be based on performance characteristics rather than cost, with 4116 offering modest improvements in corrosion resistance and durability.