When it comes to selecting the right rebar for your construction project, understanding the nuances between ASTM A706 and ASTM A615 can be crucial. Both types of rebar serve distinct purposes and offer unique benefits, but which one is the best fit for your specific needs? In this comprehensive comparison, we’ll delve into the mechanical properties, typical applications, cost considerations, weldability, and ductility of these two rebar types. We’ll explore their suitability for seismic applications and general building construction, helping you make an informed decision. Whether you’re looking to optimize material costs or ensure compliance with industry standards, this guide will provide the insights you need to choose between ASTM A706 and ASTM A615. Are you ready to discover which rebar reigns supreme in your next project? Let’s dive in.

Introduction

Importance of the Comparison

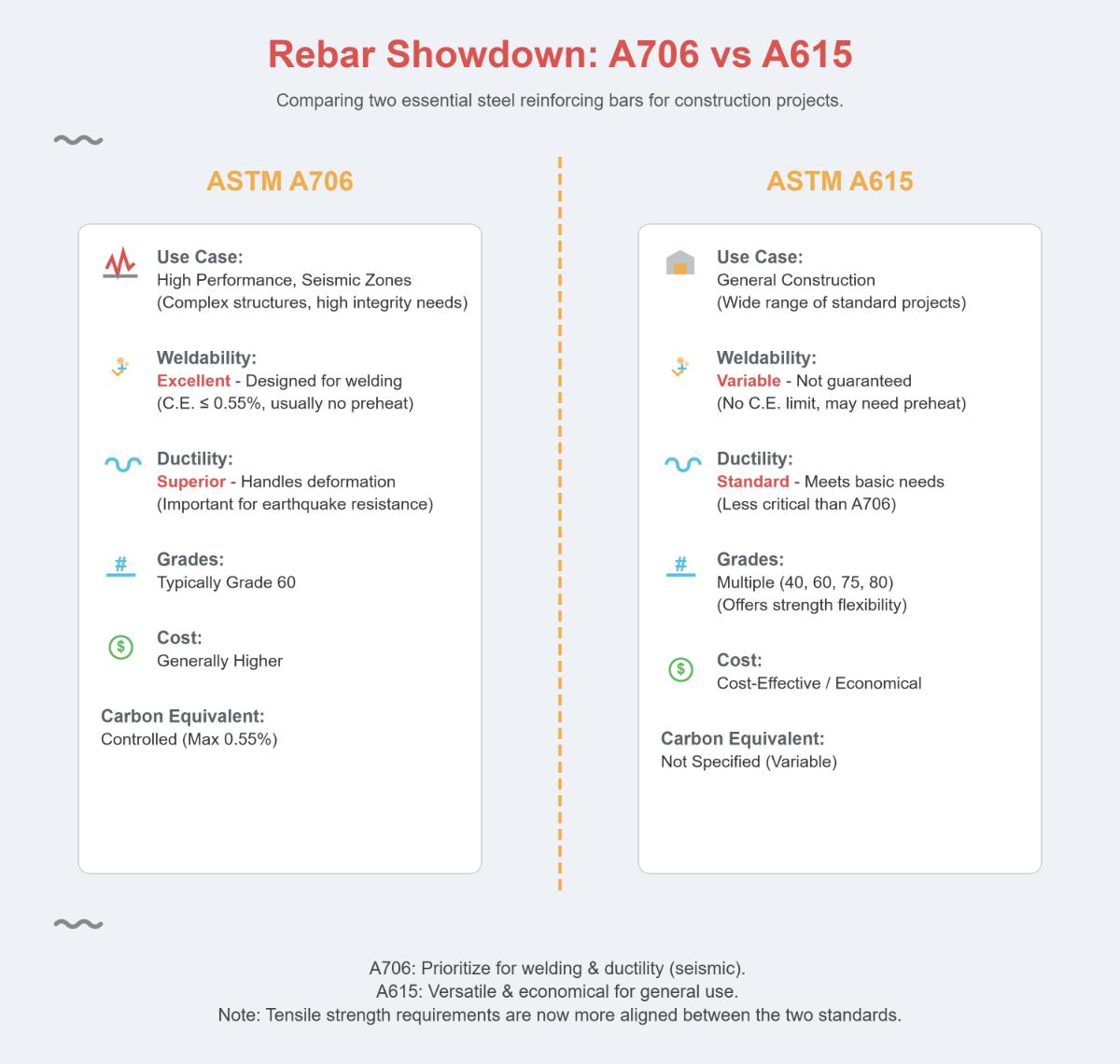

Choosing the right reinforcing steel bars (rebar) for concrete construction is essential, and understanding the differences between ASTM A706 and ASTM A615 standards helps in making the best choice.

Target Audience

This comparison is particularly relevant for construction and engineering professionals who need to select the appropriate rebar for their projects. It provides intermediate-level insights into the distinct characteristics and applications of ASTM A706 and ASTM A615 rebar, addressing the needs of those who require a deeper understanding of the materials but are not necessarily experts in metallurgy or materials science.

Comparative Analysis

Mechanical Properties

ASTM A706 and ASTM A615 rebar have distinct mechanical properties. ASTM A615 rebar is strong and cost-effective, making it suitable for general construction. ASTM A706 rebar is more flexible and easier to weld, making it ideal for projects in areas prone to earthquakes and other dynamic stresses.

Chemical Composition

The chemical makeup of these rebars is different as well. ASTM A615 rebar doesn’t have a set upper limit for carbon, which can make welding tricky and often requires testing before welding. ASTM A706 rebar has a controlled carbon content, making it easier to weld reliably without preheating and reducing the risk of cracks.

Applications

The choice between ASTM A706 and ASTM A615 rebar is influenced by the specific requirements of the construction project. ASTM A615 is widely used in general building construction due to its availability and cost-effectiveness. ASTM A706, however, is preferred for projects in seismic regions where enhanced ductility and weldability are critical.

Recent Developments

Recent updates to ASTM standards have matched the tensile strength requirements for ASTM A615 and ASTM A706 rebar, especially for Grades 60 and 80. Now, ASTM A706 rebar meets or surpasses the strength needs of ASTM A615, making it easier to choose rebar that is certified for both standards.

Key Differences in Mechanical Properties

When comparing ASTM A706 and ASTM A615 rebar, it’s important to understand the standards that govern their use. ASTM A706 is designed for seismic applications, featuring weldability and ductility, whereas ASTM A615 is a general-purpose rebar used in non-seismic and general construction.

Mechanical Properties

Yield Strength and Tensile Strength

ASTM A706 rebar is known for its controlled mechanical properties. The yield strength of ASTM A706 ranges from 60 ksi to 98 ksi, with the most common grade being 60 ksi. Its tensile strength matches these yield strengths, with Grade 60 having a tensile strength of 80 ksi and Grade 80 reaching 100 ksi.

ASTM A615 rebar, prior to the 2020 revisions, had a yield strength range of 40 ksi to 75 ksi for Grade 60, and 80 ksi to 95 ksi for Grade 80. Post-2020, the tensile strength has been standardized to match ASTM A706, with Grade 60 and Grade 80 having tensile strengths of 80 ksi and 100 ksi, respectively.

Ductility and Seismic Performance

Ductility is crucial for seismic applications, and ASTM A706 rebar is designed to handle significant deformation without losing strength. This makes it suitable for structures in earthquake-prone areas, as it can undergo substantial elongation and maintain its load-bearing capacity during seismic events.

In contrast, ASTM A615 rebar has lower ductility and is less suited for high-seismic regions. The variability in its elongation and reduced post-yield deformation capacity make it less reliable under cyclic loading conditions typical of seismic activities.

Weldability and Chemical Composition

Weldability is a key difference between these rebars. ASTM A706 has a controlled carbon equivalent, ensuring it can be welded without preheating, reducing cracking risks. Its low-carbon alloy composition (≤ 0.30% carbon) further enhances its weldability and ductility.

ASTM A615 rebar, however, does not have an upper limit for carbon content, leading to variations in its carbon equivalent. This makes welding more challenging and often necessitates chemical analysis to determine the appropriate welding procedures. The higher carbon content in ASTM A615 can increase brittleness and complicate welding processes.

Corrosion Resistance

Corrosion resistance is important for rebar, especially in moist and chloride-rich environments. Studies show ASTM A706 rebar has higher corrosion rates and lower chloride thresholds compared to ASTM A615, which may perform better in such conditions.

Typical Applications

Given these mechanical properties, the application of each rebar type varies significantly. ASTM A706 is preferred in seismic zones due to its superior ductility and weldability. It’s also commonly used in projects requiring extensive welding, such as bridges, high-rise buildings, and critical infrastructure.

ASTM A615 rebar is generally used in non-seismic areas and for general construction purposes. Its cost-effectiveness and availability make it suitable for residential buildings, commercial structures, and other projects where seismic performance is not a primary concern.

Applications for Each Rebar Type

Seismic Applications

Importance in Seismic Construction

Seismic construction requires materials that can endure dynamic stresses and significant deformation without losing structural integrity. Rebar plays a crucial role in reinforcing concrete structures in such environments, ensuring they can endure and recover from seismic activities.

ASTM A706 Suitability

ASTM A706 rebar is specifically designed for seismic applications. Its enhanced ductility and controlled chemical composition make it ideal for structures in earthquake-prone areas. The high ductility allows the rebar to deform significantly under seismic loads without losing strength, providing better energy dissipation and structural resilience. Additionally, its weldability ensures reliable connections without preheating, which is vital for constructing complex frameworks in seismic zones.

ASTM A615 Suitability

ASTM A615 rebar, while strong and cost-effective, is less suited for high-seismic regions due to its lower ductility. It is not designed to handle the same level of deformation as ASTM A706, making it less reliable under cyclic loading conditions typical of seismic events. However, it can still be used in seismic applications where ductility requirements are not as stringent, provided that proper engineering assessments are conducted.

General Building Construction

Usage Scenarios for ASTM A706

ASTM A706 rebar is beneficial for general building construction where high performance and reliability are needed. It is often used in key infrastructure projects such as bridges, high-rise buildings, and industrial facilities. The rebar’s controlled carbon content ensures consistent welding quality, making it suitable for projects involving extensive welding.

Usage Scenarios for ASTM A615

ASTM A615 rebar is widely used in general building construction due to its availability and cost-effectiveness. It is suitable for residential buildings, commercial structures, and other projects where seismic performance is not a primary concern. Despite its variable weldability, ASTM A615 remains a reliable and economical choice for many general construction needs.

Cost Considerations

Material Costs

When comparing ASTM A706 and ASTM A615 rebar, material cost is a crucial consideration. ASTM A615 rebar generally has a lower cost due to its carbon steel composition and simplified manufacturing process. The widespread use of ASTM A615 in general construction projects further reduces its price, benefiting from economies of scale.

In contrast, ASTM A706 rebar tends to be more expensive. This higher cost is attributed to its controlled chemical composition, which includes a limited carbon equivalent (CE ≤ 0.55%) to ensure enhanced ductility and weldability. The stringent quality assurance measures required for seismic and welding applications also contribute to the increased cost of ASTM A706.

Long-Term Cost Implications

The long-term cost implications of using ASTM A706 versus ASTM A615 rebar are influenced by their performance in corrosive environments, where ASTM A615 may offer better corrosion resistance. Studies indicate that ASTM A615 may have better corrosion resistance in certain conditions compared to ASTM A706. ASTM A706 rebar has been found to have lower critical chloride thresholds and higher corrosion rates, which could lead to increased maintenance and replacement costs over time in chloride-rich environments.

Despite its higher initial cost, ASTM A706 rebar can offer cost savings in the long run due to its superior ductility. In seismic zones, the enhanced ductility of ASTM A706 reduces the risk of cracking and structural failure, potentially lowering repair and maintenance costs over the lifecycle of the structure. This makes ASTM A706 a more cost-effective option for projects in high-risk seismic areas, where structural integrity and resilience are paramount.

Availability and Market Factors

ASTM A615 rebar is universally available and supported by multiple suppliers, ensuring competitive pricing and short lead times. The widespread availability of ASTM A615 makes it a convenient and cost-effective choice for many construction projects.

The availability of ASTM A706 rebar is more specialized, often limited to regions that prioritize seismic safety or welding requirements. This specialized availability can sometimes lead to longer procurement timelines and higher costs, especially in areas where ASTM A706 is not commonly stocked.

Specification Updates Impacting Costs

Recent updates to the ASTM standards have synchronized the tensile strength requirements for Grades 60 and 80 of ASTM A615 and ASTM A706 rebar, facilitating the production of dual-certified rebar. These revisions have enabled the production of dual-certified rebar that meets both standards. This alignment can reduce costs by allowing the use of a single type of rebar for projects that require compliance with both ASTM A615 and ASTM A706 specifications.

Dual-certified rebar, marked with both “W” and “S” for ASTM A615 and ASTM A706, can streamline procurement processes in regions requiring compliance with both standards. This dual certification can reduce administrative overhead and simplify material management, potentially leading to cost savings.

Application-Driven Cost Efficiency

For cost-sensitive projects without welding or seismic requirements, ASTM A615 is the optimal choice. Its lower cost and widespread availability make it ideal for residential, commercial, and non-seismic construction applications.

In projects where seismic performance and welding reliability are critical, the premium cost of ASTM A706 is justified by its controlled properties. The enhanced ductility and weldability of ASTM A706 make it the preferred choice for bridges, high-rise buildings, and other critical infrastructure in seismic zones.

Key Comparison Table

| Factor | ASTM A615 | ASTM A706 |

|---|---|---|

| Cost | Lower (carbon steel, mass-produced) | Higher (controlled chemistry) |

| Weldability | Limited (variable carbon content) | Optimized (CE ≤ 0.55%) |

| Ductility | Standard | Enhanced (seismic-ready) |

| Certification | Single (“S” marking) | Dual (“W” or “W+S”) |

| Best For | Non-seismic, general concrete work | Bridges, high-rise, seismic zones |

Strategic Recommendations

Mixing ASTM A615 and ASTM A706 rebar can be a strategic approach to optimize costs while ensuring structural integrity. For example, using ASTM A706 for critical joints and ASTM A615 for other areas can balance performance with cost-efficiency. However, clear field markings are essential to avoid confusion during construction.

Verifying dual-certified bars (ASTM A615/A706) can leverage updated tensile requirements and cost synergies, simplifying procurement and reducing costs.

Prioritizing ASTM A706 in corrosive environments should be done with caution. Given its susceptibility to corrosion, it is advisable to combine ASTM A706 with protective measures to ensure long-term durability and cost-effectiveness.

Weldability and Ductility

Weldability

Weldability refers to how well a metal can be welded under specific fabrication conditions and how effectively it performs in its intended use. ASTM A706 rebar is specifically designed with enhanced weldability in mind. Its chemical composition includes a controlled carbon content of ≤ 0.30% and a carbon equivalent (C.E.) not exceeding 0.55%, minimizing the risk of weld cracking and ensuring consistent weld quality. These controls improve the steel’s ability to form reliable welds, making ASTM A706 the preferred choice for projects that involve extensive welding, such as seismic reinforcement and complex structural connections.

In contrast, ASTM A615 rebar does not have a controlled upper limit for carbon content, which can lead to significant variability in its weldability. Each batch requires chemical analysis to assess this variability. Higher carbon content can make the rebar more brittle and prone to cracking when welded, often requiring additional precautions such as preheating or post-weld heat treatment.

Ductility

Ductility is the ability of a material to deform significantly before breaking. In construction, particularly in seismic applications, ductility is crucial as it allows structures to absorb and dissipate energy, reducing the risk of catastrophic failure during dynamic loading events like earthquakes.

ASTM A706 rebar is engineered for high ductility. Its controlled chemical composition and low-carbon alloy design enable it to deform plastically without fracturing. This makes it ideal for seismic applications, where structures must endure significant deformation while maintaining their load-bearing capacity. The yield strength of ASTM A706 rebar typically ranges from 60 ksi to 98 ksi, with tensile strengths reaching 80 ksi for Grade 60 and 100 ksi for Grade 80. These properties ensure that ASTM A706 can handle the dynamic loads experienced during seismic events, providing enhanced structural resilience.

ASTM A615 rebar has lower ductility compared to ASTM A706 due to its higher and less controlled carbon content, which reduces its ability to deform plastically under dynamic loads. While ASTM A615 is cost-effective and widely available for general construction, its performance under cyclic or dynamic loading conditions is less reliable. Yield strength for ASTM A615 varies widely, commonly ranging from 40 ksi to 75 ksi for Grade 60 and 80 ksi to 95 ksi for Grade 80. This variability in mechanical properties makes ASTM A615 less ideal for use in high-seismic regions or other applications where high ductility is essential.

Comparative Summary

When comparing ASTM A706 and ASTM A615 rebar, the differences in weldability and ductility are significant:

- Weldability: ASTM A706 offers superior weldability due to its controlled chemical composition, making it suitable for projects requiring extensive welding. ASTM A615 has variable weldability, often necessitating additional welding precautions.

- Ductility: ASTM A706 excels in ductility, making it ideal for seismic applications where structures must endure significant deformation. ASTM A615, with its lower and more variable ductility, is better suited for general construction in non-seismic areas.

Understanding these distinctions helps in selecting the appropriate rebar for specific construction needs, ensuring both safety and structural integrity.

Industry Trends and Standards Compliance

Current Industry Trends

The construction and engineering industries are experiencing significant trends and developments in the use of ASTM A706 and ASTM A615 rebar, driven by evolving standards, market demands, and technological advancements.

Dual Certification

The alignment of tensile strength requirements for Grades 60 and 80 in both ASTM A706 and ASTM A615 standards has facilitated the production of dual-certified rebar, marked with both “W” for ASTM A706 and “S” for ASTM A615. This dual certification simplifies procurement and field identification, ensuring broader acceptance of rebar that meets the stringent requirements of both standards.

Seismic Performance Focus

The increased focus on seismic performance has driven the demand for ASTM A706 rebar, known for its superior ductility and weldability, making it the preferred choice for structures in earthquake-prone regions. Engineering specifications in high seismic zones increasingly mandate the use of ASTM A706 or dual-certified bars for critical structural elements to ensure enhanced resilience and energy dissipation during seismic events.

Technological Advancements

Advancements in metallurgical technology have improved the production processes for both ASTM A706 and ASTM A615 rebar, resulting in more consistent and reliable performance. This consistency is crucial for meeting the stringent requirements of modern construction projects, particularly those involving dynamic loading and seismic activity.

Standards Compliance

Compliance with ASTM standards is essential for ensuring the quality and performance of rebar in construction projects. Both ASTM A706 and ASTM A615 rebar are subject to rigorous standards that define their chemical composition, mechanical properties, and performance criteria.

ASTM A706 Compliance

ASTM A706 rebar is specifically designed to meet high-performance requirements for seismic applications. Its controlled chemical composition includes a maximum carbon content of 0.30% and a carbon equivalent (C.E.) capped at 0.55%. These controls ensure enhanced weldability and ductility, making ASTM A706 compliant with the demanding needs of seismic reinforcement.

ASTM A615 Compliance

ASTM A615 rebar is the most common rebar used in general construction due to its cost-effectiveness and widespread availability. It does not specify an upper carbon limit, which can lead to variability in weldability and ductility. Compliance with ASTM A615 standards requires chemical analysis to determine suitability for welding and other specific applications.

Practical Considerations in Standards Compliance

Corrosion Resistance

Corrosion resistance is a significant factor in standards compliance, especially for projects exposed to marine or chloride-rich environments. Research indicates that ASTM A706 rebar may exhibit higher corrosion rates compared to ASTM A615. This difference in corrosion performance can influence the choice of rebar depending on environmental exposure and protective measures employed.

Field Identification

Correct field identification of rebar is crucial for ensuring compliance with ASTM standards. Rebar marked with “W” for ASTM A706 and “S” for ASTM A615 must be properly identified and placed according to project specifications. The trend towards dual-certified bars simplifies this process, but careful delineation is still required to avoid confusion during construction.

Here is a summary comparison of the key features and typical applications for ASTM A706 and ASTM A615 rebar:

| Feature | ASTM A706 | ASTM A615 |

|---|---|---|

| Chemical Composition | Low carbon (≤0.30%), controlled C.E. ≤0.55% | Higher carbon, no upper limit on C.E. |

| Yield Strength | 60–98 ksi (Grade 60/80) | 40–95 ksi (Grade 60/80) |

| Tensile Strength | 80 ksi (Grade 60), 100 ksi (Grade 80) | Typically ≥ yield strength, less controlled |

| Ductility | High, suitable for seismic/dynamic loads | Moderate, suitable for general use |

| Weldability | Superior, no preheating needed | Variable, often requires preheating |

| Corrosion Resistance | Lower critical chloride threshold, higher corrosion rate | Better corrosion resistance |

| Typical Application | Seismic zones, welded structures | General construction, cost-sensitive projects |

| Markings | “W” | “S” |

| Dual Certification | Bars marked “W” and “S” accepted as dual grade | Bars marked “S” and “W” accepted as dual grade |

This comprehensive comparison highlights ASTM A706’s advantages in ductility, weldability, and seismic suitability against ASTM A615’s cost-effectiveness and general-purpose use. The choice between these standards should be based on structural demands, environmental conditions, and project specifications.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the differences between ASTM A706 and ASTM A615 rebar?

ASTM A706 and ASTM A615 are two common types of rebar used in construction, each with distinct characteristics suited to different applications. ASTM A706 rebar is designed for high-performance applications, emphasizing weldability and ductility, making it ideal for projects requiring complex structural integrity and seismic resilience. It typically has a controlled carbon equivalent (C.E.) of no more than 0.55%, enhancing its weldability without the need for preheating in most cases. This rebar is often used in seismic construction due to its superior ductility and weldability.

In contrast, ASTM A615 rebar is widely used for general construction purposes and comes in various grades (40, 60, 75, and 80), offering a broader range of yield and tensile strengths. Unlike A706, A615 does not have an upper carbon limit, which can result in variable weldability and often necessitates a C.E. calculation to determine preheating requirements. ASTM A615 is cost-effective and suitable for projects where the specific demands of weldability and ductility are less critical.

Recent updates in specifications have aligned the tensile strength requirements of ASTM A615 with those of A706, allowing for greater flexibility in choosing between them based on project needs. Overall, ASTM A706 is preferred for applications requiring enhanced weldability and ductility, while ASTM A615 is more versatile and economical for general construction.

When should I use ASTM A706 or ASTM A615 rebar?

ASTM A706 rebar should be used in applications requiring high weldability and ductility, such as seismic construction and high-performance structures. Its controlled low-carbon content and consistent mechanical properties make it ideal for environments where structural integrity under dynamic loads is crucial. For projects where welding is frequent and the risk of weld cracking must be minimized, A706 is the preferred choice.

ASTM A615 rebar, on the other hand, is better suited for general building construction where cost-effectiveness is a priority and specific weldability and ductility requirements are less stringent. It is commonly used in routine structural projects where dynamic performance is not a critical concern. A615 rebar provides a broader range of yield strengths, making it versatile for various standard construction needs.

How do seismic applications impact the choice of rebar?

Seismic applications significantly impact the choice of rebar due to the demanding requirements for safety and structural integrity during earthquakes. ASTM A706 rebar is specifically designed to meet these needs, offering superior ductility and weldability. This rebar type can undergo large deformations without failing, which is crucial for absorbing and dissipating seismic energy through hysteresis loops under cyclic loading. Additionally, ASTM A706’s controlled chemical composition ensures reliable performance in welded connections, enhancing constructability and load transfer in seismic zones.

In contrast, ASTM A615 rebar, while suitable for general construction, lacks the necessary ductility and weldability for seismic applications. It is more prone to brittle failure under the repeated stress reversals typical of earthquakes. Consequently, ASTM A706 is the preferred choice in seismic design codes to ensure structures can withstand and recover from seismic events effectively, thereby improving overall safety and resilience.

What are the cost differences between ASTM A706 and ASTM A615 rebar?

The cost differences between ASTM A706 and ASTM A615 rebar primarily arise from their respective manufacturing processes and applications. ASTM A706 rebar, which is designed for enhanced ductility and weldability, typically costs about 10-20% more than ASTM A615 rebar. This price premium is due to the stricter control of chemical composition and higher quality assurance standards required for ASTM A706 to ensure its performance in seismic and critical structural applications.

Conversely, ASTM A615 rebar is a general-use carbon steel rebar that benefits from simpler manufacturing processes and economies of scale, making it more affordable. The typical price range for ASTM A706 rebar is approximately $495-$556 per ton, while ASTM A615 rebar ranges from $400-$500 per ton. Contractors report that ASTM A706 costs about $20 more per truckload compared to ASTM A615, but this difference is often considered justified in projects where enhanced properties are necessary.

Which rebar type is better for weldability?

When comparing ASTM A706 and ASTM A615 rebar in terms of weldability, ASTM A706 is the superior choice. ASTM A706 rebar is specifically designed for welding applications, with a controlled chemical composition that includes lower carbon content and other alloying elements to minimize the risk of weld-induced cracking and brittle fractures. This makes it suitable for conventional arc welding without the need for special preheating or post-weld heat treatment procedures.

On the other hand, ASTM A615 rebar has higher carbon content and less stringent control over its chemical composition, making it more prone to welding issues such as cracking and brittleness. Consequently, welding ASTM A615 rebar requires more complex and costly procedures, including preheating and post-weld treatments, to ensure structural integrity.

How does ductility affect the performance of rebar in construction?

Ductility significantly impacts the performance of rebar in construction by enhancing the ability of structures to withstand stress and deformation without failure. Ductility refers to the capacity of a material to undergo plastic deformation before breaking. In rebar, high ductility is particularly crucial for seismic-resistant constructions as it allows buildings to absorb and dissipate energy during events like earthquakes, reducing the risk of catastrophic collapse.

ASTM A706 rebar is designed with higher ductility compared to ASTM A615, making it more suitable for seismic applications where flexibility and energy absorption are essential. This characteristic allows structures reinforced with ASTM A706 to bend and stretch under seismic loads, thereby maintaining structural integrity and preventing sudden failures. Conversely, ASTM A615 rebar, while adequate for general-purpose construction, typically exhibits lower ductility, making it less ideal for environments where high plastic deformation is required.