When it comes to understanding the materials that shape our world, cast iron stands as a cornerstone of industrial and domestic applications. This fascinating metal, renowned for its historical significance and unique properties, has been utilized in everything from majestic bridges to humble cookware. But what makes cast iron so widely used, and what are its potential pitfalls? In this article, we will delve into the main advantages and disadvantages of cast iron metal, exploring its durability, cost-effectiveness, and impressive heat retention capabilities, while also addressing its brittleness, weight, and corrosion issues. By the end, you’ll have a clear picture of how cast iron compares to other materials like steel and aluminum, and whether it might be the right choice for your needs. Ready to uncover the secrets of this versatile metal? Let’s dive in.

Introduction to Cast Iron

Cast iron is an iron – carbon alloy that contains more than 2% carbon. It usually also contains silicon and manganese, which contribute to its unique properties such as high strength, especially under compressive loads, and good wear – resistance.

The history of cast iron goes back to ancient China around the 8th century BC and became popular in Europe during the 15th century. Compared to wrought iron, cast iron was more economical to produce and had sufficient strength. This made it a widely used material in many engineering projects, playing a crucial role in the development of infrastructure and machinery.

Types of Cast Iron

- Gray Cast Iron: Gray cast iron contains graphite flakes that make it easy to machine into different shapes but also reduce its hardness. It is commonly used in engine blocks and machine bases.

- White Cast Iron: It contains cementite, which makes it very hard but also brittle. Due to its brittleness, it is less used in modern applications.

- Ductile Cast Iron: Ductile cast iron, with its spherical graphite nodules, offers greater ductility and toughness, making it ideal for use in automotive parts like crankshafts.

Properties and Applications of Cast Iron

Material Properties of Cast Iron

Cast iron is renowned for its unique combination of properties that make it suitable for various applications. Here are some of the key material properties:

Compressive Strength

Cast iron exhibits excellent compressive strength, making it ideal for structures subjected to compressive loads. This property is particularly beneficial in construction, where the material must withstand significant weight and pressure.

Wear Resistance

Different types of cast iron offer varying levels of wear resistance; for example, white cast iron is highly wear-resistant due to its cementite content, making it suitable for applications involving high abrasion and impact.

Heat Resistance

Cast iron has good thermal conductivity and heat retention capabilities. These properties make it an excellent choice for cookware, where even heat distribution is crucial.

Machinability

Gray cast iron, with its graphite flake structure, offers high machinability. This means it can be easily cut, shaped, and finished, which is advantageous in manufacturing processes, reducing tool wear and production time.

Brittleness

While cast iron is strong under compression, it is relatively brittle with limited tensile strength and ductility. This brittleness makes it susceptible to cracking under impact or tensile stress, which must be considered in its applications.

Corrosion Resistance

Cast iron generally has low corrosion resistance. However, this can be improved with the addition of alloying elements or through protective coatings, making it more suitable for environments where corrosion is a concern.

Common Applications of Cast Iron

Cast iron’s unique properties make it suitable for a wide range of applications across various industries. Here are some of the most common uses:

Cookware

Cast iron cookware, such as skillets and Dutch ovens, is prized for its excellent heat retention and even heat distribution. These properties ensure consistent cooking results, and with proper seasoning, cast iron cookware can develop a natural non-stick surface.

Engine Blocks

In the automotive industry, cast iron is commonly used for engine blocks and cylinder heads. Its high strength, wear resistance, and ability to dampen vibrations make it ideal for these critical components, contributing to the durability and performance of vehicles.

Construction

Cast iron is extensively used in construction for pipes, fittings, and architectural elements. Its high compressive strength and longevity make it suitable for structural applications, including columns and beams in buildings and bridges.

Machinery

Cast iron is used in various machinery components such as valves, gears, and pumps. Its durability, wear resistance, and ease of machining make it a preferred material for parts that require precise manufacturing and long service life.

Additional Applications

Beyond the primary uses, cast iron finds applications in many other areas:

- Decorative Items: Cast iron is used to create intricate designs in fences, gates, and furniture due to its ability to be cast into complex shapes.

- Tools: Cast iron is used in the production of tools and equipment that require high strength and durability, such as anvils and vices.

- Infrastructure: In addition to construction, cast iron is used in infrastructure projects for manhole covers, drainage systems, and other components that need to withstand heavy loads and harsh conditions.

The versatility of cast iron, combined with its beneficial properties, makes it an essential material in numerous industries and applications.

Advantages of Cast Iron

Cooking Benefits

Iron Supplementation

Cast iron cookware releases small amounts of iron into food, enhancing dietary iron intake. This is particularly beneficial for individuals with iron deficiency, offering a simple way to boost iron levels without supplements.

Chemical-Free Non-Stick

Properly seasoned cast iron cookware offers a natural non-stick surface. Unlike some non-stick pans with harmful chemicals, cast iron offers a safe, chemical-free cooking option.

Reduced Oil Usage

The non-stick property of seasoned cast iron allows for cooking with minimal oil. This can contribute to a healthier diet by reducing fat intake, which is beneficial for heart health.

Excellent Heat Retention

Cast iron is known for its superior heat retention capabilities. It ensures even cooking by distributing heat uniformly across the cooking surface, which helps in preserving the nutrients in food.

Versatility in Cooking Methods

Cast iron cookware is versatile, suitable for searing, baking, frying, and more. It is also compatible with different heat sources, such as stoves, ovens, and even campfires, making it an all-around kitchen essential.

Manufacturing and Material Properties

Ease of Casting

Cast iron is easier to cast than steel due to its lower melting temperature and better flowability. This makes it more cost-effective to produce, as it requires less energy and effort during the casting process.

High Compressive Strength

One of the standout properties of cast iron is its high compressive strength. This makes it ideal for construction uses, such as in building columns and heavy machinery.

Machinability

Cast iron, particularly gray cast iron, is easier to machine compared to many other metals. Its graphite content acts as a lubricant during machining, reducing tool wear and enhancing production efficiency.

Improved Corrosion Resistance

While cast iron is not immune to corrosion, it offers better surface corrosion resistance than carbon steel. However, to enhance its durability in corrosive environments, protective coatings or alloying elements can be added.

Durability and Cost-Effectiveness

Longevity

Cast iron products, especially cookware, are known for their incredible durability. With proper care, cast iron items can last for generations, making them a long-term investment that pays off over time.

Affordability

Despite its durability and numerous benefits, cast iron cookware is often competitively priced compared to other types of cookware. This makes it a cost-effective option for consumers looking for high-quality, long-lasting kitchenware.

Vibration Damping Qualities

Cast iron has excellent vibration damping properties, which is why it is commonly used in machinery bases and engine blocks. This quality helps in reducing noise and vibration, leading to smoother operation and longer lifespan of mechanical components.

Disadvantages of Cast Iron

Brittleness and Potential for Cracking

One major drawback of cast iron is its brittleness, which means it can crack or shatter under sudden impacts or tension. Unlike materials such as steel, which can absorb and redistribute stress, cast iron lacks the ability to withstand such forces. This brittleness limits its use in applications where flexibility and impact resistance are essential, like components subjected to dynamic or shock loads.

Heaviness and Handling Difficulties

The density of cast iron means that even small components can be quite weighty, requiring additional effort and sometimes specialized equipment for movement and installation. This heaviness can also make cast iron less desirable for applications where weight is a critical factor, such as in the aerospace industry.

Corrosion Susceptibility Without Proper Care

While cast iron can be durable, it is also prone to rust and corrosion if not adequately maintained. This is especially true for cast iron cookware, which needs regular seasoning to prevent rust. In industrial applications, cast iron components often need protective coatings or treatments to enhance their corrosion resistance, adding to the maintenance requirements and operational costs. Proper care and use of cast iron, whether in the kitchen or in industrial settings, are crucial to prolonging its lifespan and ensuring its optimal performance.

Lower Tensile Strength Compared to Other Metals

Cast iron has lower tensile strength compared to metals like steel, meaning it’s not suitable for applications needing high tension resistance. Tensile strength is the resistance of a material to breaking under tension. As a result, cast iron is often used in applications where compressive strength is more critical than tensile strength.

Challenges in Welding and Machining

The high carbon content in cast iron makes welding difficult, as it often forms brittle welds that can crack. Machining can also be tough due to its hardness and graphite content, which can wear down cutting tools. These challenges can increase production time and costs, making cast iron less attractive for certain manufacturing processes.

High Maintenance in Cookware

Cast iron cookware requires significant maintenance to keep it in good condition. Regular seasoning is necessary to maintain its non – stick properties and prevent rusting. Additionally, cast iron pans need to be carefully cleaned and dried after each use to avoid rust. This high maintenance can be a drawback for users who prefer low – maintenance cookware options.

Reactivity with Acidic Foods

In culinary applications, cast iron can react with acidic foods such as tomatoes or citrus, which can affect the taste of the food and potentially damage the seasoning layer. This reactivity limits the types of dishes that can be prepared using cast iron cookware, making it less versatile than other types of cookware materials.

Comparison with Other Materials

Cast Iron vs Steel

Tensile Strength

Steel has high tensile strength, meaning it can better withstand stretching and pulling forces compared to cast iron. Cast iron, on the other hand, excels in compressive strength but has limited tensile strength, making it ideal for structures like columns that mainly experience compressive forces.

Corrosion Resistance

Steel is generally more resistant to corrosion than cast iron, which can rust if not properly maintained. In environments where corrosion is a concern, such as near the ocean or in industrial settings with chemicals, steel may be more suitable. Cast iron can have its corrosion resistance improved with protective coatings or alloying elements.

Weight and Handling

Cast iron is heavier than steel, which can make it more difficult to handle and transport, especially for large components. In applications where weight is a critical factor, like in the aerospace industry, steel is often preferred over cast iron.

Cast Iron vs Aluminum

Heat Conductivity

Aluminum heats up and cools down much more quickly than cast iron, making it ideal for applications that require rapid heat transfer, like heat exchangers or fast-cooking cookware. However, cast iron’s ability to retain heat makes it perfect for slow-cooking tasks where a consistent temperature needs to be maintained.

Weight

Aluminum is significantly lighter than cast iron, making it easier to handle and suitable for applications where weight reduction is important, such as in automotive parts or portable equipment.

Durability

Cast iron is more durable and wear-resistant than aluminum, making it a better choice for heavy-duty applications like engine blocks or machinery components that need to withstand tough conditions.

Environmental Impact of Cast Iron

Environmental Advantages

Recyclability

Cast iron stands out for its exceptional recyclability, as it can be reused endlessly without losing its core qualities. This makes cast iron a sustainable choice, reducing the demand for new raw materials and conserving natural resources.

Slow Oxidation

Cast iron oxidizes slowly, and the carbon-based residue from this process can help support plant and plankton growth. This can potentially aid in combating global warming by enhancing the natural carbon-sequestering capabilities of these organisms.

Lower Production Impact Compared to Steel

Producing cast iron is less energy-intensive than steel, resulting in lower environmental impacts and fewer emissions.

Environmental Disadvantages

Manufacturing Emissions

Manufacturing cast iron releases greenhouse gases, contributing to air pollution and climate change.

Disposal and Waste

Cast iron is non-biodegradable. If it is not properly recycled, it can take hundreds of years to break down, leading to environmental pollution as large amounts of cast iron waste accumulate over time.

Installation Impact

Installing cast iron pipes often requires trenching, which can disrupt local ecosystems by removing vegetation and disturbing the natural habitats of various organisms, thereby affecting local biodiversity.

Frequently Asked Questions

Below are answers to some frequently asked questions:

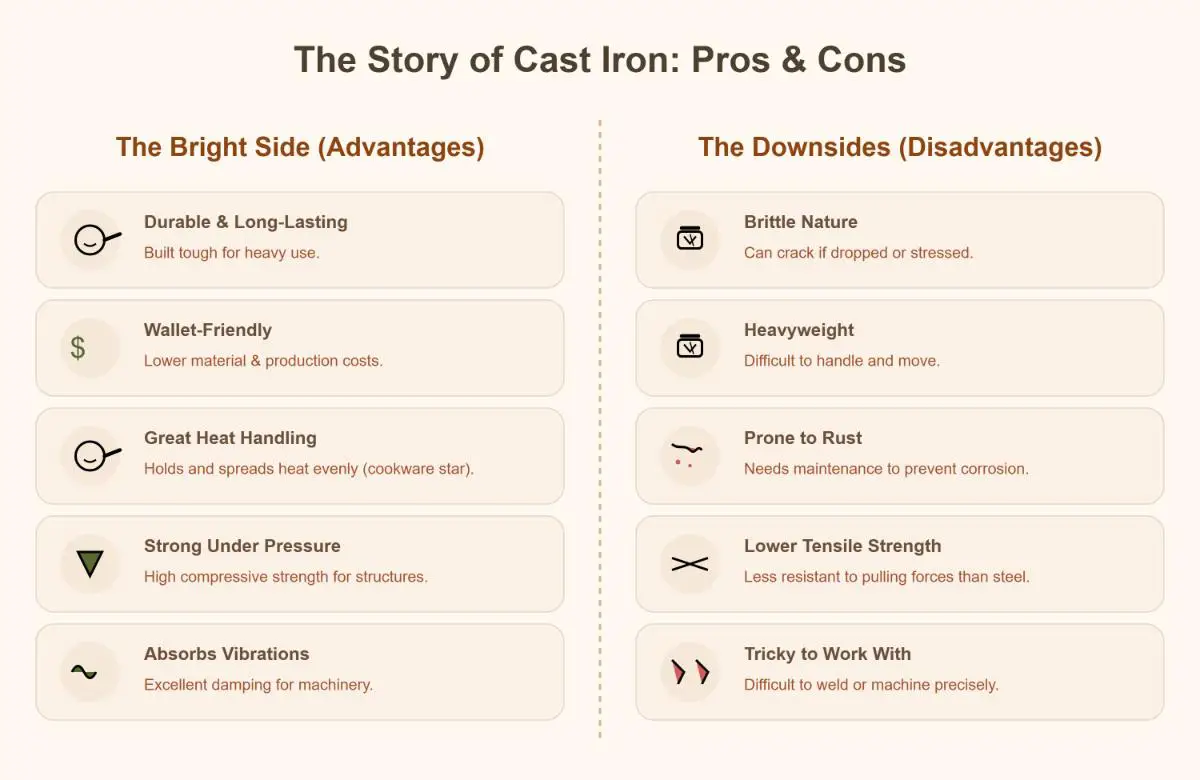

What are the main advantages and disadvantages of cast iron?

Cast iron is a versatile and widely used metal known for its unique properties. The main advantages of cast iron include its durability and longevity, making it ideal for heavy-duty applications. It is cost-effective due to its relatively low material and manufacturing costs. Cast iron retains and distributes heat well, which is particularly beneficial for cookware. It has high compressive strength and excellent vibration damping qualities, making it suitable for machinery and construction.

However, cast iron also has several disadvantages. It is brittle and can crack under impact or stress. The material is heavy, which can make handling and transportation challenging. Cast iron is susceptible to corrosion if not properly maintained, and it has lower tensile strength compared to other metals like steel. Additionally, it can be difficult to weld and machine, requiring specialized techniques and care.

How does cast iron compare to other materials like steel or aluminum?

Cast iron differs from steel and aluminum in several key ways. Compared to steel, cast iron has a higher carbon content, between 2% to 4% versus less than 2% in steel. Cast iron is stronger under compression and is cheaper and easier to machine. However, steel has better tensile strength and corrosion resistance. Cast iron is great for cookware and engine blocks, while steel is used in infrastructure and tools.

When compared to aluminum, cast iron is much heavier, with a density of about 7.2 g/cm³ against aluminum’s 2.7 g/cm³. Aluminum resists corrosion better as it forms a protective oxide layer. Cast iron is more durable and wear – resistant but also more brittle. Aluminum is used in automotive and aerospace due to its lightness, while cast iron is preferred for heavy machinery and cookware.

What are the best uses for cast iron in construction and manufacturing?

Cast iron is widely used in construction and manufacturing due to its unique properties. In construction, it’s used for sanitary fittings like manholes and water pipes because of its corrosion resistance. Structural elements such as metal columns and bases, casting molds for staircases and gates, and railway components like rail chairs and carriage wheels also often use cast iron. In manufacturing, it’s a key material for automotive parts like engine blocks and brake disks, cookware for its durability and non – toxicity, and machinery parts like gears and shafts thanks to its strength and wear resistance. Different types of cast iron, like grey, white, and ductile, are chosen based on specific requirements of each application.

How do I maintain and care for cast iron cookware?

To maintain and care for cast iron cookware, it’s essential to follow a few key steps to ensure its longevity and performance. First, seasoning the cookware is crucial. This involves applying a thin layer of vegetable or flaxseed oil to the surface and heating it to create a protective, non-stick coating. Regular seasoning helps prevent rust and maintains the non-stick quality.

For cleaning, use warm water and a soft brush or sponge. Avoid metal scrubbers, which can damage the seasoning. For stubborn food residue, scrub with kosher salt and a wooden spoon. Never soak cast iron in water, as it can lead to rust.

After cleaning, dry the cookware thoroughly using heat from a stovetop or oven. Store it in a dry place, and if stacking multiple pieces, place a paper towel between them to absorb moisture and prevent rust.

Avoid using soap, as it can strip the seasoning. If rust appears, remove it with a mild abrasive like kosher salt or a chain mail scrubber, then re-season the pan. Following these steps will keep your cast iron cookware in excellent condition for years to come.

Are there any environmental concerns with using cast iron?

Yes, there are environmental concerns with using cast iron. The production of cast iron is energy-intensive and results in significant CO2 emissions, contributing to environmental pollution. Additionally, the extraction of raw materials like iron ore and coal used in cast iron production can have negative impacts on ecosystems. Despite these concerns, cast iron also has environmental advantages. It is fully recyclable, can be reused indefinitely without losing its properties, and its durability reduces the need for frequent replacements, minimizing waste. Proper care and sustainable practices can help mitigate some of the environmental impacts associated with cast iron.

What standards apply to the quality of cast iron products?

The quality of cast iron products is governed by several standards that ensure their reliability, safety, and performance across various applications. Notable standards organizations include ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization).

Key ASTM standards include:

- ASTM A48/A48M: Specifies the tensile strength requirements for gray iron castings.

- ASTM A536: Outlines the mechanical properties and microstructure requirements for ductile iron castings.

- ASTM A319: Covers the specifications for malleable iron castings, focusing on tensile strength and elongation.

These standards ensure that cast iron products meet specific criteria for mechanical properties, structure, and performance, providing a benchmark for quality and consistency.