When it comes to ensuring the corrosion resistance and longevity of stainless steel, choosing the right passivation standard is crucial. Two of the most widely recognized standards in this field are ASTM A967 and ASTM A380. But how do you determine which one is best suited for your needs? In this comprehensive guide, we’ll delve into the key differences between ASTM A967 and ASTM A380, examining their scope, applications, and specific requirements. Whether you’re a professional in the stainless steel industry or simply looking to deepen your understanding, this comparative analysis will provide valuable insights to help you make an informed decision. Ready to uncover which standard aligns with your specific stainless steel type? Let’s dive in.

Overview of ASTM A967 and ASTM A380

Introduction to ASTM Standards

ASTM A967 and ASTM A380 are essential standards that govern the passivation processes of stainless steel components. Passivation is a chemical treatment aimed at enhancing the corrosion resistance of stainless steel by removing free iron and other contaminants from its surface.

Importance in Stainless Steel Passivation

These standards are crucial for ensuring the quality and durability of stainless steel parts. By adhering to these standards, manufacturers can achieve a clean, smooth finish on stainless steel surfaces, which is crucial for preventing corrosion and maintaining the integrity of the material in various applications.

Overview of ASTM A967

Scope

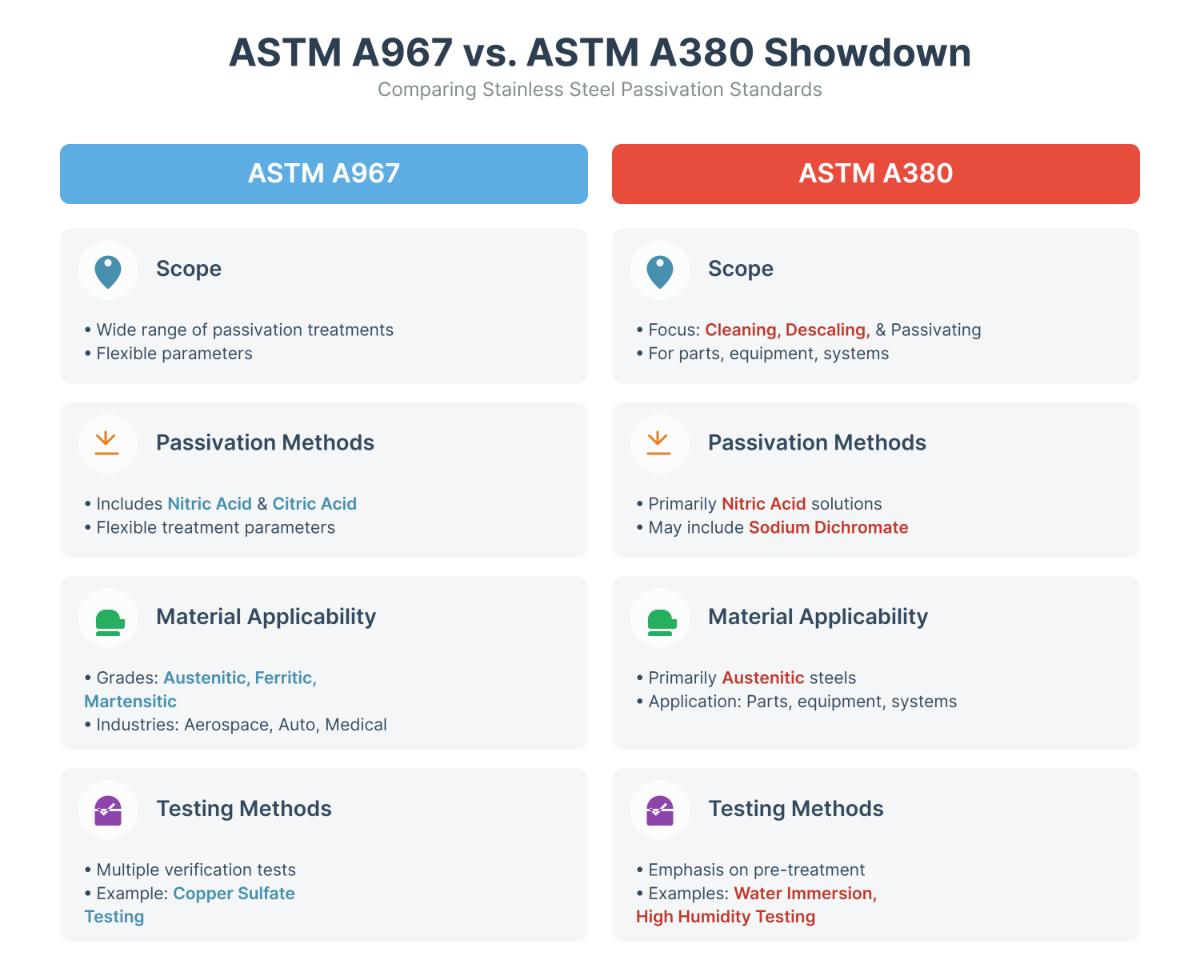

ASTM A967 provides detailed guidelines for chemically passivating stainless steel parts. It encompasses a wide range of procedures, including cleaning, pickling, and passivation using different chemicals such as nitric acid and citric acid. This versatility makes ASTM A967 suitable for various types of stainless steels, including austenitic, ferritic, and martensitic grades.

Treatments

This standard provides detailed instructions for five distinct passivation treatments, each tailored to different stainless steel types. These treatments enhance the corrosion resistance and surface quality of stainless steel.

Tests and Compliance

ASTM A967 includes specific tests to evaluate the quality of the passivated surface. These tests are critical for ensuring that the passivation process has been effective in removing contaminants and enhancing the material’s resistance to corrosion. Additionally, ASTM A967 offers a compliance verification checklist to assist manufacturers in meeting the standard’s requirements.

Material Suitability

The broad applicability of ASTM A967 makes it suitable for a wide range of stainless steel grades and related materials. This standard can accommodate the diverse needs of different industries, ensuring that the passivation process is effective across various applications.

Overview of ASTM A380

Scope

ASTM A380 is a practice standard focused on the cleaning, descaling, and passivating of stainless steel parts, equipment, and systems. It primarily addresses austenitic stainless steels and provides essential guidelines for high-quality passivation.

Treatments

The treatments outlined in ASTM A380 predominantly involve nitric acid-based solutions, with citric acid offered as an alternative. Unlike ASTM A967, this standard does not cover pickling, which is a more aggressive cleaning process.

Tests and Compliance

ASTM A380 specifies simpler tests, such as water immersion and high humidity testing, to verify the effectiveness of the passivation process. Even without a detailed compliance checklist, these tests ensure that the stainless steel surfaces are properly passivated.

Material Suitability

This standard is mainly applicable to austenitic stainless steels, providing guidelines for different conditions such as annealed or work-hardened states. It ensures that the passivation process is tailored to the specific needs of austenitic stainless steel components.

Detailed Comparison of ASTM A967 and ASTM A380

Scope and Application Differences

ASTM A967

ASTM A967 covers a broad range of specifications for chemical passivation treatments of stainless steel parts. This standard includes detailed instructions for cleaning, pickling, and passivation processes, making it versatile for different stainless steel grades such as austenitic, ferritic, and martensitic types. It offers five distinct passivation treatments, including nitric acid and citric acid methods, providing flexibility to accommodate various industrial requirements.

ASTM A380

ASTM A380 focuses on the practice of cleaning, descaling, and passivating stainless steel parts, equipment, and systems. It is primarily designed for austenitic stainless steels and emphasizes the importance of thorough surface preparation and cleaning before passivation, unlike ASTM A967 which includes pickling. This standard limits its scope to less intensive cleaning and passivation methods.

Visual Comparison

| Feature | ASTM A967 | ASTM A380 |

|---|---|---|

| Scope | Broad, includes cleaning, pickling, and passivation | Focused on cleaning, descaling, and passivation |

| Stainless Steel Grades | Austenitic, ferritic, martensitic | Primarily austenitic |

| Passivation Treatments | Nitric acid, citric acid, high-purity water | Nitric acid, citric acid |

| Surface Preparation | Detailed cleaning and pickling instructions | Emphasis on cleaning before passivation |

| Testing Methods | Comprehensive, including high-purity water rinsing | Water immersion, high humidity tests |

| Compliance Verification | Includes a compliance checklist | Process validation and documentation required |

Test Methods and Compliance

Test Methods for ASTM A967

ASTM A967 specifies various tests to check the quality of the passivated surface. These include:

- Nitric Acid Test: This method involves immersing the stainless steel parts in a nitric acid solution to remove free iron and other contaminants.

- Citric Acid Test: An alternative to nitric acid, this test uses citric acid to achieve passivation.

- High-Purity Water Rinsing: Ensures that all chemical residues are thoroughly removed from the surface, enhancing corrosion resistance.

These tests are designed to provide a detailed assessment of the passivation process’s effectiveness, ensuring high-quality results.

Test Methods for ASTM A380

ASTM A380 employs simpler testing methods compared to ASTM A967. Key tests include:

- Water Immersion Test: This test involves immersing the stainless steel parts in water to check for the presence of free iron on the surface.

- High Humidity Test: The parts are exposed to a high-humidity environment to verify the passivation process’s effectiveness.

Although less comprehensive than ASTM A967, these tests still provide a reliable means of verifying that the stainless steel surfaces are properly passivated.

Compliance Requirements

Compliance for ASTM A967

ASTM A967 includes a Compliance Verification Checklist to ensure that all passivation processes adhere to the standard. This checklist helps manufacturers maintain detailed documentation of the passivation process, including the type of treatment used, the stainless steel grade, and the testing methods employed. Such thorough documentation is crucial for verifying compliance and ensuring consistent quality.

Compliance for ASTM A380

While ASTM A380 does not provide a specific compliance checklist, it requires manufacturers to validate their passivation processes and maintain detailed documentation. Compliance certificates typically include information about the process type, material type, and results of post-passivation inspections. This documentation is essential to show compliance with the standard and ensure the reliability of the passivation process.

Material Considerations for Passivation

Material Considerations for Passivation

Passivation is a critical process for enhancing the corrosion resistance of stainless steel by eliminating free iron and other surface contaminants. The material considerations for passivation are essential to ensure the effectiveness of this process. ASTM A967 and ASTM A380 provide distinct guidelines for passivating stainless steel, each catering to different material requirements and treatment methods.

Stainless Steel Passivation Explained

Passivation involves treating stainless steel surfaces with acid solutions to remove iron particles and other impurities, forming a passive oxide layer that protects the steel from corrosion. The choice of passivation standard and method depends significantly on the type of stainless steel and its intended application.

Material Suitability in ASTM A967

ASTM A967 focuses on chemical passivation treatments, primarily using nitric acid and citric acid. This standard is applicable to a wide range of stainless steel types, including austenitic, ferritic, and martensitic grades. However, it excludes high carbon martensitic steels like 440C because they can become brittle during acid treatment.

Citric Acid vs. Nitric Acid Treatments

- Citric Acid Passivation: Preferred for its gentleness and environmental friendliness, citric acid effectively removes surface impurities without being as harsh as nitric acid. It is suitable for most stainless steel types except high carbon martensitic steels.

- Nitric Acid Passivation: Nitric acid is more commonly used for its effectiveness in removing iron contaminants. It is suitable for a broad range of stainless steel grades and provides robust corrosion resistance.

Material Suitability in ASTM A380

ASTM A380 encompasses cleaning, descaling, and passivation processes. It is primarily designed for austenitic stainless steels but also applies to other stainless steel types such as the 200, 300, and 400 series. This standard is comprehensive, including descaling procedures with acids like hydrofluoric and nitric acid.

Comparison of Material Considerations

| Aspect | ASTM A967 | ASTM A380 |

|---|---|---|

| Scope | Focuses solely on chemical passivation treatments. | Covers cleaning, descaling, and passivation. |

| Methods | Focuses on nitric and citric acid treatments. | Primarily uses nitric acid and nitric acid with sodium dichromate. |

| Material Suitability | Excludes high carbon martensitic steels. | Similar exclusions, with a focus on chromium content. |

Chromium Content

Both ASTM A967 and ASTM A380 emphasize the importance of chromium content in forming a passive layer on stainless steel surfaces. Steels with more than 11% chromium are generally suitable for passivation, as chromium helps in creating a stable, protective oxide layer.

Specific Material Considerations

High Carbon Martensitic Steels

Both standards avoid high carbon martensitic steels due to the risk of hydrogen embrittlement during acid treatment. This type of steel is not ideal for strong acid passivation, requiring alternative treatments.

Citric vs. Nitric Acid

- Citric Acid: Gentler and more environmentally friendly, making it suitable for a wide range of stainless steel types. Preferred in applications where less aggressive treatment is required.

- Nitric Acid: Offers robust cleaning and passivation, ensuring thorough removal of iron contaminants. It is more commonly used in ASTM A380 for its effectiveness.

Material considerations play a crucial role in determining the appropriate passivation standard and method. By understanding the specific requirements of ASTM A967 and ASTM A380, manufacturers can choose the most suitable process for their stainless steel components, ensuring optimal corrosion resistance and material integrity.

Test Methods and Compliance

Test Methods for ASTM A967

ASTM A967 specifies several test methods to ensure that the stainless steel surface is clean and has the necessary corrosion resistance. These tests verify the effectiveness of the passivation process by detecting contaminants and confirming the integrity of the protective oxide layer.

Copper Sulfate and High-Purity Water Rinsing Tests

The copper sulfate test detects free iron on the stainless steel surface. During this test, the part is immersed in a copper sulfate solution. If free iron is present, it reacts with the solution, resulting in a copper deposit on the surface.

Similarly, the high-purity water rinsing test ensures thorough removal of chemical residues from the passivated surface. After passivation, the stainless steel part is rinsed with high-purity water. No residues mean the surface is clean and the passivation layer is intact, ensuring optimal corrosion resistance.

Nitric Acid and Citric Acid Passivation Tests

These tests involve immersing stainless steel parts in nitric or citric acid solutions to remove free iron and other contaminants while forming a protective oxide layer. Nitric acid is more aggressive, while citric acid is more environmentally friendly, allowing for application-specific choices.

Test Methods for ASTM A380

ASTM A380 outlines simpler test methods, focusing on verifying the cleanliness and passivation effectiveness of the stainless steel surface.

Water Immersion Test

The water immersion test involves submerging the stainless steel part in water to detect free iron. If iron is present, rust spots will form on the surface, indicating an incomplete passivation process. This straightforward test provides a clear indication of surface cleanliness.

High Humidity Test

In the high humidity test, the stainless steel part is exposed to a controlled high-humidity environment. Rust or discoloration indicates a failure in the passivation process, while a clean surface confirms effective passivation.

Compliance Requirements

ASTM A967 includes a comprehensive Compliance Verification Checklist that requires detailed documentation of the passivation process, including the type of treatment used, stainless steel grade, testing methods employed, and test results. This thorough documentation is crucial for verifying compliance and ensuring consistent quality.

In contrast, ASTM A380 emphasizes process validation and documentation without a specific checklist. Manufacturers are required to maintain detailed records of the passivation process, including cleaning and passivation methods, material type and condition, and inspection results. Compliance certificates typically include information about the process type, material specifications, and inspection results. This documentation ensures the reliability of the passivation process and adherence to the standard.

Practical Applications

Practical Applications of ASTM A967 and ASTM A380

ASTM A967 involves a detailed passivation process, including pickling, which is not explicitly covered by ASTM A380. ASTM A967 offers detailed procedures for using both nitric and citric acid, allowing manufacturers to choose the most suitable treatment for their specific needs, making it versatile for various stainless steel grades.

ASTM A380 focuses on thorough cleaning and descaling before passivation to remove contaminants, which is crucial for effective passivation. It specifies different nitric acid solutions for various types of stainless steel, mainly austenitic grades.

ASTM A967 applies to a broader range of stainless steel grades, including austenitic, ferritic, and martensitic types, making it suitable for diverse applications. For example, it is ideal for aerospace and defense sectors that require high precision and diverse material handling.

ASTM A380 is generally used for austenitic stainless steels in environments where corrosion resistance is critical. It is often applied in general manufacturing and construction industries where these types of stainless steels are commonly used.

Both ASTM A967 and ASTM A380 aim to enhance the corrosion resistance of stainless steel by forming a passive layer on the surface. ASTM A967, with its broader treatment options, can offer more uniform results across different material types. This flexibility allows for varying concentrations of citric and nitric acids to achieve the desired surface finish and corrosion resistance.

ASTM A380 ensures that the surface is thoroughly prepared and passivated using nitric acid solutions, resulting in a clean, corrosion-resistant surface that meets the specific needs of applications requiring high durability in corrosive environments.

ASTM A967 includes a variety of tests to verify the effectiveness of the passivation process, such as high-purity water rinsing and specific chemical tests. These comprehensive testing methods provide assurance that the passivation process has been successful and that the stainless steel parts will perform reliably in their intended applications.

ASTM A380 uses simpler testing methods like water immersion and high humidity tests to validate the passivation process. These tests are effective in ensuring that the stainless steel surfaces are properly passivated and free from free iron, which could lead to corrosion. While less comprehensive than ASTM A967, these tests provide a reliable means of confirming the quality of the passivated surface.

ASTM A967 is frequently used in industries that require high precision and diverse material handling, such as aerospace and defense. The flexibility in treatment options and stringent testing requirements make ASTM A967 ideal for applications where reliability and corrosion resistance are paramount.

ASTM A380 is commonly applied in general manufacturing and construction industries, where the use of austenitic stainless steels is prevalent. This standard’s focus on thorough cleaning and descaling processes before passivation ensures that the stainless steel components are well-prepared for environments where corrosion resistance is crucial. Industries such as food processing, pharmaceuticals, and chemical manufacturing often utilize ASTM A380 for its effectiveness in maintaining clean and corrosion-resistant surfaces.

When comparing ASTM A967 and ASTM A380, several critical differences become apparent. ASTM A967 offers a broader scope, encompassing cleaning, pickling, and various passivation treatments suitable for a wide range of stainless steel grades, including austenitic, ferritic, and martensitic steels. In contrast, ASTM A380 primarily focuses on the cleaning and passivation of austenitic stainless steels, with specific processes for different conditions.

ASTM A967 provides multiple treatment options, such as nitric acid and citric acid methods, allowing flexibility based on the material and desired results. ASTM A380 mainly uses nitric acid treatments, with variations in solution compositions to suit different stainless steel types.

ASTM A967 includes comprehensive testing methods like nitric acid passivation, citric acid passivation, and high-purity water rinsing to ensure the passivated surface’s quality. ASTM A380 uses simpler tests, such as water immersion and high humidity testing, to verify the effectiveness of passivation.

Choosing between ASTM A967 and ASTM A380 depends on factors such as the type of stainless steel used and the specific application requirements. ASTM A967 is preferred for diverse stainless steel grades and industries needing flexible passivation processes and high corrosion resistance. Conversely, ASTM A380 is suitable for applications involving austenitic stainless steels, commonly used in general manufacturing, construction, food processing, and pharmaceutical industries, where clean and corrosion-resistant surfaces are essential.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the key differences between ASTM A967 and ASTM A380?

ASTM A967 and ASTM A380 are both standards for passivating stainless steel, but they differ significantly in scope, passivation methods, and material applicability.

ASTM A967 covers a wide range of passivation treatments, including both nitric acid and citric acid processes, allowing flexibility in treatment parameters. It applies to various grades of stainless steel, including austenitic, ferritic, and martensitic types, making it suitable for diverse industries such as aerospace, automotive, and medical devices. Additionally, ASTM A967 includes multiple test methods to verify passivation effectiveness, such as copper sulfate testing.

In contrast, ASTM A380 focuses primarily on cleaning, descaling, and passivating stainless steel parts, equipment, and systems using nitric acid solutions, sometimes combined with sodium dichromate. This standard is more limited in scope and primarily applies to austenitic stainless steels. ASTM A380 emphasizes pre-treatment processes and includes tests like water immersion and high humidity testing to evaluate surface quality.

Which standard is more suitable for specific types of stainless steel?

ASTM A967 is generally more suitable for a broader range of stainless steel types, including austenitic, ferritic, and martensitic grades. It provides various passivation methods, such as nitric acid and citric acid treatments, and offers flexibility in choosing the appropriate method based on the specific stainless steel type and application. This makes ASTM A967 ideal for applications requiring high corrosion resistance and versatility in treatment options.

On the other hand, ASTM A380 is primarily focused on austenitic stainless steels and emphasizes cleaning, descaling, and passivating processes using nitric acid treatments. It is more specialized for certain types of stainless steel parts, particularly where specific cleaning and passivation conditions are required.

How do ASTM standards ensure quality in stainless steel passivation?

ASTM standards ensure quality in stainless steel passivation by providing detailed guidelines and methods for treating stainless steel to enhance its corrosion resistance. ASTM A967 focuses on chemical passivation treatments, specifying the use of nitric acid, citric acid, and electrochemical methods. It emphasizes thorough rinsing and neutralization to remove chemical residues, and includes various tests such as water immersion, high humidity, salt spray, copper sulfate, and potassium ferricyanide-nitric acid to confirm the effectiveness of passivation.

ASTM A380, on the other hand, covers broader procedures for cleaning, descaling, and passivating stainless steel parts. It provides recommendations for removing surface contaminants through chemical descaling, acid pickling, and mechanical methods, ensuring that the passive oxide film is properly formed to improve corrosion resistance.

By adhering to these standards, manufacturers can ensure that stainless steel components are free from contaminants that could compromise their integrity, thus guaranteeing their performance and durability in critical applications across various industries.

What industries commonly use ASTM A967 and ASTM A380?

Industries commonly using ASTM A967 and ASTM A380 include aerospace, automotive, medical devices, food and beverage processing, construction, industrial equipment, and chemical plants. ASTM A967 is particularly valued in sectors where corrosion resistance is crucial, such as aerospace, automotive, and medical devices, ensuring components can withstand harsh environments and maintain integrity. On the other hand, ASTM A380 is essential for initial cleaning and passivation of stainless steel parts, making it vital in industries like food processing and chemical plants, where cleanliness and system integrity are paramount. Both standards ensure high-quality stainless steel performance across diverse applications.

Are there any recent updates or changes to these standards?

As of the latest information available, there have been no recent updates or changes to the ASTM A967 and ASTM A380 standards within the last 12 months. The most notable recent updates for ASTM A967 were in 2017, which introduced new tests, clarified restrictions on hydrogen embrittlement, and provided additional guidance for selecting appropriate passivation treatments for different stainless steel grades. ASTM A380, which covers a broader scope including cleaning, descaling, and passivation, has not seen significant changes since its 2013 revision. Both standards remain crucial for ensuring the quality and corrosion resistance of stainless steel in various industries.

How do the test methods for ASTM A967 and ASTM A380 differ?

The test methods for ASTM A967 and ASTM A380 differ primarily in their scope and detail. ASTM A967 is specifically dedicated to the passivation of stainless steel and provides five distinct testing practices to ensure the effectiveness of passivation. These include the water immersion test, high humidity test, salt spray test, copper sulfate test, and potassium ferricyanide-nitric acid test. These tests are designed to verify that the passivated surface is corrosion-resistant and free from contaminants.

In contrast, ASTM A380 covers a broader range of cleaning and surface preparation processes, including passivation. While it includes some testing methods to ensure cleanliness and passivation, it is less detailed than ASTM A967. ASTM A380 often references ASTM A967 for more comprehensive passivation procedures, indicating that ASTM A967 provides a more thorough approach to testing the effectiveness of passivation. This distinction makes ASTM A967 more suitable for applications requiring precise control over the passivation process.