When it comes to choosing the right metal for industrial applications, the decision between aluminium and copper is far from straightforward. These two metals, each with their unique properties and advantages, play crucial roles across various sectors, from manufacturing to construction. The price difference between aluminium and copper can significantly impact project costs, but the comparison doesn’t end there. How do these metals fare in terms of durability, conductivity, and long-term investment? This article delves into the intricate details of both materials, exploring their market prices, historical trends, and future predictions. By the end, you’ll have a clear understanding of which metal suits your specific needs and why. So, which metal will come out on top for your next big project? Let’s dive in to find out.

Introduction

Introduction to Aluminium vs Copper

Aluminium and copper are two of the most widely used metals in various industries, each offering unique properties that suit different applications. As industry professionals seek to optimize their projects, understanding the differences and comparative advantages of these metals becomes critical.

Both aluminium and copper are integral to numerous sectors such as construction, manufacturing, transportation, and electrical engineering. Their unique qualities determine their suitability for particular uses, impacting project efficiency, cost, and performance.

Aluminium is prized for being lightweight, highly resistant to corrosion, and very malleable, making it perfect for applications needing both lightness and durability. Copper is highly valued for its excellent electrical and thermal conductivity, as well as its strength and flexibility, making it ideal for electrical wiring and heat management systems.

Economically, aluminium is often preferred because it is more abundant and less expensive than copper, resulting in significant cost savings for large-scale projects. Additionally, both metals are highly recyclable, which enhances their sustainability credentials and reduces the environmental impact of their production and use.

The choice between aluminium and copper often depends on the specific requirements of an application. For instance, in electrical systems where conductivity is paramount, copper is typically favored. Conversely, in aerospace and automotive industries, where weight reduction is critical, aluminium is preferred.

Understanding the nuanced differences between aluminium and copper allows industry professionals to make informed decisions, ensuring that the selected material aligns with the technical and economic goals of their projects.

Aluminium vs Copper Price Comparison

Overview of Current Market Prices

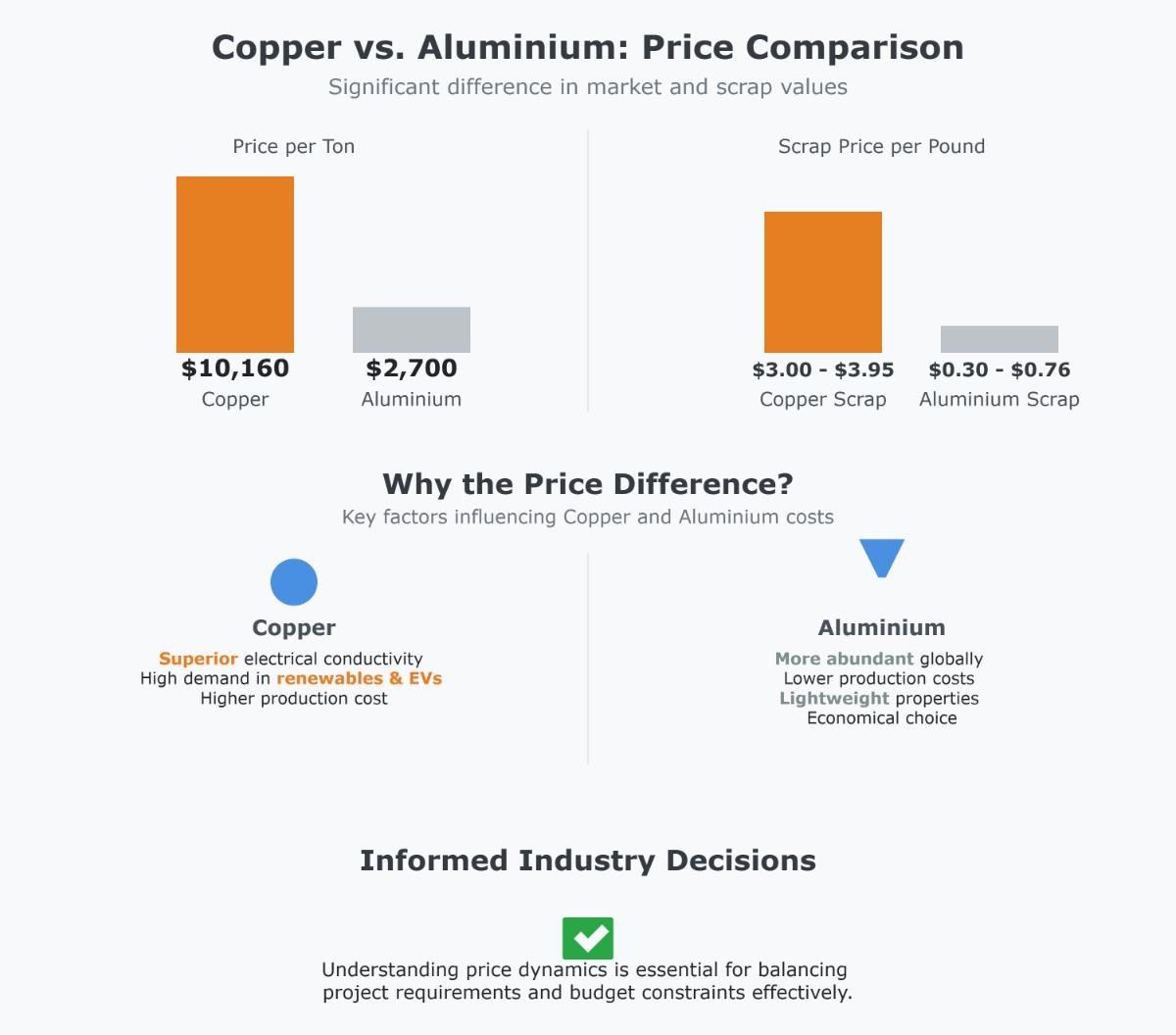

Recent forecasts reveal a significant price difference between aluminium and copper. Goldman Sachs projects the average price for aluminium in 2025 to be around $2,700 per ton, while Bank of America predicts a slightly higher average of $2,813 per ton. In contrast, Goldman Sachs forecasts copper prices to average $10,160 per ton in 2025, and Bank of America projects an average of $9,438 per ton. These figures clearly show that copper is much more expensive than aluminium.

Historical Price Trends

Historically, while both aluminium and copper prices have fluctuated, aluminium has generally been more stable due to its abundant supply. Copper prices, on the other hand, have experienced more volatility, often influenced by changes in global economic conditions and demand from major economies like China.

Factors Influencing Price Fluctuations

Demand and Supply

Both metals are significantly affected by demand from large economies. However, copper’s supply is limited because older mines are depleting, and the development of new mines is slow. This supply constraint contributes to its higher price. Aluminium, being more abundant, is less affected by such supply-related issues.

Geopolitical Factors

Trade policies and tensions, particularly between the U.S. and China, significantly impact the prices and supply chains of both metals. For instance, tariffs and trade restrictions can disrupt the flow of these metals in the global market, leading to price fluctuations.

Applications and Industry Use

The various uses of aluminium and copper also affect their prices. Aluminium is favored in the automotive and aerospace sectors for its lightweight properties. The demand in these industries can drive up the price of aluminium but is often offset by its abundance. Copper, crucial for electrical wiring and renewable energy systems due to its superior electrical conductivity, has a consistent and high-end demand, which supports its relatively high price.

Real-Time Market Data Insights

Tracking real-time market data offers valuable insights into the price dynamics of aluminium and copper. Factors such as inventory levels, production rates, and sudden changes in demand can cause short-term price movements. For example, an unexpected increase in copper demand for a large-scale renewable energy project can quickly drive up its price, while a surplus in aluminium production can lead to a temporary price drop.

Market Trends for Aluminium and Copper

Analysis of Global Market Conditions

The global markets for aluminium and copper have undergone significant changes in recent years due to economic, technological, and geopolitical influences.

Demand Drivers

Aluminium’s demand is driven by its lightweight, corrosion-resistant properties, making it essential in the automotive, aerospace, and packaging industries. The growing popularity of electric vehicles (EVs) and lightweight transport solutions is boosting aluminium demand. Copper, known for its superior electrical and thermal conductivity, is indispensable in electrical wiring, electronics, and renewable energy projects. The global transition to green energy significantly boosts copper demand, particularly for use in solar panels and wind turbines.

Supply Dynamics

The supply dynamics of aluminium and copper are notably different. Aluminium production enjoys stability from a widespread network of bauxite mines and smelters worldwide, resulting in a more reliable supply chain. However, copper supply is more constrained, with fewer large-scale mines and slower development of new mining projects. This supply limitation often results in higher price volatility for copper compared to aluminium.

Impact of Geopolitical Factors on Prices

Geopolitical events significantly influence the prices of both aluminium and copper. Trade policies, such as tariffs and trade wars, can disrupt the supply chain and affect market prices. For instance, tensions between the U.S. and China have previously led to fluctuations in metal prices due to uncertainty in trade relations. Additionally, environmental regulations in major producing countries like China can influence production costs and availability, further impacting global prices.

Chinese Market Influence

China’s role as a leading producer and consumer of both metals cannot be overstated. Chinese policies on environmental regulation, production quotas, and import tariffs significantly affect global prices. For aluminium, China’s capacity controls and environmental crackdowns have periodically tightened supply, supporting higher prices. Similarly, China’s substantial copper demand for infrastructure and technology development keeps global copper prices elevated.

Technological Advancements Influencing Market Dynamics

Technological advancements play a crucial role in shaping the market dynamics of aluminium and copper. Innovations in recycling technology have made aluminium recycling more efficient, reducing the demand for primary aluminium and stabilizing prices. In contrast, copper recycling, though advanced, faces challenges due to the complexity of recovering copper from electronic waste, maintaining higher demand for mined copper.

Advancements in Manufacturing

The development of new manufacturing technologies, such as additive manufacturing and advanced alloys, has expanded the applications of both metals. Aluminium’s use in 3D printing and high-strength alloys enhances its appeal in aerospace and automotive sectors. Copper’s incorporation into advanced electronic components and improved conductivity materials supports its continued demand in high-tech industries.

Predictions for Price Trends in 2025

Looking ahead to 2025, market analysts predict that aluminium prices will remain relatively stable, with forecasts averaging between $2,700 and $2,813 per ton. This stability is attributed to the diversified supply base and advancements in recycling technologies. On the other hand, copper prices are expected to stay high, with projections around $9,438 to $10,160 per ton. High copper prices are expected to persist due to strong demand from the renewable energy and electronics sectors, along with limited supply growth.

Long-Term Market Outlook

In the long term, aluminium’s market outlook is supported by its increasing use in lightweight and sustainable solutions, which aligns with global trends towards energy efficiency and carbon reduction. Copper’s long-term prospects are equally promising due to its critical role in renewable energy infrastructure and the ongoing electrification of various industries. Both metals will continue to be pivotal in driving technological and industrial advancements.

Industrial Applications of Aluminium and Copper

Electrical and Electronics Industry

Copper’s Superior Conductivity

Copper is highly valued in the electrical and electronics industry for its exceptional ability to conduct electricity and heat. This makes copper the preferred choice for applications such as wiring, cables, motors, transformers, circuit boards, and heat sinks. Its ability to efficiently conduct electricity and heat ensures optimal performance and reliability in electrical systems and electronic devices.

Aluminum’s Cost-Effective Alternative

While aluminum has lower conductivity compared to copper, it is still widely used in the electrical industry due to its lightweight and cost-effective nature. Aluminum is particularly favored for long-distance power transmission lines where reducing structural loads and cost is crucial. Its lower density allows for easier installation and maintenance, thereby further reducing expenses.

Construction and Infrastructure

Aluminum’s Lightweight Advantage

In the construction sector, aluminum is preferred for its lightweight, corrosion resistance, and ease of processing. It is commonly used in windows, curtain walls, and various structural components. Aluminum’s reduced weight simplifies installation and maintenance, offering significant cost savings and efficiency in building projects.

Copper’s Durability and Aesthetic Appeal

Copper is known for its durability, resistance to corrosion, antimicrobial properties, and aesthetic appeal. These characteristics make copper an excellent choice for premium building materials such as water pipes, HVAC systems, and high-end decorative elements. Copper’s longevity and attractive appearance enhance the quality and value of construction projects.

Transportation

Aluminum’s Lightweight Properties

The transportation industry extensively utilizes aluminum due to its high strength-to-weight ratio, making it a key material in automotive, aerospace, and rail sectors. Aluminum is a key material in these sectors where reducing vehicle and aircraft weight is crucial for enhancing fuel efficiency and sustainability. Its lightweight properties contribute to better performance and lower emissions in transportation systems.

Copper’s Role in Electric Vehicles

Copper is essential in electric vehicles (EVs) for components that require high conductivity and efficient cooling, such as battery connectors and cooling systems. Copper’s superior electrical properties ensure the effective operation and longevity of EV systems, supporting the growing demand for sustainable transportation solutions.

Cooling Systems

Copper’s High Thermal Conductivity

Copper is ideal for high-performance cooling systems because it conducts heat very well. It is widely used in advanced electronic devices and high-performance computers, where efficient heat dissipation is critical. Copper’s ability to conduct heat effectively ensures optimal cooling and prevents overheating in sensitive electronic components.

Aluminum’s Cost-Effectiveness

Aluminum is used in standard cooling applications where moderate thermal conductivity is sufficient. Its affordability makes aluminum a practical choice for cooling systems in settings with lower cooling demands, balancing performance and cost-effectiveness.

Packaging Industry

Aluminum’s Barrier Properties

Aluminum is extensively used in the packaging industry due to its excellent barrier properties against moisture, air, and light. It is commonly found in food and pharmaceutical packaging, where preserving product quality and extending shelf life are paramount. Aluminum’s lightweight and recyclable nature further enhance its appeal in sustainable packaging solutions.

Recycling and Environmental Impact

Aluminum’s Environmental Advantages

Aluminum recycling consumes significantly less energy compared to primary production, making it a highly sustainable material. Aluminum can be recycled indefinitely without losing quality, which reduces environmental impact and supports a circular economy.

Copper’s Recycling Benefits

Copper’s high recycling rate is driven by its economic value and environmental benefits. Recycling copper saves substantial energy compared to mining raw materials, and the metal retains its superior properties through multiple recycling processes. This contributes to the sustainability and cost-efficiency of using copper in various industries.

Cost and Availability

Copper’s High Cost

Copper is more expensive than aluminum due to its superior conductivity and durability. The higher price of copper is influenced by its limited supply and strong demand, particularly in electrical and renewable energy applications. Copper scrap prices are also significantly higher, reflecting its value and recyclability.

Aluminum’s Cost-Effectiveness

Aluminum’s lower cost makes it a preferred choice for large-scale projects where budget constraints are critical. Despite requiring larger conductors for electrical applications, aluminum’s affordability and abundance provide significant cost savings, especially in construction and transportation industries.

When evaluating aluminium and copper for industrial applications, professionals must consider a range of factors that influence their decision-making process.

Performance and Application Suitability

Aluminium is known for its lightweight nature and excellent corrosion resistance. It is also cost-effective. These properties make aluminium a versatile material in industries such as automotive, aerospace, and packaging. Its lower density is particularly advantageous in applications where weight reduction is crucial. This is especially important in transportation and construction.

In contrast, copper is renowned for its superior electrical and thermal conductivity. These characteristics make it indispensable in electrical wiring, electronics, and renewable energy systems. Additionally, copper’s high ductility and strength contribute to its widespread use in industrial machinery and high-performance applications.

Cost and Economic Impact

From an economic standpoint, aluminium generally offers a lower-cost alternative to copper. This makes it suitable for budget-conscious projects. The average price forecasts for aluminium in 2025 suggest stability, which enhances its appeal for large-scale applications where material costs are a significant consideration.

However, copper’s higher price reflects its superior performance characteristics, particularly in electrical and thermal applications. The projected price trends indicate that copper will remain a premium material. Its limited supply and strong demand, especially in emerging technologies and renewable energy sectors, contribute to its high value.

Environmental and Sustainability Considerations

Both aluminium and copper are highly recyclable, which contributes to their sustainability credentials. Aluminium recycling is notably energy-efficient, using up to 95% less energy than primary production. For example, the recycling of aluminium cans saves enough energy to power a television for three hours. This makes aluminium an environmentally friendly choice for projects prioritizing sustainability.

Similarly, copper offers significant environmental benefits through recycling. It saves up to 85% of the energy required for primary extraction. For instance, recycled copper is often used in new electrical wiring, reducing the need for new mining activities. This recyclability ensures that copper remains a valuable resource in a circular economy, reducing the environmental impact of its use.

Safety and Maintenance

In terms of safety and maintenance, copper generally requires less upkeep. It also poses fewer risks of overheating and electrical fires, making it a safer choice for critical electrical applications. Aluminium, on the other hand, needs careful installation and regular maintenance. This is because it can oxidize, leading to electrical resistance and potential overheating. Regular checks and proper installation techniques are essential to ensure its safe performance.

Future Outlook

The future outlook for both metals suggests continued importance in their respective applications. Aluminium’s role in lightweight, cost-effective solutions will persist, driven by advancements in manufacturing technologies and recycling. Copper’s essential role in electrical and renewable energy applications will sustain its high demand, supported by ongoing developments in green energy infrastructure.

Professionals must weigh these factors carefully to determine the most suitable material for their specific needs, balancing performance requirements, cost constraints, and environmental impact.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is the price difference between aluminium and copper?

The price difference between aluminium and copper is substantial, primarily due to their distinct properties and industrial demand. As of recent data, copper is priced around $10,160 per ton, significantly higher than aluminium, which is approximately $2,700 per ton. This disparity is also evident in scrap metal values, with copper scrap fetching $3.00 to over $3.95 per pound, compared to $0.30 to $0.76 per pound for aluminium.

Several factors contribute to this price difference. Copper’s superior electrical conductivity and its critical role in renewable energy and electric vehicles drive high demand and thus higher prices. Conversely, aluminium’s abundance and lower production costs, along with its lightweight properties, make it a more economical choice for applications where weight and cost are crucial considerations.

Understanding these price dynamics is essential for industry professionals to make informed decisions based on specific project requirements and budget constraints.

How do aluminium and copper compare in terms of industrial applications?

Aluminium and copper are both extensively used in various industrial applications, each offering distinct advantages. In the electrical and electronics industry, copper is favored for its superior electrical and thermal conductivity, making it ideal for wiring, motors, and transformers. Aluminium, though less conductive, is more cost-effective and is often used in overhead power lines due to its lightweight nature.

In construction and infrastructure, copper is valued for its durability and corrosion resistance, commonly used in high-end applications like water pipes and HVAC systems. Aluminium, on the other hand, is preferred for structural components, windows, and curtain walls due to its lightweight and low maintenance.

In the transportation sector, aluminium’s high strength-to-weight ratio is crucial for automotive and aerospace industries, enhancing fuel efficiency and reducing emissions. Copper is essential in electric vehicles for its conductivity in wiring and battery components.

For cooling systems, copper is chosen for high-performance applications due to its excellent thermal conductivity, while aluminium is used in standard systems for its cost-effectiveness. In packaging, aluminium’s barrier properties protect against moisture and air, extending product shelf life.

Environmentally, both metals are recyclable, but aluminium is more energy-efficient in recycling processes. While copper offers long-term benefits in high-performance applications, aluminium’s cost-effectiveness and versatility make it indispensable across various industries.

What are the predicted price trends for aluminium and copper in 2025?

Predicted price trends for aluminium and copper in 2025 show distinct patterns influenced by global economic conditions, supply-demand dynamics, and technological advancements. Aluminium prices are forecasted to average around $2,813 per tonne, reflecting a slight decline due to fluctuating demand and supply constraints. This trend is expected to stabilize as production capacity increases and recycling technologies advance.

On the other hand, copper prices present a mixed outlook. Forecasts range from $8,750 to $10,160 per tonne, driven by the energy transition and the rising demand for electric vehicles and renewable energy infrastructure. While the long-term outlook for copper remains bullish due to these factors, innovations in recycling and alternative materials may temper some of the demand pressures.

In summary, aluminium prices are expected to experience modest declines, whereas copper prices will likely see significant fluctuations, heavily influenced by the global shift towards green energy.