Imagine you’re planning a project that requires sturdy, reliable steel. You might find yourself torn between two popular options: carbon steel and galvanized steel. But what’s the difference? Understanding how these two types of steel differ can make a world of difference in your decision-making process. Carbon steel, known for its strength and hardness, comes with its own set of advantages and disadvantages. On the other hand, galvanized steel boasts superior corrosion resistance thanks to its protective zinc coating. In this article, we’ll dive deep into their definitions, compositions, key properties, and typical uses, helping you to determine which type of steel best suits your needs. Ready to make an informed choice? Let’s explore the nuances of carbon steel versus galvanized steel.

Definition and Composition of Carbon Steel

Understanding Carbon Steel

Carbon steel is an alloy consisting primarily of iron and carbon. Thanks to its versatility and wide range of applications, carbon steel is a fundamental material in many industries.

Composition of Carbon Steel

Carbon steel is composed mainly of iron and carbon, with the carbon content varying between 0.05% and 2.1% by weight. The properties of carbon steel are largely determined by its carbon content.

- Iron: The base metal, providing the fundamental structure.

- Carbon: Ranges from 0.05% to 2.1%, which affects the steel’s hardness, strength, and ductility.

- Additional Elements: Small amounts of manganese (up to 1.65%), silicon (up to 0.60%), and copper (not exceeding 0.60%) may be present to enhance certain properties.

Classification of Carbon Steel

Carbon steel is categorized based on its carbon content, which directly impacts its mechanical properties and suitability for different applications.

- Low Carbon Steel (Mild Steel):

- Carbon Content: 0.05% to 0.25%

- Properties: High ductility, good weldability, and relatively low strength.

- Applications: Commonly used in automotive panels, structural shapes, and pipelines due to its high ductility and good weldability.

- Medium Carbon Steel:

- Carbon Content: 0.29% to 0.54%

- Properties: Balanced strength and ductility, with good wear resistance.

- Applications: Well-suited for machinery parts, axles, and gears due to its balanced strength and ductility.

- High Carbon Steel:

- Carbon Content: 0.55% to 2.1%

- Properties: High strength and hardness, but less ductile.

- Applications: Commonly used in cutting tools, springs, and high-strength wires.

Key Characteristics of Carbon Steel

- Strength and Hardness: Increases with higher carbon content, making the steel suitable for applications requiring high strength and wear resistance.

- Ductility: Decreases as carbon content rises, impacting the material’s ability to deform without breaking.

- Heat Treatment: Carbon steel can be heat treated to alter its mechanical properties, enhancing hardness and strength through processes such as quenching and tempering.

Knowing the composition and types of carbon steel helps in choosing the right kind for specific applications, ensuring optimal performance and durability.

What is Galvanized Steel and How It Is Produced

Understanding Galvanized Steel

Galvanized steel is a type of steel that has undergone a galvanization process to enhance its resistance to corrosion. This process involves coating the steel with zinc to create a protective barrier against rust and other forms of corrosion.

Production Process of Galvanized Steel

The production of galvanized steel involves several key steps designed to ensure the zinc coating adheres effectively to the steel surface. These steps include cleaning, pickling, fluxing, and hot-dip galvanizing.

Initially, the steel is cleaned with a degreasing solution to remove contaminants, followed by a pickling process where it is immersed in a hot sulfuric acid bath to remove any remaining impurities. This step ensures the steel surface is clean and prepared for the subsequent coating process.

Fluxing

The fluxing process involves treating the steel with an aqueous solution, commonly zinc-ammonium chloride. The purpose of this step is to further clean the steel and help the zinc adhere better during the galvanization process.

Hot-Dip Galvanizing

The final step in the production process is hot-dip galvanizing. In this step, the steel is submerged in a bath of molten zinc, typically heated to around 450°C. The molten zinc reacts with the steel surface to form a series of zinc-iron alloy layers, creating a strong and durable coating.

Benefits of Galvanized Steel

Galvanized steel offers several advantages, making it a preferred choice in many applications:

- Corrosion Resistance: The zinc coating significantly enhances the steel’s ability to resist corrosion, especially in outdoor and high-moisture environments.

- Durability: The zinc coating extends the steel’s lifespan, making it more durable in harsh environments.

- Versatility: Due to its improved properties, galvanized steel is widely used in various industries, including construction, automotive, and agriculture.

Comparison: Carbon Steel vs Galvanized Steel

One of the most notable differences between carbon steel and galvanized steel is corrosion resistance. The zinc coating on galvanized steel offers superior protection against rust, making it more durable in environments with frequent exposure to moisture and other corrosive elements.

Due to its enhanced properties, galvanized steel is often used in applications where long-term durability and resistance to weathering are crucial. Common uses include building frames, roofing, and fencing. Carbon steel, on the other hand, is typically used in dry environments and applications where corrosion is less of a concern, such as machinery parts and tools.

Galvanized steel combines the strength of steel with the added benefit of corrosion resistance, making it an ideal material for projects requiring durability and longevity in challenging conditions.

Key Differences in Properties

Composition and Production

Carbon steel and galvanized steel differ significantly in their composition and production processes. Carbon steel is primarily made from iron and carbon, with minimal alloying elements, making it straightforward in its composition. It is produced through methods such as high-frequency induction heating and converter refining, which provide it with its essential mechanical properties.

Galvanized steel is produced by coating mild steel with a layer of zinc, typically through the hot-dip galvanizing process. This involves immersing the steel in molten zinc, creating a zinc-iron alloy layer that offers enhanced corrosion resistance. This coating process not only alters the surface characteristics but also adds a protective layer that carbon steel lacks in its natural form.

Strength and Corrosion Resistance

Carbon steel is known for its high strength and rigidity, making it suitable for applications that demand structural integrity. However, it is susceptible to corrosion and fatigue, particularly in environments with high moisture or aggressive elements, unless it is protected by additional coatings.

Galvanized steel, while it maintains good strength, stands out for its superior corrosion resistance. The zinc layer acts as a barrier against moisture and oxygen, significantly reducing the risk of rust and extending the material’s lifespan in corrosive environments. This makes galvanized steel a preferred choice for outdoor and high-moisture applications where corrosion resistance is critical.

Appearance and Durability

In terms of appearance, carbon steel typically has a uniform look but requires protective coatings to prevent rusting. Without these treatments, it is less durable in outdoor settings. Its aesthetic can vary depending on the finish applied, such as paint or powder coating.

Galvanized steel has a distinct shiny finish due to the crystallization of zinc. The shiny appearance is both aesthetically pleasing and indicates durability. The zinc coating ensures that galvanized steel remains resilient in harsh weather conditions, with a lifespan that can exceed 50 years in moderate climates.

Applications

The properties of carbon steel make it ideal for applications requiring high strength and durability, such as in the manufacturing of mechanical parts and structural components. Its use is prevalent in dry environments where corrosion is not a significant concern.

Conversely, galvanized steel is better suited for applications demanding corrosion resistance and a pleasing appearance. It is commonly used in building structures, automobile parts, and various outdoor applications where exposure to weather elements is unavoidable.

Cost Considerations

Carbon steel is generally less expensive upfront, making it attractive for budget-conscious projects. However, it may incur higher long-term costs due to the need for protective coatings and maintenance to combat corrosion.

Galvanized steel, while having a higher initial cost due to the zinc coating process, can offer long-term savings. Its reduced maintenance needs and extended lifespan can make it more cost-effective over time, especially in environments where corrosion is a constant challenge.

Typical Uses and Industry Applications

Carbon Steel Applications

Structural Construction

Carbon steel is extensively used in structural construction due to its high strength and durability. Its ability to handle significant loads makes it perfect for supporting structures like buildings and bridges.

Automotive Industry

In the automotive industry, carbon steel is crucial for manufacturing engine parts, axles, and other components where strength is essential. Its strength ensures the reliability and long life of critical automotive parts, enhancing vehicle safety and performance.

Heavy Machinery

Carbon steel is favored in heavy machinery manufacturing due to its wear resistance and strength, making it ideal for parts like gears, shafts, and machine frames that endure high stress and friction.

Pressure Vessels and Tanks

The construction of pressure vessels and tanks often utilizes carbon steel due to its ability to withstand high pressure. This application is critical in industries that handle fluids or gases under pressure, such as chemical processing and power generation.

Gas and Oil Pipelines

Carbon steel pipes are commonly used for transporting gases and fluids in the gas and oil industry. Their high strength and resistance to internal pressures make them suitable for long-distance pipeline systems.

Galvanized Steel Applications

Outdoor Structures

Galvanized steel is ideal for outdoor structures like fences, gates, and poles due to its excellent corrosion resistance. The zinc coating prevents rust, ensuring durability even in harsh weather.

Construction Materials

In construction, galvanized steel is used for roofing, wall panels, and other building materials. Its resistance to corrosion helps protect buildings from the elements, enhancing the durability of structures.

Automotive Body Parts

Galvanized steel is used in automotive body parts, especially in areas prone to rust such as undercarriages and wheel wells. The zinc coating provides a protective barrier that prevents rust, extending the life of the vehicle.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems benefit from the use of galvanized steel in ductwork and piping. The material’s corrosion resistance ensures that these components remain functional and free from rust over time.

Marine and Chemical Industries

In marine and chemical environments, galvanized steel is used for pipes and other components exposed to wet and corrosive conditions. Its durability in these harsh environments makes it a reliable choice for long-term applications.

Key Differences in Industry Use

Strength vs Corrosion Resistance

Carbon steel is known for its superior strength, making it suitable for applications requiring high mechanical strength and rigidity. However, it lacks the inherent corrosion resistance found in galvanized steel. On the other hand, galvanized steel provides excellent protection against rust due to its zinc coating, making it more suitable for environments where corrosion is a significant concern.

Cost and Workability

Galvanized steel typically has a higher initial cost due to the galvanization process, and it can be more challenging to weld or shape compared to carbon steel. Carbon steel, being less expensive and easier to work with, is often chosen for applications where corrosion is not a primary concern.

Environmental Conditions

Galvanized steel is ideal for damp or corrosive environments, like coastal areas or industrial settings exposed to chemicals. Its corrosion resistance ensures long-term performance and reduced maintenance. Carbon steel is better suited for dry environments or applications where its high strength is more critical than its resistance to corrosion.

Advantages and Disadvantages

Carbon steel offers several benefits that make it a popular choice in various industries:

Carbon steel is renowned for its high strength and rigidity, making it suitable for applications requiring durability and resistance to heavy loads, such as structural beams, machinery components, and automotive parts. Its ability to endure high pressure makes it perfect for gas and oil pipelines, pressure vessels, and industrial tools. Moreover, the production process of carbon steel is relatively straightforward, leading to lower initial costs compared to galvanized steel, making it an attractive option for budget-sensitive projects. Additionally, carbon steel can be easily welded and molded into complex shapes, enhancing its applicability across various sectors like construction, automotive, and manufacturing.

Despite its strengths, carbon steel has certain drawbacks. Carbon steel’s tendency to corrode necessitates frequent inspections and treatments in harsh environments. This ongoing maintenance can increase long-term costs and effort. Furthermore, carbon steel lacks the polished finish of galvanized steel, making it less suitable for applications where visual appeal is important.

Galvanized steel provides unique benefits, especially in environments prone to corrosion. The zinc coating on galvanized steel provides excellent rust protection, making it ideal for outdoor structures, roofing, and marine environments. This corrosion resistance significantly extends the material’s lifespan. Additionally, galvanized steel requires minimal maintenance compared to carbon steel, reducing long-term costs, particularly in humid or corrosive settings. Galvanized steel’s smooth, shiny finish makes it aesthetically versatile for visible applications like architectural panels or automotive trims.

However, galvanized steel also has certain limitations. The zinc coating, while beneficial for corrosion resistance, makes galvanized steel softer and less suitable for high-load applications compared to carbon steel. This limits its use in projects requiring maximum strength. Damage to the zinc layer, such as scratches or dents, can expose the underlying steel to corrosion, and maintaining the integrity of the coating is essential for preserving the material’s protective properties. Additionally, the galvanizing process adds to the initial expense of galvanized steel, which may be a consideration for budget-conscious projects.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is the difference between carbon steel and galvanized steel?

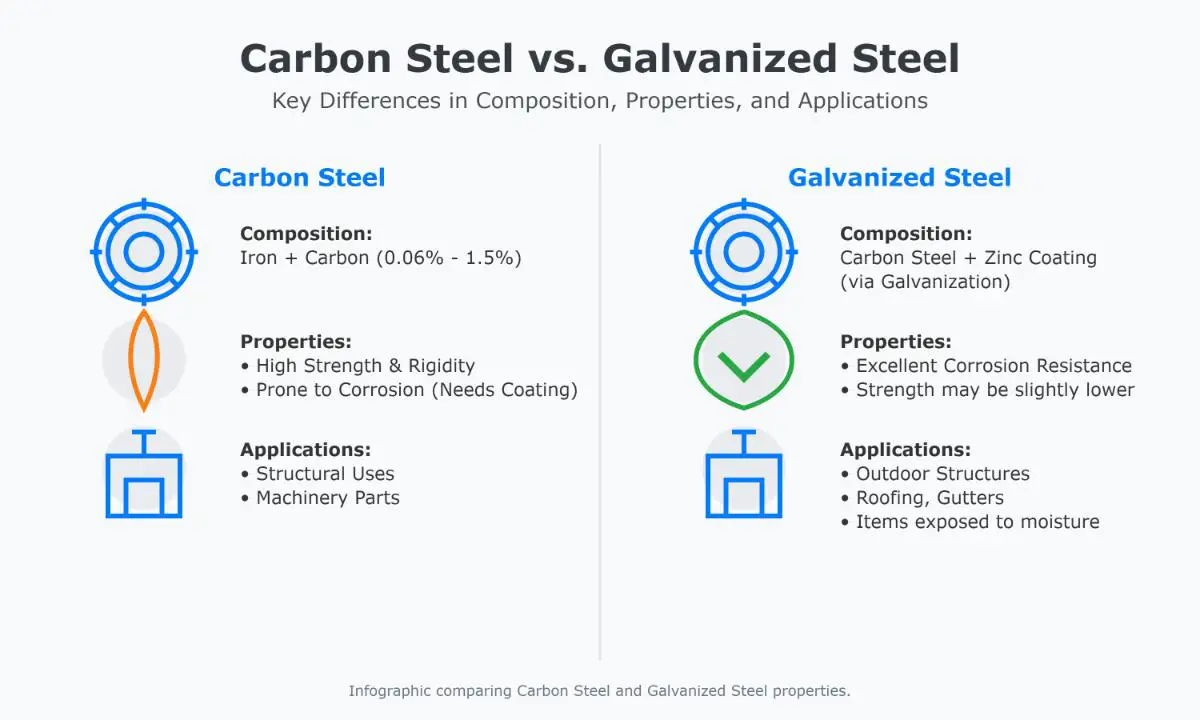

Carbon steel and galvanized steel differ primarily in composition and properties. Carbon steel is composed mainly of iron and carbon, with a carbon content typically between 0.06% and 1.5%. It is known for its high strength and rigidity, making it ideal for structural applications and machinery parts. However, it is prone to corrosion if not protected by additional coatings.

Galvanized steel, on the other hand, starts as carbon steel but is coated with a layer of zinc through a process called galvanization. This zinc coating provides excellent corrosion resistance, making galvanized steel suitable for outdoor structures, roofing, and applications exposed to moisture. While galvanized steel is less prone to rust, it may have lower strength compared to carbon steel due to the added coating.

What are the advantages and disadvantages of carbon steel?

Carbon steel, as discussed earlier, offers several advantages and disadvantages.

Advantages:

- Strength and Durability: Carbon steel is highly robust, making it ideal for construction and tool manufacturing due to its enhanced crystal lattice structure.

- Heat Treatability: It can be heat-treated to improve hardness and wear resistance, especially in medium and high-carbon steel grades.

- Cost-Effectiveness: Generally, carbon steel is less expensive compared to alloy steels because it primarily consists of iron and carbon.

- Environmental Benefits: Carbon steel is recyclable and can be produced in thin sections, contributing to its cost-effectiveness and environmental friendliness.

Disadvantages:

- Corrosion Susceptibility: Carbon steel is prone to rust as it lacks chromium, a component that provides corrosion resistance in stainless steel.

- Difficulty in Shaping: Its strength makes it challenging to bend and mold into complex shapes, limiting its use in applications requiring flexibility.

- High Initial Cost for Specific Grades: Certain high-carbon grades can be more expensive initially.

- Low Weldability in Some Grades: High-carbon steel grades can be difficult to weld, posing challenges in fabrication processes.

How does galvanization protect steel from corrosion?

Galvanization protects steel from corrosion primarily through the application of a zinc coating. This process involves immersing the steel in molten zinc, which creates a protective barrier. The zinc layer prevents corrosive elements like oxygen and moisture from reaching the steel, ensuring that the underlying metal remains intact. Additionally, zinc offers cathodic protection; it is anodic to steel, meaning it will corrode first if the coating is damaged, thereby continuing to protect the steel. Over time, the zinc coating also forms a patina layer, enhancing its protective properties. This makes galvanized steel highly resistant to rust and suitable for long-term use in harsh environments.

What are the common uses of high-carbon steel?

High-carbon steel, which contains 0.6-1.0% carbon, is known for its exceptional hardness, strength, and wear resistance. These properties make it ideal for various applications where durability and the ability to maintain a sharp edge are crucial. Common uses of high-carbon steel include:

- Cutting tools: Items such as knives, saw blades, drill bits, and chisels utilize high-carbon steel because it retains sharpness even under heavy use.

- Hand tools: Tools like screwdrivers, wrenches, and hammers benefit from high-carbon steel’s durability and resistance to deformation.

- Industrial components: High-carbon steel is used in manufacturing springs, gears, and high-strength wires due to its excellent elastic properties and tensile strength.

- Precision tooling: Molds, dies, and punches rely on high-carbon steel for its toughness and suitability for heat treatment.

These applications highlight high-carbon steel’s ability to perform well in scenarios requiring high strength and resistance to wear, despite its susceptibility to rust if not properly maintained.

How do I choose between carbon steel and galvanized steel for my project?

Choosing between carbon steel and galvanized steel for your project requires evaluating several factors. First, consider the environment where the material will be used. Galvanized steel, with its protective zinc coating, offers superior corrosion resistance, making it ideal for projects exposed to moisture or corrosive elements. On the other hand, carbon steel, known for its high strength and rigidity, is better suited for applications requiring durability and structural integrity without the need for corrosion protection.

Cost is another important factor; galvanized steel is generally more expensive due to the additional coating process but provides a more aesthetically pleasing finish. Additionally, consider the specific requirements of your project—whether strength, corrosion resistance, or cost is the priority. By weighing these factors, you can select the most appropriate material based on your project’s needs and environmental conditions.

Is galvanized steel more cost-effective in the long run?

Yes, galvanized steel is more cost-effective in the long run compared to carbon steel. While galvanized steel has a higher initial cost due to the zinc coating applied during the galvanization process, this investment pays off over time. The zinc layer provides excellent corrosion resistance, significantly reducing maintenance needs and prolonging the material’s lifespan. This means fewer expenses related to repairs, treatments, or replacements that carbon steel typically requires due to its susceptibility to rust.

Moreover, galvanized steel can last 2 to 6 times longer than untreated carbon steel, especially in harsh environments. When considering the total life-cycle cost, including purchase, installation, and maintenance, galvanized steel proves to be more economical. Its durability and lower ongoing maintenance costs make it a preferred choice for projects where long-term performance and cost-efficiency are crucial.