Steel is the backbone of modern infrastructure, yet not all steel is created equal. Two of the most widely used types—boron steel and carbon steel—possess unique properties that make them suitable for different applications. But what sets them apart? Whether you’re an industry professional or a curious enthusiast, understanding the nuances between these two steel types is crucial for making informed decisions. In this article, we will delve into the mechanical properties, cost considerations, and industrial applications of boron steel versus carbon steel. By exploring their advantages and disadvantages, you’ll gain a clearer picture of which material best suits your needs. Ready to dive into the world of steel alloys and discover what makes boron steel distinct from carbon steel? Let’s get started.

Introduction to Steel Types

Steel is essential in modern engineering and manufacturing due to its versatility and diverse properties. It is an alloy mainly composed of iron and carbon, but it can include other elements to enhance specific characteristics. The two prominent categories of steel alloys are carbon steel and boron steel, each with distinct compositions and applications.

Importance of Steel in Various Industries

Steel plays a critical role in numerous industries due to its unique combination of strength, ductility, and cost-effectiveness. It is fundamental in construction, automotive manufacturing, energy sectors, and consumer goods production. The specific type of steel chosen for an application can significantly impact performance, durability, and overall efficiency.

Carbon Steel

Carbon steel is one of the most widely used steel types, characterized by its varying carbon content. It is typically categorized into three subtypes:

- Low-Carbon Steel (Mild Steel): Contains less than 0.3% carbon, making it highly ductile and easy to weld. Commonly used in construction and manufacturing.

- Medium-Carbon Steel: Contains approximately 0.3% to 0.6% carbon, offering a balance between strength and ductility. Suitable for automotive components and machinery parts.

- High-Carbon Steel: Contains more than 0.6% carbon, known for its high hardness and strength but lower ductility, used in cutting tools and high-strength wires.

Boron Steel

Boron steel is enhanced with a small amount of boron, usually between 0.0015% and 0.003%. This addition significantly improves the steel’s hardenability, allowing it to achieve high hardness levels with simpler heat treatments. Boron steel is ideal for applications needing high wear resistance and strength.

Comparative Analysis of Carbon Steel and Boron Steel

Composition and Properties

- Carbon Steel: Varies widely in carbon content, influencing its hardness, strength, and ductility. Higher carbon content typically results in increased hardness and strength but decreased weldability and ductility.

- Boron Steel: Contains minimal boron, which enhances its hardenability. This allows for high strength and wear resistance without the need for extensive alloying.

Applications

- Carbon Steel: Versatile and used in a broad range of applications such as construction (rebar, beams), automotive (body panels, frames), and machinery (gears, tools).

- Boron Steel: Ideal for applications requiring high wear resistance and strength, such as automotive safety components (door beams, bumper reinforcements) and agricultural equipment.

Cost Considerations

Carbon steel is generally more affordable due to its simpler production process and widespread availability. Boron steel, while slightly more expensive due to the addition of boron, offers a cost-effective solution for high-hardness applications.

Key Differences

- Hardenability: Boron steel offers superior hardenability compared to carbon steel, which is beneficial for achieving high hardness with simpler heat treatments.

- Weldability: Higher carbon content in carbon steel can reduce weldability, while boron steel may face challenges due to boron segregation if not carefully controlled.

- Mechanical Properties: Boron steel typically offers greater tensile strength and hardness, making it suitable for demanding applications.

Understanding these differences allows engineers and manufacturers to select the appropriate type of steel for their specific needs, optimizing performance and cost-efficiency in their projects.

Mechanical Properties of Boron Steel vs. Carbon Steel

Definitions and Explanations

Understanding the definitions and key characteristics of boron steel and carbon steel is crucial for comparing their mechanical properties.

Boron Steel

Boron steel is a type of steel alloy that includes a small amount of boron (typically around 0.0005% to 0.003%). The addition of boron significantly enhances the steel’s hardenability, allowing it to achieve high levels of hardness and strength with simpler heat treatments. This makes boron steel particularly valuable for applications requiring high wear resistance and durability.

Carbon Steel

Carbon steel is an alloy composed primarily of iron and carbon, with varying carbon content (up to 2%). It is one of the most widely used steel types due to its versatility and cost-effectiveness. Carbon steel is categorized into low, medium, and high carbon steel based on its carbon content, which influences its hardness, strength, and ductility.

Hardenability

Hardenability refers to the ability of steel to harden in depth under specific heat treatment conditions. This property is critical for determining the steel’s performance in various applications.

Boron Steel Hardenability

The presence of boron in boron steel significantly improves its hardenability. Even a tiny amount of boron can significantly increase the depth to which the steel hardens. This property is particularly beneficial in applications requiring high wear resistance and impact strength, such as automotive safety components and agricultural machinery.

Carbon Steel Hardenability

Carbon steel’s hardenability is primarily influenced by its carbon content. Higher carbon content generally increases hardenability, but not to the extent seen in boron steel. This makes carbon steel suitable for applications where moderate hardness and strength are sufficient, such as structural components and general manufacturing.

Strength

Boron Steel Strength

Boron steel exhibits superior strength due to its enhanced hardenability and the presence of other alloying elements like manganese and chromium. This makes it ideal for high-stress environments where durability and resistance to deformation are critical.

Carbon Steel Strength

Low-carbon steel is ductile but less strong, high-carbon steel is stronger but less ductile, and medium-carbon steel balances both properties, making it versatile.

Toughness

Toughness is the ability of a material to absorb energy and plastically deform without fracturing. It is a crucial property for materials subjected to dynamic loads and impact.

Boron Steel Toughness

Boron steel typically exhibits good toughness due to its balanced composition and enhanced hardenability. This makes it suitable for applications that require both high strength and the ability to withstand impact forces, such as automotive crash structures.

Carbon Steel Toughness

Low-carbon steel is tougher because it is more ductile, whereas high-carbon steel is less tough because it is harder and more brittle.

Other Material Properties

Elongation and Fatigue Resistance

- Boron Steel: Boron steel offers good elongation and fatigue resistance, making it suitable for components subjected to cyclic loading and repeated stress.

- Carbon Steel: The elongation and fatigue resistance of carbon steel vary with its carbon content. Low-carbon steel provides better elongation, while high-carbon steel offers less due to its higher hardness.

Machinability

- Boron Steel: Adding boron improves machinability compared to other hard steels.

- Carbon Steel: Generally easy to machine, especially low-carbon types, which are softer and more ductile.

Weldability

- Boron Steel: Boron steel can be welded, but care must be taken to avoid boron segregation and to control heat input during the welding process.

- Carbon Steel: Carbon steel, especially low-carbon variants, has excellent weldability. High-carbon steel requires more preheating and controlled cooling to prevent cracking.

By understanding these mechanical properties, engineers and manufacturers can make informed decisions when selecting between boron steel and carbon steel for specific applications.

Material Cost and Availability Considerations

Material Cost Considerations

Boron Steel

The addition of boron to steel significantly enhances its hardenability. Because only a small amount of boron (typically between 0.0005% and 0.003%) is needed, boron steel can achieve properties similar to other alloys at a lower cost. However, carbon steel, being the base material, typically has a lower initial cost compared to boron steel.

Carbon Steel

As the base material, carbon steel is more affordable due to its simpler production process. But in applications where high – performance and durability are crucial, such as automotive parts, the enhanced properties of boron steel might offset the initial cost difference over time.

Material Availability Considerations

Boron Steel

Boron steel is widely available, especially in the automotive sector, for components that demand high strength and toughness. Controlled boron addition ensures these steels meet standards set by the Society of Automotive Engineers (SAE), making them reliable in relevant industries.

Carbon Steel

Carbon steel is one of the most commonly used metals globally. It is highly available and accessible for various applications. Its wide – spread use and large – scale production make it the first choice for many manufacturers due to its familiarity and ease of sourcing.

Challenges and Considerations

Boron Content Control

In boron steel, precise control of boron content is essential. Excessive boron can lead to embrittlement and welding issues, which may increase costs related to quality control and re – work.

Welding and Fabrication

Although weldable, boron steel requires careful handling during welding due to potential segregation issues. In contrast, carbon steel is generally easier to weld, reducing the complexity and cost associated with fabrication.

Regulatory Compliance

In some regions, regulations limit the amount of boron in structural steels to prevent problems like embrittlement. For example, the EU restricts boron to 8 ppm in certain structural steels. These regulations can limit the use and availability of boron steel in certain regions.

Advantages and Disadvantages of Using Boron Steel Compared to Carbon Steel

Advantages of Boron Steel

Enhanced Hardenability

Boron steel exhibits significantly improved hardenability due to the small addition of boron. This means boron steel can reach higher strength levels with easier heat treatments than carbon steel. Enhanced hardenability allows the steel to harden more deeply and evenly, which is particularly beneficial for components with thicker sections.

Cost-Effectiveness

Adding boron to steel boosts its mechanical properties without significantly increasing carbon or alloy content, making it a cost-effective alternative to higher alloy steels. This provides excellent performance at a lower cost, enabling manufacturers to produce high-strength components without the need for expensive alloying elements.

Improved Weldability and Formability

Boron steels usually have good weldability and formability, important for fabrication. This makes boron steel suitable for applications where complex shapes and welding are required, such as in automotive manufacturing.

Better Machinability

Boron steel can sometimes be easier to machine than similarly hard steels due to its finer grain structure, which improves machining efficiency and reduces manufacturing time and costs. This enhances the overall productivity and cost-effectiveness of manufacturing processes.

Disadvantages of Boron Steel

Risk of Embrittlement

Too much boron can cause embrittlement, as boron tends to gather at grain boundaries, reducing toughness and potentially leading to brittle failure. This is particularly problematic for load-bearing structures that require high toughness.

Welding Challenges

High boron content can cause segregation in welds, leading to potential cracks during cooling. Proper control of heat input and welding techniques is necessary to mitigate these issues, adding complexity to the fabrication process.

Limited Usage

Boron steel is not suitable for all applications. It is particularly challenging to use in applications requiring high toughness or where welding is a critical process. The risk of embrittlement and welding issues restricts its usage in certain industries and applications.

Comparative Summary

| Feature | Carbon Steel | Boron Steel |

|---|---|---|

| Composition | Primarily iron and carbon | Carbon steel with added boron |

| Hardenability | Variable based on carbon content | Significantly improved with boron |

| Cost-Effectiveness | Generally cost-effective | Cost-effective due to lower alloy need |

| Machinability | Varies based on carbon content | Can be improved in specific contexts |

| Usage | Wide range of applications | Mainly automotive and structural |

| Disadvantages | Prone to corrosion, less weldable | Risk of embrittlement, welding issues |

The choice between boron steel and carbon steel depends on the specific requirements of the application. Boron steel offers advantages in hardenability and cost-effectiveness, but it also comes with challenges related to embrittlement and welding. Carbon steel, while versatile and economical, lacks the enhanced hardenability provided by boron steel.

Industrial Applications and Case Studies

Automotive Industry

Both boron steel and carbon steel are used in the automotive industry, but they serve different purposes due to their unique properties.

Boron Steel in Automotive

Boron steel is highly valued for its exceptional strength and hardenability. This makes it ideal for safety-critical components that require high impact resistance and durability. For example, boron steel is commonly used in the production of crash-resistant door beams, B-pillars, and bumper reinforcements. These components benefit from boron steel’s ability to achieve high tensile strength (over 1500 MPa) after hot stamping, making them capable of withstanding high-impact forces while remaining lightweight.

Carbon Steel in Automotive

In contrast, carbon steel is commonly used for general automotive parts that do not require extreme strength. Low-carbon steel is often employed in body panels and frames due to its excellent ductility and ease of welding. Medium-carbon steel is used in engine parts and other components that require a balance of strength and ductility. High-carbon steel, with its higher hardness, is used in cutting tools and other high-strength applications within the automotive sector.

Construction Sector

The construction industry relies on both boron steel and carbon steel for various structural applications.

Boron Steel in Construction

In the construction industry, boron steel is favored for components that must withstand high wear and stress. Its enhanced hardenability allows it to be used in reinforced concrete structures, where high strength and durability are essential. Boron steel is also used in the construction of heavy-duty equipment, such as bulldozer blades and excavator buckets, which require a combination of toughness and wear resistance.

Carbon Steel in Construction

Carbon steel remains a staple in construction due to its cost-effectiveness and versatility. Low-carbon steel is commonly used in rebar, beams, and columns, providing the necessary structural support in buildings and infrastructure projects. The ease of fabrication and welding of carbon steel makes it an ideal choice for large-scale construction projects where cost and availability are significant considerations.

Energy Applications

Both boron steel and carbon steel play crucial roles in the energy sector, particularly in the oil and gas industry.

Boron Steel in Energy Applications

Boron steel is utilized in the energy sector for its superior strength and wear resistance. It is often used in drilling equipment and pipelines, where high performance under extreme conditions is required. Boron steel’s ability to retain its properties at high temperatures makes it ideal for components exposed to heat and pressure, like those in geothermal energy systems and steam pipelines.

Carbon Steel in Energy Applications

Carbon steel is extensively used in the energy sector due to its wide availability and cost-effectiveness. It is commonly used in the construction of pipelines, storage tanks, and structural components in oil and gas facilities. Low-carbon steel is preferred for its weldability and ductility, making it easier to fabricate and install in various energy applications.

In-Depth Case Studies of Boron Steel Applications

Automotive Safety Components

A notable case study involves the use of boron steel in automotive safety components. In particular, the hot-stamped boron steel known as 22MnB5 has been widely adopted for manufacturing door beams and B-pillars. These components are critical for vehicle crashworthiness, providing enhanced protection to occupants during collisions. The high strength and lightweight properties of boron steel contribute to improved fuel efficiency and overall vehicle performance.

Industrial Equipment

Another case study highlights the application of boron steel in industrial equipment. Boron steel’s wear resistance makes it ideal for mining and construction machinery. For example, boron steel is used in the manufacturing of drill bits and forklift arms, which require durability and the ability to withstand abrasive environments. The enhanced hardenability of boron steel ensures that these components have a longer service life and reduced maintenance costs.

Aerospace & Defense

In the aerospace and defense industries, boron steel is used for its high strength-to-weight ratio. Components such as landing gear and armored panels benefit from boron steel’s mechanical properties, which provide the necessary strength without significantly increasing weight. This application demonstrates the versatility of boron steel in high-performance environments where both strength and weight are critical factors.

Challenges and Considerations

Boron Content Limitations

While boron steel offers numerous advantages, it is essential to control the boron content precisely. Excessive boron can lead to brittleness and reduced ductility, impacting the performance and reliability of the steel in critical applications. This necessitates careful quality control during the production process to ensure optimal boron levels.

Carbon Interaction

In carbon steel, the interaction between carbon and other alloying elements can influence its properties. For example, higher carbon content increases hardness and strength but reduces weldability and ductility. This trade-off must be considered when selecting carbon steel for specific applications to ensure that the material meets the required performance criteria.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the advantages and disadvantages of using boron steel compared to carbon steel?

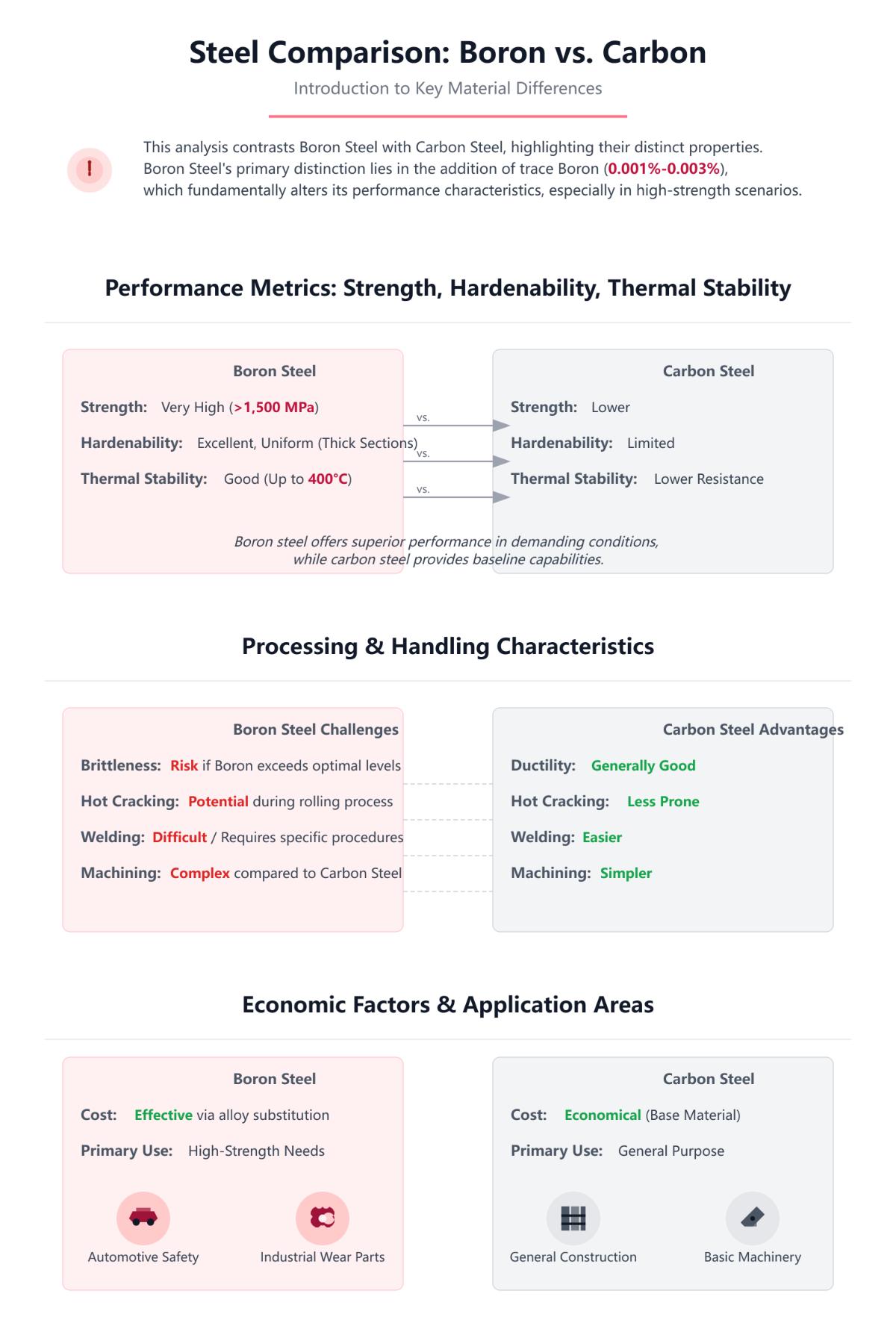

Boron steel, enhanced with trace amounts of boron (0.001% to 0.003%), offers significant advantages over carbon steel, particularly in terms of hardenability and strength. Boron steel’s ability to achieve uniform hardening in thicker sections and its high tensile strength (exceeding 1,500 MPa after hot stamping) make it ideal for high-strength applications such as automotive safety components and industrial wear parts. Additionally, boron steel is thermally stable up to 400°C and can be more cost-effective by substituting more expensive alloying elements.

However, boron steel has its disadvantages. It can become brittle if boron content exceeds optimal levels, leading to reduced impact toughness. Processing boron steel can be challenging due to potential hot cracking during rolling and difficulties in welding. Machining boron steel is also more complex compared to carbon steel.

On the other hand, carbon steel is economically viable and easier to weld and machine. It is widely used in general construction and basic machinery due to its cost-effectiveness. However, it has limited hardenability and lower tensile strength compared to boron steel, making it less suitable for applications requiring high durability and resistance to wear and high temperatures.

How does boron affect the properties of steel?

Boron significantly enhances the properties of steel by improving its hardenability. When added in small quantities (typically less than 1%), boron enables steel to harden more deeply during heat treatment. This is especially advantageous for thicker sections, as it allows for higher mechanical properties without increasing the carbon or alloy content. Boron delays the transformation from austenite to softer structures like ferrite and pearlite, favoring the formation of harder martensite. Economically, boron steel can reduce the need for more expensive alloying elements like chromium and nickel, making it a cost-effective alternative. However, excessive boron can lead to issues like embrittlement and hot shortness, so its content must be carefully controlled. These enhancements make boron steel particularly suitable for high-strength applications in industries such as automotive and construction.

What industries primarily use boron steel?

Boron steel is primarily used in several key industries due to its enhanced mechanical properties. In the automotive industry, it is utilized for components like crash-resistant door beams, B-pillars, and electric vehicle battery shields, where its high strength-to-weight ratio enhances fuel efficiency and safety. The aerospace and defense sectors use boron steel for landing gear components and armored panels because of its strength and durability. In construction, boron steel is employed in structural parts of buildings and bridges for its superior strength and durability. Additionally, it is used in industrial and heavy machinery for parts like mining drill bits and forklift arms, and in energy infrastructure for applications such as nuclear reactor control rods and wind turbine shafts. These uses highlight boron steel’s versatility and effectiveness across various demanding applications.

What is the difference in hardenability between boron steel and carbon steel?

Boron steel and carbon steel differ significantly in hardenability. Boron steel, with small boron additions (0.0015% – 0.003%), delays austenite transformation during cooling, enabling martensite formation and uniform hardening in thicker sections, even at low boron concentrations. It allows for deeper hardening without fast quenching or high alloy content. In contrast, carbon steel’s hardenability depends on carbon content; higher levels increase hardenability but may reduce ductility and increase brittleness. Boron steel is more cost – effective for achieving hardenability, while high – carbon or alloyed carbon steel can be more expensive.

How do steel alloys impact industrial applications?

Steel alloys significantly impact industrial applications due to their diverse properties. Alloying elements like chromium, nickel, and molybdenum enhance strength, corrosion resistance, and high – temperature stability. Boron steel, with a small amount of boron, improves hardenability, hardness, and wear resistance, making it suitable for wear – resistant applications. Carbon steel, mainly composed of carbon and iron, is affordable and easy to machine, used in basic construction and automotive body parts. In construction, alloy steels are for high – strength components, while carbon steel is for basic frameworks. In the energy and automotive sectors, alloy steels are crucial for parts in harsh conditions, while carbon steel is common in less demanding areas.