When it comes to choosing between chrome plated brass and stainless steel, the decision can be as complex as the materials themselves. Both options offer unique advantages and present distinct challenges, making the choice highly dependent on specific needs and applications. Are you prioritizing durability and resistance to corrosion, or is cost-efficiency and ease of maintenance more critical for your project? This comprehensive comparison will delve into the strengths and weaknesses of chrome plated brass and stainless steel, providing you with the insights needed to make an informed decision. From performance metrics to practical installation tips, we will explore every aspect to determine which material truly stands out. Ready to uncover the pros and cons of each? Let’s dive in.

Introduction to Materials

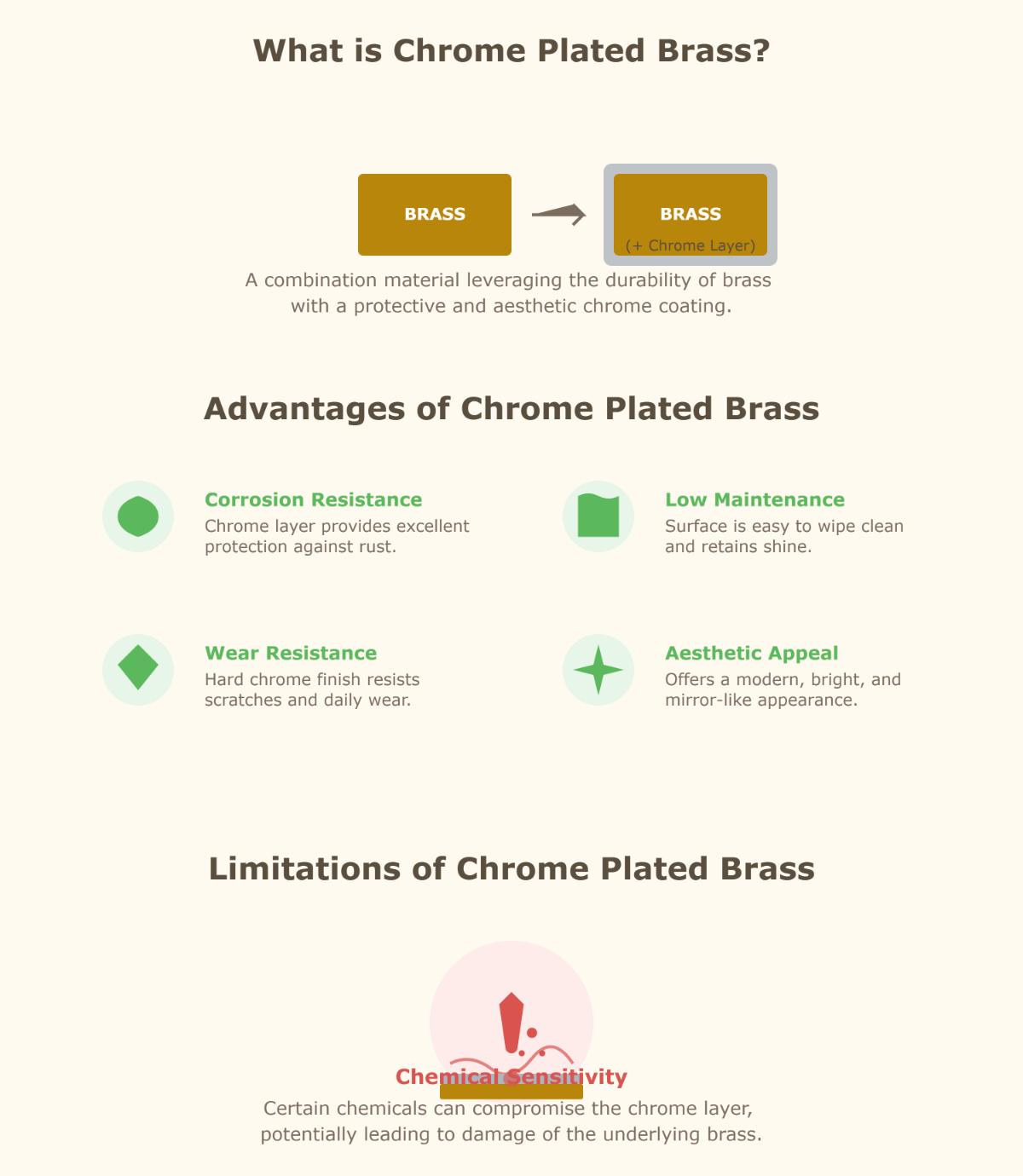

Chrome plated brass is popular for its appealing look and moderate resistance to corrosion, making it suitable for various uses. This material combines brass, an alloy made of approximately 85% copper and 15% zinc, with a thin layer of chromium applied through the electroplating process. The chrome layer provides a shiny, attractive finish and enhances the corrosion resistance of the underlying brass.

Composition and Properties

- Composition: Brass (85% copper, 15% zinc) with a chromium layer.

- Corrosion Resistance: Moderate, reliant on the integrity of the chrome layer.

- Strength: Brass has lower yield and tensile strength compared to stainless steel.

- Density: Approximately 8.4-8.7 g/cm³.

- Melting Point: Between 900-940°C.

- Electrical Conductivity: Higher due to the copper content.

- Thermal Conductivity: Higher, around 109-121 W/m·K.

Stainless steel is an iron-based alloy known for its exceptional corrosion resistance and high strength. It contains at least 10.5% chromium, which forms a self-healing passive oxide layer that protects the material from rust and corrosion. Stainless steel may also include other elements such as nickel or molybdenum to further enhance its properties.

Composition and Properties

- Composition: Iron-based alloy with at least 10.5% chromium, often with additional elements like nickel or molybdenum.

- Corrosion Resistance: Excellent, due to the chromium content and the formation of a passive oxide layer.

- Strength: Higher yield and tensile strength compared to chrome plated brass.

- Density: Approximately 7.5-8.0 g/cm³.

- Melting Point: Between 1400-1530°C.

- Electrical Conductivity: Lower, around 2.5% IACS.

- Thermal Conductivity: Lower, around 16-24 W/m·K.

Comparative Analysis

Performance and Durability

Stainless steel is stronger and more durable than chrome plated brass, making it ideal for demanding applications. It also offers superior corrosion and wear resistance, thanks to its natural protective layer.

Maintenance Requirements

- Cleaning and Upkeep of Chrome Plated Brass: Requires regular maintenance to preserve the chrome layer, which can peel off over time.

- Cleaning and Upkeep of Stainless Steel: Maintaining stainless steel is generally easier because of its self-healing properties, which require less frequent upkeep compared to chrome plated brass.

Cost Comparison

- Initial Purchase Cost: Chrome plated brass is typically less expensive upfront.

- Long-Term Cost Efficiency: Stainless steel offers better durability and lower maintenance costs, making it more cost-effective over time.

Applications and Suitability

- Home Improvement Uses: Chrome plated brass is popular in decorative items and plumbing fittings where aesthetics are important.

- Industrial and Commercial Applications: Stainless steel is preferred for applications requiring high strength, durability, and corrosion resistance, such as food processing, construction, and offshore platforms.

Material Comparison

Performance and Durability

Strength and Longevity

Stainless steel has a much higher tensile and yield strength compared to chrome plated brass, making it the preferred choice for high-integrity applications. For example, in construction projects, stainless steel can withstand greater stress and load without deformation, while chrome plated brass, despite its inherent strength from the brass base, does not benefit significantly from its thin chrome layer. Over time, especially under heavy use, the relatively lower strength of chrome plated brass may lead to more visible signs of wear and tear.

Resistance to Corrosion and Wear

Stainless steel offers excellent corrosion resistance due to the self-healing passive oxide layer formed by its chromium content. This makes it highly suitable for environments with high chemical exposure, such as industrial settings or areas with high humidity. However, chrome plated brass has only moderate corrosion resistance. The thin chrome layer can wear away over time, especially in harsh environments, leaving the underlying brass vulnerable to corrosion. In terms of wear resistance, stainless steel also outperforms chrome plated brass, as its harder surface can better withstand abrasion.

Maintenance Requirements

Cleaning and Upkeep of Chrome Plated Brass

Maintaining chrome plated brass requires regular attention. The chrome layer can be damaged by harsh chemicals and abrasive cleaners. To keep its appearance intact, use gentle cleaning agents and avoid scratching the surface. Over time, the chrome layer may start to peel or fade, and in such cases, more intensive restoration work may be needed.

Cleaning and Upkeep of Stainless Steel

Stainless steel is generally easier to maintain. Its self-healing properties mean that minor scratches and abrasions are less likely to cause long-term damage. Regular cleaning with mild soap and water is usually sufficient to keep it looking good. Additionally, stainless steel is more resistant to staining, which reduces the frequency of deep cleaning.

Cost Comparison

Initial Purchase Cost

Chrome plated brass is typically less expensive than stainless steel. This makes it an attractive option for budget-conscious projects, especially those where the upfront cost is a major consideration. For example, in some home improvement projects where a large quantity of fixtures is needed, the lower initial cost of chrome plated brass can result in significant savings.

Long-Term Cost Efficiency

Although stainless steel has a higher upfront cost, its durability and low maintenance requirements mean fewer replacements and repairs over time, unlike chrome plated brass, which may need more frequent replacement due to corrosion and wear, increasing the total cost of ownership. Stainless steel’s resistance to rust, staining, and corrosion ensures that it maintains its appearance and structural integrity for a longer period, reducing the need for frequent maintenance and replacements.

Applications and Suitability

Home Improvement Uses

Chrome plated brass is popular in home improvement projects for decorative items and plumbing fittings. Its shiny appearance can add an elegant touch to bathrooms and kitchens. However, it is more commonly used in non-potable water applications. Stainless steel is also used in home improvement, especially in areas where durability and hygiene are important, such as kitchen appliances and sinks.

Industrial and Commercial Applications

Stainless steel is the preferred choice for industrial and commercial applications. Its high strength, corrosion resistance, and durability make it suitable for food processing, construction, and offshore platforms. Chrome plated brass, while having some industrial uses, is not as widely applicable in these demanding environments due to its lower performance characteristics.

Pros and Cons

Pros and Cons of Chrome Plated Brass

Advantages

Chrome plated brass is admired for its bright, shiny finish, which enhances the look of fixtures and fittings, making it a popular choice for home decor projects. Chrome plated brass offers a cost-effective solution with good electrical and thermal conductivity, which can be beneficial in specific applications. Brass is also a softer metal compared to stainless steel, making it easier to machine and fabricate into various shapes and sizes, potentially reducing manufacturing costs and time.

Disadvantages

Although the chrome layer adds some protection, the underlying brass is not as strong as stainless steel. Over time, especially in high-wear environments, the chrome layer can degrade, exposing the brass to corrosion. Chrome plated brass needs regular cleaning to maintain its shine, and using gentle cleaners is crucial to avoid damaging the chrome layer. While the chrome plating provides some corrosion resistance, it is not as effective as the passive oxide layer of stainless steel. Brass also has lower tensile and yield strength compared to stainless steel, making it less suitable for high-strength applications and limiting its use in structural or load-bearing environments.

Pros and Cons of Stainless Steel

Advantages

Stainless steel is known for its high durability, with excellent tensile and yield strength. This makes it ideal for demanding applications where long-term performance is essential. The chromium content in stainless steel forms a self-healing passive oxide layer that provides outstanding resistance to corrosion, even in harsh and chemically aggressive environments. Stainless steel is relatively easy to maintain due to its self-healing properties. Regular cleaning with mild soap and water is usually sufficient to keep it looking good, and it is more resistant to staining and scratching. Its strength, durability, and hygienic properties make stainless steel versatile for a wide range of applications, from industrial and commercial settings to home improvement projects.

Disadvantages

The upfront cost of stainless steel is generally higher than that of chrome plated brass, which can be a significant consideration for projects with tight budgets. Stainless steel has lower electrical and thermal conductivity compared to brass, which can be a limitation in applications where high conductivity is required. Stainless steel is heavier than brass, which might be a drawback in applications where reducing weight is important. Additionally, stainless steel is harder to machine and fabricate than brass due to its higher strength and hardness, which can increase manufacturing costs and time.

Practical Tips and Tutorials

Installation Tips

Installing Chrome Plated Brass Fixtures

When installing Chrome Plated Brass Fixtures, first clean the surface to ensure it is free of debris. Handle the fixtures carefully to avoid scratching the chrome layer.

Use appropriate brass fittings to ensure a secure connection. Avoid over-tightening, as this can damage the threads and the chrome finish.

Apply plumber’s tape or pipe joint compound on the threads to prevent leaks. Be cautious not to apply too much, which can cause excess pressure and damage.

If soldering is required, remove the chrome layer from the area to be soldered. Use fine sandpaper or emery cloth to expose the brass underneath.

After installation, check for leaks and ensure all connections are secure. Clean any fingerprints or smudges with a soft cloth to maintain the fixture’s appearance.

Installing Stainless Steel Fixtures

When installing Stainless Steel Fixtures, ensure the installation area is clean and dry. Handle the fixtures with care to avoid scratches.

Use stainless steel fasteners to prevent galvanic corrosion. Stainless steel screws, bolts, and nuts will provide a long-lasting, corrosion-resistant connection.

Apply a suitable sealant, especially in areas exposed to moisture, such as joints and seams. Silicone-based sealants are often recommended for their durability.

For welding, select the appropriate stainless steel filler material. Ensure the weld area is clean and free from contaminants to avoid corrosion.

After installation, inspect all joints and connections for integrity. Clean the surface with mild detergent and water to remove any residues.

Maintenance and Care

Best Practices for Maintaining Chrome Plated Brass

Regularly clean the surface with a soft, damp cloth. Avoid abrasive cleaners and pads that can scratch the chrome layer.

Occasionally polish the chrome surface with a non-abrasive metal polish to maintain its shine. Follow the manufacturer’s instructions for the best results.

If the chrome layer is damaged, apply clear lacquer immediately to protect the brass. This can prevent further corrosion.

For minor scratches, use a chrome polish or a fine abrasive paste. For deeper scratches, professional re-chroming may be necessary.

Keep harsh chemicals and cleaners away from chrome plated brass fixtures. Acids and alkalis can degrade the chrome layer, leading to corrosion.

Best Practices for Maintaining Stainless Steel

Clean stainless steel regularly with mild soap and water. Use a soft cloth or sponge to avoid scratching the surface.

For stubborn stains and to restore shine, use a paste made of baking soda and water. Apply with a non-abrasive cloth and rinse thoroughly.

Use a stainless steel polish to remove minor scratches and enhance the finish. Follow the grain of the steel for the best results.

Although stainless steel is corrosion-resistant, it can rust in certain conditions, such as exposure to saltwater, chlorine, or acidic substances. Regularly clean and dry the surface to prevent rust formation.

Avoid contact with iron or steel tools that can cause contamination and rust spots. Use stainless steel or plastic tools for maintenance tasks.

User Experience and Feedback

User Preferences and Aesthetic Appeal

Chrome plated brass is often favored for its aesthetic qualities, particularly in settings where visual appeal is paramount. Users appreciate its shiny, polished finish, which enhances the look of fixtures and adds a touch of elegance to spaces like bathrooms and kitchens. The material’s affordability also contributes significantly to its popularity, especially in non-industrial environments where budget constraints are a concern. However, users need to be mindful of the maintenance required to keep its appearance intact, as the chrome layer can wear off over time.

Performance and Reliability

Stainless steel is highly regarded for its performance and reliability, especially in environments where durability is crucial. Users consistently report satisfaction with its ability to withstand harsh conditions, such as high humidity and exposure to chemicals. This is due to its self-healing passive oxide layer, which provides exceptional corrosion resistance. The strength and long-lasting nature of stainless steel make it a preferred choice in industrial and commercial applications. While its initial cost may be higher, users find its long-term reliability and lower maintenance needs to be a worthwhile investment.

Maintenance and Longevity

In terms of maintenance, stainless steel requires less frequent upkeep, which users find advantageous in reducing long-term costs and effort. The material’s resistance to staining and ease of cleaning contribute to positive user feedback. On the other hand, chrome plated brass demands regular attention to maintain its shine and prevent corrosion, which can be seen as a drawback by users seeking low-maintenance solutions.

User Experience in Various Applications

In home improvement projects, chrome plated brass is often preferred for its decorative appeal and affordability. For instance, it is commonly used in plumbing fixtures and decorative items, where the emphasis is on aesthetics rather than heavy-duty performance. In contrast, stainless steel is favored in applications requiring robustness and hygiene. Users often choose stainless steel for kitchen appliances, sinks, and countertops, where durability and ease of cleaning are paramount. Its ability to maintain a sleek, modern look while offering high functionality makes it a popular choice in these environments.

Feedback on Cost Efficiency

Users often highlight the cost efficiency of chrome plated brass in projects where initial expenses need to be minimized. Its lower upfront cost allows for more budget-friendly installations, making it attractive for homeowners and small-scale renovations. Stainless steel, while more expensive initially, receives positive feedback for its cost efficiency over time, as users experience fewer replacements and repairs due to its durability.

Common Challenges and Resolutions

Users sometimes face challenges with chrome plated brass, particularly regarding wear and maintenance in high-moisture environments. Frequent cleaning and gentle care are necessary to preserve its appearance. For stainless steel, issues are less common, but when they arise, they often relate to specific environmental factors like exposure to saltwater, which can lead to localized corrosion. Users typically resolve these issues with regular cleaning and protective measures.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the pros and cons of chrome plated brass?

Chrome plated brass combines the durability of brass with a protective chrome layer. Its advantages include superior corrosion resistance due to the chrome coating, low maintenance requirements, improved wear resistance, and high aesthetic appeal with a mirror-like finish. However, it has limitations such as reduced resistance to certain chemicals that can penetrate the chrome layer and cause damage to the underlying brass.

Which is more durable: chrome plated brass or stainless steel?

Stainless steel is more durable than chrome plated brass. Stainless steel is an alloy known for its superior strength, corrosion resistance, and wear resistance, owing to its self-healing passive oxide layer. It maintains its integrity in harsh environments, such as those with high moisture or chemical exposure, and has high impact resistance across various grades. Conversely, chrome plated brass, while enhanced by a chromium layer, only offers moderate corrosion and wear resistance. This chrome layer can wear off over time, especially in harsh conditions, leading to a decrease in durability. Therefore, for long-term applications, particularly in demanding environments, stainless steel is generally the better choice.

How do I maintain chrome plated brass fixtures?

To maintain chrome plated brass fixtures, start with a gentle cleaning routine using a soft, lint – free cloth and a mixture of warm water and mild soap. This is suitable for frequently – touched items like faucets and handles. Protect the fixtures from scratches by avoiding sharp objects and abrasive cleaners, and use a soft wrench for adjustments. To address mineral deposits and water spots, soak a soft cloth in vinegar and apply it to the affected area for a few minutes before wiping clean. Applying carnauba wax twice a year can prevent mineral buildup. Consider periodic professional maintenance to catch early signs of wear. Compared to stainless steel, chrome plated brass requires more regular care.

What are the common applications for stainless steel?

Stainless steel is widely used across various industries due to its exceptional strength, durability, corrosion resistance, and aesthetic appeal. Common applications for stainless steel include:

- Automotive Industry: Utilized in exhaust systems, fuel tanks, and other components due to its high temperature resistance and durability.

- Aerospace Industry: Employed in jet engines, aircraft frames, and structural components for its ability to withstand extreme temperatures and corrosion.

- Healthcare Industry: Preferred for medical instruments, surgical tools, hospital equipment, and implants because of its ease of sterilization and corrosion resistance.

- Architecture and Construction: Used in structural supports, building frameworks, decorative elements, cladding, handrails, and sculptures for its strength and aesthetic qualities.

- Food Industry: Found in kitchen appliances, sinks, countertops, and cooking equipment because it is easy to clean and resistant to corrosion.

- Energy Sector: Used in power plants, turbines, heat exchangers, and piping systems due to its resistance to high temperatures and corrosion.

These diverse applications highlight stainless steel’s versatility and reliability in demanding environments.

Is chrome plated brass more cost – effective than stainless steel in the long run?

When considering long-term cost-effectiveness, stainless steel generally outperforms chrome plated brass. Although chrome plated brass has a lower initial cost, it tends to require more frequent maintenance and potential re-plating due to its susceptibility to corrosion and wear over time. The thin chrome layer on brass can degrade, especially in harsh environments, leading to increased long-term expenses.

On the other hand, stainless steel, despite its higher upfront cost, offers superior durability and corrosion resistance. Its inherent chromium content forms a self-healing oxide layer, reducing the need for frequent maintenance and ensuring a longer lifespan. This translates to lower overall costs in the long run, as the need for replacements and repairs is significantly diminished.

How do user experiences differ between chrome plated brass and stainless steel?

User experiences with chrome plated brass and stainless steel differ across multiple aspects. Chrome plated brass offers a highly polished, appealing finish suitable for decorative uses and has lower initial costs. However, it requires regular cleaning, its chrome layer can degrade and may need re – plating, and it’s more prone to scratches and corrosion if the coating is damaged. On the other hand, stainless steel has a clean, modern look. It provides superior corrosion resistance, strength, and durability, making it ideal for harsh environments and high – stress applications. Although initially more expensive, it has lower long – term costs due to reduced maintenance needs.