In the vast landscape of the steel industry, the choice between ASTM A1011 and A1008 can be a game-changer for intermediate-level professionals. These two steel grades, governed by ASTM standards, differ significantly due to their manufacturing processes—hot-rolled for A1011 and cold-rolled for A1008. These processes greatly influence mechanical properties like tensile and yield strength. But which one is better for structural applications?

As we delve deeper, discover how these differences impact cost, durability, and sustainability. So, are you ready to uncover the ideal steel grade for your next project?

Introduction to ASTM Standards

Understanding ASTM Standards

ASTM International, previously known as the American Society for Testing and Materials, is a global leader in creating and providing voluntary consensus standards. These standards are widely used in industries like construction and manufacturing to ensure quality, safety, and efficiency.

Importance of ASTM Standards in the Steel Industry

ASTM standards play a critical role in the steel industry by providing guidelines and specifications for materials, ensuring consistency and reliability. These standards help manufacturers, engineers, and consumers make informed decisions by defining the properties and performance of different steel grades.

Overview of ASTM A1011 and ASTM A1008

ASTM A1011

ASTM A1011 covers hot-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high-strength steel sheet and strip, in coils and cut lengths. This specification is crucial for applications needing specific mechanical properties and chemical compositions, offering detailed guidelines on producing quality hot-rolled steel products.

ASTM A1008

ASTM A1008 applies to cold-rolled, carbon, structural, high-strength low-alloy, high-strength low-alloy with improved formability, and ultra-high-strength steel sheet and strip, in coils and cut lengths. The specification outlines the requirements for cold-rolled steel products, emphasizing superior surface quality, dimensional accuracy, and mechanical properties suitable for more precise applications.

Key Differences Between ASTM A1011 and ASTM A1008

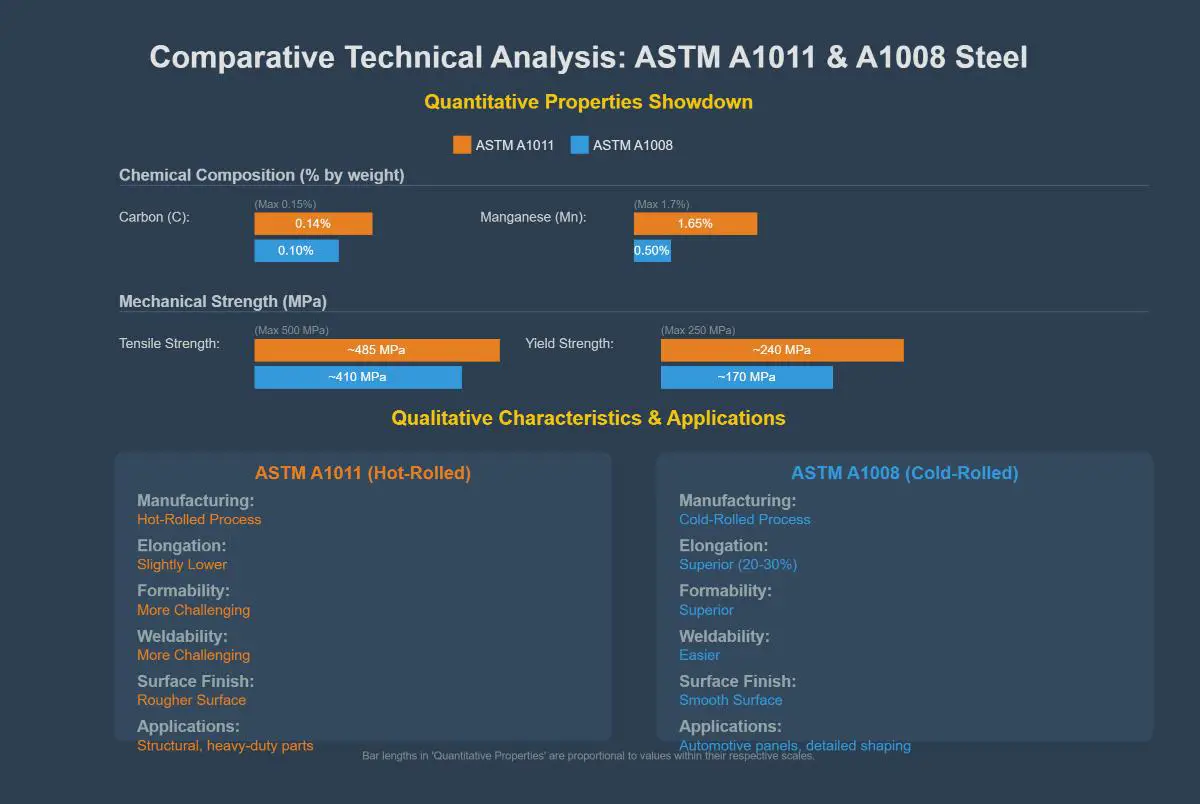

Chemical Composition

- ASTM A1011: It typically has higher carbon content and additional alloying elements, enhancing strength and durability but reducing formability.

- ASTM A1008: Features lower carbon content and fewer alloying elements, resulting in improved ductility and surface finish, making it more suitable for applications requiring intricate shapes and bends.

Mechanical Properties

- ASTM A1011: Known for higher tensile and yield strength due to its hot-rolled manufacturing process, making it ideal for structural and heavy-duty applications.

- ASTM A1008: Exhibits better elongation and formability, attributed to the cold-rolled process, which also provides a smoother, brighter surface finish.

Manufacturing Processes and Their Impact

Hot Rolled Steel (ASTM A1011)

Hot rolling heats steel to a high temperature before rolling it to the desired thickness, enhancing strength but resulting in a rougher surface finish and less precise dimensions.

Cold Rolled Steel (ASTM A1008)

Cold rolling is performed at room temperature, following the initial hot rolling process. This method improves the steel’s surface quality, dimensional accuracy, and mechanical properties, making it ideal for applications requiring high precision and an aesthetically pleasing finish.

Manufacturing Processes: Hot Rolled vs Cold Rolled

Definition and Process of Hot Rolled Steel

Hot rolled steel is made by rolling the steel at very high temperatures, usually above 1700°F (927°C), which is above its recrystallization point. The process involves heating steel slabs or billets in a furnace, rolling them through large rollers to achieve the desired thickness and shape, and then cooling the steel at room temperature.

Characteristics of Hot Rolled Steel

- Surface Finish: Hot rolled steel has a rough, scaled surface due to the cooling process.

- Dimensional Precision: Due to shrinkage during cooling, hot rolled steel often has less precise dimensions and slightly rounded edges.

- Internal Structure: The process results in a normalized structure with minimal internal stresses, enhancing its ductility.

- Cost: It is generally more cost – effective due to the simpler and quicker manufacturing process.

Mechanical Properties of Hot Rolled Steel

- Malleability and Ductility: Hot rolled steel is more malleable and easier to shape, making it suitable for large structural components.

- Strength: Although it has lower strength and hardness compared to cold rolled steel, it is adequate for many structural applications.

Definition and Process of Cold Rolled Steel

Cold rolled steel is produced from hot rolled steel that undergoes further processing at room temperature. The additional processing steps include:

- Rolling: The hot rolled steel is passed through rollers at room temperature to further reduce its thickness and improve surface finish.

- Annealing: This step involves heating the steel in a controlled environment and then cooling it to enhance its ductility and reduce internal stresses.

- Temper Rolling: The final step involves light rolling to achieve the desired mechanical properties and surface finish.

Characteristics of Cold Rolled Steel

- Surface Finish: Cold rolled steel has a smooth, shiny surface with better aesthetics.

- Dimensional Precision: It offers tighter dimensional tolerances and more precise shapes, making it suitable for applications requiring high precision.

- Internal Stresses: The process introduces higher internal stresses due to work hardening, which may require stress relief treatments before further processing.

Mechanical Properties of Cold Rolled Steel

Cold rolled steel is stronger and harder than hot rolled steel because of the work hardening process, which increases its tensile and yield strength. The enhanced surface finish facilitates painting and coating, and the steel exhibits improved formability for intricate shapes.

Impact of Each Process on Steel Properties

The hot rolling and cold rolling processes greatly influence the steel’s physical and mechanical properties:

- Surface Finish: Hot rolled steel has a rough surface, while cold rolled steel is smooth and aesthetically pleasing.

- Dimensional Accuracy: Cold rolled steel offers tighter tolerances and precision, whereas hot rolled steel has less precise dimensions.

- Mechanical Strength: Cold rolled steel is typically stronger and harder due to work hardening, while hot rolled steel is more ductile and easier to form.

- Cost: Hot rolled steel is generally more cost – effective due to the simpler process, while cold rolled steel incurs higher costs due to additional processing steps.

Understanding these differences helps in selecting the appropriate steel type for specific applications, balancing factors such as strength, precision, surface finish, and cost.

Mechanical Properties Comparison

Tensile Strength

Tensile strength measures the maximum stress a material can endure while being stretched or pulled before it breaks.

ASTM A1011

With a tensile strength of around 70,300 psi, ASTM A1011 steel is ideal for applications that require the material to withstand significant forces and stresses.

ASTM A1008

In contrast, ASTM A1008 steel has a tensile strength of about 44,000 psi for hot-rolled and 59,500 psi for cold-rolled versions. While lower than A1011, it is adequate for applications where less structural stress is expected and higher formability is required.

Yield Strength

Yield strength is the point at which a material starts to deform permanently.

ASTM A1011

With a yield strength of around 34,800 psi, ASTM A1011 steel is beneficial for structural applications requiring high resistance to deformation.

ASTM A1008

ASTM A1008 steel has a lower yield strength, which varies depending on the processing method. For hot-rolled A1008, the yield strength is around 24,500 psi, while for cold-rolled A1008, it is about 41,500 psi. This makes cold-rolled A1008 steel suitable for applications requiring moderate strength and good formability.

Elongation

Elongation measures the ductility of the steel, indicating how much it can stretch before breaking. It is expressed as a percentage of the original length.

ASTM A1011

ASTM A1011 steel exhibits good elongation but is generally less ductile than ASTM A1008 due to its higher carbon content. This moderate elongation is sufficient for structural applications where some flexibility is needed but not at the expense of strength.

ASTM A1008

ASTM A1008 steel typically shows better elongation, ranging from 20% to 30%. This higher ductility makes it ideal for applications requiring significant shaping and bending without cracking.

Comparative Table of Mechanical Properties

Here is a summarized table comparing the mechanical properties of ASTM A1011 and ASTM A1008 steel grades:

| Property | ASTM A1011 | ASTM A1008 (Hot-Rolled) | ASTM A1008 (Cold-Rolled) |

|---|---|---|---|

| Tensile Strength | ~70,300 psi | ~44,000 psi | ~59,500 psi |

| Yield Strength | ~34,800 psi | ~24,500 psi | ~41,500 psi |

| Elongation | Moderate | High (20-30%) | High (20-30%) |

This table provides a clear comparison, highlighting the strengths and suitability of each steel grade for different applications based on their mechanical properties.

Application Suitability

Strength & Durability

ASTM A1011, known for its high yield and tensile strength, is ideal for applications requiring substantial load – bearing capacity. Structural frames, heavy machinery, bridges, and construction equipment benefit from A1011’s resistance to deformation under significant stress. In contrast, ASTM A1008 has moderate strength and is better suited for applications where ductility and formability are more important than high – end strength, such as automotive panels and appliances.

Formability

ASTM A1008 excels in formability. It can be shaped into complex forms without cracking, making it perfect for detailed manufacturing like automotive panels and appliances. While ASTM A1011 has good formability, it is less than that of A1008. A1011 is more suitable for applications with moderate shape complexity where strength is the primary concern.

Weldability

The weldability of these two steel grades also differs significantly. ASTM A1008, with its low carbon and impurity content, offers excellent weldability and is ideal for manufacturing processes involving extensive welding, such as in the automotive and appliance industries. ASTM A1011 can be welded but requires careful techniques due to its higher carbon content, making it suitable for structural welding with appropriate precautions.

Surface Finish

The surface finish of the steel is a critical factor in many applications. ASTM A1008, being cold – rolled, has a smooth, shiny surface. This makes it the preferred choice for indoor, aesthetic, or precision applications like furniture and appliance manufacturing. In contrast, ASTM A1011, a hot – rolled steel, has a rougher, darker finish with mill scale and imperfections. It is more suitable for outdoor, rustic, or non – cosmetic applications such as fences, gates, and heavy equipment.

Corrosion Resistance

When it comes to corrosion resistance, ASTM A1008 generally performs better. Its lower carbon and alloy content make it more resistant to corrosion, which is beneficial for applications in exposed environments that require moderate protection. ASTM A1011, with its higher carbon and alloy content, has relatively lower corrosion resistance.

Cost

ASTM A1008 is more cost – effective due to its simpler composition and less energy – intensive cold – rolling process, making it ideal for budget – sensitive projects needing good finish and formability. ASTM A1011, with its hot – rolling and alloying elements, comes with a higher cost. However, its enhanced strength and durability justify the expense for applications that demand high – performance materials.

Standards Compliance and Industry Requirements

Overview of ASTM Standards

Compliance with ASTM standards is crucial in the steel industry to ensure product quality, safety, and performance. ASTM standards specify the chemical composition, mechanical properties, and manufacturing processes required for steel grades like ASTM A1011 and ASTM A1008, ensuring that they meet the stringent requirements for various applications.

Compliance Requirements for ASTM A1011

ASTM A1011 is predominantly used in structural applications due to its high strength and durability. To comply with ASTM A1011 standards:

- Chemical Composition: The steel must contain specific amounts of carbon (up to 0.14%), manganese, and other elements to achieve the desired mechanical properties.

- Mechanical Properties: The steel must meet minimum requirements such as a yield strength of approximately 240 MPa and a tensile strength of around 485 MPa.

- Manufacturing Process: It must be produced through a hot-rolled process, which influences its strength and surface characteristics.

- Testing and Certification: Compliance includes rigorous testing for mechanical properties and chemical composition, along with certification to verify that the steel meets ASTM standards.

Compliance Requirements for ASTM A1008

ASTM A1008 is favored for applications requiring high formability and a smooth finish. To meet ASTM A1008 standards:

- Chemical Composition: The steel must have a lower carbon content (maximum of 0.10%) and fewer alloying elements, enhancing its ductility and formability.

- Mechanical Properties: It must achieve a minimum yield strength of 170 MPa for hot-rolled variants. For cold-rolled variants, the yield strength must be 41,500 psi, with tensile strengths of around 410 MPa and 44,000 psi, respectively.

- Manufacturing Process: The steel must be cold-rolled to attain the precise dimensions and surface quality expected.

- Testing and Certification: Similar to A1011, ASTM A1008 steel undergoes stringent testing and certification processes to ensure it meets the specified standards.

Industry Requirements

The selection of ASTM A1011 or A1008 steel grades depends on the specific requirements of the industry and the application:

- Structural Applications: ASTM A1011 is preferred for construction and structural projects due to its higher strength and durability. Compliance with industry standards ensures that the steel can withstand significant loads and stresses.

- Automotive and Appliance Manufacturing: ASTM A1008, with its superior formability and surface finish, is ideal for automotive panels and household appliances. Industry requirements for these applications include excellent weldability and aesthetic surface quality, which ASTM A1008 provides.

- Cost Considerations: ASTM A1011 is generally more expensive because of its hot-rolled process and higher strength, while ASTM A1008 is a cost-effective option for formability- and finish-focused applications.

Sustainability and Environmental Compliance

Both ASTM A1011 and A1008 steel grades must adhere to environmental and sustainability standards. This includes:

- Promoting Recycling: Ensuring that manufacturing processes minimize waste and promote recycling of steel materials.

- Implementing Energy Efficiency: Utilizing energy-efficient practices in the production of both hot-rolled and cold-rolled steel to reduce the carbon footprint.

- Meeting Environmental Regulations: Complying with local and international environmental regulations to ensure that the production processes for these steel grades are sustainable and environmentally friendly.

Understanding these compliance and industry requirements is essential for selecting the appropriate steel grade for specific applications, ensuring that the chosen material meets both performance and regulatory standards.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the differences in mechanical properties between ASTM A1011 and A1008 steel?

ASTM A1011 and ASTM A1008 steel grades differ significantly in mechanical properties due to their distinct chemical compositions and manufacturing processes. ASTM A1011 is a hot-rolled carbon steel with a higher carbon content (up to 0.14%) and manganese content (up to 1.65%), leading to increased tensile strength (approximately 485 MPa) and yield strength (around 240 MPa). This makes it more suitable for structural and heavy-duty applications where strength and durability are crucial. However, it has slightly lower elongation and is more challenging to weld and form due to its hot-rolled nature, which results in a rougher surface finish.

In contrast, ASTM A1008 is a cold-rolled carbon steel with lower carbon (up to 0.10%) and manganese content (up to 0.50%), resulting in lower tensile strength (approximately 410 MPa) and yield strength (around 170 MPa). It offers superior formability and elongation (20-30%), making it ideal for automotive panels and applications requiring detailed shaping and a smooth surface finish. Additionally, A1008 is easier to weld and form due to its lower carbon content and cold-rolled process.

Which steel grade is more suitable for structural applications?

For structural applications, ASTM A1011 is generally more suitable. It has a higher carbon content, leading to enhanced strength and hardness. With a minimum yield strength of about 240 MPa and a tensile strength of approximately 485 MPa, it outperforms A1008. The hot – rolling process makes it stronger and more durable, ideal for heavy – duty uses like building frames and bridges. Although more expensive, its superior mechanical properties and robustness are well – suited for demanding structural needs.

How do the hot-rolled and cold-rolled processes affect steel properties?

The hot-rolled and cold-rolled processes significantly impact the properties of steel, influencing factors such as mechanical strength, surface finish, dimensional tolerances, and internal stresses.

Hot-rolled steel, such as ASTM A1011, is processed at temperatures above its recrystallization point, making it more malleable and easier to form into large shapes. This high-temperature processing results in a rough, scaled surface and coarser grain structure, yielding lower tensile and yield strengths but higher ductility and toughness. The gradual cooling process helps relieve internal stresses, making hot-rolled steel stable and suitable for structural applications.

Cold-rolled steel, like ASTM A1008, undergoes further processing at or near room temperature after initial hot rolling. This process increases tensile and yield strengths by inducing strain hardening, producing a smooth, shiny surface, and providing tighter dimensional tolerances. However, cold rolling introduces higher internal stresses, which may require annealing or temper rolling to relieve. Cold-rolled steel’s enhanced strength and superior surface finish make it ideal for precision parts and applications where aesthetics are critical.

What are the cost implications of choosing ASTM A1011 over A1008?

Choosing ASTM A1011 over A1008 involves several cost implications primarily due to differences in manufacturing processes and material properties. ASTM A1011 is hot-rolled, requiring high temperatures and specialized equipment, which results in a stronger and more durable steel but increases production costs due to the energy-intensive process. In contrast, ASTM A1008 is cold-rolled, which is less energy-intensive and less expensive to produce, resulting in a smoother finish suitable for applications where appearance is important.

Furthermore, ASTM A1011 has a higher carbon content and additional alloying elements, enhancing its strength and durability but also raising its production cost. These factors make A1011 more suitable for structural and heavy-duty applications where strength is critical, justifying the higher cost. On the other hand, A1008, with its lower carbon content and fewer alloying elements, is more ductile and cost-effective, making it ideal for applications such as furniture, appliances, and automobile parts.

How does sustainability factor into the choice between ASTM A1011 and A1008?

Sustainability considerations play a significant role in the choice between ASTM A1011 and A1008 steel grades. ASTM A1011, produced through hot-rolling, demands higher energy consumption and results in greater carbon emissions due to the high-temperature processing involved. Conversely, ASTM A1008, manufactured via cold-rolling after an initial hot-rolling phase, has a lower energy demand and reduced emissions, making it more environmentally friendly in terms of production.

In terms of material composition, ASTM A1011 contains higher levels of carbon and manganese, leading to more energy-intensive extraction and processing, whereas ASTM A1008’s simpler composition with lower carbon content enhances its recyclability and lessens resource consumption.

From a lifecycle perspective, ASTM A1011 offers superior strength and durability, which can reduce the frequency of replacements and associated waste in long-term applications. However, ASTM A1008, used in shorter lifecycle products, may result in higher material turnover and waste.

Are there any specific industry standards or compliance requirements for these steel grades?

Yes, there are specific industry standards and compliance requirements for ASTM A1011 and A1008 steel grades. These standards are defined by the ASTM (American Society for Testing and Materials), which outlines the chemical composition, mechanical properties, and manufacturing processes for these steels. ASTM A1011 is associated with hot-rolled processes, while ASTM A1008 is linked with cold-rolled processes.

Compliance with these standards ensures that the steel meets regulatory requirements for safety, performance, and environmental considerations. For example, ASTM A1011 steel, with its higher strength, is often used in structural applications where durability is critical. In contrast, ASTM A1008 steel, known for its formability, is typically used in automotive panels and appliances.

Adhering to these ASTM standards is crucial for manufacturers to ensure that their products meet industry-specific requirements and maintain quality and reliability in their applications.