When it comes to selecting the right stainless steel for your project, understanding the nuances between different standards is crucial. You might have encountered ASTM A240 and ASTM A666, two commonly referenced specifications, and wondered, “What exactly sets them apart?” These standards govern different aspects of stainless steel, from chemical composition to mechanical properties, influencing their suitability for various applications such as pressure vessels and architectural designs. In this article, we will delve into the key differences between ASTM A240 and ASTM A666, providing you with a comparative analysis to help determine which standard best meets your project needs. Are you ready to uncover the essential distinctions that could impact your material choice? Let’s dive in.

Overview of ASTM A240 and ASTM A666 Standards

Definition of ASTM A240

ASTM A240 is a standard set by ASTM International for chromium and chromium-nickel stainless steel plates, sheets, and strips used in pressure vessels, industrial boilers, and various other applications. This standard ensures materials maintain structural integrity under high stress, extreme temperatures, and corrosive environments by detailing the necessary chemical composition, including chromium, nickel, and molybdenum percentages. ASTM A240 is widely used in industries where high strength and corrosion resistance are paramount, such as in the manufacturing of reactors, heat exchangers, and other pressure-containing parts.

Definition of ASTM A666

ASTM A666, on the other hand, is tailored for applications prioritizing formability, surface finish, and aesthetic appeal, rather than high-stress or high-temperature conditions. It specifies different temper conditions, like 1/4 Hard and 1/2 Hard, to improve the material’s strength and flexibility. ASTM A666 is often used in architectural, household, and consumer products, where precise forming and a high-quality surface finish are necessary.

Importance of ASTM Standards in the Metal Industry

ASTM standards, such as ASTM A240 and A666, are crucial in the metal industry as they provide a consistent framework for material properties, quality, and performance, ensuring safety, reliability, and efficiency across various applications. By adhering to ASTM standards, manufacturers can guarantee that their products will perform as expected under specified conditions, reducing the risk of failure and enhancing overall product quality. These standards facilitate global trade and compatibility, as they are widely recognized and accepted by industries worldwide.

Key Differences Between ASTM A240 and ASTM A666

Scope and Primary Application

ASTM A240 is primarily used for stainless steel plates, sheets, and strips designed for heavy-duty industrial applications, such as pressure vessels. This standard emphasizes specific chemical compositions and mechanical properties to ensure materials can withstand high pressure and temperature conditions. It is widely adopted in industries requiring robust and durable materials.

ASTM A666, on the other hand, focuses on stainless steel sheet and strip intended for architectural, household, and general-purpose applications. This standard focuses on ease of forming and attractive surface finishes, making it suitable for applications where visual appearance and ease of forming are critical.

Material Properties and Mechanical Requirements

ASTM A240 specifies minimum strength and chemical composition requirements to produce pressure vessel-grade stainless steel, ensuring materials have the necessary strength, corrosion resistance, and heat resistance for demanding environments. Common grades include austenitic stainless steels such as 304 and 316.

While ASTM A666 covers similar stainless steel grades, it includes a wider range of structural strength variants. The standard emphasizes formability and surface finish quality. Mechanical properties vary across different tempers, such as 1/4 Hard and 1/2 Hard, accommodating various bending and forming operations. This flexibility is particularly important in architectural and household products.

Manufacturing and Testing Standards

ASTM A240 includes guidelines for manufacturing and testing to ensure consistent quality in heavy-duty applications, often requiring inspections and tests to meet stringent requirements. The standard often requires mill inspections, chemical testing, and mechanical testing to ensure materials meet the stringent requirements for pressurized environments.

ASTM A666 places more emphasis on surface quality and formability. Testing procedures are tailored to evaluate bending, hardness, and surface finish, which are crucial for architectural and household uses. The standard includes bend tests and hardness measurements for different tempers to ensure the material can be formed without cracking or damage.

Surface Finish and Appearance

While surface finish is controlled under ASTM A240, the focus is primarily on functional performance rather than aesthetics. Finishes are typically matte or dull to meet industrial requirements. However, additional specifications for surface finish can be referenced from ASTM A480.

ASTM A666 ensures the surface finish quality meets high standards required for visible applications, such as decorative panels or household appliances. This is essential for applications where appearance is critical, ensuring that the surface finish quality meets the high standards required for such visible applications.

Applications of ASTM A240 and ASTM A666

Pressure Vessels

ASTM A240 is ideal for pressure vessels because it demands strict chemical composition and mechanical properties. The high strength and excellent corrosion resistance of ASTM A240 stainless steel make it the preferred choice for pressure vessels, ensuring safety and longevity in chemical processing, power generation, and petrochemical industries.

Case Studies and Examples

- Chemical Reactors: ASTM A240 stainless steel is commonly used in chemical reactors where resistance to corrosive chemicals and high temperatures is crucial.

- Heat Exchangers: The durability of ASTM A240 stainless steel ensures efficient heat transfer and long service life in heat exchangers.

Architectural Applications

ASTM A666 meets architectural needs, emphasizing formability and surface finish. ASTM A666 stainless steel is perfect for architectural uses because it can be cold worked to increase strength while keeping a high-quality finish.

Case Studies and Examples

- Building Facades: ASTM A666 stainless steel is used for exterior building facades, providing a sleek, modern look along with durability.

- Roofing: The material’s formability allows for intricate roofing designs that are both functional and visually appealing.

Industrial Equipment

Both ASTM A240 and ASTM A666 have applications in industrial equipment, though their use depends on specific requirements.

Detailed Examples and Scenarios

- Heavy-Duty Equipment: ASTM A240 stainless steel, known for its strength and corrosion resistance, is often used in heavy-duty machinery and equipment exposed to harsh environments.

- Light-Duty Equipment: ASTM A666 stainless steel is used for light-duty industrial equipment where formability and surface finish are more critical than extreme strength. Examples include components that require detailed shaping and a polished appearance.

Household Applications

ASTM A666 is frequently employed in household applications where visual appeal and formability are key considerations.

Detailed Examples and Scenarios

- Kitchen Appliances: ASTM A666 stainless steel is used in kitchen appliances such as refrigerators, ovens, and dishwashers, offering a high-quality finish and ease of maintenance.

- Fixtures and Fittings: The standard’s focus on surface finish makes it ideal for household fixtures and fittings, including faucets, handles, and decorative panels.

Choosing the Right Standard Based on Project Needs

Understanding Project Requirements

To choose between ASTM A240 and ASTM A666, first understand your project’s specific needs, including its intended application, environmental conditions, and mechanical stresses. This initial assessment will help you determine which standard is most suitable.

Key Factors to Consider

Corrosion Resistance

- ASTM A240: Ideal for environments where corrosion resistance is critical, such as chemical processing plants or marine applications. The stringent requirements for chromium and nickel content ensure high resistance to corrosive elements.

- ASTM A666: Offers good corrosion resistance and is suited for less aggressive environments where aesthetic appeal and formability are prioritized.

Mechanical Strength

- ASTM A240: Suitable for high-pressure or high-temperature conditions, specifying higher mechanical strength and rigorous testing to withstand such stresses.

- ASTM A666: Provides sufficient strength along with superior formability and surface finish, ideal for applications where extreme mechanical strength is not the primary concern.

Formability and Surface Finish

- ASTM A240: Can be formed and finished to a high standard, but its primary focus is on durability and strength, making it less suitable for applications requiring intricate shaping and aesthetic finish.

- ASTM A666: Excels in applications needing excellent formability and a high-quality surface finish, perfect for architectural and household applications.

Decision-Making Framework

Assessing Environmental Conditions

Assess the conditions the material will face, like chemicals, humidity, and temperature extremes. ASTM A240 is preferable for harsh industrial environments, while ASTM A666 is better suited for controlled environments where aesthetics and formability are more critical.

Application-Specific Needs

Determine the primary function of the material:

- For pressure vessels, reactors, or heat exchangers, ASTM A240 ensures safety and durability under extreme conditions.

- For architectural elements, household appliances, and decorative components, ASTM A666 provides the necessary formability and aesthetic finish.

Additional Considerations

Surface Finish and Tolerances

- ASTM A240: Often paired with ASTM A480 for detailed surface finish and flatness tolerances, ensuring the material meets high-quality industrial standards.

- ASTM A666: Emphasizes aesthetic qualities and formability, making it the preferred choice for visually critical applications.

Compliance and Testing

Both standards have specific testing and compliance requirements:

- ASTM A240: Includes rigorous testing for pressure and mechanical properties, ensuring materials meet high-performance standards under stress.

- ASTM A666: Focuses on structural integrity and finish quality, with tests tailored to formability and surface appearance.

Practical Examples and Scenarios

Heavy-Duty Industrial Projects

For pressure vessels, reactors, or heat exchangers, ASTM A240 ensures safety and durability under extreme conditions.

Architectural and Household Projects

For building facades, kitchen appliances, and decorative panels, ASTM A666 provides the necessary formability and aesthetic finish, making it the ideal choice.

Common Misconceptions and Clarifications

Although ASTM A240 and ASTM A666 both cover stainless steel grades such as 304 and 316, they are meant for different uses. ASTM A240 is specifically designed for pressure vessels and industrial equipment, focusing on mechanical properties and corrosion resistance under stress. Conversely, ASTM A666 is tailored for architectural and household applications, prioritizing formability, surface finish, and aesthetic appeal.

Contrary to the misconception that ASTM A666 is inferior for structural use, it is optimized for different contexts. ASTM A240 includes stricter guidelines for welding and pressure tolerance, making it more suitable for critical structural components. However, ASTM A666 offers higher structural strength in specific applications, especially for formed or fabricated parts that require precision, such as medical devices and consumer goods.

Surface finish requirements also differ between these standards. ASTM A240 often pairs with ASTM A480 for finish specifications in industrial settings, focusing on functional performance. In contrast, ASTM A666 includes stricter surface quality criteria to ensure consistency for visible components, such as appliances and architectural trim, where aesthetic appeal is critical.

ASTM A666’s scope extends beyond household use. It is widely used in the medical and energy sectors for components requiring excellent formability and lack of magnetic attraction. ASTM A240 remains the default for high-temperature or corrosive environments, such as chemical processing, but ASTM A666 is equally critical in its designated applications.

Both standards can use the same alloys, such as 304 and 316L, but they have different performance requirements. ASTM A240 emphasizes chemical homogeneity and resistance to stress corrosion cracking, ensuring reliability under high stress. ASTM A666 ensures a consistent grain structure for deep drawing or spinning, catering to applications where formability and surface quality are paramount.

Key Selection Criteria

| Factor | ASTM A240 | ASTM A666 |

|---|---|---|

| Primary Use | Pressure vessels, industrial equipment | Architecture, consumer goods, medical |

| Why It Matters | These applications need materials that can withstand high pressure and stress without corroding. | These applications benefit from materials that can be easily formed and have a high-quality surface finish. |

| Strength Focus | High tensile/yield strength | Formability and surface finish |

| Why It Matters | Ensures the material can endure heavy loads and high pressure. | Ensures the material can be shaped into complex forms without compromising surface quality. |

| Testing | Pressure tolerance, weld integrity | Mechanical forming performance |

| Why It Matters | Critical for applications where the material will be exposed to high stress and need reliable welds. | Important for applications requiring precise shaping and aesthetic finishes. |

| Standards Pair | A480 (finish tolerances) | A484 (general requirements) |

| Why It Matters | Ensures the material meets stringent finish and tolerance requirements for industrial use. | Ensures the material meets general requirements for quality and formability. |

To make informed decisions, replace ASTM A167 with ASTM A240 for modern projects, as A167 is obsolete. Specify ASTM A666 only if the application demands superior forming characteristics or stricter finish tolerances. Combine standards (e.g., ASTM A240 + A480) for industrial projects requiring both material integrity and surface quality.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is the main difference between ASTM A240 and ASTM A666?

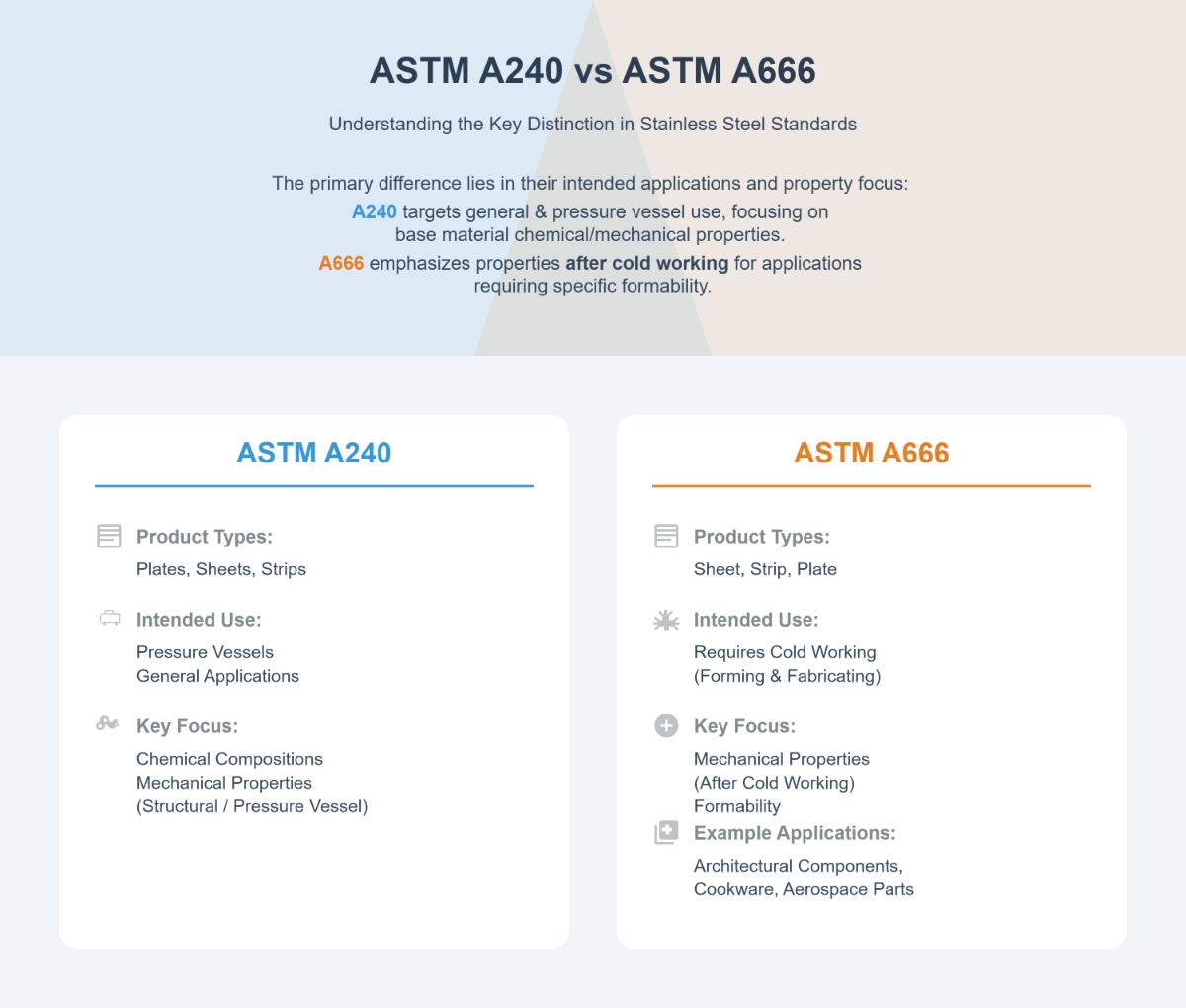

The main difference between ASTM A240 and ASTM A666 lies in the types of stainless steel products they cover and their typical applications. ASTM A240 is a specification for stainless steel plates, sheets, and strips primarily intended for use in pressure vessels and general applications. It includes a broad range of stainless steel grades and focuses on chemical compositions and mechanical properties suitable for structural and pressure vessel applications.

On the other hand, ASTM A666 specifies stainless steel sheet, strip, and plate, specifically emphasizing the mechanical properties after cold working. It is intended for products used where forming and fabricating by cold working processes are required. This standard focuses on the mechanical performance and formability of stainless steel after cold working, making it suitable for applications like architectural components, cookware, and aerospace parts.

Which standard should be used for pressure vessels?

For pressure vessels, ASTM A240 is the preferred standard. This specification is tailored for heat-resisting chromium and chromium-nickel stainless steel plate, sheet, and strip, focusing on the chemical, mechanical, and manufacturing requirements essential for safe and reliable pressure vessel construction. ASTM A240 is widely accepted and specified for pressure vessel applications due to its detailed requirements for material properties and quality assurance, ensuring it meets the demands of high-stress environments.

In contrast, ASTM A666 covers austenitic stainless steels in various conditions, mainly for structural, architectural, and some limited pressure vessel uses. However, it is not primarily focused on the stringent requirements needed for pressure containment, making ASTM A240 the more suitable choice for pressure vessels.

Is ASTM A666 suitable for architectural applications?

Yes, ASTM A666 is suitable for architectural applications. This standard covers austenitic stainless steels in both annealed and cold-worked conditions, which are typically used in sheets, strips, plates, and flat bars. These materials are intended for various applications, including architectural uses.

However, there are some considerations to keep in mind. The cold working process used in ASTM A666 materials can increase strength but may also make the material more challenging to form into complex shapes, which is often required in architectural projects. Additionally, welding can reduce the cold-worked strength, potentially limiting its practical benefits in welded architectural components.

In comparison, ASTM A240, which covers annealed stainless steel products, offers better formability and maintains properties after welding, making it generally more suitable for intricate architectural fabrications. Therefore, while ASTM A666 can be used in architectural applications, ASTM A240 is often preferred for its ease of fabrication and welding.

How do the mechanical properties differ between ASTM A240 and A666?

The mechanical properties of ASTM A240 and ASTM A666 differ primarily due to the intended applications and processing methods specified by each standard. ASTM A240 covers stainless steel plates, sheets, and strips used in pressure vessels and structural applications, requiring a broad range of tensile strengths, yield strengths, and hardness values depending on the specific grade. For example, austenitic grades like 304 and 316 typically have a tensile strength of around 75 ksi and a yield strength of 30 ksi, with elongation values of approximately 40%.

In contrast, ASTM A666 focuses on cold-rolled and annealed austenitic stainless steel sheets and strips designed for enhanced formability and fabrication. The mechanical properties under ASTM A666 are generally characterized by lower tensile and yield strengths to facilitate better ductility and elongation. For instance, austenitic stainless steel grades like 304 under ASTM A666 maintain similar tensile strength (around 75 ksi) but are annealed to achieve higher elongation and formability, which is crucial for applications involving extensive forming and shaping processes.

Thus, while both standards may overlap in tensile strength values for certain grades, ASTM A240 generally specifies higher mechanical strength and hardness limits suitable for more demanding structural and pressure vessel applications, whereas ASTM A666 emphasizes ductility and workability for fabrication purposes.

What are the specific corrosion resistance properties of ASTM A240 and ASTM A666?

ASTM A240 and ASTM A666 both involve austenitic stainless steels known for their corrosion resistance, but they cater to different applications and emphasize different properties.

ASTM A240 specifies chromium and chromium-nickel stainless steel plates, sheets, and strips. It is particularly noted for its high corrosion resistance due to its composition, which includes 18% chromium and 8% nickel. This composition forms a protective oxide layer that prevents corrosion, making ASTM A240 ideal for industries such as food processing, chemicals, pharmaceuticals, and petrochemicals. Specific grades like 304/304L and 316 offer varying levels of corrosion resistance, with 316 being particularly resistant in marine environments due to its molybdenum content.

ASTM A666, on the other hand, covers austenitic stainless steel sheet, strip, plate, and flat bar, focusing more on mechanical properties and formability. While it shares similar corrosion resistance benefits due to its chromium and nickel content, it is less detailed in its documentation compared to ASTM A240. ASTM A666 is often used in applications requiring high formability and general fabrication.

Can ASTM A240 and ASTM A666 be used interchangeably in industrial equipment applications?

No, ASTM A240 and ASTM A666 should not be used interchangeably in industrial equipment applications. ASTM A240 is specifically designed for high-strength applications, such as pressure vessels and industrial equipment, where durability and corrosion resistance are critical. It provides guidelines for manufacturing and testing to ensure consistent quality for heavy-duty uses. Conversely, ASTM A666 focuses on stainless steel for household and architectural applications, emphasizing aesthetic finish and appearance rather than structural strength. Therefore, selecting the appropriate standard depends on the project’s requirements: ASTM A240 for robust, high-strength applications and ASTM A666 for aesthetic purposes.