Advantages of Cold Extrusion Process

Compared to other manufacturing methods, cold extrusion has emerged as one of the most advanced processes in metal plastic deformation, boasting numerous technical and economic advantages.

Significant Reduction in Raw Material Consumption

Cold extrusion is a method of plastic forming of metals. It enables plastic transformation of the metal volume without damaging the metal, resulting in minimal to no chips and forming the metal into the required shape and size. This process eliminates the large amount of metal shavings produced during machining, greatly saving various metal materials.

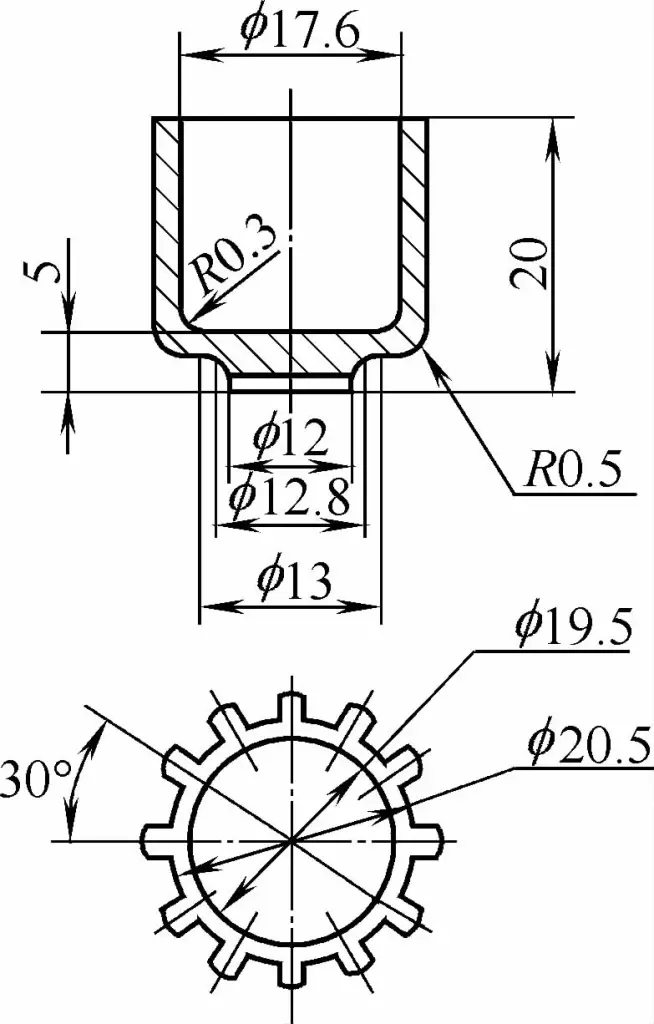

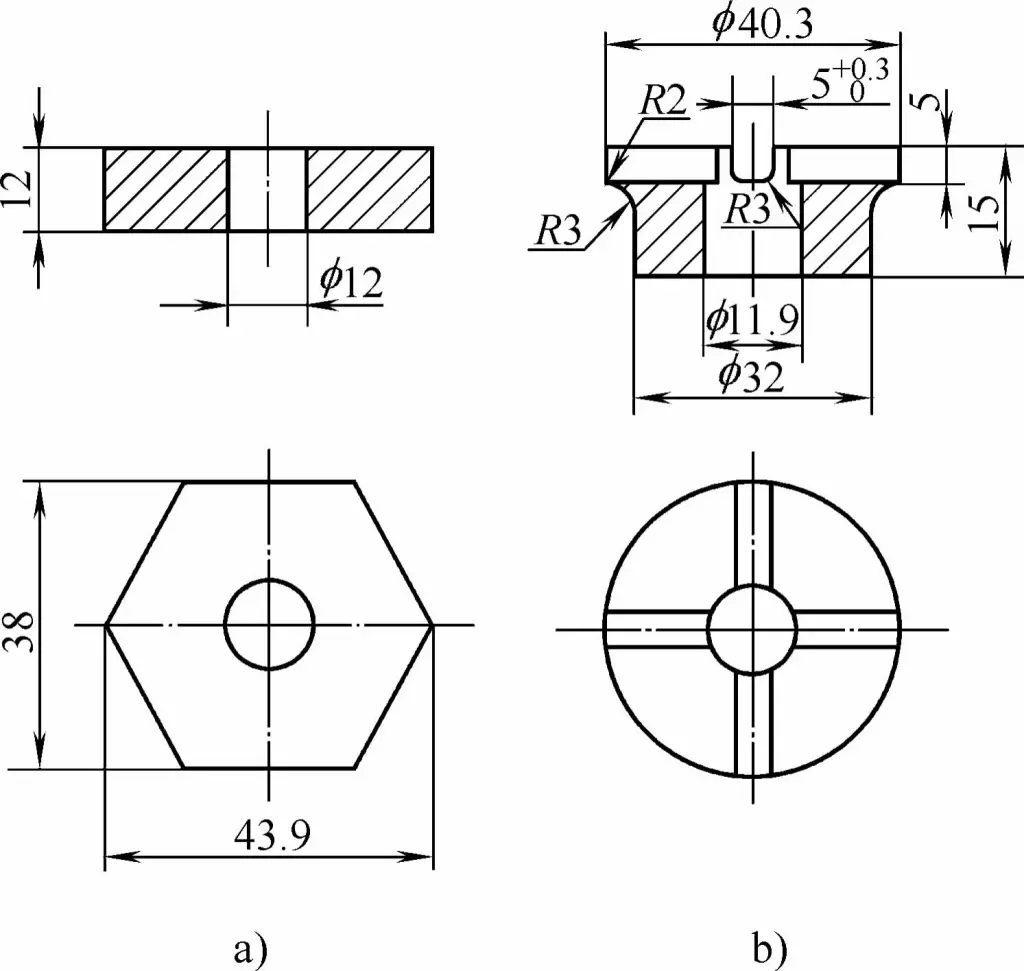

Consequently, 1 ton of metal material can be used to produce 2 tons, and even up to 3-5 tons of product. For instance, the pure iron base in the communication equipment shown in Figure 1-72 is cold extruded, reducing material consumption to just one-tenth of the original machining process. This means that the material for one component can now be used to manufacture ten products.

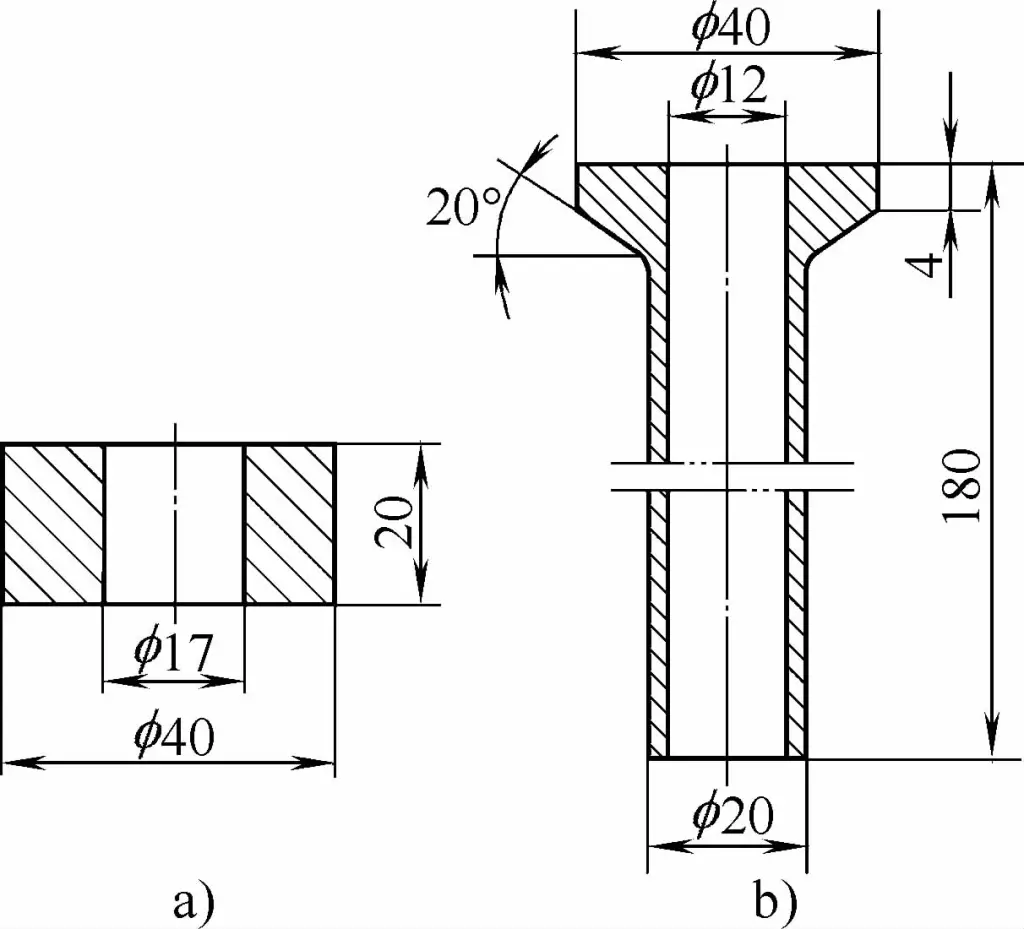

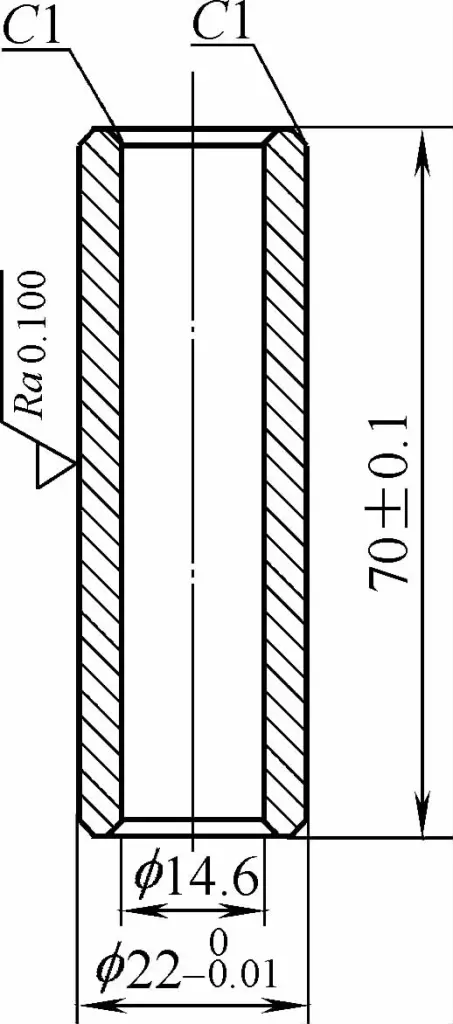

The pure aluminum rotary joint shown in Figure 1-73 was originally machined from a solid blank of Φ22mm×21mm. After cold extrusion, it only requires a blank material of Φ20.3mm×6mm, reducing material consumption to about a quarter of the original. The oxygen-free copper exhaust pipe shown in Figure 1-74 was originally machined from a cylindrical blank of Φ40mm×180mm.

a) Hollow Blank

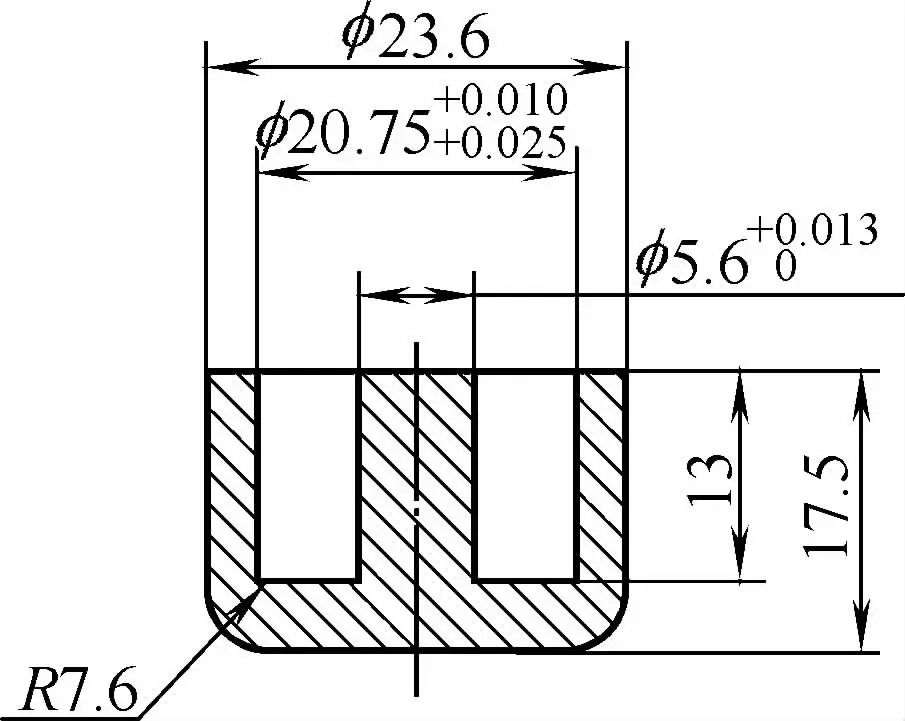

b) Extruded PartFigure 1-75 Stainless Steel Water-Cooled Connector

Now, with cold extrusion, it only requires a hollow flat blank of Φ40mm×17mm×20mm, significantly saving raw materials to just one-ninth of the original. The double water-cooled turbine generator water cooling joint component shown in Figure 1-75 is made of austenitic stainless steel. After cold extrusion, the material consumption is halved compared to the original machining process.

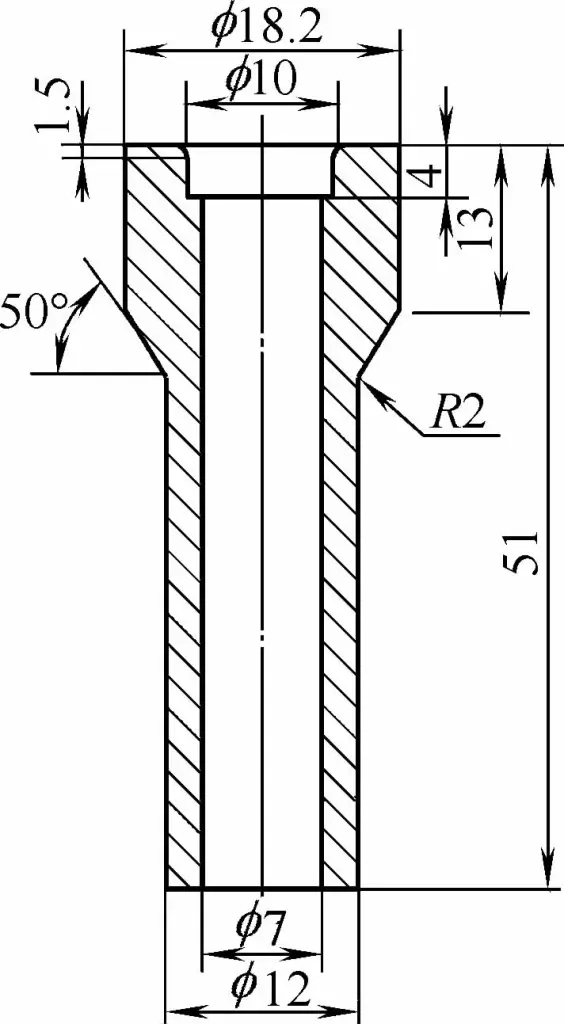

The material of the automobile engine piston pin cold extrusion part shown in Figure 1-76 is low alloy structural steel 20Cr. The original machining process had a single piece consumption quota of 0.282kg (Jump brand piston pin). After switching to cold extrusion, it decreased to 0.149kg.

Enhanced Productivity

Cold extrusion parts are processed on a press, which is straightforward to operate, easy to master, and highly productive. The pure iron base shown in Figure 1-72, for example, is challenging to machine due to the softness of pure iron and its poor cutting performance. By using cold extrusion, not only is raw material saved, but productivity is also increased 30-fold.

The pure copper high-voltage switch component depicted in Figure 1-77 is made directly from a hexagonal hollow blank (with no waste material dropped on the press) through cold extrusion, eliminating the previous turning and milling (cross-slot) work hours. The pure aluminum knob connector shown in Figure 1-73, after being processed by cold extrusion, saw its processing time drop from the previous 5.84 minutes using mechanical processing to just 1 minute.

The work hours for the stainless steel water-cooled connector part shown in Figure 1-75 also dropped from 15 minutes of previous cutting processing to 1.5 minutes, improving efficiency by nine times. The automotive engine piston pin shown in Figure 1-76, when processed by cold extrusion, can improve productivity by 3.2 times compared to turning (using the Leapfrog brand piston pin as an example).

Now, automatic machines for cold extrusion piston pins have been produced, further increasing productivity. The production rate of one cold extrusion automatic machine is equivalent to 100 horizontal lathes or 10 four-axis automatic lathes.

Capable of forming complex-shaped parts

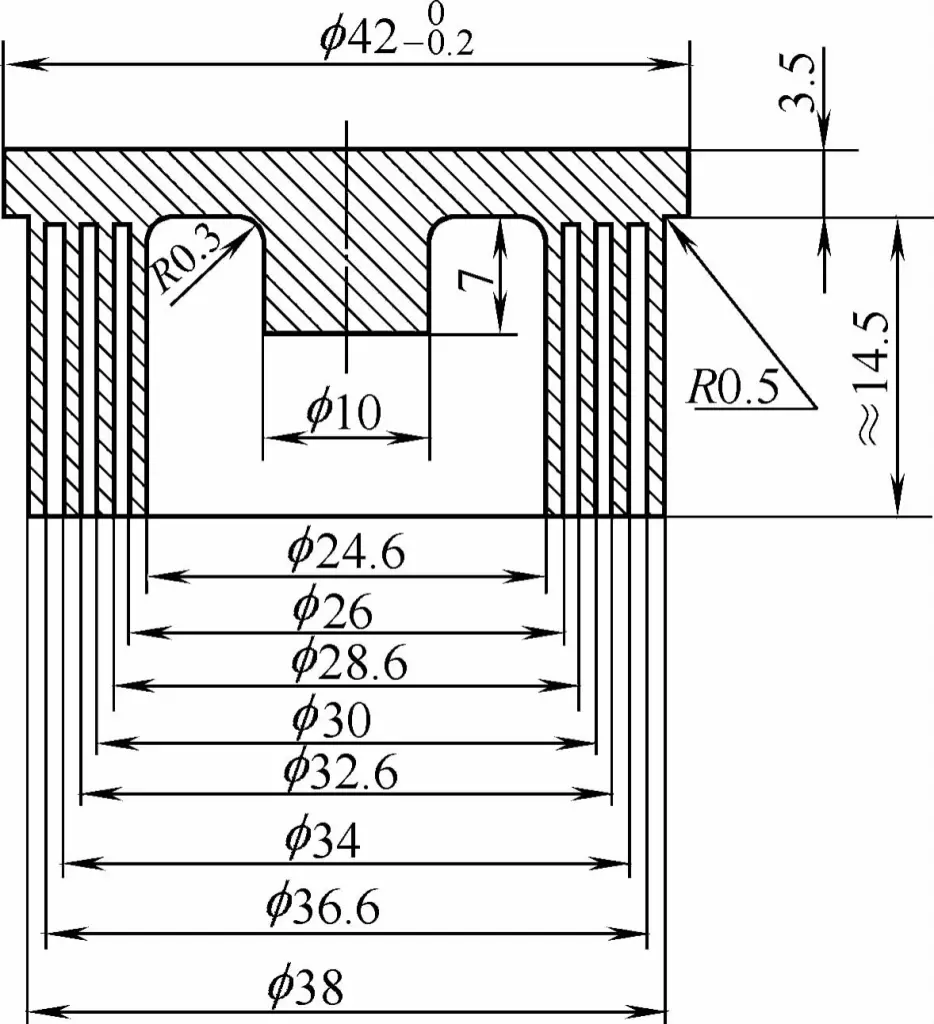

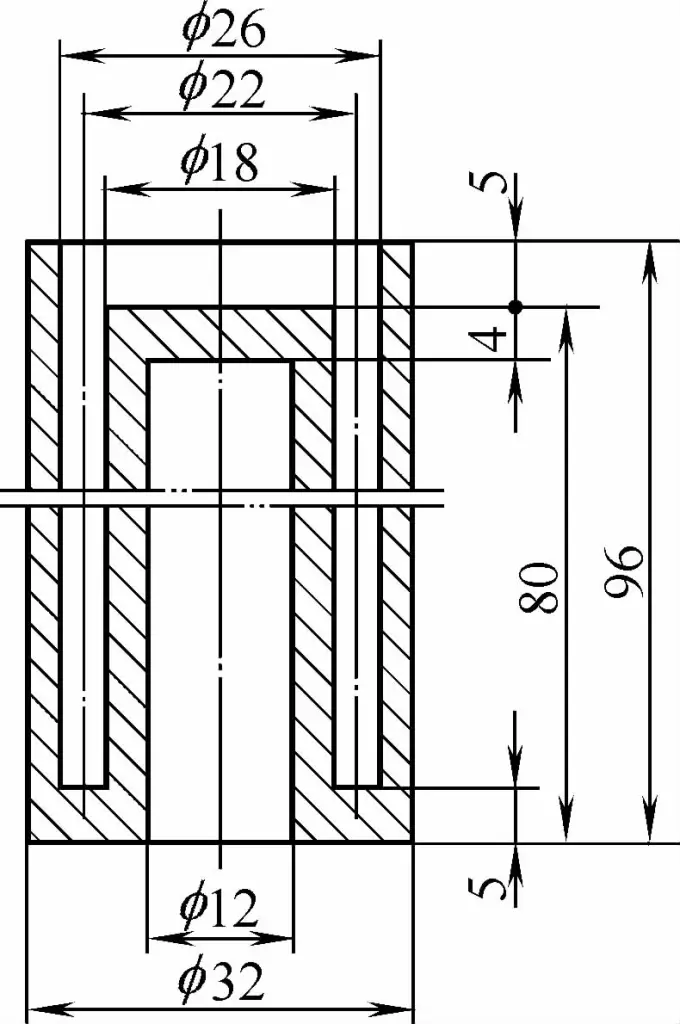

Under the reciprocating linear movement of the press, complex machining operations can be completed, producing intricately shaped parts. As depicted in Figure 1-78, a multi-layer variable capacitor made from pure aluminum, and in Figure 1-79, a double-layered sleeve part also made from pure aluminum, both exhibit complex shapes and small dimensions with strict requirements.

If manufactured using cutting methods, not only would the production rate be low and material consumption high, but the manufacturing process would also prove to be very challenging. However, using cold extrusion processing makes it significantly more convenient.

Enhancing the mechanical properties of parts

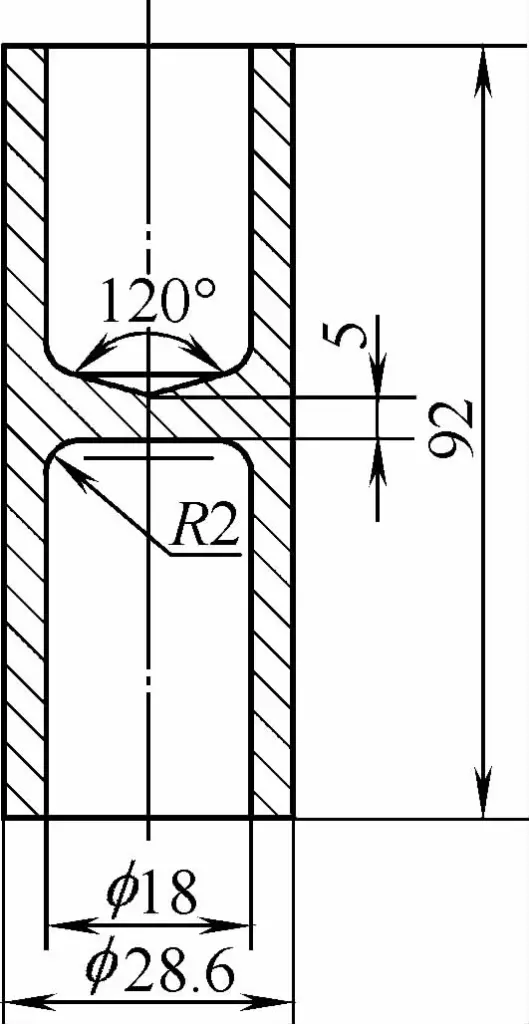

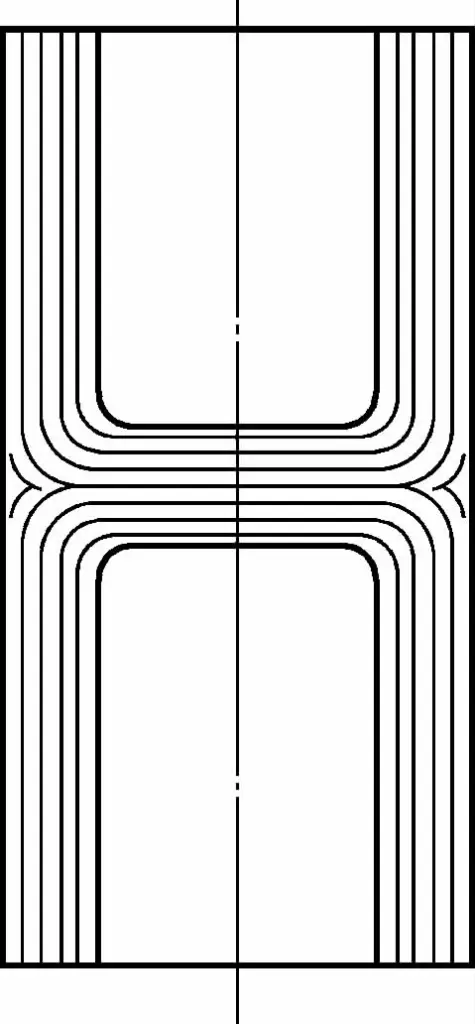

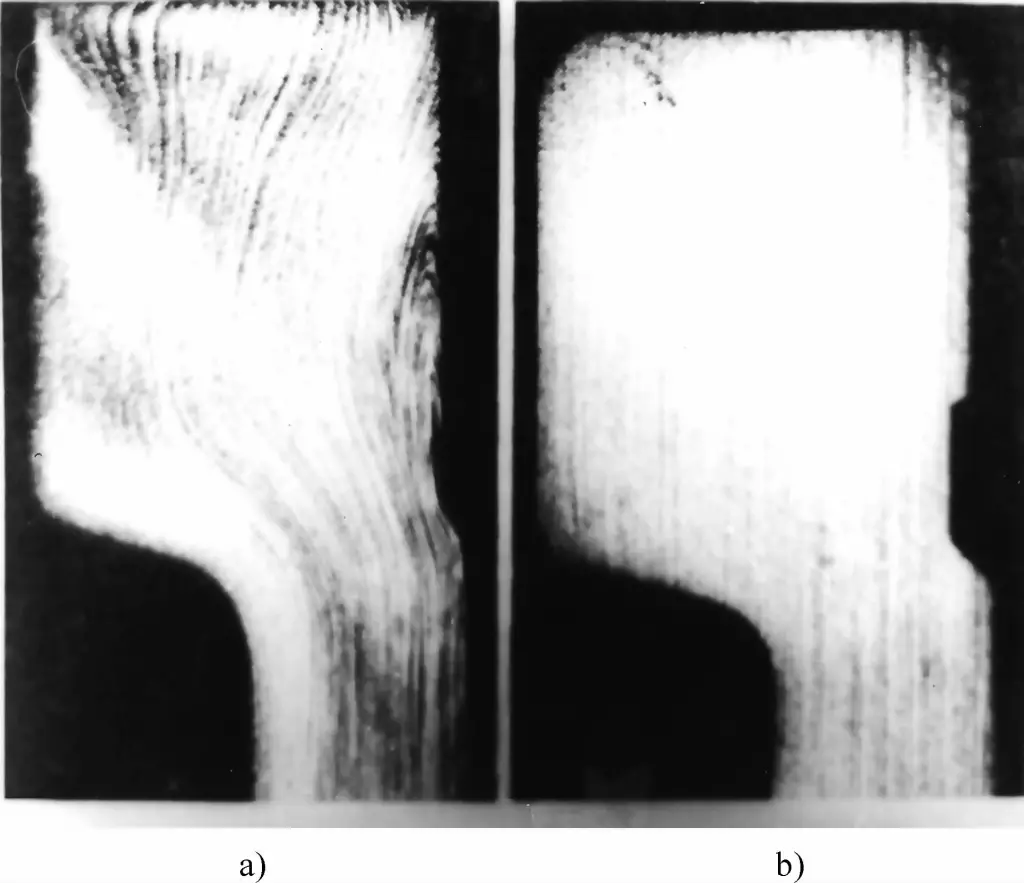

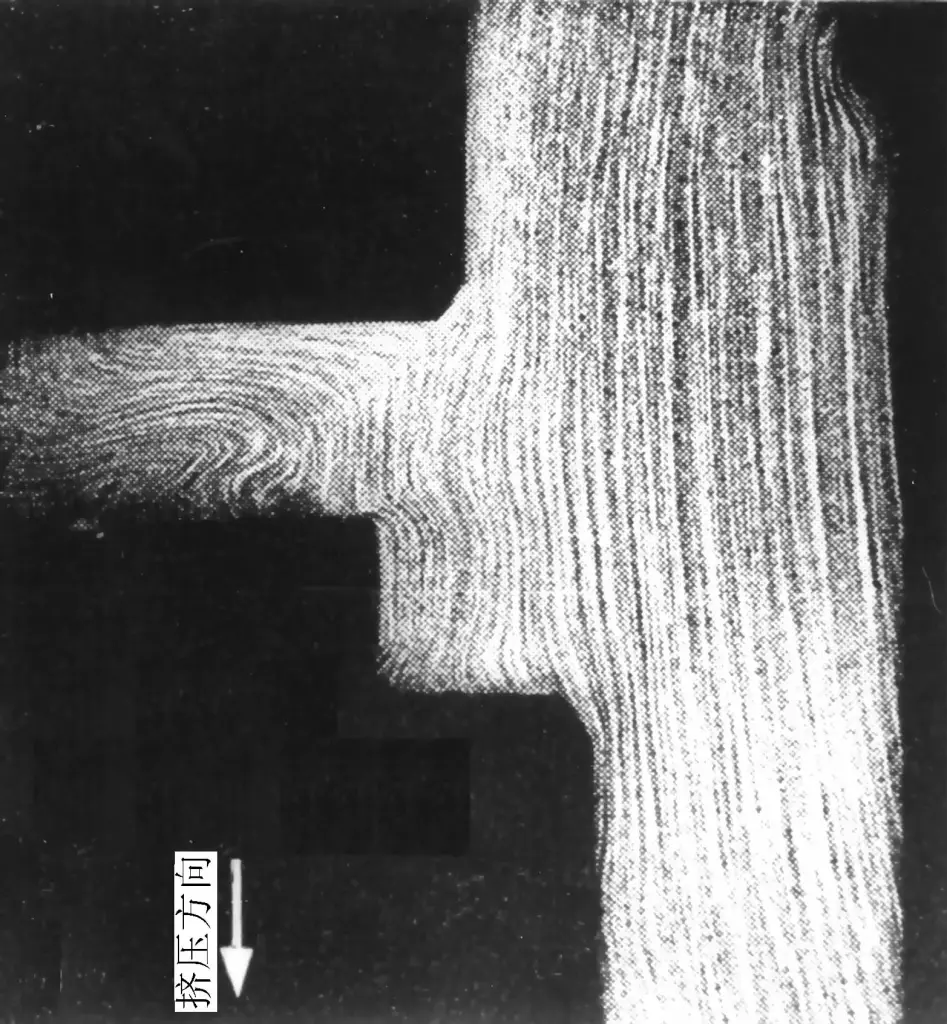

During the cold extrusion process, the metal material is subjected to triaxial compressive stress. After extrusion deformation, the grain structure of the metal material becomes denser, and the metal flow lines are not interrupted, becoming continuous flow lines distributed along the contour of the extruded part, as shown in Figure 1-80 for the metal flow lines of a cold extruded piston pin.

Figures 1-81 and 1-82 show the state of fibers on various cold extruded parts, with no sharp discontinuities observed in any of the fibers. Simultaneously, because cold extrusion utilizes the work hardening characteristics of cold deformation of metal materials, it greatly increases the strength of the extruded parts, thereby providing the possibility of replacing high-strength steel with low-strength steel.

For instance, China used to produce automobile engine piston pins by machining, using 20Cr low alloy structural steel as the raw material. However, by switching to cold extrusion, the mechanical properties of the piston pin parts can be improved, hence 20 low carbon steel is used.

Experimental measurements have shown that all mechanical performance indicators are higher with cold extrusion than with machining.This demonstrates that by switching to cold extrusion for the machining of piston pins, 20 steel can replace the original 20Cr steel.

Parts with Higher Dimensional Accuracy and Lower Surface Roughness Can Be Produced

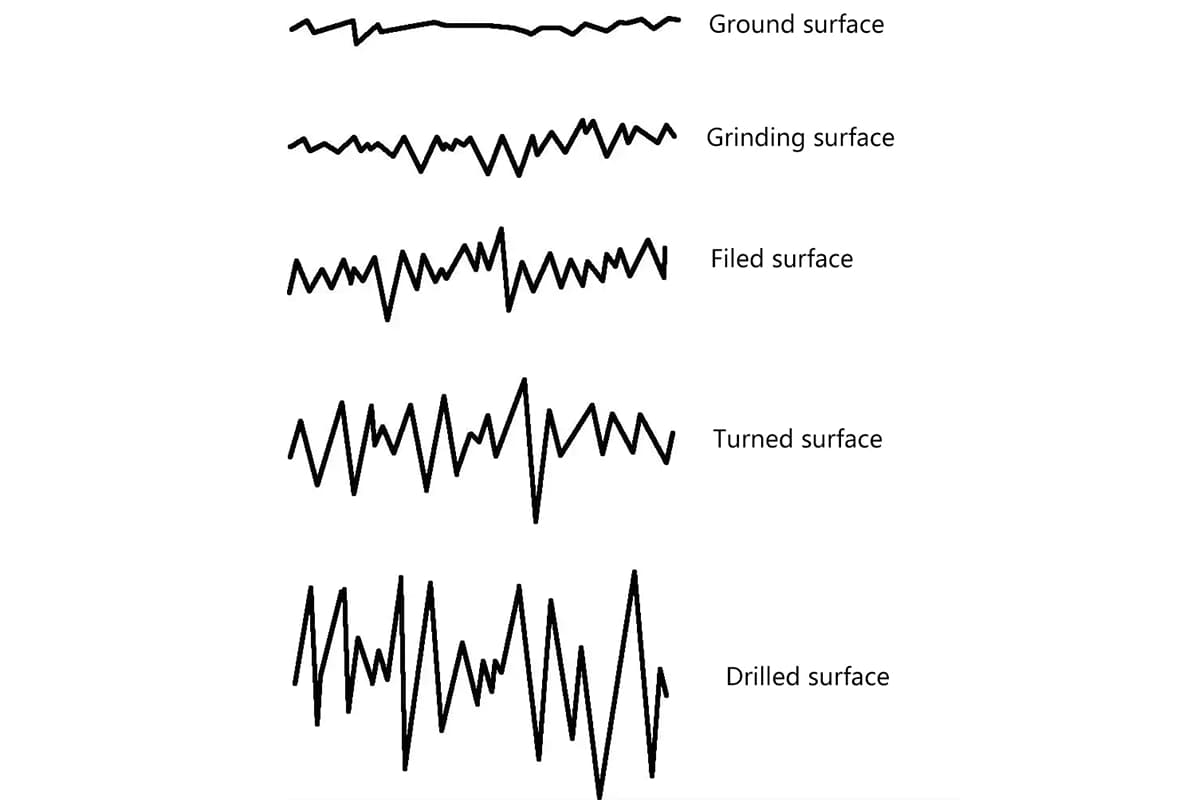

Cold extrusion results in components with excellent surface quality. During the cold extrusion process, the metal surface is ironed by the smooth surface of the mold under high pressure, resulting in a very low surface roughness and greatly enhanced surface strength. The surface roughness Ra of typical cold extruded parts is less than 1.25µm.

With appropriate process treatment of the mold cavity, especially when ideal lubrication is used in the cold extrusion of non-ferrous metals, a surface roughness value surpassing grinding but less than polishing (Ra=0.08~0.16µm) can be achieved. As such, parts processed by cold extrusion can have reduced machining allowances, and in some cases, no machining allowance is needed to meet the technical requirements of the product drawings.

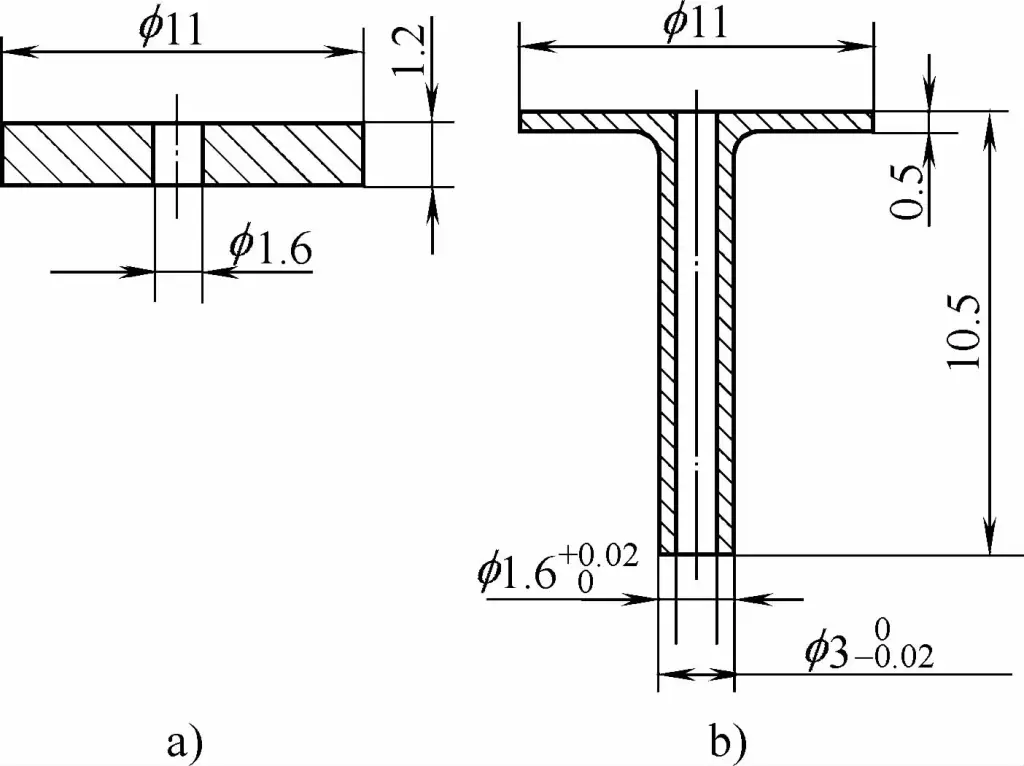

The dimensional accuracy of cold extruded parts can generally reach precision levels IT8~IT9, and the tolerance range for individual dimensions can be controlled within 0.015mm. For instance, the inner hole dimensional tolerance of the sewing machine shuttle core sleeve made of ordinary carbon steel, as shown in Figure 1-83, is only 0.015mm.

Cold extrusion can achieve ideal part surface roughness and dimensional accuracy. Some parts, after extrusion, no longer require cutting, paving the way for cold extrusion to replace forging, casting, and cutting of certain parts.

Shortening the Production Cycle

Cold extrusion is a process of metal plastic deformation in a closed mold cavity. The resulting extruded parts have no flash, eliminating the need for subsequent deburring (or punching) operations, thereby shortening the production cycle.

Reducing Equipment Investment

Compared with die forging, cold extrusion does not produce flash, thus eliminating the need for deburring dies and presses, significantly reducing equipment investment. Besides, cold extrusion processing can be performed on dedicated cold extrusion presses, universal hydraulic presses, or even on general presses not specifically designed for cold extrusion, such as universal presses or friction presses.

Lowering the Manufacturing Cost of Parts

Cold extrusion can significantly save raw materials and processing time, thus inevitably reducing the manufacturing cost of components. For example, the car piston pin shown in Figure 1-84 can be manufactured by cutting from round steel or by cold extrusion, or it can be made from seamless steel pipe. The cost comparison of these three processing methods is shown in Table 1-6.

The data in Table 1-6 shows that the cost of cold extrusion processing piston pins is the lowest, reducing the cost by 45% compared to cutting, and by 29% compared to processing from seamless steel pipe.

Table 1-6: Cost Comparison of Different Manufacturing Methods for Automobile Piston Pins

| Item | Cold Extrusion | Machining | Seamless Steel Tube Processing |

| Blank Shape and Size | Cold Drawn Round Steel Φ22.6mm | Hot Rolled Round Steel Φ25mm | Cold Drawn Steel Tube d25mm×5mm |

| Standard Material Usage per Piece/kg | 0.149 | 0.282 | 0.14 |

| Material Cost per Piece/USD | 6 | 9.9 | 12.6 |

| Processing Time per Piece/min | 2.5 | 5.5 | 3 |

| Processing Time Cost per Piece/USD | 6.25 | 13.75 | 7.5 |

| Heat Treatment Cost/USD | 2 | 2 | 2 |

| Total Cost per Piece/USD | 14.25 | 25.65 | 22.1 |

Disadvantages of Cold Extrusion Process

In long-term production practice, cold extrusion has shown many advantages compared to other manufacturing processes, but it often has certain issues. The disadvantages of the cold extrusion process are as follows:

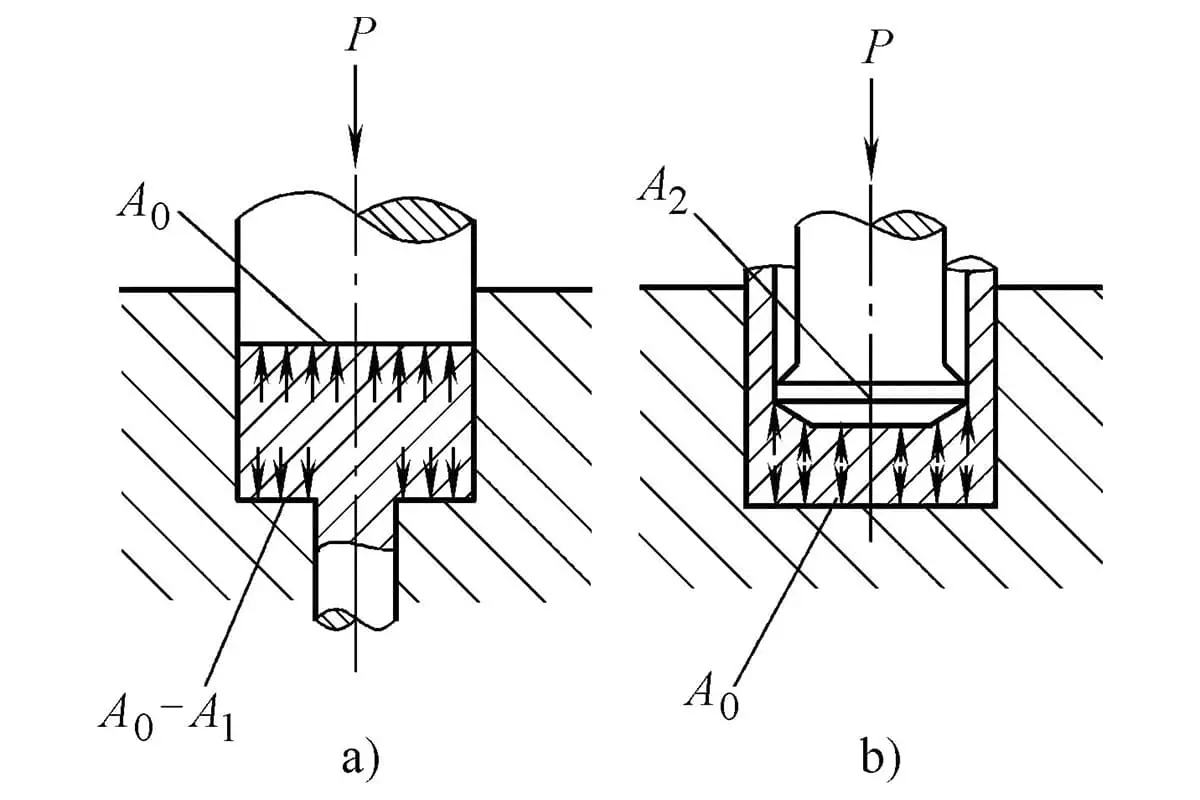

High Deformation Resistance

During cold extrusion, the deformation resistance of the extruded material is high. The most practical is cold extrusion of steel, where the deformation resistance can reach over 2000MPa. Such ultra-high pressure demands higher requirements for mold material, structure, and manufacturing.

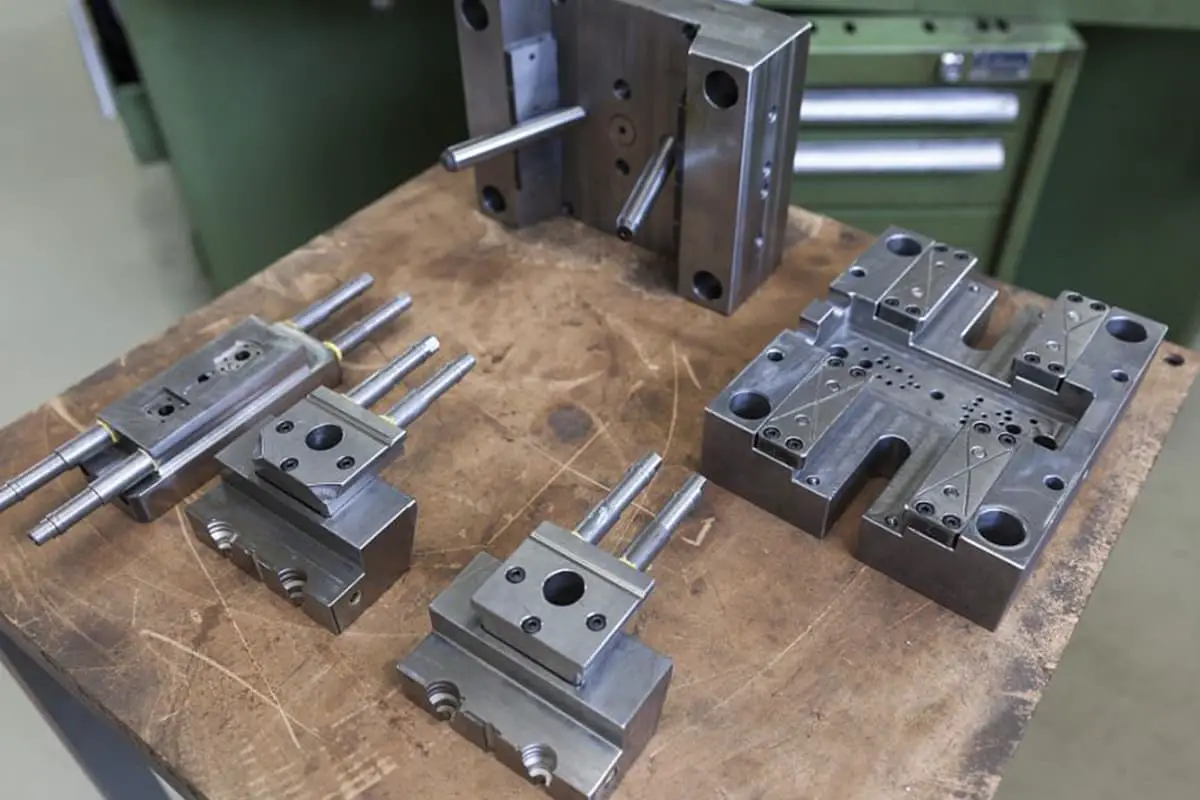

Short Mold Life

Due to the high unit pressure borne by the cold extrusion mold, reaching up to 3000MPa, the mold is prone to wear and damage. Although many effective measures have been taken in terms of mold materials and structure, its lifespan is still lower compared to stamping molds.

According to relevant statistics, the average lifespan of steel convex molds used for positive extrusion is around 20,000 pieces, and concave molds around 30,000 pieces; whereas the lifespan of molds used for punching or deep drawing is generally over 100,000 pieces.

High Requirements for Blanks

The requirements for blanks during cold extrusion are higher than other metal plastic forming processes, otherwise, the mold may suffer damage. For cold extrusion blanks, in addition to requiring accurate geometric shapes and high dimensional accuracy, it is also necessary to undergo certain softening annealing and surface lubrication treatments before cold extrusion deformation.

High Requirements for Cold Extrusion Equipment

When implementing the cold extrusion process, in addition to requiring the cold extrusion equipment to have greater strength, it is also required to have good rigidity. Furthermore, the equipment should have good precision and a reliable safety device.

Scope of Application for Cold Extrusion Technology

From the analysis above, it’s clear that cold extrusion is a superior, high-yield, low-consumption, and cost-effective advanced process, offering significant value both technologically and economically.

Currently, cold extrusion technology has been widely adopted in various industrial sectors in our country, including automotive, motorcycles, instrumentation, telecommunication equipment, light industry, construction, aerospace, shipbuilding, military, and hardware. It has become an indispensable part of metal plastic forming techniques.

Cold extrusion, as a unique category within advanced manufacturing techniques that produces little to no chips, is gaining prominence. While the disadvantages of cold extrusion processing are secondary when compared to its advantages, these are relative to current technological conditions.

With the rapid development of science and technology, research and development of new mold steel materials, and rationalization of mold structure design, the issues will be resolved and the advantages will be fully exploited. Therefore, it can be anticipated that this advanced metal plastic forming process will play an increasingly significant role and find broader application across various industries.