Accurately calculating the weight of cast iron is a critical step in ensuring efficiency and precision across engineering, manufacturing, and construction projects. Whether you’re estimating material requirements for a structural component or optimizing costs for large-scale production, understanding the relationship between cast iron’s density and volume is key to making informed decisions. But what’s the best way to tackle this calculation without risking errors or wasting valuable time? From tried-and-true formulas to modern online calculators, there are tools and techniques designed to simplify this process. Ready to uncover the secrets to mastering cast iron weight measurement and explore how these calculations can transform your projects? Let’s dive in!

Understanding Cast Iron Properties

Cast Iron and Its Applications

Cast iron, an iron-carbon alloy, is widely used across industries for its unique strength, durability, and cost-effectiveness. Comprising 2% to 4% carbon, 1% to 3% silicon, and small amounts of other elements such as manganese, sulfur, and phosphorus, it is a staple material in manufacturing, construction, and engineering. Its applications range from engine blocks and piping systems to cookware and structural components, highlighting its versatility.

Importance of Accurate Weight Calculation

Accurate weight measurement is critical when working with cast iron in industrial settings. Weight influences material handling, transportation, structural stability, and ensures optimal material selection, cost efficiency, and compliance in manufacturing. Miscalculations can result in safety hazards, increased expenses, or compromised performance, emphasizing the importance of accurate weight measurement methods.

Role of Density in Weight Calculations

Cast iron’s density, around 7.9 g/cm³, is one of its key characteristics and plays a vital role in determining the weight of components. Slight variations in density may occur depending on the specific type of cast iron, such as gray cast iron or ductile cast iron, which differ in graphite content and microstructure. Engineers and manufacturers rely on these density values to perform precise weight calculations using standardized formulas, ensuring consistent and reliable results.

Standards Compliance for Accuracy

Industry standards, such as those established by ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization), play a crucial role in maintaining accuracy and quality. These standards specify density ranges and tolerances, ensuring consistency in calculations and performance. Compliance with these guidelines helps guarantee safety, efficiency, and compatibility in both construction and manufacturing processes.

Applications of Cast Iron Weight Calculations

Importance in Construction Projects

Calculating the precise weight of cast iron is crucial for maintaining structural stability and safety in construction projects. Accurate weight calculations enable engineers to evaluate load-bearing capacities while preventing overloading that could compromise the integrity of structures. At the same time, these measurements assist in selecting materials that meet project specifications and comply with safety standards, ensuring adherence to regulatory requirements.

Relevance in Manufacturing Processes

Precise weight data helps manufacturers estimate costs for materials and labor, streamlining production planning and budgeting. This accuracy is particularly important for fabricating machinery components, pressure vessels, or heat exchangers, where weight directly influences operational reliability. By ensuring components meet quality standards, manufacturers can optimize their processes and produce durable, high-performance products.

Environmental and Cost Efficiency

Optimizing cast iron weight improves both environmental sustainability and cost-effectiveness. Reducing material waste and enhancing transport logistics helps lower costs and minimize environmental impact. Lightweight yet durable designs not only conserve resources but also reduce energy consumption during transportation, contributing to greener practices and more efficient operations.

Metal Weight Calculation Formulas

Metal Weight Calculation

The weight of a metal object is calculated using its volume and density:

This formula applies to all metals, including cast iron, steel, and aluminum. To ensure accurate results, measurements must be in consistent units.

Common Units for Calculations

Common units for weight calculations include volume (cm³, m³, in³), density (g/cm³, kg/m³, lb/in³), and weight (g, kg, lb).

Cast Iron Weight Calculation

Cast iron typically has a density between 7.3 g/cm³ and 7.9 g/cm³, depending on the specific type. For example, if the volume of a cast iron object is 1000 cm³ and its density is 7.8 g/cm³:

Metal Weight Formulas for Common Shapes

Cylindrical Shapes

For cylindrical objects like rods or pipes:

Calculate the volume:

where (r) is the radius and (l) is the length.

Multiply the volume by the density to determine the weight:

For hollow cylinders, subtract the inner radius from the outer radius before calculating the volume:

Rectangular Prisms

For rectangular objects like blocks or plates:

Calculate the volume:

Multiply the volume by the density:

Spherical Shapes

To calculate the volume of a sphere, use the formula:

Then, multiply the volume by the density to determine the weight.

Factors Influencing Accuracy

Several factors can affect the accuracy of weight calculations:

- Measurement Precision: Accurate dimensions are essential for precise volume calculations.

- Density Variations: Different types of metals and alloys have slightly varying densities.

- Material Consistency: Impurities or inconsistencies in the material may alter its density.

- Unit Consistency: Ensure all units are consistent throughout the calculation process.

Simplified Approximation for Common Materials

For quick approximations, simplified formulas are often used. For instance, the weight of a steel bar with a density of 7850 kg/m³ can be estimated using:

Here, (d) is the diameter in millimeters, and (l) is the length in meters. Similar methods can be adapted for cast iron using its average density.

Practical Applications

Engineers and manufacturers use these formulas for material selection, cost estimation, and structural analysis. These calculations ensure efficient material usage and help design safe, durable components.

Using Online Weight Calculators

Benefits of Online Weight Calculators

Online weight calculators make it quick and easy to calculate the weight of cast iron and other metals. They save time and reduce human error by eliminating the need for manual calculations. These tools are especially valuable for engineers and manufacturers who require fast, accurate measurements for project planning, material selection, or cost estimation. By automating the process, online calculators provide consistent and reliable results across various applications.

Step-by-Step Guide to Using a Cast Iron Weight Calculator

Selecting the Metal Type

Most online calculators let you choose from a list of metals, including cast iron. If cast iron is not listed, you can typically input its density manually, which usually ranges from 7,300 kg/m³ to 7,900 kg/m³, depending on the specific type.

Inputting Dimensions

To calculate weight, you need to input dimensions based on the object’s shape. Common shapes include:

- Cylindrical objects: Enter the diameter and length.

- Rectangular objects: Enter the width, height, and length.

- Spherical objects: Enter the radius or diameter.

Inputting accurate measurements, such as diameter and length, is critical because errors in dimensions can significantly affect the weight calculation.

Calculating the Volume

The calculator automatically determines the volume based on the entered dimensions. For instance:

- Cylinders: (π x r² x l )

- Rectangular prisms: (Width x Height x Length )

- Spheres: (4/3×π×r3 )

Applying Density

Once the volume is calculated, the tool multiplies it by the density of cast iron. This step, using either preset density values or user-provided inputs, gives the final weight of the object.

Verifying the Results

For additional accuracy, consider cross-checking the results by performing manual calculations or using multiple calculators to compare outputs.

Comparing Features of Online Calculators

Online calculators vary in quality. Look for key features such as:

- Preloaded Density Values: Some calculators include preset densities for common metals, streamlining the process.

- Support for Multiple Shapes: Advanced tools handle complex geometries like hollow cylinders or custom shapes.

- Unit Flexibility: The best calculators allow you to switch between metric and imperial units, ensuring compatibility with different measurement systems.

- Batch Calculations: Certain calculators can compute the weight of multiple items simultaneously, which is especially helpful for large-scale projects.

Ensuring Accuracy and Reliability

For accurate results with online weight calculators:

- Double-Check Input Values: Ensure that dimensions and density values are entered correctly.

- Use Reputable Sources: Opt for calculators from trusted engineering or manufacturing websites.

- Account for Variations: Be aware of slight density differences between types of cast iron, such as gray iron or ductile iron.

- Consider Manufacturing Tolerances: Real-world variations in material composition may lead to slight discrepancies between calculated and actual weights.

Practical Applications of Online Calculators

Engineers and manufacturers rely on these tools for various purposes, such as:

- Structural Analysis: Assessing load-bearing capacities for cast iron components in construction projects.

- Cost Estimation: Calculating material costs based on weight for budgeting purposes.

- Logistics Planning: Optimizing transportation and storage by accurately predicting material weight.

Online weight calculators simplify complex calculations, allowing professionals to focus on design and execution without compromising precision or efficiency.

Frequently Asked Questions

Below are answers to some frequently asked questions:

How do I calculate the weight of cast iron?

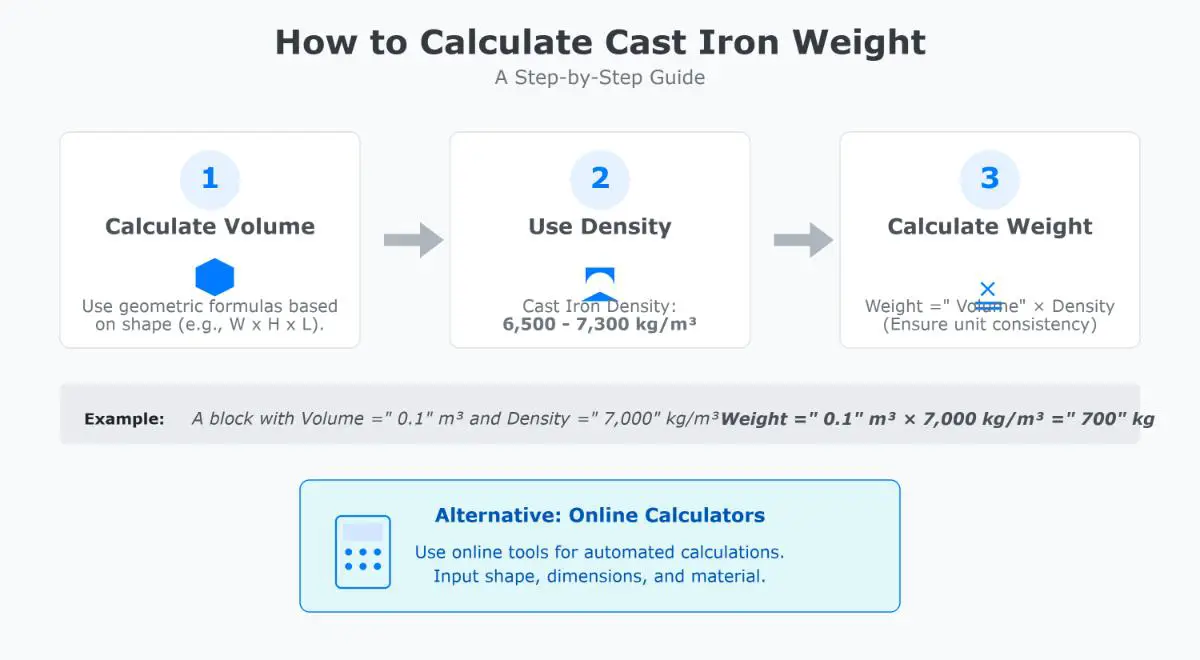

To calculate the weight of cast iron, determine the volume of the piece using geometric formulas (e.g., for a rectangular prism: width × height × length) and multiply it by the density of cast iron, which typically ranges from 6,500 to 7,300 kg/m³. Ensure unit consistency, such as volume in cubic meters and density in kg/m³, to avoid errors. For example, a cast iron block with a volume of 0.1 m³ and an average density of 7,000 kg/m³ would weigh approximately 700 kg. Alternatively, online calculators can simplify this process by automating calculations based on shape, dimensions, and material.

What is the formula for calculating metal weight?

The formula for calculating metal weight is: Weight = Volume × Density. Volume is determined based on the object’s shape, using geometric formulas (e.g., length × width × height for a rectangular prism or π × (diameter/2)² × length for a circular prism). Density is specific to the material, with cast iron typically around 7,300 kg/m³. Ensure consistent units for accurate results. This formula helps estimate metal weights for applications in construction and manufacturing, as discussed earlier, and can be simplified using online tools that account for material type and dimensions.

How does density affect metal weight?

Density directly affects metal weight because it defines the mass per unit volume of a material. In weight calculations, the formula Weight = Volume × Density highlights how a higher density results in a heavier weight for the same volume. For cast iron, with a typical density of about 7.9 g/cm³, accurate density values are crucial to ensure precise weight measurements, especially in applications like construction and manufacturing. Factors such as alloy composition and temperature variations can influence density, making it essential to use reliable, standardized values for accurate and consistent results.

Are online weight calculators reliable for professional use?

Online weight calculators can be reliable for professional use when accurate input parameters, such as precise dimensions and material density, are provided. They offer convenience and efficiency, especially for quick estimations in manufacturing or construction projects. However, their reliability depends on the quality of the calculator, its adherence to standards, and proper user input. For critical applications, results should be validated through manual calculations or expert consultation to account for variables like material inconsistencies or structural safety requirements. As discussed earlier, understanding limitations and verifying outputs ensure these tools are effective and trustworthy in professional contexts.

What standards should I follow when calculating cast iron weight?

To calculate the weight of cast iron accurately, follow recognized standards such as ASTM or ISO guidelines, which ensure consistency and reliability in measurements. Use the formula Weight = Volume × Density, ensuring unit consistency (metric or imperial) and precise measurements of dimensions. Refer to specific density values for the type of cast iron, as they vary between alloys like gray or ductile cast iron. Online calculators with pre-entered densities can streamline the process, but verifying their accuracy is essential. Compliance with standards guarantees reliable calculations for manufacturing, construction, and engineering applications.

How does weight calculation impact construction and manufacturing projects?

Accurate weight calculation is essential in construction and manufacturing projects as it ensures structural integrity, optimizes resource allocation, and aids in precise cost estimation. In construction, it helps determine load-bearing capacities, comply with safety standards, and minimize material waste. In manufacturing, it supports material selection, design optimization, and logistical planning. Tools like Cast Iron Weight Calculators enhance accuracy and efficiency, reducing errors and saving costs in material procurement and transportation. By providing precise measurements, these calculations contribute to safer, more efficient, and cost-effective project outcomes across both industries.