When it comes to selecting the right material for your project, the choice between bronze and steel can be a perplexing one. Both metals have a storied history and a set of unique properties that make them suitable for various applications. But what sets them apart in terms of strength, durability, and aesthetic appeal? Are you curious about which material will withstand the elements better for your outdoor installations, or perhaps which one will age gracefully over time?

In this article, we’ll delve into the key differences between bronze and steel, exploring their tensile strength, corrosion resistance, and suitability for different environments. We’ll also discuss the visual characteristics of each metal and how they change with age, helping you make an informed decision for your next project. So, if you’ve ever wondered about the intricacies of these two materials, read on to discover which one emerges as the best fit for your needs.

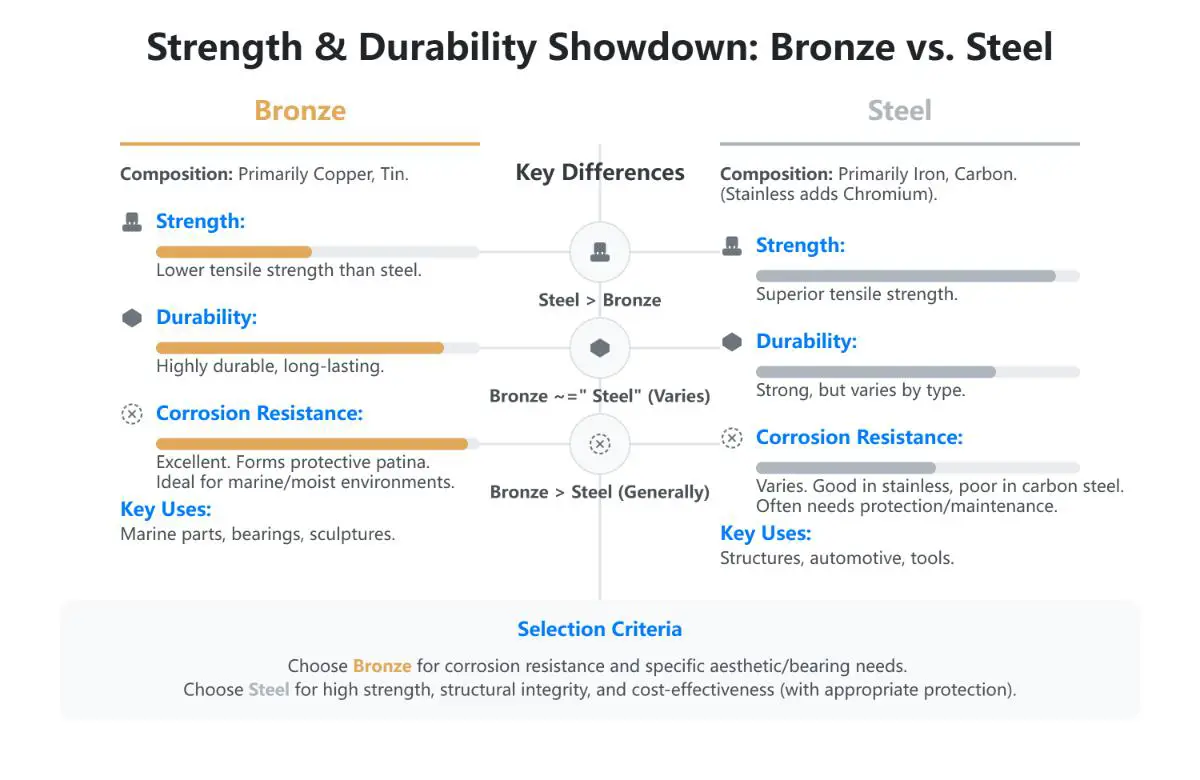

Key Differences Between Bronze and Steel

Composition and Properties

Bronze

Bronze is mainly an alloy of copper and tin, but it may also include elements like zinc, aluminum, or nickel to improve its properties. This combination gives bronze its notable characteristics such as low friction, resistance to corrosion, and a distinctive reddish-brown color.

Steel

Steel is primarily composed of iron and carbon, with carbon content usually less than 2%. Additional elements such as chromium, manganese, and nickel are often added to produce different types of steel, such as stainless steel. These additions enhance properties like hardness, tensile strength, and resistance to wear and corrosion.

Mechanical Properties

Tensile Strength

Tensile strength measures the maximum stress a material can endure before breaking.

- Bronze: Bronze’s tensile strength ranges from 200-800 MPa, making it suitable for moderate strength applications, especially where corrosion resistance is essential.

- Steel: Steel typically has a tensile strength ranging from 400 to over 2000 MPa, depending on the type and treatment, making it ideal for high load-bearing applications.

Durability

Bronze

Bronze is highly durable, especially in corrosive environments. It resists wear and can withstand long-term exposure to marine and industrial conditions.

Steel

Steel is exceptionally durable, particularly when alloyed to form stainless steel, which includes chromium to resist corrosion. Plain carbon steel requires protective coatings or galvanization to prevent rust. Steel’s ability to withstand dynamic loads and its high impact resistance make it indispensable in construction, automotive, and heavy machinery industries.

Corrosion Resistance

Bronze

Bronze naturally resists corrosion, making it suitable for use in marine and other harsh environments. The formation of a protective patina on its surface further enhances its corrosion resistance, providing long-term durability with minimal maintenance.

Steel

While plain carbon steel is susceptible to rust, alloying steel with chromium to create stainless steel significantly improves its corrosion resistance. Stainless steel is used extensively in environments where both strength and resistance to corrosion are required, such as in food processing, medical devices, and exterior architectural elements.

Aesthetic Appeal

Bronze

Bronze is highly valued for its warm, reddish-brown color and the unique patina it develops over time, which can range from green to brown, adding character and historical appeal. This makes bronze a favored material for sculptures, decorative elements, and historical restorations.

Steel

Steel, especially when polished or brushed, offers a sleek and modern appearance. Stainless steel maintains its lustrous finish and does not tarnish, making it popular for contemporary architectural designs, household appliances, and kitchenware.

Cost and Maintenance

Bronze

Bronze is costly due to copper and tin prices, but its low maintenance and long-term durability in corrosive environments can justify the initial investment.

Steel

Steel is generally more affordable than bronze, particularly carbon steel. The cost increases with the addition of alloying elements such as chromium and nickel for stainless steel. While steel may require more maintenance to prevent rust (in the case of carbon steel), the lower material cost and high strength-to-weight ratio make it an economical option for many applications.

Historical and Industrial Use

Bronze

Historically, bronze was one of the first alloys used by humans, dating back to the Bronze Age. It was prized for its workability and corrosion resistance, leading to its use in tools, weapons, and art. Today, bronze continues to be used in applications where its historical and aesthetic qualities are valued.

Steel

The development of steel, particularly with the advent of mass production techniques like the Bessemer process, revolutionized industries. Steel’s strength, versatility, and cost-effectiveness have made it indispensable in modern construction, manufacturing, and transportation sectors.

Strength and Durability

Tensile Strength

Tensile strength is a key factor in comparing the mechanical properties of bronze and steel. It measures the maximum stress a material can withstand while being stretched or pulled before breaking.

Bronze

Bronze alloys typically exhibit moderate tensile strength, ranging from 200 to 800 MPa, influenced by specific alloy compositions with elements like tin and phosphorus. While bronze is not as strong as steel, it is stronger than iron, making it suitable for applications where moderate strength and excellent corrosion resistance are needed.

Steel

Steel, especially when alloyed and heat-treated, has significantly higher tensile strength than bronze, ranging from 400 MPa to over 2000 MPa. The addition of carbon and other alloying elements like chromium and manganese enhances steel’s strength, making it ideal for high-load applications.

Durability Factors

Durability includes more than tensile strength; it also involves resistance to wear, impact, and environmental factors like corrosion.

Bronze

Bronze is highly durable in corrosive environments, forming a protective patina that prevents further oxidation, making it ideal for marine and industrial applications. Additionally, bronze alloys have good wear resistance, particularly in applications involving friction, such as bearings and bushings.

Steel

Steel’s durability is largely dependent on its type. Plain carbon steel, while strong, is prone to rust without protective coatings or treatments like galvanization. In contrast, stainless steel, with its chromium content, offers superior corrosion resistance. Steel’s high impact resistance and ability to withstand dynamic loads make it indispensable in construction, automotive, and heavy machinery industries.

Comparison of Strength and Durability

- Strength: Steel surpasses bronze in terms of tensile strength, making it more suitable for applications requiring high load-bearing capacity.

- Durability: Bronze excels in corrosive environments due to its natural patina, while steel’s durability varies with its composition and treatment. Stainless steel offers excellent durability and corrosion resistance, whereas plain carbon steel requires more maintenance to prevent rust.

Corrosion Resistance

Understanding Corrosion Resistance

Corrosion resistance determines how well a material can withstand damage from oxidation and other chemical reactions. This property is particularly crucial in highly corrosive environments such as marine settings, industrial sites, and outdoor applications.

Bronze Corrosion Resistance

Bronze, an alloy primarily composed of copper and tin, is highly regarded for its natural corrosion resistance. This resistance is largely due to the copper content, which reacts with atmospheric oxygen to form a protective patina—a thin layer of corrosion products that shields the underlying metal from further damage.

Key Features of Bronze:

- Patina Formation: The patina protects and enhances the aesthetic appeal of bronze, making it suitable for decorative and historical applications, and it is particularly effective in marine environments due to its resistance to saltwater corrosion.

- Marine Applications: Bronze is especially effective in marine environments. Aluminum bronze, a variant with added aluminum, exhibits even higher resistance, making it ideal for shipbuilding and underwater equipment.

- Low Maintenance: The natural patina reduces the need for frequent maintenance, ensuring long-term durability with minimal upkeep.

Steel Corrosion Resistance

Steel, primarily composed of iron and carbon, varies widely in its corrosion resistance depending on the type and alloying elements. Plain carbon steel is highly susceptible to rust, requiring protective coatings or galvanization to prevent corrosion. Stainless steel, however, offers significantly improved resistance due to the addition of chromium, which forms a stable oxide layer.

Key Features of Steel:

- Alloy Composition: Chromium in stainless steel grades like 304 and 316 forms a protective layer that prevents rust and enhances durability.

- Protective Coatings: Carbon steel often requires coatings like paint, galvanization, or powder coating to protect against corrosion, increasing maintenance needs.

- Application Flexibility: Stainless steel’s high corrosion resistance makes it suitable for a wide range of applications, from kitchen appliances to medical instruments and exterior architectural elements.

Comparative Analysis of Corrosion Resistance

When comparing bronze and steel in terms of corrosion resistance, several factors must be considered:

Material Comparison:

- Bronze: Exhibits high natural corrosion resistance, particularly in marine environments. The patina formation provides long-term protection with low maintenance requirements.

- Steel: Corrosion resistance varies significantly among different types. Stainless steel offers excellent resistance due to its protective chromium oxide layer, while carbon steel requires additional treatments to prevent rust.

Applications:

- Bronze: Ideal for marine applications, decorative elements, and parts requiring low friction and wear resistance.

- Steel: Suitable for general construction, high-strength applications, and environments where both strength and corrosion resistance are needed.

Maintenance Needs:

- Bronze: Generally low to moderate maintenance due to the protective patina.

- Steel: Higher maintenance required, especially for carbon steel, to ensure the longevity of protective coatings.

Suitability for Various Environments

Marine Environments:

- Bronze: Preferred for its exceptional resistance to saltwater corrosion and minimal maintenance.

- Stainless Steel: Effective in resisting pitting and crevice corrosion in salty conditions, making it a viable alternative.

Industrial Applications:

- Bronze: Suitable for components exposed to corrosive industrial atmospheres, particularly where low friction is required.

- Steel: Stainless steel is popular in industrial settings for its strength and corrosion resistance, but carbon steel may need extra protection.

Outdoor Use:

- Bronze: The patina offers natural protection, making it ideal for outdoor sculptures and architectural features.

- Steel: Requires protective coatings for carbon steel, while stainless steel is well-suited for outdoor applications without additional treatments.

Choosing between bronze and steel depends on the environment, maintenance needs, and the balance between strength and corrosion resistance.

Choosing the Right Material for Your Project

Evaluating Material Properties

When choosing the right material for your project, understanding the distinct properties of bronze and steel is essential. Each material offers unique benefits and drawbacks that must be considered in the context of your specific application.

Strength and Load-Bearing Capacity

Steel generally has higher tensile strength than bronze, making it better for structural applications that need to support significant loads. This enhanced strength is due to the combination of iron and carbon, which can be further modified with heat treatments to increase fracture resistance. However, the brittleness of steel under certain conditions necessitates careful handling.

Bronze, while generally softer than steel, offers sufficient strength for many applications. Its ability to deform under stress without breaking makes it ideal for components that must endure gradual wear. The choice between the two materials should consider the specific strength requirements of the project.

Corrosion Resistance

Bronze naturally resists corrosion, especially in marine environments, due to the formation of a protective patina. This makes it an excellent choice for applications exposed to harsh weather or saltwater. Steel, particularly stainless steel, also offers good corrosion resistance thanks to chromium, which forms a stable oxide layer. However, plain carbon steel needs additional coatings, such as galvanization, to prevent rust. The environmental conditions of your project will significantly influence the material choice.

Environmental Impact

Considering the environmental impact of materials is crucial for sustainable project planning.

Bronze production does not involve processes like galvanization, which can have detrimental environmental effects. However, the extraction of copper and tin, the primary components of bronze, is resource-intensive.

Steel production, while also resource-intensive, involves the use of iron ore and coal. The environmental impact can vary depending on the type of steel and the production methods used. Assessing the sustainability of your project should include a lifecycle analysis of the materials.

Aesthetic Considerations

Bronze is known for its warm, classic look, which develops a unique patina over time, making it popular for decorative and artistic uses.

Steel, especially stainless steel, provides a sleek, modern appearance suitable for contemporary designs. While steel can be painted for different color finishes, this requires regular maintenance to preserve the appearance.

Application Suitability

When deciding on the right material, it’s important to consider where and how it will be used.

Bronze is ideal for applications requiring high corrosion resistance, such as marine hardware, sculptures, and decorative architectural elements. Its low friction properties are also beneficial for components like bearings and bushings.

Steel is preferred for projects demanding high strength and durability, such as structural elements in construction, industrial settings, and modern architectural designs. Stainless steel, in particular, is favored for its combination of strength and corrosion resistance.

Cost Implications

The cost of materials is a significant factor in decision-making.

Bronze is generally more expensive than steel due to the cost of copper and tin. However, its low maintenance and long-term durability in corrosive environments can offset the initial investment.

Steel is typically more affordable, especially plain carbon steel. The cost increases with the addition of alloying elements like chromium and nickel for stainless steel. The choice should balance material costs with the required performance and maintenance over the project’s lifespan.

Outdoor Applications

Corrosion Resistance

When evaluating materials for outdoor applications, corrosion resistance is a crucial factor.

Bronze

Bronze is inherently resistant to corrosion, thanks to its composition of copper and tin. This resistance is especially important in marine environments where saltwater can accelerate corrosion. Over time, bronze develops a protective patina, enhancing its aesthetic appeal and adding an extra layer of protection against corrosion. This makes bronze an excellent choice for outdoor sculptures, fountains, and architectural features exposed to the elements.

Steel

Steel varies in its corrosion resistance. Plain carbon steel is prone to rust and requires protective coatings, such as paint or galvanization, to withstand outdoor conditions. Stainless steel, which includes chromium, forms a protective oxide layer that resists corrosion, making it suitable for outdoor applications, especially where regular maintenance can ensure the protective layer remains intact.

Durability and Strength

Durability and strength are key considerations for materials used in outdoor structures and installations.

Bronze

Although not as strong as some high-strength steels, bronze is particularly effective in high-friction environments, such as bearings and bushings, due to its wear resistance and longevity in corrosive conditions. This makes bronze suitable for load-bearing applications and environments with high friction.

Steel

Steel is renowned for its high tensile strength, ideal for structural applications. It can bear significant loads and is often used in construction, bridges, and other infrastructure projects. Stainless steel combines strength with corrosion resistance, making it a versatile material for outdoor environments where both properties are essential.

Aesthetic Appeal

The visual impact of a material is an important consideration in many outdoor projects.

Bronze

Bronze is valued for its warm, golden color that matures into a rich patina over time. This aging process enhances its character and historical appeal, making bronze a favored choice for statues, monuments, and decorative architectural elements. The patina not only protects the metal but also enhances its aesthetic value.

Steel

Steel, particularly stainless steel, offers a sleek, modern look that can be finished in various ways, including polishing, brushing, or painting. This versatility allows it to fit into contemporary designs and applications where a clean, industrial aesthetic is desired. However, it does not develop the same natural patina as bronze, which can be a drawback for projects seeking a more traditional or antique appearance.

Environmental Impact

The environmental impact of a material is an increasingly important consideration.

Bronze

Bronze production is relatively straightforward and does not require additional protective coatings, which can make bronze a more environmentally friendly option compared to galvanized steel. However, the extraction of copper and tin can be resource-intensive.

Steel

Steel production involves significant energy consumption and the use of raw materials like iron ore and coal. Galvanizing steel to improve corrosion resistance also has environmental consequences. However, steel is highly recyclable, which can offset some of its environmental impacts over its lifecycle.

Cost and Availability

Cost and availability are practical considerations that can influence material choice.

Bronze

Due to the cost of copper and tin, bronze is generally more expensive than steel. Its specialized applications and aesthetic qualities can justify the higher price in certain contexts, although its availability is more limited compared to steel.

Steel

Steel is more widely available and typically less expensive than bronze. The broad range of steel types and treatments allows for cost-effective solutions for various outdoor applications, making steel a practical choice for large-scale projects where budget constraints are significant.

Longevity

The lifespan of a material is critical for long-term outdoor applications.

Bronze

Bronze can last indefinitely in outdoor environments, with its natural patina providing ongoing protection. This longevity makes it a cost-effective option in the long run, despite its higher initial cost.

Steel

The longevity of steel depends on its type and the protective measures used. Stainless steel can last for decades with proper maintenance, while galvanized steel may eventually require renewal of its protective coatings. Regular maintenance is essential to ensure the longevity of steel in outdoor applications.

Aesthetic Appeal

Color and Patina Development

Bronze

Bronze starts with a warm, golden hue that adds a touch of elegance to any design. Over time, bronze develops a patina that can range from rich brown to greenish-blue, depending on the environment. This patina enhances the aesthetic appeal of bronze while also serving as a protective layer against further oxidation. This unique characteristic makes bronze a popular choice for both historical restorations and contemporary decorative elements.

Steel

Steel, particularly stainless steel, is known for its modern, sleek appearance. The initial color of steel is typically gray or silvery, and it can be finished in various ways, such as brushed, polished, or matte, to suit different design preferences. Unlike bronze, steel does not develop a patina, so it retains its original appearance with minimal maintenance. This consistency makes steel a favored material for contemporary and industrial designs.

Design Versatility

Bronze

Bronze offers remarkable design versatility due to its ability to be cast into intricate shapes and forms. This makes it an excellent choice for artistic and architectural applications where detailed designs are required. The variety of finishes, from highly polished to rustic, allows bronze to fit both traditional and modern settings.

Steel

Steel, while less flexible in terms of casting intricate forms compared to bronze, excels in structural applications. Its strength and durability make it ideal for components like façades, handrails, and support structures. Steel can be manipulated into various shapes through processes like welding and bending, and its range of finishes allows for diverse aesthetic applications, from minimalist modern to rugged industrial.

Historical and Artistic Significance

Bronze

Historically, bronze has been a material of choice for artists and architects since the Bronze Age. Its warm color and the ability to develop a patina have made it a favored material for sculptures, monuments, and decorative panels. The historical and artistic significance of bronze adds a layer of cultural richness to any project, making it a timeless material that connects the past with the present.

Steel

Steel, particularly in the modern era, has become synonymous with progress and innovation. Its use in iconic structures and modern art shows its significance in contemporary design. The sleek, clean lines achievable with steel contribute to its popularity in creating a futuristic and industrial aesthetic, making it a staple in both functional and artistic applications.

Maintenance and Longevity

Bronze

Maintaining the aesthetic appeal of bronze involves allowing the patina to develop naturally, which requires minimal intervention. However, if a polished look is desired, regular cleaning and polishing are necessary. The patina itself acts as a protective layer, reducing the need for extensive maintenance and ensuring the longevity of bronze in both indoor and outdoor environments.

Steel

Steel, especially stainless steel, is relatively low maintenance. It does not tarnish and requires only occasional cleaning to maintain its appearance. For carbon steel, protective coatings are necessary to prevent rust and maintain its aesthetic appeal. The longevity of steel in aesthetic applications is ensured through proper maintenance, making it a durable and reliable choice for various projects.

Comparative Analysis

| Feature | Bronze | Steel |

|---|---|---|

| Initial Color | Warm, golden | Gray or silvery |

| Patina Development | Develops rich, protective patina | No patina; retains original look |

| Design Flexibility | Highly versatile for detailed forms | Strong and versatile for structures |

| Aesthetic Appeal | Classic, historical significance | Modern, sleek, industrial look |

| Maintenance | Low to moderate; patina as protection | Low; occasional cleaning for stainless |

Bronze offers a classic aesthetic with historical significance and a natural patina that enhances its appeal over time. Steel provides a modern, consistent look with minimal maintenance, making it suitable for contemporary designs. The choice between bronze and steel will depend on the desired visual impact and the specific requirements of the project.

Metal Properties Comparison

Composition

Bronze is primarily an alloy of copper and tin, often enhanced with elements like zinc, aluminum, or nickel to improve specific properties. This composition gives bronze its notable characteristics, including good corrosion resistance and a distinctive reddish-brown color.

Steel is an alloy mainly composed of iron and carbon, with the carbon content usually less than 2%. Additional elements such as chromium, manganese, and nickel are often included to improve properties like strength, hardness, and corrosion resistance. These variations result in different types of steel, including stainless steel.

Mechanical Properties

Tensile strength measures a material’s ability to withstand tension without breaking. Bronze typically exhibits tensile strengths ranging from 200 to 800 MPa, making it suitable for applications requiring moderate strength and high corrosion resistance. Steel, on the other hand, offers significantly higher tensile strength, ranging from 400 MPa to over 2000 MPa, depending on the type and treatment, ideal for high load-bearing applications.

Durability

Durability encompasses a material’s resistance to wear, impact, and environmental factors such as corrosion.

Bronze forms a protective patina in corrosive environments, which prevents further oxidation, making it ideal for marine and industrial applications. Bronze also has good wear resistance, particularly in applications involving friction, such as bearings and bushings.

Steel’s durability varies with its type. Plain carbon steel is strong but prone to rust without protective coatings or treatments like galvanization. Stainless steel, with its chromium content, offers superior corrosion resistance. Steel’s high impact resistance and ability to withstand dynamic loads make it indispensable in construction, automotive, and heavy machinery industries.

Corrosion Resistance

Corrosion resistance is crucial for materials exposed to harsh environments, affecting their longevity and maintenance needs.

Bronze naturally resists corrosion, especially in marine environments. The formation of a protective patina enhances its corrosion resistance, providing long-term durability with minimal maintenance.

Steel’s corrosion resistance depends on its composition. Plain carbon steel requires protective coatings to prevent rust. Stainless steel, however, resists corrosion effectively due to its chromium oxide layer, making it suitable for applications where both strength and resistance to corrosion are required.

Thermal and Electrical Conductivity

Bronze exhibits moderate thermal and electrical conductivity. It is suitable for applications where good but not high-performance conductivity is required.

Steel has lower thermal and electrical conductivity compared to bronze. This limits its use in applications requiring high conductivity, although it remains suitable for many structural and industrial applications.

Aesthetic Appeal

Bronze is appreciated for its warm color and the unique patina it develops over time, which ranges from green to brown. This aesthetic quality makes bronze popular in art, architecture, and decorative items.

Steel, especially stainless steel, offers a sleek, modern look. It is commonly used in contemporary designs and applications requiring a durable, clean appearance.

Maintenance and Longevity

Bronze requires less maintenance in outdoor environments due to its protective patina, and its durability is enhanced by its resistance to brittleness. Steel’s maintenance needs vary; stainless steel requires minimal maintenance to prevent corrosion, whereas carbon steel needs regular protective treatments to maintain its integrity.

Antimicrobial Properties

Bronze exhibits antimicrobial properties due to the oligodynamic effect, making it suitable for hygienic applications.

Steel does not inherently possess antimicrobial properties and requires regular cleaning to maintain hygiene.

Cost and Accessibility

Bronze is historically more expensive than steel due to the rarity of tin. However, its unique properties justify its cost for specific applications.

Steel is generally cheaper and more widely available than bronze, contributing to its widespread use in construction and manufacturing.

Bronze

Composition and Characteristics

Bronze is mainly made of about 88% copper and 12% tin. This combination gives bronze its distinctive reddish-brown color and a range of beneficial properties, including high strength, excellent corrosion resistance, and good thermal and electrical conductivity. These characteristics make bronze a versatile material suitable for various applications, from artistic sculptures to industrial machinery components.

Types of Bronze

There are various types of bronze, each with unique properties from added elements:

- Phosphor Bronze: Contains phosphorus, enhancing strength and conductivity, making it ideal for springs and electrical contacts.

- Silicon Bronze: Includes silicon, which provides excellent corrosion resistance, suitable for marine hardware.

- Aluminum Bronze: Contains aluminum, known for its high strength and corrosion resistance, often used in aggressive environments.

- Manganese Bronze: Includes manganese, enhancing strength and wear resistance, commonly used in gears and bearings.

Common Uses and Advantages

Applications

Bronze is highly valued in various fields due to its unique properties:

- Marine Hardware: Its resistance to saltwater corrosion makes it ideal for ship fittings, propellers, and underwater equipment.

- Artistic Sculptures: The aesthetic appeal and ability to develop a patina over time make bronze a favorite for artists and sculptors.

- Industrial Components: Bronze’s properties, such as low friction and high conductivity, make it ideal for bearings, bushings, gears, and electrical connectors.

Advantages

The advantages of bronze include:

- Corrosion Resistance: Bronze naturally resists corrosion, especially in marine environments, due to the formation of a protective patina.

- Durability: It is highly durable and can withstand long-term exposure to harsh conditions without significant degradation.

- Aesthetic Appeal: The development of a patina over time adds character and visual appeal, making bronze suitable for decorative applications.

- Conductivity: Good thermal and electrical conductivity make it useful in applications requiring efficient heat and electricity transfer.

Limitations

Despite its many benefits, bronze has some limitations:

- Cost: Bronze is generally more expensive than other materials like steel due to the cost of copper and tin.

- Strength: Although strong, bronze is not as strong as high-tensile steels, limiting its use in applications requiring extreme strength.

- Weight: Bronze is denser and heavier than materials like aluminum, which may be a drawback in applications where weight is a critical factor.

Comparison with Other Materials

Bronze vs. Steel

When comparing bronze with steel, several key differences emerge:

- Corrosion Resistance: Bronze has superior natural corrosion resistance, especially in marine environments, while steel requires alloying elements like chromium to achieve similar resistance.

- Strength: Steel generally has higher tensile strength than bronze, making it more suitable for load-bearing applications.

- Cost: Bronze is more expensive than steel, though its long-term durability in corrosive environments can offset the initial investment.

Bronze vs. Aluminum

Bronze and aluminum are often compared for their respective advantages:

- Weight: Aluminum is lighter than bronze, making it preferable in applications where weight reduction is critical.

- Corrosion Resistance: Both materials resist corrosion well, but bronze’s patina provides an additional protective layer.

- Strength: Aluminum alloys can be engineered for high strength, though bronze remains stronger in specific contexts, such as wear resistance and bearing applications.

Bronze’s unique properties make it valuable in many industries, including art and engineering.

Steel

Composition and Characteristics

Steel is mainly an alloy of iron and carbon, typically containing less than 2% carbon. The properties of steel can be significantly enhanced by adding other elements such as chromium, nickel, manganese, and molybdenum. These additional elements can improve various attributes, including strength, hardness, and corrosion resistance.

Types of Steel

- Carbon Steel: Contains up to 2% carbon, with minimal other alloying elements. Known for its high tensile strength, it is widely used in construction and manufacturing.

- Stainless Steel: Includes at least 10.5% chromium, providing excellent corrosion resistance. It is used in applications ranging from kitchenware to medical devices.

- Alloy Steel: Contains additional alloying elements like nickel, vanadium, or tungsten, enhancing specific properties such as toughness, strength, and wear resistance.

- Tool Steel: Designed to be very hard and wear-resistant, making it ideal for cutting and drilling tools.

Mechanical Properties

Tensile Strength

Steel exhibits high tensile strength, making it suitable for structural applications. Depending on the type and treatment, steel’s tensile strength can range from 400 MPa to over 2000 MPa, allowing for tailored use in various applications requiring different strength levels.

Yield Strength

Yield strength, the stress at which a material begins to deform plastically, is a critical property for steel, particularly in construction where it ensures the material can withstand significant loads without permanent deformation.

Ductility

Steel’s ductility, or its ability to deform without breaking, varies with its composition. Low-carbon steel is more ductile and can be easily formed and welded. High-carbon steel is less ductile but offers greater hardness and strength.

Hardness

Steel’s hardness can be increased through processes like quenching and tempering. This makes it resistant to surface wear and suitable for applications requiring high durability, such as in machinery and cutting tools.

Physical Properties

Density

Steel has a relatively consistent density of about 7.85 g/cm³ for carbon steel. This density contributes to its strength-to-weight ratio, making it a preferred material for load-bearing structures.

Thermal Conductivity

Steel has moderate thermal conductivity, making it useful in applications requiring heat transfer. However, its conductivity can vary depending on the specific type and microstructure.

Electrical Conductivity

While not as conductive as metals like copper, steel’s electrical conductivity is adequate for certain applications, particularly when combined with its other mechanical properties.

Chemical Properties

Corrosion Resistance

Steel’s corrosion resistance can be significantly enhanced by alloying with elements like chromium and nickel. Stainless steel, in particular, is known for its excellent resistance to corrosion, making it ideal for environments exposed to moisture and chemicals.

Chemical Reactivity

The chemical reactivity of steel depends on its composition and the environmental conditions. Proper selection and maintenance can ensure long-term resistance to chemical attacks.

Common Uses and Advantages

Applications

Steel’s versatility shines in various fields: It’s the backbone of construction in beams, columns, and reinforcements; the go-to material in the automotive industry for its strength and cost-effectiveness; a staple in manufacturing tools, machinery, and equipment; and a favorite in households for kitchen appliances and fixtures.

Advantages

- Strength: High tensile and yield strength make steel ideal for load-bearing applications.

- Durability: Excellent resistance to wear and impact, especially in alloyed forms.

- Corrosion Resistance: Stainless steel offers superior resistance to rust and corrosion.

- Cost-Effectiveness: Generally more affordable than materials like bronze, with widespread availability.

- Versatility: Can be tailored for specific applications through alloying and heat treatments.

Limitations

- Corrosion: Plain carbon steel is susceptible to rust and requires protective coatings.

- Weight: Steel is heavier than materials like aluminum, which can be a drawback in applications where weight is a critical factor.

- Brittleness: High-carbon steel can be brittle and requires careful handling.

Comparative Analysis with Bronze

Strength and Durability

Steel generally offers higher tensile strength compared to bronze. This makes it more suitable for high-load applications, although bronze excels in environments with high friction and corrosion.

Corrosion Resistance

While stainless steel matches or exceeds bronze in corrosion resistance, plain carbon steel is more vulnerable and needs additional protection. Bronze naturally forms a patina that protects it from further corrosion, particularly in marine environments.

Cost and Maintenance

Steel is typically more cost-effective and widely available than bronze. However, bronze’s low maintenance and long-term durability in corrosive environments can justify its higher initial cost for certain applications.

Aesthetic Appeal

Steel provides a sleek, modern look, whereas bronze offers a classic, historical appeal with its unique patina. The choice between the two materials often depends on the desired visual impact and the specific requirements of the project.

Environmental Impact and Sustainability

Environmental Impact of Bronze

Resource Intensity

Bronze is primarily composed of copper and tin. Extracting and processing these metals consume a lot of energy, leading to resource depletion and environmental damage. The mining activities required for copper and tin can cause significant land disturbance and pollution.

Corrosion Resistance

Bronze forms a protective patina over time, which helps prevent further corrosion. This patina shields it from wear, but exposure to moisture, UV radiation, and pollutants can affect its lifespan and performance.

Toxicity and Emissions

Bronze production involves substantial energy consumption and waste generation. The use of tin in bronze is considered more environmentally friendly than some other alloying metals. Nonetheless, the overall environmental impact of bronze production remains significant due to the mining, smelting, and transportation processes involved.

Environmental Impact of Steel

Carbon Footprint

Steel production is one of the most carbon-intensive industrial processes, with the BF-BOF route emitting more CO2 than the more energy-efficient EAF route, which uses recycled steel.

Resource Usage

Steel production requires large amounts of iron ore, coal, and energy. However, steel’s recyclability offers a significant advantage. Recycling steel reduces energy consumption dramatically—using about 25% of the energy required for virgin steel production.

Durability and Waste

Steel is highly durable and can last for decades, reducing the need for frequent replacement. However, if not properly disposed of or recycled, steel can contribute significantly to environmental waste. Encouraging steel recycling can mitigate some of these issues and improve its overall environmental impact.

Sustainability Comparisons

| Aspect | Bronze | Steel |

|---|---|---|

| Material Composition | Copper and Tin | Iron, Carbon, sometimes Chromium and Nickel |

| Corrosion Resistance | Moderate | High |

| Energy Consumption | High (due to copper and tin extraction) | High (steel production), but reduced through recycling |

| Environmental Impact | Less toxic than brass, with environmental impact mainly from energy consumption and resource extraction | High carbon footprint, significant resource and energy consumption |

| Recyclability | Recyclable, but less emphasis compared to steel | Highly recyclable, with significant energy savings |

Specific Application Guides

In construction, both bronze and steel have unique advantages and are chosen based on specific project needs.

Load-Bearing Structures

Steel is preferred for load-bearing structures due to its high tensile strength and durability, making it ideal for building frameworks, bridges, and infrastructure projects. The ability to withstand high dynamic loads and impact makes steel indispensable for these applications.

Bronze, while not as strong as steel, is used in construction where corrosion resistance is critical, such as in decorative elements, fittings, and components exposed to the elements. Its patina development adds an aesthetic appeal, making it suitable for both functional and decorative applications.

Corrosion Resistance in Construction

Steel resists corrosion well when alloyed with chromium to produce stainless steel, making it suitable for various applications. However, plain carbon steel requires protective coatings to prevent rust, which can increase maintenance efforts.

Bronze naturally resists corrosion and is particularly effective in coastal and marine construction due to its ability to form a protective patina. This makes bronze an excellent choice for outdoor sculptures, architectural features, and fittings that need to withstand harsh weather conditions.

Bronze vs Steel for Marine Applications

Marine environments present unique challenges, including exposure to saltwater, which accelerates corrosion. Both materials are used in marine applications, but their suitability depends on specific conditions and requirements.

Marine Hardware and Components

Bronze is highly favored for marine hardware like propellers and ship fittings due to its excellent resistance to saltwater corrosion and minimal maintenance needs. The patina that develops on bronze provides an additional protective layer, ensuring long-term durability.

Steel: Stainless steel, particularly grades like 316, is used in marine environments due to its high resistance to pitting and crevice corrosion. While it does not develop a patina, its chromium oxide layer provides effective protection against corrosion. Carbon steel, however, is less suitable without extensive protective coatings.

Bronze vs Steel for Industrial Use

In industrial settings, materials must withstand harsh conditions, high loads, and wear. Both bronze and steel are utilized based on their mechanical and chemical properties.

Bearings and Bushings

Bronze is ideal for bearings and bushings due to its low friction and wear resistance. Bronze components perform well in applications involving continuous movement and heavy loads, such as in machinery and heavy equipment.

Steel: Alloy steel and tool steel are used for components requiring high strength and durability. Steel bearings and bushings are common in industrial machinery where high tensile strength and resistance to deformation are critical.

Industrial Equipment and Machinery

Steel is widely used in manufacturing industrial equipment and machinery because of its strength, versatility, and cost-effectiveness. Steel’s ability to handle high stress and impact makes it suitable for heavy-duty applications.

Bronze is used in specific industrial applications where corrosion resistance and low friction are essential. Bronze gears, valves, and connectors are common in environments exposed to corrosive substances or where smooth operation is required.

Cost-Benefit Analysis

Initial Costs and Production Processes

When comparing bronze and steel, understanding the initial costs and production processes is essential.

Bronze

Bronze is generally more expensive than steel due to the cost of its raw materials, primarily copper and tin. The production process of bronze, involving alloying and casting, requires skilled craftsmanship, which contributes to higher initial costs. However, bronze’s high machinability can reduce the costs associated with manufacturing complex parts and components.

Steel

Steel, especially stainless steel, can also be costly due to its raw material components like iron, chromium, and nickel. The manufacturing process for steel is complex and energy-intensive, involving steps like smelting, casting, and rolling. Despite these higher initial costs, steel’s superior strength and durability make it cost-effective for high load-bearing applications, while the widespread availability and lower cost of carbon steel offer an economical option for many projects.

Mechanical Properties and Applications

The mechanical properties of bronze and steel play a crucial role in determining their suitability for various applications.

Bronze

Bronze is known for its high strength, durability, and excellent corrosion resistance. These characteristics make bronze perfect for applications like marine hardware, electrical components, and bearings. Bronze’s high friction resistance and good machinability further enhance its suitability for these uses, providing long-term performance with minimal maintenance.

Steel

Steel, particularly stainless steel, is renowned for its exceptional strength, durability, and corrosion resistance. These characteristics make steel suitable for a wide range of applications, including construction, medical devices, and marine environments. Steel’s ability to withstand high stress and impact loads makes it indispensable in structural and industrial applications.

Long-Term Benefits

Evaluating the long-term benefits of bronze and steel is vital for a comprehensive cost-benefit analysis.

Bronze

Despite higher initial costs, bronze offers significant long-term benefits. Its durability and reduced maintenance needs can lead to substantial cost savings over time. The aesthetic appeal of bronze, which develops a protective patina, enhances its longevity and visual appeal, making it a valuable material for decorative and functional applications alike.

Steel

Stainless steel’s superior corrosion resistance and strength often justify its higher initial cost by providing long-term reliability and minimal maintenance requirements. In harsh environments, stainless steel keeps its integrity and appearance, reducing the need for frequent replacements and repairs, thus ensuring long-term cost-effectiveness.

Environmental Considerations

Environmental impact is an increasingly important factor in material selection.

Bronze

Bronze production is energy-intensive due to the melting and alloying processes involved. However, bronze’s recyclability and ability to extend product lifetimes by reducing waste are environmentally beneficial. The long lifespan and minimal maintenance requirements of bronze contribute to its sustainability.

Steel

Steel production requires significant natural resources and energy, leading to potential environmental impacts such as resource depletion and water pollution. However, steel’s high recyclability helps mitigate these impacts. The energy savings from recycling steel are substantial, making it a more sustainable option in the long term.

Market Demand and Competition

Market demand and supplier competition influence the prices of both bronze and steel.

Bronze

The price of bronze can fluctuate based on the availability of copper and tin, as well as the demand for high-quality alloyed products. Limited supply and high demand can drive up costs, while increased competition among suppliers may lead to lower prices.

Steel

Steel prices are similarly affected by market demand and the availability of raw materials. High demand for steel in construction and manufacturing can increase prices, while competition among steel producers can help stabilize or reduce costs. The broad range of steel types and treatments available allows for competitive pricing across different applications.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the key differences between bronze and steel in terms of strength and durability?

Bronze and steel differ significantly in terms of strength and durability, influencing their use in various industries.

Bronze, an alloy primarily composed of copper and tin, is known for its mechanical strength, but it generally exhibits lower tensile strength compared to steel. This makes bronze less suitable for applications requiring extremely high strength. However, bronze is highly durable in environments where corrosion resistance is critical. It forms a protective patina over time, enhancing its durability and making it ideal for marine applications and settings with high moisture exposure.

Steel, particularly carbon steel, offers superior tensile strength, making it a preferred material for structural and high-stress applications. Steel’s durability varies with its alloy composition; stainless steel, for example, includes chromium which significantly improves its corrosion resistance. Despite this, regular maintenance is often necessary to preserve its resistance to rust and corrosion.

Which material is better suited for outdoor applications?

For outdoor applications, the choice between bronze and steel largely depends on the specific environmental conditions and project requirements. Bronze is inherently more resistant to corrosion, developing a protective patina over time that enhances its durability, making it ideal for marine environments and locations with high moisture or salt exposure. It also offers aesthetic appeal due to its warm, golden color and the natural aging process. However, bronze can be more expensive.

Steel, particularly stainless steel, is known for its strength and durability, making it suitable for structural applications. While it can corrode in harsh environments, protective coatings like galvanization can be applied, though these require maintenance over time. Stainless steel’s modern appearance and lower cost compared to bronze make it a common choice for various outdoor uses.

How do bronze and steel compare aesthetically?

Bronze and steel exhibit distinct aesthetic qualities that influence their selection for various applications. Bronze starts with a golden hue and develops a rich brown or greenish patina over time due to oxidation, adding character and depth. This aging process gives bronze a warm, classic appearance, making it suitable for historical and luxurious settings. Its versatility in design allows for intricate shapes, ideal for decorative elements and sculptures.

In contrast, steel presents a sleek, modern look with a gray or silvery finish. It can be enhanced through painting or powder coating, offering a range of color options. Steel’s contemporary appeal is favored in modern designs due to its clean lines and neutral tones. Polished steel achieves a high sheen, appealing in minimalist or abstract designs.

What are the specific applications where bronze outperforms steel?

Bronze, an alloy of copper and tin, excels over steel in specific applications due to its unique properties. Its superior corrosion resistance makes it ideal for marine environments, where aluminum bronze is often used for boat hardware and shipbuilding due to its ability to withstand saltwater corrosion and develop a protective patina over time. Bronze’s low friction and high wear resistance are advantageous in applications such as valve stems and bearings, where smooth operation and durability under repeated stress are essential. Additionally, bronze’s aesthetic appeal, with its warm color and ability to develop a desirable patina, makes it a preferred choice for sculptures, architectural elements, and decorative items. Bronze also has moderate electrical conductivity, making it suitable for certain electrical components like grounding rods and connectors. Furthermore, its antimicrobial properties are valuable in hygienic applications, such as in medical or food processing settings. While steel is stronger and more durable under high-stress conditions, bronze’s unique attributes cater to specialized needs where corrosion resistance, low friction, aesthetic appeal, electrical conductivity, and antimicrobial properties are more critical.

What are the cost implications of choosing bronze over steel?

Choosing bronze over steel involves several cost implications due to the inherent differences in material composition and market factors. Generally, bronze is more expensive than steel because its primary component, copper, is costlier than the iron and carbon used in steel. This price difference can be around 20-30%, with bronze’s higher cost reflecting the value of its raw materials and the complexity of its production process.

In construction and architecture, while steel is initially cheaper, bronze can offer long-term savings through its superior durability and low maintenance needs. For example, bronze windows, though more expensive upfront, may prove cost-effective over time due to their longevity and minimal upkeep requirements.

In manufacturing and industrial applications, the higher cost of bronze can be justified by its excellent corrosion resistance and durability, which can lead to fewer replacements and repairs. Additionally, bronze’s higher scrap value can offset some of the initial expenses in recycling scenarios.

How sustainable are bronze and steel in terms of environmental impact?

Bronze and steel both have distinct environmental impacts that influence their sustainability profiles.

Bronze is primarily composed of copper and tin, with potential additions like phosphorus or silicon. Its production demands significant energy due to high alloying temperatures and relies on the extraction of copper and tin, leading to resource depletion and potential environmental degradation. However, bronze is recyclable, which helps reduce its

Steel, on the other hand, is mainly made from iron, chromium, and nickel. It is highly carbon-intensive, with substantial CO2 emissions associated with its production—approximately 1.85 tons of CO2 per ton of steel. Steel production also requires large quantities of iron ore and coal, contributing to resource depletion. Nevertheless, steel is highly recyclable, with processes like the Electric Arc Furnace (EAF) route significantly reducing emissions through the use of recycled steel.

In summary, while steel has a higher initial environmental impact due to its carbon footprint, its recyclability and durability can make it a more sustainable choice for long-term applications. Bronze, despite its lower recycling efficiency, offers unique benefits like antimicrobial properties and a slightly lower environmental impact compared to pure copper. The choice between the two should consider project-specific requirements, recycling potential, and material longevity.