Imagine a metal that seamlessly blends remarkable strength, superior corrosion resistance, and exceptional heat tolerance. This is precisely what AMS 5653 stainless steel offers, making it a standout material in various high-stakes industries. In this article, we delve into the technical properties and diverse industrial applications of AMS 5653, providing you with a comprehensive understanding of its unique composition, mechanical attributes, and performance under challenging conditions. Whether you are curious about its chemical makeup or how it fares against other stainless steel grades, our deep dive will shed light on why AMS 5653 is a preferred choice in aerospace, chemical processing, and beyond. So, what sets AMS 5653 apart from its counterparts, and how can it enhance your projects? Read on to uncover the answers.

Overview of AMS 5653 Stainless Steel

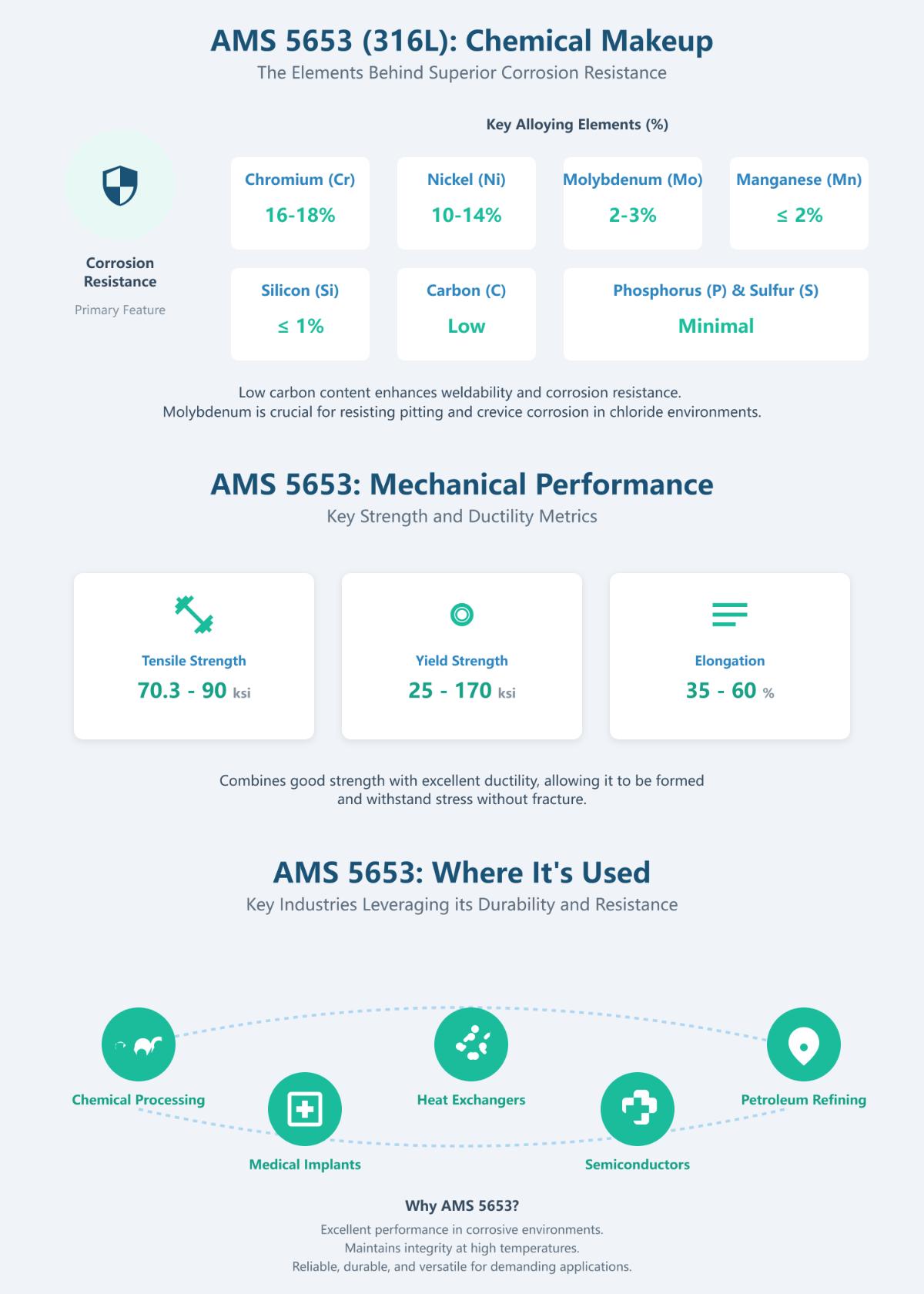

AMS 5653 is a specification for 316L stainless steel, known for its exceptional corrosion and heat resistance. This alloy is highly valued in materials science for its robust properties, especially its low-carbon content that enhances weldability and minimizes the risk of carbide precipitation during welding. This makes AMS 5653 ideal for high-strength, durable applications in corrosive environments.

The relevance of AMS 5653 in materials science is significant due to its versatile applications across various industries. Its chemical composition, which includes chromium, nickel, and molybdenum, provides excellent resistance to corrosion, particularly against chlorides and other industrial chemicals. This resistance is crucial in environments such as chemical processing plants, where exposure to aggressive substances is common.

AMS 5653’s high tensile and yield strength, combined with its performance in various temperatures, make it ideal for structural applications and high-temperature environments like heat exchangers and condensers. Its ability to maintain performance under a wide range of temperatures further enhances its suitability for high-temperature environments.

AMS 5653 stainless steel is available in several forms, including bars, forgings, rings, tubing, and wire. This variety allows engineers and manufacturers to select the most appropriate form for their specific application needs, ensuring optimal performance and longevity of the material in use.

Adherence to AMS specifications ensures that the material meets rigorous quality standards, which are essential for applications where reliability and consistency are paramount. AMS 5653 complies with top industry standards, including AMS 5448, AMS-QQ-S-763, AMS-S-7720, ASTM A276, ASTM A479, and ASTM A484.

The corrosion resistance of AMS 5653 stainless steel is one of its most notable features. The inclusion of molybdenum in its composition significantly improves its resistance to pitting and crevice corrosion, particularly in chloride-containing environments. This makes it a preferred choice for marine applications and chemical processing industries.

AMS 5653 maintains its integrity and performance at high temperatures. This property is particularly important for applications involving heat exchangers, surface condensers, and other high-temperature equipment.

The mechanical strength of AMS 5653 stainless steel is robust, with tensile strengths ranging from 70.3 to 90 ksi (485 to 621 MPa) and yield strengths varying depending on the specific form and orientation of the material. This high strength makes it suitable for demanding structural applications.

AMS 5653 stainless steel finds extensive use in various industries due to its exceptional properties:

- Chemical and Petrochemical Processing: Its corrosion resistance makes it ideal for handling aggressive chemicals.

- Aerospace Industry: The material’s reliability and performance under extreme conditions are essential for aerospace applications.

- Medical Implants and Instrumentation: The biocompatibility and corrosion resistance of AMS 5653 make it suitable for medical devices and implants.

- Semiconductors: Its purity and resistance to contamination benefit semiconductor manufacturing processes.

- Petroleum Refining: The material’s corrosion resistance is critical in petroleum refining environments.

Chemical Composition of AMS 5653

The chemical composition of AMS 5653 stainless steel is designed to enhance its corrosion and heat resistance. Each element in the alloy plays a specific role in improving its overall performance.

- Carbon (C): Maximum 0.030%

- Manganese (Mn): 1.25% to 2.00%

- Silicon (Si): Maximum 1.00%

- Phosphorus (P): Maximum 0.040%

- Sulfur (S): Maximum 0.030%

- Chromium (Cr): 16.00% to 18.00%

- Nickel (Ni): 10.00% to 14.00%

- Molybdenum (Mo): 2.00% to 3.00%

- Copper (Cu): Maximum 1.00%

Role of Each Element

Carbon (C)

Carbon is kept at a low maximum of 0.030% to minimize the risk of carbide precipitation during welding, which can lead to intergranular corrosion. This low carbon content is crucial for maintaining the alloy’s corrosion resistance, especially in welded structures.

Manganese (Mn)

Manganese, present in the range of 1.25% to 2.00%, acts as a deoxidizer and helps improve the steel’s hot-working properties. It also contributes to the alloy’s strength and hardness, enhancing its overall durability and wear resistance.

Silicon (Si)

Silicon, with a maximum content of 1.00%, serves as a deoxidizer during the steelmaking process. It also enhances the alloy’s strength and provides resistance to oxidation at high temperatures.

Phosphorus (P) and Sulfur (S)

Both phosphorus (maximum 0.040%) and sulfur (maximum 0.030%) are kept at low levels to prevent brittleness and ensure good weldability, as high levels can lead to hot shortness and reduced ductility.

Chromium (Cr)

Chromium (16.00% to 18.00%) is essential for forming a protective layer of chromium oxide on the surface, which significantly enhances corrosion resistance.

Nickel (Ni)

Nickel, at 10.00% to 14.00%, improves toughness, ductility, and corrosion resistance. It also helps maintain the alloy’s mechanical properties at various temperatures by stabilizing the austenitic structure.

Molybdenum (Mo)

Molybdenum content ranges from 2.00% to 3.00%, providing additional corrosion resistance, particularly against pitting and crevice corrosion in chloride environments. Molybdenum also enhances the alloy’s high-temperature strength.

Copper (Cu)

Copper (maximum 1.00%) enhances resistance to certain types of corrosion, such as sulfuric acid corrosion, and contributes to the alloy’s strength and workability.

Comparison with Other Stainless Steel Grades

AMS 5653 is often compared to other stainless steel grades, particularly 316L, due to its similar composition and properties. However, the specific limits and the balance of elements like manganese, molybdenum, and copper can provide AMS 5653 with slight advantages in specific environments, especially where enhanced corrosion resistance is required.

Importance of Chemical Composition

The precise chemical composition of AMS 5653 stainless steel is fundamental to its performance characteristics. By carefully controlling the amounts of carbon, manganese, silicon, phosphorus, sulfur, chromium, nickel, molybdenum, and copper, this alloy achieves a balance of corrosion resistance, strength, and ductility. These properties make AMS 5653 suitable for demanding applications in various industries, including chemical processing, medical devices, and high-temperature environments.

Mechanical Properties of AMS 5653

Tensile Strength

Tensile strength measures AMS 5653 stainless steel’s ability to endure tension without breaking. This property typically ranges from 70.3 to 90 ksi (kilopounds per square inch). The variability in tensile strength can be attributed to different processing conditions and specific applications. This high tensile strength ensures that the material can endure significant loads and stresses, making it suitable for demanding industrial applications.

Yield Strength

Yield strength, which ranges from 25 to 170 ksi for AMS 5653, indicates the stress level at which the material begins to deform plastically. This range reflects the influence of material orientation, processing techniques, and specific engineering requirements. The high yield strength of AMS 5653 makes it ideal for applications that require materials to retain their shape under high stress.

Elongation

Elongation measures the ductility of AMS 5653 stainless steel, indicating how much the material can stretch before breaking. Generally, AMS 5653 exhibits elongation values between 35% and 60%. High elongation means the material is ductile and can be shaped into complex forms without cracking. Such ductility is particularly valuable in manufacturing processes that involve bending, drawing, or forming.

Hardness

Hardness is an indicator of the resistance of AMS 5653 stainless steel to deformation and wear. While the AMS 5653 specification does not explicitly list hardness values, 316L stainless steel, which it pertains to, typically exhibits a hardness around 130 ± 8 HRC (Rockwell Hardness) in sintered conditions. This hardness helps the material resist wear and extends the lifespan of components.

Impact Toughness

Impact toughness measures the ability of AMS 5653 stainless steel to absorb energy and resist fracture under sudden impacts. This property is crucial for applications where the material may be subjected to dynamic or shock loading. The specific impact toughness values can vary, but AMS 5653 is generally known for its good toughness, even at low temperatures, making it suitable for applications in cryogenic environments.

Fatigue Strength

Fatigue strength refers to the ability of AMS 5653 to withstand cyclic loading over an extended period without failure. This is crucial for parts that face repeated stress, like in rotating machinery. AMS 5653 stainless steel typically exhibits excellent fatigue strength, contributing to its reliability and durability in dynamic applications.

Mechanical Properties Summary

The combination of high tensile and yield strengths, substantial elongation, adequate hardness, and excellent impact and fatigue toughness makes AMS 5653 stainless steel a versatile and robust material. These mechanical properties ensure that AMS 5653 can perform reliably in a wide range of demanding industrial environments, from chemical processing plants to aerospace and medical applications. The alloy’s ability to maintain its mechanical integrity under various loading conditions and temperatures further underscores its suitability for high-performance applications.

Comparison with Stainless Steel 316L

Overview of Stainless Steel 316L

Stainless Steel 316L is an austenitic stainless steel known for its excellent corrosion resistance and superior weldability. It is widely used in industries requiring high durability and resistance to harsh environments, such as chemical processing, marine, and pharmaceutical applications.

Chemical Composition

The chemical composition of 316L stainless steel includes:

- Carbon (C): 0.03%

- Manganese (Mn): 2.00%

- Silicon (Si): 0.75%

- Phosphorus (P): 0.045%

- Sulfur (S): 0.03%

- Chromium (Cr): 16.00% – 18.00%

- Nickel (Ni): 10.00% – 14.00%

- Molybdenum (Mo): 2.00% – 3.00%

Technical Properties

Corrosion Resistance

316L stainless steel exhibits excellent corrosion resistance, particularly in chloride environments. This is due to the presence of molybdenum, which enhances resistance to pitting and crevice corrosion. This makes 316L ideal for applications exposed to seawater and harsh chemicals.

Mechanical Strength

With a typical yield strength around 25,000 psi (170 MPa), 316L stainless steel provides sufficient mechanical strength for many industrial applications, even though it is not as high as AMS 5653. The tensile strength of 316L is approximately 70,000 psi (485 MPa), providing a good balance between strength and ductility.

Weldability

The low carbon content of 316L stainless steel minimizes carbide precipitation during welding, preventing intergranular corrosion. This property is particularly important in maintaining the integrity of welded structures in corrosive environments.

Temperature Resistance

316L stainless steel is resistant to high temperatures and can maintain its mechanical properties in a wide range of industrial processes. It performs well in both cryogenic and elevated temperature conditions, making it versatile for various thermal applications.

Comparative Analysis

Corrosion Resistance

While both AMS 5653 and 316L stainless steel offer corrosion resistance, 316L is particularly effective in chloride-rich environments due to its higher molybdenum content. AMS 5653 also provides good corrosion resistance, but its performance can vary depending on its specific composition and the presence of other alloying elements.

Strength and Hardening

AMS 5653 stainless steel is known for its high yield strength, often exceeding 100 ksi, due to precipitation hardening. This makes it suitable for high-strength applications such as aerospace components. In contrast, 316L stainless steel relies on its balanced composition for strength, making it more suitable for applications where extreme strength is not the primary requirement but corrosion resistance and weldability are crucial.

Weldability and Fabrication

316L stainless steel is easier to weld and fabricate due to its low carbon content, which reduces the risk of carbide precipitation. AMS 5653, on the other hand, can be more challenging to weld because of its precipitation-hardening characteristics, which may require specific heat treatment procedures to avoid compromising the material’s integrity.

Cost and Availability

Compared to AMS 5653, 316L stainless steel is generally more affordable and readily available. The specialized processing and heat treatment required for AMS 5653 can increase its cost, making 316L a more economical choice for many applications.

Industrial Applications

AMS 5653 Stainless Steel

- Aerospace: High-strength fasteners and structural components.

- Chemical and Petrochemical Processing: Components requiring high mechanical properties.

- Marine: Parts exposed to high-stress marine environments.

316L Stainless Steel

- Chemical Processing: Equipment and piping in corrosive environments.

- Pharmaceutical: Clean room and sterile applications.

- Marine Hardware: Components exposed to seawater.

- Food Processing: Equipment and containers requiring high hygiene standards.

Corrosion and Heat Resistance

Corrosion Resistance

Corrosion resistance is a key property of AMS 5653 stainless steel, making it ideal for use in harsh environments. The alloy’s resistance to corrosion is primarily derived from its chemical composition, which includes significant amounts of chromium and molybdenum.

Role of Chromium

Chromium is crucial in stainless steel alloys, providing excellent corrosion resistance by forming a passive oxide layer on the surface, which acts as a protective barrier against oxidation and deterioration. In AMS 5653, the chromium content ranges from 16% to 18%, ensuring a stable and durable passive film even in aggressive environments.

Role of Molybdenum

Molybdenum, present at 2% to 3%, boosts resistance to pitting and crevice corrosion in chloride-rich environments like marine and chemical processing. It enhances the robustness of the passive layer, making AMS 5653 capable of withstanding localized corrosion that could otherwise compromise the material’s integrity.

Low Carbon Content

The low carbon content (maximum 0.03%) reduces the risk of carbide precipitation during welding, which can lead to intergranular corrosion along the grain boundaries. By maintaining a low carbon content, AMS 5653 ensures that its corrosion resistance is not compromised during fabrication and welding processes.

Heat Resistance

AMS 5653 stainless steel is designed to perform well in high-temperature environments, maintaining its mechanical properties and corrosion resistance thanks to chromium and nickel, which provide protection from oxidation and structural stability.

Stability at High Temperatures

The alloy retains its mechanical properties and corrosion resistance at elevated temperatures due to the presence of chromium and nickel. Chromium contributes to the formation of stable oxides that protect the material from oxidation, while nickel enhances the alloy’s structural stability at high temperatures.

Applications in High-Temperature Environments

AMS 5653 is suitable for use in heat exchangers, surface condensers, and other equipment operating under high thermal loads. The material’s ability to resist scaling and maintain its strength at temperatures up to 870°C (1600°F) makes it ideal for these applications. Additionally, its resistance to thermal fatigue ensures a long service life even under cyclic thermal conditions.

Heat Treatment and its Effects

Heat treatment processes such as solution annealing play a crucial role in optimizing the heat resistance and mechanical properties of AMS 5653 stainless steel. Solution annealing involves heating the material to a temperature range of 1850 to 2050°F, followed by rapid cooling. This process dissolves any precipitates and restores the alloy’s corrosion resistance by promoting the formation of a homogenous austenitic structure.

Passivation

Passivation, a post-heat treatment process, can further enhance the corrosion resistance of AMS 5653. This process involves treating the stainless steel with an acid solution to remove any free iron from the surface, allowing the formation of a thicker and more protective oxide layer. Passivation is particularly beneficial for components exposed to highly corrosive environments.

Implications for Various Environments

The corrosion and heat resistance properties of AMS 5653 make it a preferred choice for a wide range of industrial applications. In chemical and petrochemical processing, the alloy’s resistance to aggressive chemicals and high temperatures ensures reliable and safe operation of equipment. In the aerospace industry, the material’s ability to withstand extreme conditions without losing its mechanical integrity is critical for the performance of aircraft components.

Industrial Applications of AMS 5653

Chemical and Petrochemical Processing

AMS 5653 stainless steel is widely used in chemical and petrochemical processing industries because it resists corrosion exceptionally well. Its ability to withstand aggressive chemicals like acids, chlorides, and sulfur compounds, along with its high molybdenum content that enhances resistance to pitting and crevice corrosion, makes it ideal for components like valves, pumps, and piping systems in harsh environments.

Aerospace Industry

The aerospace industry values AMS 5653 stainless steel for its strength, durability, and resistance to extreme conditions. It is used in manufacturing critical components such as fasteners, landing gear, engine parts, and structural elements. The alloy’s ability to maintain mechanical properties at high temperatures and its resistance to corrosion under various atmospheric conditions are crucial for ensuring the safety and performance of aerospace equipment.

Medical Implants and Instrumentation

Its biocompatibility and resistance to body fluids make AMS 5653 stainless steel ideal for medical implants and surgical instruments. The alloy’s low carbon content reduces the risk of carbide precipitation, ensuring that medical devices remain corrosion-resistant even after sterilization processes. Its high strength and ductility allow for the fabrication of complex shapes, which is essential for customized implants and intricate surgical tools.

Heat Exchangers and Surface Condensers

The excellent thermal stability of AMS 5653 stainless steel makes it ideal for heat exchangers and surface condensers used in various industrial applications. The alloy can withstand high thermal loads and resist scaling, ensuring efficient heat transfer and long service life. Its corrosion resistance is particularly beneficial in environments where the equipment is exposed to steam, water, and other corrosive fluids.

Semiconductors

AMS 5653 stainless steel is used in semiconductor manufacturing equipment for its clean, corrosion-resistant properties. The alloy’s purity and resistance to contamination are crucial for maintaining the integrity of semiconductor processes. Its mechanical properties and corrosion resistance ensure that semiconductor equipment performs reliably under demanding conditions.

Petroleum Refining

In petroleum refining, AMS 5653 stainless steel is employed in equipment that must endure high temperatures and corrosive substances. The alloy’s resistance to sulfur-containing compounds and its ability to maintain mechanical strength at elevated temperatures make it suitable for refining processes. Components such as reactors, distillation columns, and heat exchangers benefit from the durability and corrosion resistance of AMS 5653.

Marine Applications

AMS 5653 stainless steel is ideal for marine applications due to its excellent resistance to seawater and marine atmospheres. The alloy’s ability to resist pitting and crevice corrosion in chloride-rich environments makes it suitable for manufacturing boat fittings, propeller shafts, and other marine hardware. Its high strength and durability ensure reliable performance in harsh marine conditions.

Case Studies and Practical Examples

Chemical Processing Plant

A chemical processing plant implemented AMS 5653 stainless steel in its piping systems and reactors to handle aggressive chemicals. The alloy’s resistance to corrosion and high strength resulted in reduced maintenance costs and increased operational efficiency.

Aerospace Component Manufacturing

An aerospace manufacturer utilized AMS 5653 stainless steel for landing gear components. The material’s high tensile strength and resistance to atmospheric corrosion ensured the safety and reliability of the landing gear under extreme conditions.

Medical Device Production

A medical device company chose AMS 5653 stainless steel for producing surgical instruments. The alloy’s biocompatibility and corrosion resistance provided long-lasting and sterile surgical tools that met stringent medical standards.

Heat Exchanger in Power Plant

A power plant integrated AMS 5653 stainless steel heat exchangers into its cooling systems. The alloy’s thermal stability and resistance to scaling ensured efficient heat transfer and extended the lifespan of the heat exchangers.

Sustainability and Environmental Impact of AMS 5653

Sustainable Manufacturing Practices

AMS 5653 stainless steel, primarily composed of 316L, offers several sustainable manufacturing advantages. The alloy’s inherent properties contribute to environmentally friendly production processes and reduced ecological footprints.

Energy Efficiency

Producing AMS 5653 stainless steel can be made more energy-efficient. Modern steelmaking techniques, such as using electric arc furnaces with recycled scrap metal, significantly reduce energy requirements, and the high thermal conductivity of AMS 5653 ensures efficient heat transfer, lowering energy consumption in industrial applications.

Waste Minimization

AMS 5653 manufacturing processes aim to minimize waste. Advanced machining and forming techniques ensure precise material usage, reducing scrap and byproducts. Additionally, any scrap generated can be collected and recycled, further decreasing the material’s environmental impact and contributing to sustainable manufacturing practices.

Environmental Benefits

AMS 5653 stainless steel offers several environmental benefits that align with sustainable development goals. These advantages are critical in reducing the environmental impact of industrial operations.

Longevity and Durability

One of the key environmental benefits of AMS 5653 is its longevity. The alloy’s excellent corrosion and wear resistance extends the lifespan of components, reducing the need for frequent replacements. This durability translates to less material consumption and lower maintenance costs over time, contributing to overall resource efficiency.

Corrosion Resistance

AMS 5653’s superior corrosion resistance helps prevent environmental contamination. In industries where exposure to harsh chemicals and corrosive substances is common, the alloy’s resistance ensures that the integrity of containment systems is maintained, preventing leaks and spills that could harm the environment.

Recyclability

AMS 5653 stainless steel is highly recyclable, which is a significant factor in its environmental sustainability. At the end of its service life, the material can be efficiently recycled without loss of quality, conserving natural resources and reducing the need for virgin material extraction.

Closed-Loop Recycling

The recycling process for AMS 5653 often follows a closed-loop system, where the material is collected, processed, and reused within the same industry, creating a sustainable cycle. The high value of stainless steel scrap ensures that recycling is economically viable, promoting widespread adoption of recycling practices.

Environmental Impact in Applications

The use of AMS 5653 stainless steel in various industries demonstrates its positive environmental impact. By selecting this material for critical applications, industries can achieve their sustainability goals more effectively.

Chemical and Petrochemical Processing

In chemical and petrochemical processing, the use of AMS 5653 reduces the risk of leaks and failures due to its corrosion resistance. This reliability minimizes the potential for environmental contamination and improves the safety and efficiency of operations.

Medical and Pharmaceutical Industries

The biocompatibility and corrosion resistance of AMS 5653 make it suitable for medical implants and instruments. The alloy’s durability ensures long-term performance, reducing the frequency of replacements and the associated environmental impact.

Heat Exchangers and Surface Condensers

AMS 5653 is ideal for heat exchangers and surface condensers, where efficient thermal management is crucial. The alloy’s high thermal conductivity and resistance to scaling improve the efficiency of heat transfer processes, leading to energy savings and reduced emissions.

Innovative Manufacturing Techniques Using AMS 5653

Advanced Welding Techniques

Welding AMS 5653 stainless steel demands methods that maintain its mechanical properties and corrosion resistance. Advanced welding methods such as shielded fusion welding and resistance welding are often employed. Shielded fusion welding, including Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW), is preferred because it minimizes contamination and oxidation. Resistance welding techniques, such as spot welding and seam welding, are effective for joining thinner sections of AMS 5653, ensuring strong and clean welds without compromising the material’s integrity.

Precision Machining

Precision machining of AMS 5653 is essential to achieve the desired surface finish and dimensional accuracy. CNC (Computer Numerical Control) machines are widely used for this purpose, allowing for precise control over cutting parameters. Optimizing tool settings like cutting speed, feed rate, and tool geometry is essential to reduce tool wear and prevent work hardening. The use of high-speed steel or carbide tools with appropriate coatings can enhance machinability and extend tool life. Coolants and lubricants are also employed to reduce heat buildup and improve surface quality.

Premium Melting Processes

To enhance the quality and performance of AMS 5653, premium melting processes are utilized. One such process is the Special Cleanliness Quality (SCQ) melting process developed by Carpenter Technology. This process uses advanced refining techniques to minimize inclusions and impurities, enhancing the alloy’s cleanliness and uniformity. The SCQ process ensures that the final product has superior mechanical properties and enhanced corrosion resistance, making it suitable for critical applications.

Heat Treatment Optimization

Heat treatment plays a vital role in developing the desired mechanical properties of AMS 5653 stainless steel. Solution annealing, done at 1850°F to 2050°F followed by rapid cooling, dissolves precipitates and homogenizes the microstructure. This process enhances the alloy’s ductility and corrosion resistance. Precipitation hardening treatments, such as aging, can further increase the yield and tensile strengths, making the material suitable for high-stress applications. Precise control of temperature and time during heat treatment is crucial to achieve optimal results.

Additive Manufacturing

Additive manufacturing, or 3D printing, is an innovative technique gaining traction for producing complex AMS 5653 components. Selective Laser Melting (SLM) and Electron Beam Melting (EBM) are two common methods used to build parts layer by layer directly from digital models. These techniques allow for the creation of intricate geometries that are challenging to achieve with traditional manufacturing methods. Additive manufacturing also reduces material waste and shortens production lead times, providing significant advantages for prototyping and small batch production.

Surface Treatments

Surface treatments enhance the performance and longevity of AMS 5653 components. Techniques like passivation, electropolishing, and coating are used to enhance corrosion resistance and surface finish. Passivation involves treating the stainless steel with an acid solution to remove contaminants and promote the formation of a protective oxide layer. Electropolishing smooths the surface by removing a thin layer of material, reducing surface roughness and improving cleanliness. Coatings, such as PVD (Physical Vapor Deposition) or ceramic coatings, provide additional protection against wear and corrosion in harsh environments.

Integration of Automation

Automation in the manufacturing of AMS 5653 stainless steel components enhances precision, efficiency, and consistency. Automated systems, including robotic welding cells and CNC machining centers, ensure repeatable and high-quality production processes. Automation reduces human error and increases throughput, making it possible to meet the stringent demands of industries such as aerospace and medical devices. Implementing advanced sensors and monitoring systems allows for real-time process control and optimization, further improving product quality and manufacturing efficiency.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the properties and uses of AMS 5653 stainless steel?

AMS 5653 stainless steel, specified for grade 316L, is notable for its exceptional corrosion resistance and mechanical properties. Its chemical composition includes low carbon, chromium (16-18%), nickel (10-14%), molybdenum (2-3%), manganese (up to 2%), silicon (up to 1%), and minimal amounts of phosphorus and sulfur. These elements collectively enhance its resistance to pitting, crevice corrosion, and

Mechanically, AMS 5653 offers tensile strength ranging from 70.3 to 90 ksi, yield strength between 25 and 170 ksi, and elongation rates of 35-60%, demonstrating its good ductility and strength under various conditions.

Industrially, AMS 5653 is widely used in chemical and petrochemical processing, medical implants, heat exchangers, surface condensers, semiconductor manufacturing, and petroleum refining due to its ability to withstand corrosive environments and high temperatures. The alloy’s versatility and durability make it a preferred choice for applications requiring reliable performance in demanding conditions.

How does AMS 5653 differ from other stainless steel grades?

AMS 5653 stainless steel, which corresponds to the 316L grade, differs from other stainless steel grades primarily in its chemical composition and properties. Compared to standard 316 stainless steel, AMS 5653 has a lower carbon content (maximum 0.03% versus up to 0.08% for 316). This reduction in carbon minimizes the risk of carbide precipitation during welding, enhancing its resistance to intergranular corrosion.

When compared to 304 stainless steel, AMS 5653 contains higher amounts of nickel (10-14% versus 8-10.5% in 304) and molybdenum (2-3% versus none in 304). These additions significantly improve its corrosion resistance, especially in environments exposed to chlorides and other harsh chemicals.

AMS 5653 also exhibits superior mechanical properties, such as higher tensile and yield strengths, making it suitable for demanding applications in aerospace, chemical processing, and medical instrumentation. Its enhanced heat and corrosion resistance make it versatile for use in various industries, reflecting the specific advantages of this stainless steel grade over others.

What are the mechanical properties of AMS 5653?

The mechanical properties of AMS 5653 stainless steel, which is a specification for grade 316L, are crucial for understanding its performance in various applications. The tensile strength of AMS 5653 typically ranges from 70.3 to 90 ksi, which indicates the maximum stress it can withstand while being stretched or pulled. The yield strength, which measures the stress at which the material begins to deform plastically, varies between 25 and 170 ksi, depending on factors such as orientation and section thickness. Additionally, the elongation at break for AMS 5653 is between 35.0% and 60.0%, reflecting its ductility and ability to stretch significantly before failure. These properties make AMS 5653 suitable for demanding environments requiring high strength and excellent formability.

How does AMS 5653 perform in high-temperature environments?

AMS 5653 stainless steel performs exceptionally well in high-temperature environments. This material, derived from the 316L stainless steel alloy, is solution heat-treated, which significantly enhances its resistance to both heat and corrosion. AMS 5653 maintains its structural integrity and corrosion resistance up to temperatures of approximately 1600 °F (871 °C). This high-temperature performance is attributed to its chemical composition, which includes chromium, nickel, and molybdenum, elements known for their heat-resistant properties. Consequently, AMS 5653 is ideal for demanding applications in aerospace, chemical processing, and other industries where both high temperature and corrosive conditions are prevalent.

What are the corrosion resistance properties of AMS 5653?

AMS 5653 stainless steel, specified for grade 316L, exhibits excellent corrosion resistance properties due to its chemical composition, particularly the presence of chromium, nickel, and molybdenum. Chromium forms a passive film on the surface, which protects the material from general corrosion. The addition of molybdenum significantly enhances resistance to pitting and crevice corrosion, especially in chloride-rich environments. Nickel also contributes to the

These properties make AMS 5653 stainless steel highly suitable for applications in harsh environments, such as chemical processing, petrochemical industries, and marine applications, where exposure to corrosive substances is common. The alloy maintains its corrosion resistance even at elevated temperatures, making it ideal for high-temperature applications like heat exchangers.

In which industries is AMS 5653 most commonly used?

AMS 5653 stainless steel, also known as Stainless Steel Grade 316L, is commonly used in several key industries due to its exceptional properties. In the aerospace and defense sectors, it is favored for parts requiring high strength and corrosion resistance. The medical industry employs AMS 5653 for medical implants and instruments because of its biocompatibility and resistance to body fluids. In chemical and petrochemical processing, the alloy’s ability to withstand corrosive substances makes it ideal for handling aggressive chemicals. The power generation industry uses this stainless steel for equipment exposed to high temperatures and corrosive environments. Additionally, it is utilized in semiconductors and petroleum refining where resistance to chemical corrosion is crucial. These applications leverage the material’s durability, strength, and resistance to harsh conditions.