Imagine a material that stands at the crossroads of strength, versatility, and reliability, forming the backbone of numerous structural applications. This is precisely what 44W steel represents in the world of construction and manufacturing. As an intermediate reader eager to delve deeper into the technical specifics, you’re about to embark on a comprehensive journey through the intricate details of 44W steel’s composition, properties, and myriad applications.

In this article, we will dissect the chemical makeup of 44W steel, exploring how elements like carbon influence its mechanical properties and compare it with other structural steels. You’ll discover why 44W steel is a preferred choice in building construction and automotive industries, and understand the importance of standards compliance, particularly with CSA G40.21. We will also cover best practices for welding and fabricating 44W steel, addressing common challenges and solutions.

What sets 44W steel apart from its counterparts, and how does it maintain its structural integrity over time? Let’s delve into the technical depths to uncover these answers and more, ensuring you gain a robust understanding of this essential material.

Overview of 44W Steel

Definition and Classification

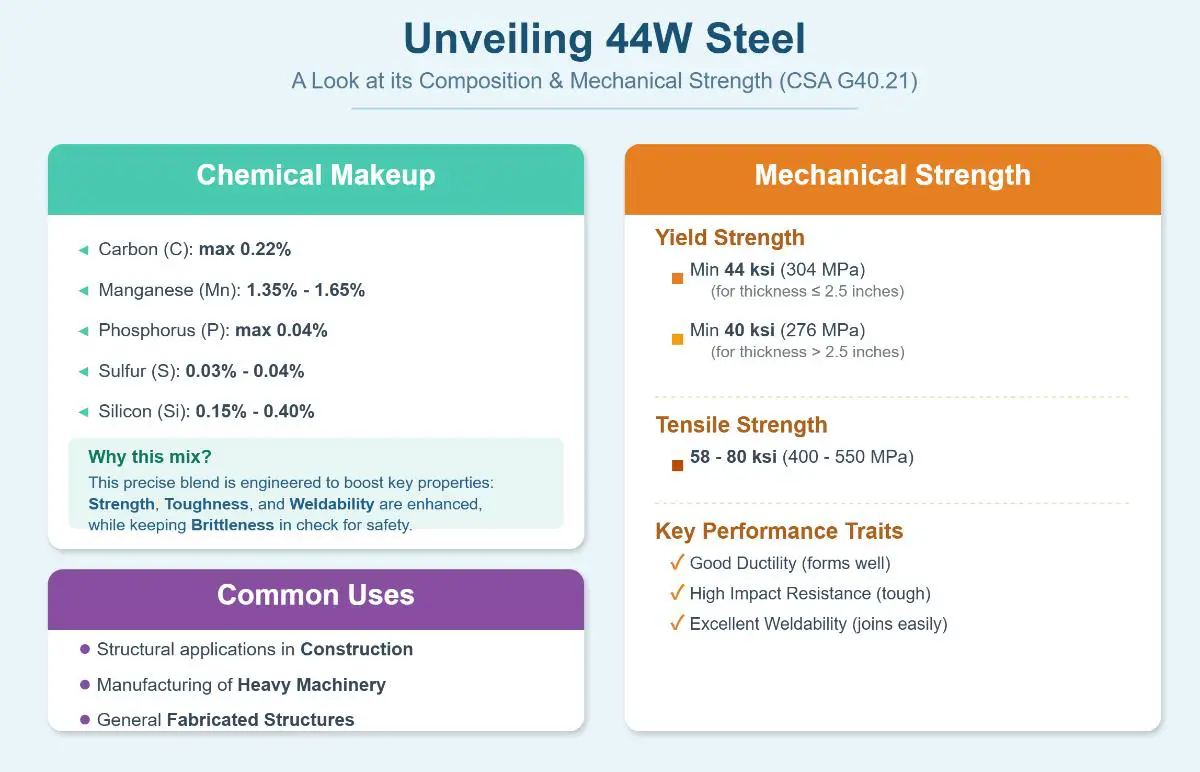

44W steel is a medium-carbon structural steel commonly used in Canada, classified under the CSA G40.21 standard. This standard specifies the requirements for various types of structural steel, and as a medium-carbon steel, 44W offers a balanced chemical composition that enhances its mechanical properties, making it suitable for high-strength applications.

Importance in Structural Applications

The significance of 44W steel in structural applications lies in its robust mechanical properties and adaptability. Engineers and builders prefer this steel for its high yield strength, tensile strength, and good ductility, which are essential for constructing durable and reliable structures. Its balanced composition allows for effective weldability, which is crucial in construction projects where different steel components need to be joined seamlessly.

Key Attributes

Chemical Composition

44W steel’s chemical composition includes up to 0.22% carbon and manganese content between 1.35% and 1.65%, ensuring adequate strength and weldability. The controlled presence of other alloying elements further optimizes its performance.

Mechanical Properties

The mechanical properties of 44W steel are impressive. It has a minimum yield strength of 44,000 psi (300 MPa) for thicknesses up to 2.5 inches and slightly reduced yield strength for thicker plates. Its tensile strength ranges from 65,000 to 90,000 psi (440 to 620 MPa), making it suitable for heavy-duty applications. Additionally, 44W steel’s ductility, indicated by elongation percentages, allows it to endure dynamic and impact loading without cracking.

Applications

44W steel is used in a variety of structural applications, including building construction (structural beams and columns), infrastructure projects (bridges and load-bearing plates), and industrial equipment (machinery bases and frames). Its strength and ductility make it ideal for constructing commercial buildings, bridges, and industrial facilities where structural performance is critical.

Comparison with Other Steels

When compared to other structural steels like A36, 44W steel stands out due to its higher yield and tensile strengths. This makes it more suitable for demanding applications requiring greater load-bearing capacity and durability.

Compliance and Standards

44W steel adheres to the CSA G40.21 standard, ensuring it meets rigorous quality and performance criteria essential for structural applications. Compliance with these standards guarantees that 44W steel can be reliably used in construction and engineering projects, providing consistency and safety in structural performance.

Chemical Composition of 44W Steel

44W steel is a versatile structural material known for its excellent balance of strength, weldability, and ductility. The carbon content in 44W steel is kept at a maximum of 0.22%, ensuring good weldability and ductility while providing sufficient hardness and strength. Additionally, manganese is present at levels ranging from 1.35% to 1.65%, significantly enhancing the tensile strength, hardenability, and toughness of the steel.

Phosphorus levels are strictly controlled with a maximum limit of 0.04% to prevent brittleness and maintain weldability. Sulfur is minimized to a maximum content of 0.03%, which reduces impurities and improves weld quality.

Silicon, found in concentrations between 0.15% and 0.40%, enhances the strength and flexibility of the steel. Compared to other structural steels like A36, 44W steel has lower carbon content and higher manganese levels, which boost its tensile strength and toughness. Strict control of phosphorus and sulfur ensures ductility and minimizes weld defects, while silicon contributes to overall strength and flexibility.

The melting point of 44W steel ranges from approximately 1424°C to 1466°C, ensuring that the steel maintains its structural integrity under elevated temperatures, which are often encountered in industrial applications. The carefully designed chemical composition of 44W steel optimizes its mechanical performance, making it an ideal choice for applications requiring a reliable balance of strength, ductility, and weldability.

Mechanical Properties of 44W Steel

Yield Strength

44W steel is known for its high yield strength, indicating the stress level at which it starts to deform permanently. For thicknesses up to 2.5 inches, the minimum yield strength is specified at 44 ksi (44,000 psi or approximately 303 MPa), ensuring the steel can withstand significant loads without permanent deformation. For thicknesses greater than 2.5 inches and up to 4 inches, the minimum yield strength slightly decreases to 40 ksi (40,000 psi or approximately 276 MPa), still offering substantial load-bearing capacity.

Tensile Strength

44W steel has a tensile strength between 65 ksi and 85 ksi (approximately 450 to 590 MPa). This range indicates the maximum stress the steel can endure while being stretched or pulled before breaking. The high tensile strength of 44W steel makes it suitable for applications where it will be subjected to high stress, ensuring structural integrity and reliability.

Ductility and Elongation

44W steel exhibits excellent ductility, which is its ability to deform under tensile stress. This is quantified by elongation values, which are at least 20% over an 8-inch gauge length and 23% over a 2-inch gauge length. High ductility is vital for applications requiring the steel to absorb energy and deform without breaking, such as in impact-resistant structures.

Hardness

The Brinell Hardness Number (BHN) for 44W steel typically ranges from 135 to 165, depending on the specific heat treatment applied. This hardness range provides a balance between wear resistance and toughness, making the steel durable for various structural uses while maintaining its ability to withstand impact and deformation.

Density

The density of 44W steel is approximately 7.85 g/cm³, which is standard for carbon steels. This density influences the overall weight and structural integrity of components made from 44W steel, ensuring they are strong enough to support significant loads without being excessively heavy.

Weldability

One of the notable properties of 44W steel is its good weldability. This is mainly due to its low carbon content and minimal alloying, making it easier to weld than higher-strength alloys like 300W steel. The ease of welding 44W steel contributes to its widespread use in construction and fabrication, as it simplifies the joining of components and reduces the need for specialized welding techniques and equipment.

| Property | Value |

|---|---|

| Minimum Yield Strength | 44 ksi (≤ 2.5″ thick), 40 ksi (> 2.5″ thick) |

| Tensile Strength | 65 – 85 ksi |

| Elongation | ≥ 20% (8″ gauge), ≥ 23% (2″ gauge) |

| Hardness (BHN) | 135 – 165 |

| Density | 7.85 g/cm³ |

| Weldability | Good (low carbon, easy to weld) |

Applications Related to Mechanical Properties

The specific mechanical properties of 44W steel make it highly suitable for a variety of structural applications:

- Structural Components in Buildings and Bridges: The moderate to high yield and tensile strength, combined with good ductility, make 44W steel ideal for use in structural beams, columns, and other load-bearing components.

- General Fabrication: Its good weldability and toughness make 44W steel a preferred material for bolts, fasteners, and other fabricated components where joining and durability are critical.

- Cost-Effective Projects: The ease of welding and overall cost-effectiveness of 44W steel make it suitable for large-scale construction projects, particularly in regions where CSA G40.21 standards are prevalent, such as in Canada.

The combination of strength, ductility, and weldability ensures that 44W steel remains a reliable choice for many structural and construction applications, offering both performance and ease of fabrication.

Applications in Construction and Automotive

Applications in Construction

Structural Frameworks

44W steel is highly valued in construction for its ability to form robust structural frameworks. Its yield and tensile strength make it ideal for beams, columns, and other load-bearing elements. These properties ensure that structures can withstand significant stress without permanent deformation, providing stability and safety in buildings and infrastructure projects. Additionally, the steel’s ductility and toughness enable it to absorb dynamic loads, such as those from wind or seismic activity, without compromising structural integrity.

Bridges and Infrastructure

In bridge construction and other infrastructure projects, 44W steel’s fatigue resistance and impact toughness are crucial. These properties allow the steel to handle repetitive loading and shocks, ensuring long-term performance and safety. The steel’s durability ensures consistent reliability under cyclic stress conditions, making it a preferred choice for bridges, overpasses, and other critical infrastructure components.

Fabrication and Erection

44W steel’s superior weldability is a significant advantage in construction. It simplifies the fabrication of complex shapes and joints, allowing for efficient assembly of prefabricated components. The ability to process the steel using both hot and cold methods provides versatility in manufacturing processes. Low levels of phosphorus and sulfur enhance weld quality, which is essential for maintaining structural integrity during and after fabrication.

General Construction Applications

Beyond large structures, 44W steel is used in various general construction applications, such as heavy machinery bases and supports. Its balance of strength and flexibility makes it suitable for components that require durability and the ability to handle dynamic loads. The steel’s good notch toughness, especially when treated for low-temperature performance, makes it ideal for construction in colder environments, preventing brittle failure in harsh conditions.

Applications in Automotive Industry

Chassis and Frame Components

The automotive industry benefits significantly from 44W steel’s properties. Its high tensile strength and good elongation make it perfect for vehicle frames and chassis, where strength and impact resistance are critical. The steel’s toughness allows it to absorb energy during collisions, enhancing vehicle safety by mitigating the effects of impacts.

Heavy-Duty Automotive Parts

44W steel is ideal for heavy-duty automotive parts like axles and suspension components that face high mechanical stress. Its fatigue resistance ensures that these components can withstand repeated loading cycles, maintaining performance and reliability throughout the vehicle’s lifespan.

Fabrication and Welding

The excellent weldability of 44W steel facilitates the assembly of complex automotive structures without compromising strength. This property enables the production of lightweight designs by allowing thinner sections, which contribute to better fuel efficiency without sacrificing durability. The steel’s compatibility with various welding techniques simplifies the manufacturing process and ensures robust joints.

Durability and Corrosion Resistance

44W steel’s resistance to abrasion and corrosion ensures longevity of automotive parts exposed to harsh conditions. This durability enhances the longevity of components exposed to elements such as road salt and varying weather conditions, ensuring that vehicles remain reliable and safe over extended periods, even under demanding conditions.

| Feature/Property | Construction Applications | Automotive Applications |

|---|---|---|

| Yield Strength | Structural beams, columns, load-bearing elements | Chassis frames, suspension parts |

| Tensile Strength | Supports heavy loads and dynamic stresses | High-stress components, impact-resistant parts |

| Ductility & Toughness | Absorbs seismic and wind forces, cold weather resilience | Energy absorption in crashes, fatigue resistance |

| Weldability | Complex fabrication and on-site welding | Efficient assembly of automotive structures |

| Fatigue Resistance | Bridges, cyclic load-bearing infrastructures | Repetitive stress parts like axles and brackets |

| Corrosion & Abrasion Resistance | Heavy machinery bases, outdoor structures | Long-lasting automotive parts exposed to elements |

Standards Compliance: CSA G40.21

Importance of Standards in Steel Manufacturing

Standards ensure the quality, safety, and reliability of structural steel used in construction. For structural steel, standards like CSA G40.21 provide specific guidelines for chemical composition, mechanical properties, and quality control measures. Adhering to these standards helps manufacturers produce consistent and high-quality steel products that meet the demands of the construction industry.

Specific Requirements for 44W Steel

Chemical Composition

CSA G40.21 sets precise guidelines for the chemical composition of 44W steel, including limits on elements such as carbon, manganese, phosphorus, sulfur, and silicon. This controlled composition ensures that 44W steel maintains its mechanical properties while optimizing weldability and reducing the risk of defects during fabrication.

Mechanical Properties

The standard defines specific mechanical properties for 44W steel:

- Tensile Strength: Approximately 440 MPa.

- Yield Strength: Around 300 MPa.

- Elongation: Minimum of 22%.

These properties ensure that 44W steel is suitable for demanding structural applications where strength and reliability are critical.

Ensuring Adherence to CSA G40.21

Quality Control Measures

Compliance with CSA G40.21 involves rigorous quality control measures throughout the manufacturing process:

- Material Testing: Conducting tensile tests, Charpy impact tests, and chemical analysis.

- Dimensional Tolerances: Ensuring strict adherence to specified thickness, width, and length tolerances.

These measures help maintain consistency and reliability in steel products, making them suitable for construction and engineering applications.

Certification Processes

Manufacturers undergo certification to prove compliance with CSA G40.21. This involves:

- Third-Party Audits: Independent audits verify that manufacturing processes and quality control measures meet the standard’s requirements.

- Documentation: Providing detailed documentation of material tests and quality control procedures.

Certification ensures that steel products meet the stringent requirements of CSA G40.21, providing confidence in their structural performance.

Testing and Certification Processes

Material Testing

Material testing is crucial for ensuring compliance with CSA G40.21. This includes:

- Tensile Tests: Measuring tensile strength and yield strength.

- Charpy Impact Tests: Assessing toughness and energy absorption during impact.

- Chemical Analysis: Verifying chemical composition.

These tests are conducted under controlled conditions to ensure accurate and reliable results.

Dimensional Tolerances

CSA G40.21 specifies strict dimensional tolerances for steel products, ensuring uniform thickness, width, and length. Adhering to these tolerances is essential for the seamless integration of steel components in structural applications.

Applications of 44W Steel under CSA G40.21

44W steel, compliant with CSA G40.21, is widely used in various structural engineering projects, such as:

- Structural Beams and Columns: Providing robust support for buildings and infrastructure.

- Bridges and Infrastructure Components: Ensuring long-term performance and safety under dynamic loading conditions.

- Sheet Piling and Retaining Walls: Offering stability and strength in construction projects.

Comparison with Other Standards

CSA G40.21 is often compared to other international standards, such as ASTM A500. Key differences include:

- Tensile Strength: CSA G40.21 requires up to 90,000 psi (~620 MPa), while ASTM A500 requires a minimum of 62,000 psi (~427 MPa).

- Minimum Elongation: CSA G40.21 mandates 22%, compared to 21% for ASTM A500.

- Usage: CSA G40.21 covers plates, shapes, and hollow sections, whereas ASTM A500 primarily covers hollow structural sections.

- Stringency: CSA G40.21 is generally more stringent, reflecting Canadian codes and standards.

These differences highlight CSA G40.21’s stricter requirements for strength and ductility, ensuring safety in Canadian construction environments. Compliance with CSA G40.21 provides confidence in the performance and durability of steel products used in structural applications.

Welding and Fabrication Techniques for 44W Steel

Composition and Properties Relevant to Welding

44W steel is known for its balanced composition, including up to 0.22% carbon, 1.35% to 1.65% manganese, 0.15% to 0.40% silicon, and controlled low levels of phosphorus (≤0.04%) and sulfur (≤0.03%). These elements provide 44W steel with a minimum yield strength of 44 ksi (303 MPa) and a tensile strength range of 65,000 to 85,000 psi (448 to 586 MPa). The steel’s excellent ductility, with elongation at break between 20% and 23%, contributes to its favorable weldability and suitability for various fabrication techniques.

Common Welding Techniques for 44W Steel

44W steel is highly compatible with several welding techniques, each offering distinct advantages depending on the application:

- Shielded Metal Arc Welding (SMAW): This method is favored for its simplicity and versatility. It is effective in both field and shop settings, providing reliable welds with appropriate electrodes such as E7018. SMAW is cost-effective and adaptable for various joint designs, making it a popular choice for structural applications.

- Gas Metal Arc Welding (GMAW or MIG Welding): GMAW is particularly useful for thicker sections (≥1/4 inch) where techniques such as vertical up welding ensure good penetration. Controlling travel speed and gun angle (5° to 15° downward from perpendicular) helps manage weld bead size and cooling rates, resulting in strong, defect-free welds.

- Gas Tungsten Arc Welding (GTAW or TIG Welding): GTAW is suitable for precise, high-quality welds, especially on thinner sections where aesthetics and minimal distortion are critical. This method is ideal for applications requiring meticulous welds with excellent appearance and structural integrity.

Fabrication Considerations

Preheating and Post-Weld Heat Treatment

44W steel generally requires little preheating, but thicker sections or complex joints may benefit from low-temperature preheat to reduce cracking risks. Post-weld heat treatment is usually unnecessary unless specified for enhanced toughness, as in the case of 44WT grades.

Filler Metals Selection

Choosing the right filler metals, such as E7018 electrodes for SMAW, ensures weld quality by matching the base metal properties. These fillers provide good mechanical properties and crack resistance, ensuring that the welds are ductile and strong, compatible with the characteristics of 44W steel.

Welding Parameters

Proper control of welding parameters, including travel speed, voltage, and amperage, is essential for achieving sound welds. For MIG welding, faster travel speeds can reduce weld bead size and penetration, which is beneficial for welding thinner metals. Moderate weaving motions can help control bead shape but should be used carefully to avoid defects.

Joint Design and Fit-up

Standard joint configurations such as butt, lap, and fillet joints are suitable for welding 44W steel. Proper fit-up and cleanliness are critical to minimize defects and ensure good fusion, especially in field welding conditions. Clean surfaces and precise alignment help achieve strong, reliable welds.

Advantages of 44W Steel in Welding and Fabrication

| Feature | Description |

|---|---|

| Weldability | Excellent; compatible with common welding methods (SMAW, MIG, TIG) |

| Preheat/Post-Heat Needs | Minimal, reducing fabrication time and cost |

| Mechanical Compatibility | Good ductility allows deformation without cracking |

| Cost Efficiency | Lower welding complexity compared to higher alloy steels like 300W |

| Versatility | Suitable for both shop and field welding |

44W steel’s composition and mechanical properties make it highly weldable using standard techniques such as SMAW, MIG, and TIG. Its low carbon content and balanced alloying minimize the need for preheating and post-weld heat treatment, simplifying fabrication workflows. Proper selection of filler metals and control of welding parameters ensure strong, ductile, and defect-free welds. These factors contribute to 44W steel’s popularity in construction and manufacturing industries where reliable, cost-effective welding is essential.

Comparative Analysis: 44W Steel vs Other Structural Steels

Composition and Properties

Chemical Composition

44W steel is a medium-carbon structural steel known for its balanced chemical composition. It contains up to 0.22% carbon, which contributes to its strength and hardness, and 1.35% to 1.65% manganese, enhancing its tensile strength and toughness. Silicon content varies between 0.15% and 0.40%, improving the steel’s flexibility and overall strength. Phosphorus and sulfur levels are kept low, at no more than 0.04% and 0.03% respectively, to maintain weldability and prevent brittleness.

Mechanical Properties

44W steel offers impressive mechanical properties, including a minimum yield strength of 44 ksi (303 MPa) for thicknesses up to 2.5 inches. Its tensile strength ranges from 65 ksi to 85 ksi (448 to 586 MPa), making it capable of withstanding significant stress before breaking. The steel exhibits excellent ductility, with elongation at break values of at least 20% for an 8-inch specimen and 23% for a 2-inch specimen. These properties make 44W steel highly suitable for structural applications requiring resilience and toughness.

Comparison with Other Structural Steels

44W vs 300W Steel

Both 44W and 300W steels have similar mechanical properties, making them ideal for structural applications, and both are highly weldable.

Differences:

- Cost: 44W steel is generally more affordable due to its simpler manufacturing process and lower alloy content. This cost efficiency makes it easier to weld and work with, reducing overall project expenses.

- Composition: 300W steel has a higher alloy content, which results in superior mechanical properties but also makes it more expensive. This steel is often chosen for applications requiring enhanced performance.

44W vs A36 Steel

44W steel, with its higher carbon content, offers greater tensile strength and yield compared to A36 steel, making it preferred for high-stress applications.

44W vs Other CSA Grades (50W, 50A)

Yield Strength: 44W steel has a minimum yield strength of 44 ksi for thicknesses up to 2.5 inches. Other grades like 50W offer higher yield strengths, making them suitable for more demanding applications.

Applications: Depending on specific project requirements, grades like 50W may be selected for higher strength needs. However, 44W steel remains widely used due to its balance of strength and cost-effectiveness.

Key Points for Comprehensive Guide

- 44W Steel Composition: The high manganese content enhances strength and weldability.

- Properties: Offers excellent ductility and formability, making it versatile for various fabrication techniques.

- Applications: Widely used in construction, automotive, transport, and heavy machinery sectors.

- Comparison with Other Steels: More affordable than 300W steel with similar mechanical properties, and offers higher strength compared to A36 steel for demanding applications.

Durability and Sustainability of 44W Steel

Durability of 44W Steel

44W steel is known for its exceptional durability, making it a popular choice for high-stress applications. Its high yield strength, reaching up to 44 ksi (303 MPa) for thicknesses up to 2.5 inches, and tensile strength allow 44W steel to withstand substantial loads without permanent deformation.

Strength and Toughness

44W steel has a tensile strength between 65,000 to 85,000 psi (448 to 586 MPa), allowing it to endure extensive stress while maintaining structural integrity. This steel’s high toughness, indicated by its ability to absorb energy and deform plastically before fracturing, is particularly beneficial in dynamic loading environments, such as bridges and heavy machinery. The elongation at break, which is at least 20% for an 8-inch specimen and 23% for a 2-inch specimen, highlights its excellent ductility, enabling it to withstand impacts and fluctuating loads without compromising its structural integrity.

Sustainability of 44W Steel

Environmental Impact

44W steel offers notable environmental advantages due to its high strength, which allows for the use of less material to achieve the same structural goals compared to lower-strength steels like A36. This reduction in material usage leads to lower resource consumption and energy expenditure during production and transportation. As a result, 44W steel is a more environmentally friendly option.

Recyclability

Like most structural steels, 44W steel is highly recyclable. The recycling process involves melting down scrap steel to produce new steel products, which significantly reduces the need for raw material extraction and the environmental impact associated with it. The durability and strength of 44W steel ensure that structures made from it have a longer lifespan, requiring less frequent replacement and maintenance, further contributing to sustainability.

Comparison with Other Structural Steels

When comparing 44W steel to other structural steels such as A36 and 4140, its environmental benefits become apparent. Despite higher initial costs, the superior strength and lower long-term maintenance requirements of 44W steel make it a cost-effective and sustainable choice for projects needing enhanced performance. Unlike higher alloy steels like 4140, which have greater environmental impacts during production, 44W steel’s composition and mechanical properties provide a more sustainable solution for structural applications.

Applications and Prospects

44W steel is widely used across various industries due to its combination of durability and sustainability. In construction, 44W steel is used in building frameworks, bridges, and other infrastructure projects where durability is essential. In the automotive industry, its strength and toughness make it ideal for vehicle frames and other high-stress components. The steel’s adaptability to different fabrication techniques and potential for further enhancement through treatments for low-temperature performance expand its application range.

As industries increasingly prioritize sustainability without compromising performance, 44W steel’s properties position it as a leading material for long-term, environmentally conscious projects.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the chemical composition and mechanical properties of 44W steel?

44W steel, classified under the Canadian Standards Association (CSA) G40.21 specification, is a structural carbon steel known for its balanced composition and mechanical properties. The chemical composition of 44W steel typically includes a maximum of 0.22% carbon, 1.35% to 1.65% manganese (often around 0.50% to 1.50%), up to 0.04% phosphorus, 0.03% to 0.04% sulfur, and 0.15% to 0.40% silicon. This composition is designed to enhance strength, toughness, and weldability while limiting brittleness.

In terms of mechanical properties, 44W steel exhibits a minimum yield strength of 44 ksi (approximately 304 MPa) for thicknesses up to 2.5 inches, and 40 ksi (276 MPa) for greater thicknesses. Its tensile strength ranges from 58 ksi to 80 ksi (400 to 550 MPa). The steel is known for good ductility, high impact resistance, and excellent weldability, making it suitable for various structural applications such as construction and heavy machinery.

What are the common applications of 44W steel?

44W steel, also referred to as 300W in the metric system, is predominantly used in various structural and fabrication applications due to its high strength, durability, and ease of workability. Common applications include:

- Construction and Infrastructure Projects: It is widely used in bridges, transmission towers, and building structures such as beams and columns because of its ability to absorb dynamic loads and provide robust support.

- Marine and Offshore Applications: Its strength and durability make it suitable for shipbuilding and offshore platforms, where it must withstand harsh environmental conditions.

- Industrial Machinery and Equipment: 44W steel is used in heavy machinery components like gears, shafts, and frames, as well as in the transportation sector for truck frames, trailers, shipping containers, and railway cars.

- Energy Sector: It is utilized in wind turbine towers and oil and gas platforms, providing the necessary structural integrity and resistance to corrosion in demanding environments.

These diverse applications highlight 44W steel’s versatility and reliability across different industries.

How does 44W steel compare to other structural steels in terms of weldability?

44W steel, known for its balanced composition and mechanical properties, is favored in construction due to its weldability. Compared to other structural steels, 44W steel offers enhanced weldability primarily because of its relatively low carbon content, which minimizes the risk of cracking or hardening during the welding process. This makes it suitable for various welded construction projects with minimal preheating and post-welding treatments required.

When compared to A36 steel, 44W steel has higher yield and tensile strength, although A36 is generally easier to weld due to its lower carbon content. In contrast, 300W steel, which has a higher strength and alloy content, poses more challenges in welding and requires specialized techniques and equipment. Consequently, while 300W steel offers superior strength, 44W steel is more cost-effective and easier to handle in projects prioritizing weldability. Overall, 44W steel strikes a balance between ease of welding, strength, and cost-efficiency, making it a preferred choice for structural applications.

What are the sustainability and environmental impacts of 44W steel?

44W steel, known for its high strength and durability, offers significant sustainability and environmental benefits. Its robust properties reduce the frequency of repairs and replacements, leading to less material consumption over time. This efficiency translates to lower energy expenditure during production and transportation. Additionally, 44W steel is highly recyclable, which helps in conserving resources and minimizing waste. Its superior strength means that structures made from 44W steel have reduced maintenance needs, contributing to lower carbon emissions and a smaller environmental footprint compared to less durable alternatives. As the steel industry continues to focus on sustainability, the use of high-strength steels like 44W is expected to play an essential role in reducing the environmental impact of construction and manufacturing processes.

What standards does 44W steel need to comply with?

44W steel must comply with the standards set by the Canadian Standards Association (CSA), specifically the CSA G40.21 specification. This standard outlines the necessary mechanical properties, including a minimum yield strength of 44,000 psi (300 MPa) for thicknesses up to 2.5 inches and 40,000 psi for thicknesses greater than 2.5 inches. Additionally, CSA G40.21 mandates strict dimensional tolerances, comprehensive testing procedures such as tensile and impact tests, and chemical analyses to ensure quality and performance. Proper marking for traceability is also required to maintain compliance and ensure safety in structural applications. This standard guarantees that 44W steel is reliable, safe, and suitable for various construction and fabrication projects.

What are the recommended welding and fabrication techniques for 44W steel?

44W steel, known for its low carbon content and excellent weldability, can be effectively welded using several conventional methods. Recommended techniques include Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW or MIG), and Gas Tungsten Arc Welding (GTAW or TIG). These methods are suitable due to 44W steel’s balanced composition, which includes a maximum of 0.22% carbon and 1.35%-1.65% manganese, providing good strength and ductility.

Minimal preheating is typically needed, reducing hydrogen-induced cracking risk. For critical applications or thicker sections, stress-relief annealing at 600-650°C can be performed to reduce residual stresses and enhance weld integrity. Post-Weld Heat Treatment (PWHT) is generally not required, except in applications demanding improved toughness.

In terms of fabrication, 44W steel’s ductility allows for both hot and cold forming processes. Standard joint designs, such as butt, fillet, and lap joints, are effective, ensuring appropriate weld bead sizes relative to material thickness. This comprehensive approach ensures high-quality welds and efficient fabrication, leveraging 44W steel’s inherent properties.