Choosing the right steel for a knife can be a daunting task, especially when faced with options like 7Cr17MoV and 440A steel. These two materials are frequently compared in the knife-making community due to their unique properties and performance characteristics. But what exactly sets them apart, and which one is better suited for your needs? In this article, we’ll delve into the composition, properties, and practical applications of both 7Cr17MoV and 440A steel. We’ll explore their edge retention, corrosion resistance, toughness, and wear resistance to help you make an informed decision. Ready to find out which steel reigns supreme for your next knife project? Let’s dive in.

Introduction

Importance of Steel Selection in Knife-Making

Choosing the right steel is crucial in knife-making because it affects the blade’s performance, durability, and maintenance. The selection of steel influences various properties of the knife, such as edge retention, corrosion resistance, toughness, and wear resistance. Each type of steel offers a unique mix of these characteristics, so understanding the differences is essential for selecting the best steel for your needs.

Purpose of the Comparison

This comparison aims to provide a detailed analysis of two popular knife-making steels: 7Cr17MoV and 440A. By examining their compositions, properties, and performance, this comparison helps knife-makers and users choose the right steel, resulting in higher quality and more reliable knives.

Overview of 7Cr17MoV and 440A Steel

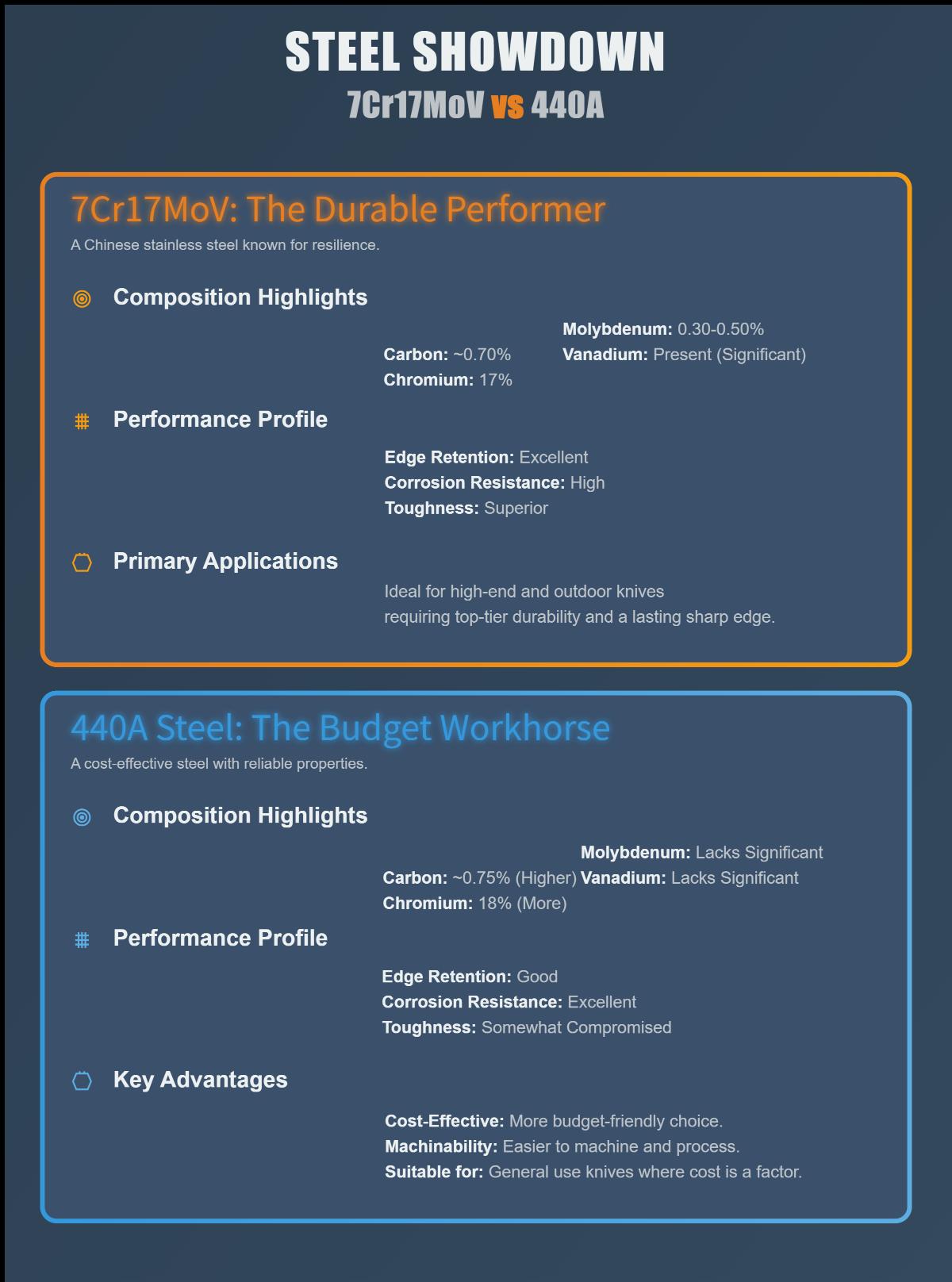

7Cr17MoV is a Chinese stainless steel alloy known for its specific composition and enhanced properties. It contains approximately 0.70% Carbon, 17% Chromium, and 0.30-0.50% Molybdenum. The addition of Vanadium (represented by the “V” in its name) plays a crucial role in improving the steel’s hardness and wear resistance. The high Chromium content provides excellent corrosion resistance, making this steel particularly suitable for applications that require exposure to moisture or harsh environments.

440A steel is a member of the 440 stainless steel family, characterized by its high carbon content (0.65-0.75%) and significant Chromium presence (16-18%). Unlike 7Cr17MoV, 440A does not include Vanadium, which impacts its hardness and wear resistance. However, it is known for its good balance of edge retention and corrosion resistance, making it a popular choice for budget-friendly knives.

General Properties and Characteristics

7Cr17MoV

- Edge Retention: Thanks to the Vanadium, 7Cr17MoV retains a sharp edge longer, making it great for knives that need to stay sharp.

- Corrosion Resistance: With 17% Chromium, 7Cr17MoV offers superior resistance to rust and corrosion, making it ideal for knives used in humid or wet conditions.

- Toughness: While it offers good – Ease of Sharpening: 7Cr17MoV is relatively easy to sharpen, which is advantageous for users who frequently maintain their knives.

440A Steel

- Edge Retention: 440A steel provides good edge retention, though it may require more frequent sharpening than 7Cr17MoV due to its lower hardness.

- Corrosion Resistance: 440A exhibits excellent corrosion resistance, making it suitable for various environments, including those with high moisture levels.

- Toughness: 440A is less brittle and more durable under rugged use compared to 7Cr17MoV, making it ideal for utility knives.

- Cost and Accessibility: 440A is generally more budget-friendly and widely accessible, making it a popular choice for everyday carry knives and other cost-effective applications.

Common Uses in Knife-Making and Other Applications

Both 7Cr17MoV and 440A steel are commonly used in knife-making, each suited to different types of blades and user needs.

7Cr17MoV Applications

Due to its excellent corrosion resistance and edge retention, 7Cr17MoV is often used in outdoor and survival knives, as well as kitchen knives that need to resist rust and maintain sharpness.

440A Steel Applications

440A is favored for producing cost-effective knives that still offer reliable performance, making it a go-to material for mass-market knife production. Its toughness and resistance to chipping make it suitable for utility knives that undergo heavy use and potential abuse. The excellent corrosion resistance of 440A steel also makes it a suitable choice for diving knives that are regularly exposed to saltwater environments.

Knife Materials

Overview of Common Materials Used in Knife-Making

Knife-making uses various materials, each affecting the blade’s performance, durability, and maintenance differently. The most common materials used in knife blades include stainless steel, carbon steel, tool steel, and alloy steels.

Stainless Steel

Stainless steel is popular for its excellent corrosion resistance, making it ideal for knives exposed to moisture or harsh environments. Popular stainless steels for knives include 7Cr17MoV, 440A, 440C, and AUS-8. These steels are favored for their ability to resist rust and staining, ensuring longevity and ease of maintenance.

Carbon Steel

Carbon steel is known for its high hardness and excellent edge retention. It is often used in applications where sharpness is a priority. However, carbon steel can rust easily and needs regular maintenance to stay corrosion-free. Popular carbon steels in knife-making include 1095, 5160, and O1.

Tool Steel

Tool steels, known for their high wear resistance and toughness, are ideal for heavy-duty applications like industrial tools and high-performance knives. Examples include D2, A2, and M2 tool steels, which offer a balance of hardness, toughness, and wear resistance.

Alloy Steels

Alloy steels are enhanced with additional elements to improve specific properties such as hardness, toughness, or corrosion resistance. These steels are versatile and used in a wide range of knife applications. Common alloy steels include VG-10, CPM-S30V, and 154CM.

How 7Cr17MoV and 440A Steel Fit Within These Materials

Both 7Cr17MoV and 440A steel are classified as stainless steels, and they are chosen for their specific properties that make them suitable for different knife applications.

7Cr17MoV Steel

7Cr17MoV is a Chinese stainless steel alloy that contains 0.70% Carbon, 17% Chromium, and 0.30-0.50% Molybdenum, with added Vanadium. This composition provides excellent corrosion resistance, high hardness, and good wear resistance. The addition of Vanadium enhances the steel’s hardness and edge retention, making it suitable for survival knives, outdoor tools, and kitchen knives that require resistance to rust and sharpness.

440A Steel

440A is part of the 440 series of stainless steels, known for its higher carbon content of 0.65-0.75% and significant Chromium presence of 16-18%. While it does not include Vanadium, it offers a good balance of edge retention, corrosion resistance, and toughness. 440A is commonly used in budget-friendly knives and utility blades, where cost-effectiveness and reliable performance are key considerations.

Comparative Analysis

When comparing 7Cr17MoV and 440A steel, several key differences stand out:

- Edge Retention: 7Cr17MoV, with its added Vanadium, generally offers better edge retention compared to 440A. This makes it more suitable for applications where maintaining a sharp edge is crucial.

- Corrosion Resistance: Both steels provide high corrosion resistance, making them suitable for use in humid or wet environments. However, 7Cr17MoV’s slightly higher Chromium content may offer a marginal advantage.

- Toughness: 440A steel tends to be tougher and less brittle, which makes it better suited for utility knives and applications requiring durability under rugged use.

- Cost: 440A is typically more budget-friendly, making it an attractive option for cost-conscious buyers without sacrificing essential performance.

By understanding these materials and their properties, knife-makers and users can make informed decisions about which steel best suits their specific needs and applications.

Detailed Comparison of Steel Properties

Edge Retention

Analysis of Edge Retention for 7Cr17MoV

7Cr17MoV steel’s added vanadium content enhances carbide formation, which improves edge retention. The presence of vanadium and higher carbon content ensure that the steel maintains a sharp edge over prolonged use, making it ideal for survival knives and other outdoor tools.

Analysis of Edge Retention for 440A Steel

440A steel has good edge retention but lacks vanadium, limiting its ability to form strong carbides like 7Cr17MoV. This results in a steel that may require more frequent sharpening to maintain its edge. Nonetheless, it still provides a reasonable balance of performance, making it a reliable choice for everyday carry knives and other general-purpose applications.

Corrosion Resistance

Corrosion Resistance Properties of 7Cr17MoV

The high chromium content in 7Cr17MoV (around 17%) offers excellent corrosion resistance. This makes it ideal for knives that are frequently exposed to moisture or harsh environments. The added molybdenum also enhances its resistance to pitting corrosion, which is particularly beneficial in saline or humid conditions.

Corrosion Resistance Properties of 440A Steel

440A steel also boasts high corrosion resistance due to its significant chromium content (approximately 16-18%). The lack of significant molybdenum does not greatly affect its corrosion resistance, as the high chromium content is sufficient to provide a protective oxide layer that prevents rust and tarnish. However, the absence of molybdenum means that 440A steel may not perform as well in highly corrosive environments compared to steels that do contain molybdenum.

Toughness

Toughness Characteristics of 7Cr17MoV

7Cr17MoV steel offers a good balance between hardness and toughness. However, its higher hardness, due to the vanadium content, can make it more susceptible to chipping under extreme stress. This makes it less suitable for applications that require significant impact resistance but ideal for cutting tasks where edge stability is more critical.

Toughness Characteristics of 440A Steel

440A steel is known for its toughness and ability to withstand rugged use. The absence of vanadium means it has a slightly lower hardness, which contributes to its increased toughness and resistance to chipping. This makes 440A a preferred choice for utility knives and other tools that may undergo significant abuse and impact during use.

Wear Resistance

Wear Resistance Comparison Between 7Cr17MoV and 440A

7Cr17MoV steel, with its added vanadium, provides better wear resistance compared to 440A. The formation of vanadium carbides significantly enhances the steel’s ability to resist wear, making it suitable for applications where the blade is subject to continuous use and abrasion. This makes 7Cr17MoV a superior choice for blades needing to maintain their integrity over extended use, while 440A is still reliable for general-purpose use but less effective in high-wear scenarios.

Applications and Cost Analysis

7Cr17MoV steel is well-known for its balanced properties, which make it an excellent choice for many types of knives. Due to its superior edge retention and corrosion resistance, it is particularly well-suited for:

- Survival Knives: The high hardness and edge retention make 7Cr17MoV ideal for survival knives that need to maintain sharpness in challenging conditions.

- Outdoor and Camping Knives: Its rust and corrosion resistance make it ideal for outdoor activities where the knife might get wet.

- Kitchen Knives: The steel’s combination of sharpness and resistance to wear and corrosion ensures long-lasting performance in culinary environments.

440A steel is popular because it is affordable and balanced, making it a good choice for many types of budget-friendly knives:

- Everyday Carry (EDC) Knives: The reasonable edge retention and high corrosion resistance make 440A a practical choice for everyday carry knives that require frequent use and easy maintenance.

- Fishing Knives: Its excellent corrosion resistance is beneficial in wet and salty environments, making it ideal for fishing tools.

- Budget-Friendly Knives: 440A is often used in mass-produced knives that provide good performance at a lower cost, appealing to budget-conscious consumers.

Several factors, mainly their composition and performance, influence the cost comparison between 7Cr17MoV and 440A steel.

- 7Cr17MoV: This steel tends to be more expensive due to the inclusion of additional elements like vanadium and molybdenum, which enhance its wear resistance and hardness. The higher manufacturing costs are reflected in the price, making knives made from 7Cr17MoV more costly but offering better performance in specific areas.

- 440A: Known for its budget-friendliness, 440A steel is less expensive to produce. The absence of high-cost alloying elements like vanadium makes it a more affordable option. This cost advantage makes 440A an attractive choice for producing knives that deliver good performance without a high price tag.

The cost-effectiveness of each steel type can be evaluated based on the intended application and user priorities:

- 7Cr17MoV: For users who prioritize edge retention, hardness, and wear resistance, the higher cost of 7Cr17MoV is justified. It is especially cost-effective for knives that must perform well over long periods and in tough conditions, like survival and outdoor knives.

- 440A: For those seeking reliable performance at a lower price, 440A offers excellent value. It is cost-effective for everyday carry knives, fishing knives, and other tools where frequent use and easy maintenance are essential. The lower price point makes it accessible for a broader audience while still providing satisfactory performance.

Choosing the Best Steel for Knife-Making

Factors to Consider When Selecting Knife Steel

When choosing the best steel for knife-making, several key factors should be considered to ensure the final product meets the desired performance and durability requirements.

Purpose and Use Case

The knife’s intended use greatly impacts the choice of steel. For example, a survival knife requires high corrosion resistance and edge retention, whereas a kitchen knife benefits from ease of sharpening and wear resistance.

Edge Retention

Edge retention is crucial for knives that need to maintain sharpness over extended use. Steels with higher carbon content and elements like vanadium, such as 7Cr17MoV, generally offer better edge retention than 440A, which lacks these enhancements.

Corrosion Resistance

Corrosion resistance is crucial for knives used in wet or humid conditions. Steels with high chromium content, like both 7Cr17MoV and 440A, provide excellent resistance to rust and corrosion, making them suitable for outdoor and kitchen knives.

Toughness

Toughness determines a knife’s ability to withstand impacts and heavy use without chipping or breaking. 440A steel, with its lower hardness, tends to offer greater toughness compared to 7Cr17MoV, making it ideal for utility knives and tools subjected to rugged conditions.

Wear Resistance

Wear resistance determines how well the blade keeps its integrity and sharpness over time. Steels like 7Cr17MoV, enhanced with vanadium, provide superior wear resistance, making them suitable for knives that experience heavy abrasion.

Recommendations Based on Different Use Cases

Best Scenarios for Using 7Cr17MoV

- Survival Knives: The high edge retention and corrosion resistance make 7Cr17MoV ideal for survival knives that need to perform reliably in harsh conditions.

- Outdoor and Camping Knives: The excellent rust resistance ensures the knife remains functional and durable in outdoor environments.

- Kitchen Knives: The combination of sharpness and resistance to wear and corrosion makes 7Cr17MoV a preferred choice for high-quality kitchen knives.

Best Scenarios for Using 440A Steel

- Everyday Carry (EDC) Knives: The balance of edge retention, toughness, and corrosion resistance makes 440A suitable for knives used daily and subjected to various tasks.

- Fishing Knives: The high corrosion resistance is beneficial for knives exposed to wet and salty conditions, such as during fishing.

- Budget-Friendly Knives: 440A’s affordability and good performance make it an attractive option for cost-effective knives that still deliver reliable functionality.

Expert Opinions and User Experiences

Knife-makers and users often share valuable insights based on their experiences with different steels. Many experts appreciate 7Cr17MoV for its superior edge retention and corrosion resistance, particularly in demanding environments. Users of 440A steel, on the other hand, often highlight its excellent toughness and affordability, making it a practical choice for everyday use and budget-friendly options.

Knowing these factors can help knife-makers and users choose the best steel, ensuring the knife performs well and meets expectations.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the differences between 7Cr17MoV and 440A steel?

7Cr17MoV and 440A steel differ primarily in their composition and performance characteristics, making each suitable for different knife applications.

7Cr17MoV, a Chinese stainless steel, contains approximately 0.70% carbon, 17% chromium, and 0.30-0.50% molybdenum, along with vanadium. This composition results in excellent edge retention, high corrosion resistance, and superior toughness, making it ideal for high-end and outdoor knives that require durability and a sharp edge.

In contrast, 440A steel has a higher carbon content of around 0.75% and more chromium at 18%, but lacks significant vanadium and molybdenum. This makes 440A more budget-friendly and easier to machine. While it offers good edge retention and excellent corrosion resistance, its toughness is somewhat compromised compared to steels with higher vanadium and molybdenum content.

Which steel is better for knife-making?

When deciding between 7Cr17MoV and 440A steel for knife-making, it’s essential to consider several factors: edge retention, corrosion resistance, toughness, and cost.

7Cr17MoV is a Chinese stainless steel known for its high carbon (0.70%) and chromium (17%) content, along with molybdenum and vanadium. This composition provides excellent edge retention, high corrosion resistance, and superior toughness, making it ideal for durable and sharp knives, especially in outdoor and survival contexts.

On the other hand, 440A steel, with a slightly higher carbon content (0.75%) and more chromium (18%), offers good corrosion resistance and decent edge retention. However, it is generally less durable than 7Cr17MoV and may require more frequent sharpening. It is more budget-friendly, making it suitable for everyday carry knives and fishing tools.

How does stainless steel compare to other types of knife steel?

Stainless steel, including 7Cr17MoV and 440A, is favored in knife-making for its excellent corrosion resistance, making it ideal for environments with high moisture exposure. Compared to other types of knife steel, stainless steel typically contains at least 11% chromium, which significantly enhances its rust resistance. While stainless steels like 7Cr17MoV and 440A might not offer the same sharpness or ease of sharpening as carbon steels, advancements in heat treatment have improved their

7Cr17MoV is known for its high corrosion resistance, ease of sharpening, and decent edge retention, making it suitable for kitchen knives and outdoor tools. It is also economical, often used in mass-produced knives. On the other hand, 440A, while less commonly discussed, offers good corrosion resistance and moderate performance, making it a viable option for budget-friendly knives.

In contrast, carbon steels provide superior sharpness and are easier to sharpen but require frequent maintenance to prevent rust. Tool steels like D2 offer high hardness and edge retention but are more challenging to maintain. High-end stainless steels, such as VG10 and 154CM, combine high carbon content with excellent corrosion resistance, providing a balance of sharpness and durability for premium knives.

What are the pros and cons of 7Cr17MoV for knife-making?

7Cr17MoV steel is a popular choice for knife-making due to several notable advantages. It offers excellent corrosion resistance, primarily due to its high chromium content, making it suitable for outdoor and survival knives. The steel is relatively easy to sharpen, which is advantageous for knives that require regular maintenance. Additionally, it is affordable, providing good value for its properties, and offers decent edge retention for everyday tasks.

However, 7Cr17MoV steel also has some drawbacks. It has lower wear resistance compared to other steels, which means it can scratch and wear more quickly. The steel’s brittleness, attributed to its high hardness and inclusions like sulfur and phosphorus, can make it prone to chipping. Consequently, it is not ideal for high-stress applications where superior durability and performance are necessary.

What are the pros and cons of 440A Steel for knife-making?

440A steel offers several advantages for knife-making, making it a popular choice among manufacturers and consumers. One of its primary benefits is its high corrosion resistance due to its substantial chromium content, making it well-suited for use in moist or salty environments. Additionally, 440A steel is relatively affordable, providing a good balance between cost and performance, which makes it accessible to a wide range of users.

Another significant advantage is its ease of sharpening. 440A steel can be sharpened without the need for advanced tools, making it convenient for casual knife users. Its machinability is also noteworthy, as its moderate hardness facilitates efficient mass production.

However, 440A steel does have some drawbacks. Its lower hardness compared to other steels, such as 440C, means that it may lose its edge more quickly and require more frequent sharpening. It also lacks the resistance to chipping and wear found in harder steels, making it less suitable for heavy-duty tasks. While its edge retention is better than that of softer stainless steels, it does not match the performance of higher-end steels like D2 or VG10.

What factors should be considered when choosing steel for knives?

When choosing steel for knives, several critical factors must be considered to ensure optimal performance and durability. These include edge retention, toughness, corrosion resistance, and hardness. Edge retention refers to how well a knife maintains its sharpness over time, which is influenced by the steel’s composition and carbide formation. Toughness measures the knife’s ability to withstand impact without chipping or breaking, necessitating a balance between hardness and brittleness. Corrosion resistance, primarily determined by chromium content, protects the knife from rust and wear, while hardness, measured on the Rockwell C scale, affects the knife’s resistance to deformation and edge maintenance.

In comparing 7Cr17MoV and 440A steel, 7Cr17MoV is easier to sharpen and offers good corrosion resistance, making it suitable for budget-friendly knives that require frequent sharpening. However, it lacks the edge retention and toughness of higher-carbon steels. On the other hand, 440A steel provides better edge retention and toughness, making it more versatile for general use knives. It offers a good balance between corrosion resistance and hardness, making it a preferred choice for everyday carry knives. Ultimately, the choice between 7Cr17MoV and 440A depends on the knife’s intended use and the desired balance of these key factors.