Steel standards can be a maze of numbers and letters, each with its own specific properties and uses. For those delving into the world of low carbon steel, understanding the differences between ASTM A569 and ASTM A1011 is crucial. Both of these standards govern hot-rolled carbon steel sheets, but they are not interchangeable. What sets ASTM A569 apart from ASTM A1011? How do their chemical compositions and mechanical properties stack up against each other? And, importantly, which one should you choose for your structural applications?

In this article, we will dissect the key differences between ASTM A569 and ASTM A1011, comparing their compositions, strengths, and practical uses. You’ll discover the advantages and disadvantages of each, and gain insights into which steel type might be the best fit for your specific needs. Ready to demystify these steel standards and make an informed decision? Let’s dive in.

Overview of ASTM A569 and ASTM A1011 Standards

Introduction to ASTM Standards

ASTM International, previously the American Society for Testing and Materials, creates and publishes technical standards for various materials, products, systems, and services. Among these standards, ASTM A569 and ASTM A1011 are crucial for specifying hot-rolled steel sheets and strips, particularly in low carbon steel applications.

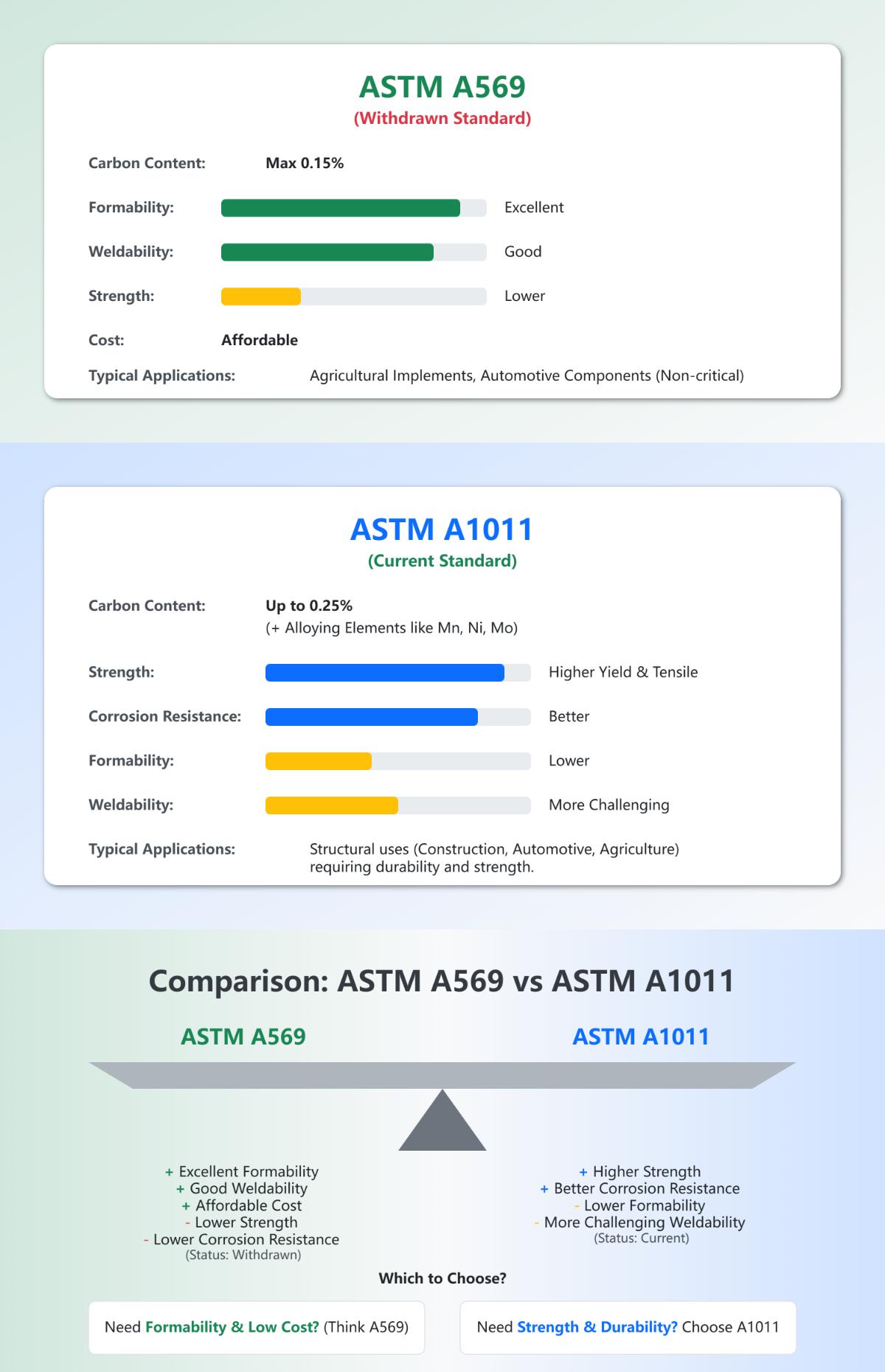

Definition and Background of ASTM A569

ASTM A569 was a standard specification for hot-rolled carbon steel sheet and strip in commercial quality, primarily for low carbon steel grades. This standard was crucial for specifying materials with good formability and weldability, essential for manufacturing and construction.

Material Characteristics

- Carbon Content: ASTM A569 specified a maximum carbon content of approximately 0.15%, which is typical for low carbon steels. This low carbon content ensures good formability and ease of welding.

- Applications: ASTM A569 steel was widely used in architectural, ornamental, and chemical applications for its moderate strength and excellent fabrication qualities.

- Current Status: ASTM A569 has been withdrawn and replaced by ASTM A1011. Despite its withdrawal, the steel previously identified as A569 generally meets the requirements of ASTM A1011.

Definition and Background of ASTM A1011

ASTM A1011 is a comprehensive, current standard that replaced older specifications like ASTM A569 and ASTM A570. This standard covers hot-rolled steel sheets and strips in various grades, broadening its scope to include structural steel and high-strength low-alloy (HSLA) steel.

Scope and Coverage

- Grades Covered: ASTM A1011 includes multiple grades such as low carbon steel, structural steel, high-strength low-alloy (HSLA) steel, and HSLA with improved formability. This range of grades allows for more versatile applications compared to ASTM A569.

- Material Properties: The standard allows for higher carbon content, typically up to 0.25%, and higher levels of manganese, which enhance yield strength, tensile strength, and overall structural performance. Alloying elements like nickel and molybdenum can also be included to improve corrosion resistance and weldability.

Comparative Analysis: ASTM A569 vs ASTM A1011

| Feature | ASTM A569 | ASTM A1011 |

|---|---|---|

| Status | Withdrawn (replaced by A1011) | Current, active standard |

| Carbon Content | Max ~0.15% | Up to 0.25% (higher carbon content allowed) |

| Steel Grades Covered | Low carbon steel only | Low carbon, structural, HSLA, and improved grades |

| Strength | Moderate strength | Higher yield and tensile strength options |

| Formability and Weldability | Good formability and weldability | Good formability; weldability may vary with higher carbon |

| Corrosion Resistance | Basic carbon steel properties | Enhanced with alloying elements possible |

| Typical Applications | Architectural, ornamental, chemical | Structural, automotive, agricultural, industrial |

| Cost Considerations | Generally more cost-effective | Potentially more expensive due to enhanced grades |

| Industry Usage | Limited, legacy standard | Widely referenced and used in modern projects |

Key Differences

- Scope and Application: ASTM A569 was limited to low carbon steel with specific applications requiring moderate strength and excellent fabrication qualities. In contrast, ASTM A1011 encompasses a broader range of steel grades, including those requiring higher strength and durability.

- Material Properties: The broader range of carbon and manganese content in ASTM A1011 enhances the steel’s mechanical properties, making it suitable for more demanding structural applications.

- Current Industry Usage: ASTM A1011 is the current and active standard, widely used across various industries, whereas ASTM A569 has been withdrawn and is considered a legacy standard.

Chemical Composition Differences and Their Impact

Low carbon steel, also known as mild steel, contains less than 0.25% carbon. This type of steel is known for its ductility, malleability, and ease of welding, making it a popular choice for a wide range of applications including construction, automotive, and manufacturing. Low carbon steels are particularly valued for their excellent formability and relatively low cost.

ASTM A569 specifies low carbon hot-rolled steel sheets and strips with a carbon content of up to 0.15%, ensuring good formability and weldability. It has lower levels of manganese, and phosphorus and sulfur are controlled to ≤0.035% and ≤0.040% respectively, enhancing surface quality and reducing brittleness.

ASTM A1011 covers various grades including low carbon, structural, and high-strength low-alloy steels, with carbon content ranging from 0.14% to 0.25% depending on the grade. Key components vary depending on the grade but typically include manganese up to 1.65%, which enhances strength and hardenability, and similar low levels of phosphorus and sulfur to ensure toughness and cleanliness. HSLA grades may include elements like niobium and vanadium for grain refinement, significantly improving strength and corrosion resistance.

The carbon content in steel directly affects its mechanical properties. Low carbon content results in excellent formability and superior weldability, making it ideal for applications requiring intricate shapes and easy joining processes. Higher carbon content increases yield strength and tensile strength, making the steel suitable for structural applications. However, it can reduce weldability due to increased hardenability, necessitating more careful welding procedures.

Below is a comparison of the chemical properties of ASTM A569 and ASTM A1011 steel types:

| Property | ASTM A569 | ASTM A1011 |

|---|---|---|

| Carbon Content | Max 0.15% | 0.14% – 0.25% (depending on grade) |

| Manganese | Lower levels | Up to 1.65% |

| Phosphorus | ≤0.035% | ≤0.035% |

| Sulfur | ≤0.040% | ≤0.040% |

| Alloying Elements | None specified | Niobium, vanadium (HSLA grades) |

| Formability | Excellent | Good |

| Weldability | Superior | Moderate (higher carbon risk) |

| Corrosion Resistance | Basic | Enhanced (with alloying elements) |

Understanding these chemical composition differences helps engineers and fabricators select the appropriate steel type for their specific applications, balancing formability, strength, weldability, and corrosion resistance based on the requirements of the project.

Mechanical Properties Comparison

Yield Strength Comparison

Yield strength defines the stress at which a material starts to deform plastically. ASTM A569 has a generally lower yield strength, making it suitable for less critical structures, whereas ASTM A1011 offers higher yield strength, often exceeding 30 ksi (207 MPa), for structural applications requiring greater load-bearing capacity.

Tensile Strength Analysis

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking. ASTM A569 provides moderate tensile strength, adequate for general fabrication. Conversely, ASTM A1011 boasts higher tensile strength, typically around 49 ksi (338 MPa), supporting applications involving heavy loads and demanding conditions.

Ductility and Elongation

Ductility, reflected by elongation, indicates how much a material can be deformed before fracturing. ASTM A569 offers excellent ductility for intricate designs, while ASTM A1011, with a minimum elongation of about 21%, balances strength and flexibility for durable applications.

Hardness and Wear Resistance

Hardness is an important factor in determining a material’s resistance to wear and abrasion. ASTM A569 has lower hardness, enhancing its formability and ease of fabrication. In contrast, ASTM A1011 features higher hardness values (Rockwell B41 / Brinell 75), which contribute to better wear resistance, making it ideal for applications exposed to abrasive environments.

Formability and Fabrication Ease

Formability is crucial for manufacturing processes that involve bending, shaping, and welding. ASTM A569 excels in formability, allowing easy fabrication and welding due to its low carbon content. ASTM A1011, while offering good formability, is slightly less malleable due to higher strength and carbon content, requiring more careful handling during fabrication.

Weldability Comparison

Weldability determines how well a material can be joined through welding processes. ASTM A569, with its low carbon content, exhibits excellent weldability, facilitating straightforward welding procedures. ASTM A1011 is also weldable but requires more care during welding due to its higher carbon content, which can affect the process.

Mechanical Properties Comparison Table

| Property | ASTM A569 | ASTM A1011 |

|---|---|---|

| Yield Strength | Generally lower, suitable for less critical structures | Higher yield strength, often ≥30 ksi (207 MPa), suitable for structural use |

| Tensile Strength | Moderate, sufficient for general use | Higher tensile strength, typically ≥49 ksi (338 MPa), supports heavy load applications |

| Elongation | Good ductility and formability | Minimum elongation around 21%, balancing strength and ductility |

| Hardness | Lower hardness, better formability | Higher hardness (Rockwell B41 / Brinell 75), better wear resistance |

| Formability | High, easy to fabricate and weld | Good, but slightly less formable due to higher strength and carbon content |

| Weldability | Excellent due to low carbon content | Good weldability but requires care because of higher carbon content |

Understanding these mechanical properties allows engineers to select the appropriate steel type based on specific application requirements, balancing factors such as strength, ductility, hardness, formability, and weldability.

Applications Suited for Each Steel Type

Suitability of ASTM A569 and ASTM A1011

ASTM A569 steel is commonly used in applications where high formability and ease of fabrication are essential. Its lower strength and moderate mechanical properties make it well-suited for non-critical structural components. This includes architectural elements, ornamental fixtures, and general construction materials requiring intricate shapes and designs without the need for high strength. Its cost-effectiveness further enhances its appeal for budget-conscious projects.

In the automotive industry, ASTM A569 steel is often utilized for parts that do not bear heavy loads but require good formability and weldability. This includes body panels, interior parts, and trim. The low carbon content ensures these parts can be easily shaped and joined, supporting efficient and cost-effective manufacturing processes.

ASTM A1011 steel, with its higher yield and tensile strength, is ideal for structural applications demanding robust performance and durability. This includes load-bearing structures, heavy-duty frameworks, and components exposed to rigorous conditions. The enhanced mechanical properties and corrosion resistance, especially in HSLA grades, make it suitable for construction projects, bridges, and industrial structures where long-term integrity is critical.

For automotive frames and structural components that must withstand high stresses and impacts, ASTM A1011 steel is preferred. Its higher strength and improved durability make it suitable for chassis, suspension systems, and other critical parts contributing to vehicle safety and performance. Its ability to stay strong under dynamic loads is crucial for automotive use.

Agricultural Equipment

For agricultural equipment, ASTM A569 steel is suitable for components that require good formability and are not subjected to extreme stress or wear. This includes housing, guards, and non-load-bearing structures. Its ease of fabrication allows for quick manufacturing and assembly, supporting the production of various agricultural tools and machinery parts.

ASTM A1011 steel is highly suitable for agricultural equipment that must endure harsh environments and heavy usage. This includes load-bearing frames, plows, and structural components requiring high strength and resistance to wear and corrosion. The steel’s superior mechanical properties ensure that equipment can operate efficiently and reliably in demanding agricultural settings.

Practical Decision-Making Framework for Engineers

When choosing between ASTM A569 and ASTM A1011 for specific applications, engineers should consider several factors:

- Formability Requirements: ASTM A569 is ideal for applications needing intricate shapes and easy fabrication.

- Strength and Durability: ASTM A1011 is better suited for applications where high mechanical strength and long-term durability are critical.

- Cost Considerations: Projects with tight budgets may benefit from the cost-effectiveness of ASTM A569.

- Environmental Exposure: ASTM A1011’s improved corrosion resistance makes it preferable for applications exposed to harsh environments.

Evaluating these factors helps engineers make informed decisions, ensuring that the selected steel type meets the specific needs of their projects efficiently and effectively.

Cost and Availability Considerations

Overview of Specifications and Relationship

ASTM A569 was initially the specification for low carbon hot-rolled steel strips, but it has since been replaced by ASTM A1011, which covers a broader range of steel types. ASTM A1011 includes hot-rolled steel sheets and strips, encompassing carbon, structural, high-strength low-alloy (HSLA), and ultra-high strength steels. Therefore, ASTM A569 falls within the low carbon steel category that ASTM A1011 also encompasses, meaning all ASTM A569 steel is essentially ASTM A1011 steel, but not all ASTM A1011 steel is ASTM A569.

Cost Considerations

ASTM A569 steel is generally more cost-effective due to its focus on low carbon content without alloying elements, making it suitable for budget-sensitive applications. In contrast, ASTM A1011 steel may be pricier because it includes higher strength grades and alloying elements like manganese, nickel, and molybdenum, which enhance its properties for structural or demanding applications.

Availability Considerations

Since ASTM A569 is no longer an active specification, it may be harder to find. ASTM A1011, on the other hand, is widely available and supported globally, making it easier to procure for current and future projects.

Performance and Application Impact Influencing Cost and Availability

The performance characteristics of ASTM A1011 steels are superior due to higher carbon and manganese content and the inclusion of alloying elements, making them suitable for structural, automotive, and agricultural applications. ASTM A569 steel is ideal for non-critical structures and designs where formability and weldability are important, such as architectural and ornamental uses. ASTM A1011 steel, with its higher strength and improved properties, is better suited for structural, automotive, and industrial applications, though its weldability might be slightly more challenging due to higher carbon content.

| Feature | ASTM A569 | ASTM A1011 |

|---|---|---|

| Specification Status | Withdrawn (replaced by A1011) | Current standard |

| Steel Grade | Low carbon, no alloying elements | Carbon, HSLA, and alloyed grades |

| Strength | Lower tensile and yield strength | Higher strength options available |

| Alloy Content | Minimal (low carbon steel) | Contains manganese, nickel, molybdenum |

| Cost | More cost-effective | Potentially higher due to enhanced properties |

| Availability | Limited, being phased out | Widely available globally |

| Typical Applications | Non-critical structures, formability-focused | Structural, automotive, agricultural equipment, demanding environments |

| Weldability | Good | Good but slightly more challenging due to higher carbon |

Welding and Fabrication Characteristics

Welding Characteristics

Weldability of ASTM A569

ASTM A569, being a low carbon steel, exhibits excellent weldability. The low carbon content minimizes the risk of weld cracking and brittleness, making it ideal for applications where welding is a primary fabrication method. Its simple composition means preheating and post-weld heat treatments are usually not needed, making welding more efficient and cost-effective. This steel allows for straightforward welding procedures, including common techniques such as MIG, TIG, and arc welding.

Weldability of ASTM A1011

ASTM A1011 includes multiple grades ranging from low carbon to high-strength low-alloy (HSLA) steels. The weldability of these grades varies. Low carbon variants within ASTM A1011 retain good weldability similar to ASTM A569, but HSLA grades, with higher carbon and alloying elements, require more careful welding procedures. These procedures may involve preheating and post-weld heat treatments to prevent hardening and cracking. While these advanced techniques ensure robust welds, they also necessitate more skilled labor and precise control during the welding process.

Fabrication Characteristics

Formability of ASTM A569

ASTM A569 steel is known for its superior formability. Its low carbon content and lack of alloying elements make it easy to bend, shape, and form into various configurations, which is especially useful for intricate designs and ornamental or architectural components. The ease of forming ASTM A569 contributes to lower fabrication costs and shorter production times.

Formability of ASTM A1011

ASTM A1011 steel encompasses a range of grades, with formability varying accordingly. Low carbon grades of ASTM A1011 are easy to form like ASTM A569, but HSLA grades are tougher to shape due to their higher strength. Despite these challenges, the enhanced mechanical properties of HSLA steels make them suitable for demanding applications where both strength and durability are critical.

Practical Considerations in Welding and Fabrication

Application Suitability

- ASTM A569: Best suited for decorative, architectural, and non-critical load-bearing applications. Its ease of welding and forming makes it ideal for projects prioritizing fabrication simplicity over mechanical strength.

- ASTM A1011: Preferred in structural, automotive, and industrial applications requiring higher strength and toughness. The steel’s enhanced mechanical properties justify the need for more controlled welding and fabrication techniques.

Cost Implications

ASTM A569 is generally more cost-effective because of its lower alloy content and simpler processing. ASTM A1011 may be more expensive but offers versatility and superior properties that can reduce long-term maintenance and enhance project durability. Choosing between these steels often involves balancing initial costs with performance requirements.

Industry Compliance and Current Usage Status

Overview and Standards Evolution

ASTM A569 was originally established as a standard specification for hot-rolled carbon steel sheets and strips, predominantly for low carbon steel. Over time, this standard has been withdrawn and replaced by ASTM A1011, which is now the current standard. ASTM A1011 provides a more comprehensive and updated set of guidelines, encompassing multiple steel grades including low carbon, structural, and high-strength low-alloy (HSLA) steels.

Material Composition and Mechanical Properties

ASTM A569 is characterized by its low carbon content and absence of alloying elements, making it a simpler and generally more cost-effective option. This steel is known for its ease of forming and welding, making it suitable for non-critical structural and ornamental applications.

In contrast, ASTM A1011 includes higher carbon and manganese content and may also incorporate other alloying elements such as nickel and molybdenum. These additions result in higher strength, enhanced corrosion resistance, and better overall performance in structural and industrial environments.

| Feature | ASTM A569 | ASTM A1011 |

|---|---|---|

| Carbon Content | Lower, no alloying elements | Higher, with alloying elements (e.g., Mn, Ni) |

| Strength | Moderate strength | Higher strength |

| Weldability | Good, easier due to low carbon | Good but may be more challenging due to higher carbon |

| Corrosion Resistance | Basic | Improved due to alloying elements |

| Formability | High | High, with additional HSLA options |

| Typical Applications | Non-critical structural, ornamental | Structural, automotive, agricultural equipment |

Industry Compliance and Current Usage

ASTM A1011 is the standard most industries reference. It applies to hot-rolled carbon steel sheets and strips. It aligns with modern requirements and testing protocols, ensuring that steel products meet stringent mechanical, chemical, and surface quality standards. The withdrawal of ASTM A569 implies that new projects and industrial specifications prefer or necessitate ASTM A1011 compliance.

ASTM A569 steel can still be found in legacy applications and some cost-sensitive projects where the lower strength and simpler composition suffice. However, for new structural or load-bearing uses, ASTM A1011 is recommended due to its superior mechanical properties and broader range of grades.

Availability and Cost Considerations

Availability and cost influence the selection of these materials. ASTM A569 steel may be less expensive and more readily available for simpler applications, while ASTM A1011 offers versatility and performance for more demanding environments. The choice between the two depends on specific project requirements such as strength, weldability, corrosion resistance, and budget constraints.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is the difference between ASTM A569 and ASTM A1011 steel?

The primary difference between ASTM A569 and ASTM A1011 steel lies in their specifications, chemical composition, and mechanical properties. ASTM A569 is a low carbon steel specification that has been withdrawn and replaced by ASTM A1011. A569 steel is known for its excellent formability, weldability, and affordability, with a maximum carbon content of 0.15%, making it suitable for non-critical applications like agricultural implements and automotive components.

In contrast, ASTM A1011 steel offers higher strength and better corrosion resistance due to its higher carbon content (up to 0.25%) and additional alloying elements such as manganese, nickel, and molybdenum. This makes A1011 ideal for structural applications in construction, automotive, and agricultural industries where durability and robust mechanical properties are crucial.

While A569 steel is easier to bend and weld due to its lower carbon content, A1011 provides enhanced yield and tensile strength, though its higher carbon content can make welding more challenging. Therefore, the choice between A569 and A1011 depends on the specific requirements of the project, with A569 being preferred for applications requiring high formability and lower costs, and A1011 being suited for projects needing higher strength and better corrosion resistance.

Which steel is better for structural applications, A569 or A1011?

When deciding between ASTM A569 and ASTM A1011 for structural applications, ASTM A1011 is generally the better choice. ASTM A1011 steel offers higher tensile and yield strength, making it more suitable for load-bearing and high-strength requirements. This steel also includes alloying elements such as nickel and molybdenum, which enhance its durability and corrosion resistance, critical factors for structural integrity in various environmental conditions.

While ASTM A569 steel is known for its excellent formability and weldability due to its low carbon content, it lacks the necessary strength and durability for demanding structural applications. ASTM A569 is more cost-effective and can be a suitable option for non-critical structures where budget constraints are a significant consideration.

What are the advantages and disadvantages of ASTM A569 steel?

ASTM A569 steel, a low-carbon steel, offers several advantages. It is highly affordable, making it a cost-effective choice for budget-conscious projects. Its low carbon content contributes to excellent flexibility and formability, allowing it to be easily bent into various shapes without cracking. This makes it suitable for applications requiring ductility and ease of welding. Additionally, ASTM A569 steel possesses good corrosion resistance, enhancing its durability in different environments.

However, there are notable disadvantages. ASTM A569 steel often has a rough surface finish if not acid-pickled, which can be undesirable for applications where surface quality is important. Furthermore, the ASTM A569 specification has been withdrawn, potentially affecting its availability and compliance with current industry standards compared to ASTM A1011. This withdrawal means that while A569 steel is still in use, it may not be as readily available or compliant with modern requirements, making ASTM A1011 a more reliable choice for certain applications.

Is ASTM A569 steel still in use or has it been replaced?

ASTM A569 steel is no longer in active use; the specification was withdrawn in 2000. ASTM A569 was a standard for hot-rolled carbon steel sheets and strips with a maximum carbon content of 0.15%, used primarily for bending, moderate forming, or drawing, and welding applications. Despite its discontinuation, some materials may still be referred to as A569 due to legacy practices. However, for new projects and specifications, ASTM A1011 is the recommended replacement. ASTM A1011 covers a broader range of steel types, including low-carbon, high-strength low-alloy, and stainless steel grades, offering enhanced weldability, machinability, and versatility, making it more suitable for modern industrial applications.

How does the corrosion resistance of ASTM A569 compare to ASTM A1011?

ASTM A569 and ASTM A1011 are both low-carbon steel grades with similar base compositions, but they differ in their alloying elements and surface treatments, which impact their corrosion resistance. ASTM A569, now withdrawn, was primarily used for non-critical applications and lacked specific corrosion-resistant treatments. On the other hand, ASTM A1011 includes controlled additions of alloying elements like manganese (up to 1.65%), enhancing its mechanical properties and indirectly supporting better performance under environmental stress.

While neither steel is explicitly designed for corrosion resistance, ASTM A1011’s higher manganese content improves its toughness and structural stability, reducing susceptibility to stress-related degradation in harsh environments. Additionally, ASTM A1011’s hot-rolled surface finish, although rougher, ensures consistency in performance when paired with protective coatings.

What factors should engineers consider when choosing between ASTM A569 and ASTM A1011?

When choosing between ASTM A569 and ASTM A1011, engineers should consider several key factors to ensure the steel meets the project’s requirements:

- Specifications and Standards: ASTM A569 has been withdrawn and replaced by ASTM A1011. ASTM A1011 encompasses a broader range of steel grades, including high-strength low-alloy (HSLA) steels, making it more versatile.

- Chemical Composition: ASTM A569 has a maximum carbon content of 0.15%, which is lower than ASTM A1011’s range of 0.15% to 0.25%. Higher carbon content in A1011 enhances strength but can complicate welding due to increased hardenability.

- Mechanical Properties: ASTM A1011 generally offers higher yield and tensile strength due to its higher carbon and alloying elements like manganese, making it suitable for more demanding applications.

- Applications: ASTM A569 is suitable for non-critical structures where formability and cost are priorities, such as architectural and ornamental uses. ASTM A1011 is preferred for high-strength, durability-requiring applications in construction, automotive, and agricultural equipment.

- Cost and Availability: ASTM A569 might be more cost-effective due to its simpler composition. However, ASTM A1011 is more commonly available and widely used today due to its replacement of A569 in many applications.

- Regulatory Compliance: Projects may require compliance with current standards, which means ASTM A1011 is often the necessary choice since ASTM A569 has been withdrawn.

By evaluating these factors—specifications, chemical composition, mechanical properties, applications, cost, and regulatory compliance—engineers can make informed decisions that align with their project’s specific needs.