Imagine a material so versatile and robust that it has become a cornerstone in industries ranging from automotive to aerospace. Chrome vanadium steel, a highly regarded alloy, stands out due to its unique blend of properties and composition. This technical reference will dive deep into the fascinating world of chrome vanadium steel, unraveling its mechanical, physical, and chemical attributes. We’ll explore how its composition influences these properties and why it is the material of choice for demanding applications. From understanding its role in manufacturing high-performance tools to comparing it with other materials, this comprehensive guide will answer all your questions and more. Are you ready to discover what makes chrome vanadium steel an indispensable asset in modern engineering? Let’s get started.

Introduction to Chrome Vanadium Steel

Chrome vanadium steel, often abbreviated as Cr-V steel, is a high-performance alloy that combines chromium and vanadium. This particular steel is highly regarded for its exceptional mechanical properties, making it a preferred material in various demanding applications.

Composition

The composition of chrome vanadium steel includes iron as the primary base metal, carbon to enhance hardness and strength, chromium to add hardness, corrosion resistance, and wear resistance, and vanadium to improve tensile strength and toughness while refining the grain structure. Manganese and silicon may also be present, contributing to the overall strength and durability.

Mechanical Properties

- Hardness: Chromium increases the steel’s hardenability, making it resistant to wear and abrasion.

- Tensile Strength: Vanadium significantly boosts tensile strength, making the steel capable of withstanding substantial stress.

- Toughness: The alloy exhibits remarkable toughness, which is crucial for applications that involve high impact forces.

- Elasticity: Chrome vanadium steel demonstrates good elasticity, allowing it to return to its original shape after bending or deformation.

- Thermal Stability: The steel maintains its mechanical properties across a wide range of temperatures, making it suitable for high-temperature applications.

Physical Properties

- Density: Similar to other alloy steels, chrome vanadium steel has a density that supports its use in robust structural applications.

- Melting Point: The alloy maintains a high melting point, ensuring stability in high-heat environments.

- Magnetic Properties: Chrome vanadium steel is typically magnetic due to its iron content.

Applications of Chrome Vanadium Steel

Thanks to its exceptional properties, chrome vanadium steel is widely used across various industries:

- Automotive Industry: Components such as engine parts, gears, and axles benefit from the steel’s strength and durability.

- Aerospace Sector: Fasteners and other critical components require the corrosion resistance and thermal stability provided by Cr-V steel.

- Hand Tools: Pliers, screwdrivers, wrenches, and sockets are often made from chrome vanadium steel because of its resilience and ability to withstand repeated use.

- Machinery and Equipment: Cutting tools, bearings, and other machinery components utilize this steel for its wear resistance and durability.

Advantages Over Other Steels

Chrome vanadium steel offers several benefits over other types of steel:

- Superior Hardness and Wear Resistance: Thanks to the chromium content, Cr-V steel outperforms many other steels in applications requiring high wear resistance.

- Enhanced Corrosion Resistance: The chromium also provides a protective layer against corrosion, making it suitable for environments exposed to moisture and chemicals.

- Improved Tensile Strength: The addition of vanadium ensures higher tensile strength compared to standard carbon steels, making it ideal for heavy-duty applications.

- Thermal Stability: Its ability to retain mechanical properties at elevated temperatures sets it apart from other steels that might degrade under similar conditions.

Composition of Chrome Vanadium Steel

Chrome vanadium steel stands out as an alloy with exceptional properties, thanks to a precise blend of key elements. Each component contributes specific characteristics that enhance the overall performance of the steel in various applications.

Carbon (C)

Carbon, typically around 0.50%, is crucial for enhancing the hardness and tensile strength of chrome vanadium steel, allowing it to undergo heat treatment processes that improve its wear resistance.

Manganese (Mn)

Manganese is included in the alloy in amounts ranging from 0.70% to 0.90%. This element plays a vital role in increasing the steel’s strength and hardness. Additionally, manganese improves the steel’s resistance to wear and impact, making it more durable in demanding applications.

Silicon (Si)

Silicon, about 0.30%, strengthens the steel and makes it more elastic. It also helps during production by removing impurities.

Chromium (Cr)

Chromium, ranging from 0.80% to 1.10%, is key to the alloy’s corrosion resistance. It forms a protective oxide layer on the surface and also improves the steel’s hardness and wear resistance.

Vanadium (V)

Vanadium, usually around 0.18%, significantly boosts the steel’s hardness and strength. It also refines the grain structure, enhancing toughness and resistance to wear and fatigue.

The specific combination of carbon, manganese, silicon, chromium, and vanadium in chrome vanadium steel results in an alloy that is remarkably strong, tough, and resistant to various forms of wear and corrosion. The interplay between these elements allows for a versatile material that can be tailored to meet the requirements of different industrial applications through controlled processing and heat treatment methods. This blend of elements ensures that chrome vanadium steel maintains its structural integrity and performance across a wide range of conditions, making it a preferred choice for tools, automotive parts, and other high-stress components.

Mechanical Properties of Chrome Vanadium Steel

Tensile Strength

Chrome vanadium steel has a high tensile strength, usually between 190 and 300 ksi (1300 to 2070 MPa). This impressive strength makes it suitable for applications that require materials capable of withstanding substantial stress without breaking or deforming. The presence of vanadium in the alloy significantly enhances this property by improving the steel’s ability to endure high loads.

Yield Strength

Yield strength indicates the stress at which the material begins to deform plastically. For example, the AISI 6150H grade has a yield strength of about 800 MPa (116,000 psi). This high yield strength ensures that the steel can maintain its shape and structural integrity under heavy loads, making it ideal for demanding applications like automotive components and industrial machinery.

Elastic Modulus

The elastic modulus (Young’s modulus) of chrome vanadium steel is around 190-205 GPa (27 to 29.7 million psi). This property measures the stiffness of the material, reflecting its ability to deform elastically when a force is applied. The high elastic modulus means the steel can return to its original shape after bending or stretching, which is particularly important for tools and springs.

Elongation at Break

With an elongation at break of 14% to 23%, chrome vanadium steel balances strength and flexibility, allowing it to absorb impacts and deform without breaking, crucial for dynamic loads and high-impact applications. This ductility is vital for applications involving dynamic loads and high-impact forces.

Brinell Hardness

The Brinell hardness of chrome vanadium steel varies depending on the specific grade, with values typically ranging from 200 to 350 HB. Some grades, like ASTM A232, can reach up to 540 HB. This hardness makes chrome vanadium steel highly resistant to wear and abrasion, ensuring a long service life for tools and components subjected to repetitive use and harsh conditions.

Impact Resistance

The combination of chromium and vanadium enhances the steel’s ability to withstand sudden and forceful impacts without cracking or breaking. This impact resistance is particularly important for hand tools and automotive parts, which often experience high-stress situations.

High-Temperature Strength

Chrome vanadium steel maintains its strength at elevated temperatures, thanks to the presence of vanadium. This high-temperature strength makes it suitable for applications that involve exposure to heat, such as engine components and industrial machinery. The steel’s ability to retain its mechanical properties under thermal stress ensures reliable performance and durability in high-heat environments.

Fatigue Resistance

Fatigue resistance means chrome vanadium steel can handle repeated loading and unloading without cracking or failing. The alloy’s composition, particularly the presence of vanadium, improves its fatigue resistance, making it ideal for applications like springs and fasteners that are subjected to continuous cyclic stresses. This property ensures the longevity and reliability of components made from chrome vanadium steel.

Physical Properties of Chrome Vanadium Steel

Strength and Toughness

Chrome Vanadium Steel is known for its exceptional strength and toughness, making it ideal for high-stress and impact applications. The presence of vanadium in the alloy refines the grain structure, resulting in a steel that can endure dynamic and cyclic stresses without fracturing. This balance of properties allows the steel to withstand heavy loads and impacts, making it perfect for tools and mechanical components.

Hardness

The hardness of Chrome Vanadium Steel is notably high, often achieved through heat treatment processes such as quenching and tempering. This steel typically reaches a hardness range of 50-60 HRC (Rockwell hardness scale), depending on the specific heat treatment applied. The combined effects of chromium and vanadium are crucial for this hardenability, providing a hard surface that resists wear while maintaining a tough core.

Corrosion and Oxidation Resistance

Chrome Vanadium Steel possesses moderate corrosion resistance due to its chromium content, which ranges from 0.8% to 1.1%. Chromium forms a protective oxide layer on the steel’s surface, which helps prevent rust and oxidation in typical working environments. Although not as corrosion-resistant as stainless steel, Chrome Vanadium Steel performs significantly better than plain carbon steels in resisting surface degradation.

Wear and Fatigue Resistance

Vanadium helps form fine carbides, which increase surface hardness and reduce wear. This property is particularly important for tools and components that undergo repetitive mechanical action. Additionally, the steel’s fatigue resistance is superior, allowing it to maintain mechanical integrity under repeated loading and unloading cycles, which is vital for springs and fasteners.

Elasticity and Density

The alloy’s elasticity and ductility are improved by the combined effects of chromium and carbon. Chrome Vanadium Steel has a density comparable to other alloy steels, supporting its use in robust structural applications. Its high melting point ensures stability and performance in high-heat environments, making it suitable for engine components and industrial machinery exposed to elevated temperatures.

Magnetic Properties

Chrome Vanadium Steel is usually magnetic because of its iron content. This property can be advantageous in applications where magnetic characteristics are desired, such as in certain types of tools and fasteners.

| Property | Description/Value |

|---|---|

| Tensile Strength | High; enhanced by vanadium and chromium |

| Hardness | Medium to high; ~50-60 HRC after heat treatment |

| Toughness | Excellent; resistant to impact and fracture |

| Corrosion Resistance | Moderate; better than carbon steel |

| Wear Resistance | High; due to fine vanadium carbides |

| Fatigue Resistance | Superior; suitable for cyclic loading applications |

| Elasticity | Improved elasticity due to chromium and carbon |

Applications Related to Physical Properties

The physical properties of Chrome Vanadium Steel make it a preferred material for:

- Hand tools (wrenches, sockets, screwdrivers) requiring hardness and toughness

- Springs and mechanical components needing high fatigue strength and elasticity

- Automotive parts subjected to wear and stress

- High-performance fasteners and blades

The alloy’s balanced strength, hardness, and corrosion resistance ensure durability and reliability in demanding environments.

Chemical Properties of Chrome Vanadium Steel

Chemical Composition and Impact

The chemical properties of chrome vanadium steel are primarily determined by its unique composition, which includes carbon, chromium, vanadium, manganese, and silicon, each contributing distinct characteristics to the alloy’s performance.

Carbon (C)

Carbon, typically around 0.50%, enhances hardness and tensile strength, allowing the steel to undergo heat treatment processes that improve wear resistance and durability. This ensures that the alloy maintains a good balance between hardness and ductility, making it suitable for high-stress applications.

Chromium (Cr)

Chromium, present in concentrations between 0.80% and 1.10%, plays a significant role in the chemical properties of chrome vanadium steel. Chromium enhances hardness, wear resistance, and corrosion resistance by forming a stable oxide layer that protects the steel from oxidation and rust. This protection is vital for the steel’s longevity and reliability in demanding environments.

Vanadium (V)

Vanadium content is approximately 0.18%, and it is a key element that significantly improves the chemical properties of chrome vanadium steel. Vanadium refines the grain structure, enhancing toughness and strength, and forms vanadium carbides that contribute to hardness and wear resistance. This ensures the steel maintains its mechanical properties even under high-stress conditions, making it ideal for tools and high-performance components.

Manganese (Mn)

Manganese is included in the alloy in amounts ranging from 0.70% to 0.90%. Manganese improves the steel’s strength and hardness by deoxidizing and removing impurities during the steelmaking process. It also enhances toughness and wear resistance, making it more durable in applications involving heavy loads and high impact forces. Manganese’s ability to improve hardenability ensures that chrome vanadium steel can be effectively heat-treated to achieve desired mechanical properties.

Silicon (Si)

Silicon, usually around 0.30%, acts as a deoxidizer, removing impurities during steelmaking, and increases strength and elasticity. This allows the steel to withstand deformation and return to its original shape, which is particularly beneficial in applications requiring flexibility and resilience, such as springs and automotive parts.

Interaction of Elements

The interaction between these elements in chrome vanadium steel creates a material with a unique set of chemical properties that are highly beneficial for various industrial applications. The balanced composition ensures that the steel exhibits excellent hardness, strength, and toughness while maintaining good corrosion resistance and wear resistance.

- Hardness and Wear Resistance: The combined effects of carbon, chromium, and vanadium result in a hard surface that resists wear and abrasion.

- Corrosion Resistance: Chromium forms a protective oxide layer, enhancing the steel’s resistance to rust and oxidation.

- Strength and Toughness: Vanadium and manganese contribute to the alloy’s high strength and toughness, making it capable of withstanding heavy impacts and loads.

- Elasticity: Silicon enhances the steel’s elasticity, allowing it to recover from deformation.

Chemical Stability and Reactivity

Chrome vanadium steel exhibits chemical stability under various environmental conditions, thanks to its composition. The protective oxide layer formed by chromium reduces the steel’s reactivity with atmospheric oxygen and moisture, preventing rust and corrosion. This stability is crucial for components exposed to harsh environments, such as automotive and industrial applications.

The chemical properties of chrome vanadium steel make it an excellent choice for applications requiring a durable, hard, and corrosion-resistant material. The precise combination of elements ensures that the steel performs reliably under demanding conditions, maintaining its integrity and functionality over extended periods.

Applications and Uses of Chrome Vanadium Steel

Chrome Vanadium Steel is highly favored in manufacturing hand tools due to its exceptional strength, toughness, and resistance to wear. The high tensile strength and hardness provided by the chromium and vanadium content ensure that tools made from this steel can withstand significant mechanical stress and repeated use.

- Wrenches and Spanners: These tools require high durability and the ability to handle torque without deforming. Chrome Vanadium Steel’s high strength and toughness make it ideal for these applications.

- Pliers and Cutters: The wear resistance of Chrome Vanadium Steel ensures that pliers and cutters maintain their sharpness and effectiveness over prolonged periods of use.

- Sockets and Ratchets: These tools benefit from the alloy’s ability to resist wear and tear, making them reliable for heavy-duty applications.

- Screwdrivers: The hardness of Chrome Vanadium Steel allows screwdrivers to maintain their shape and effectiveness even with frequent use.

In the automotive industry, Chrome Vanadium Steel is used for critical components like crankshafts, camshafts, gears, and axles because of its strength and durability. The steel’s properties make it suitable for parts that must endure high stress and wear.

In industrial machinery, Chrome Vanadium Steel is used for large-diameter spring wires and cutting tools, benefiting from its strength, fatigue resistance, and hardness. The reliability and durability of components are paramount in this industry.

The construction industry relies on Chrome Vanadium Steel for high-strength hand tools, fasteners, and connectors due to its toughness, wear resistance, and corrosion resistance. These attributes ensure long-term reliability and structural integrity.

In aerospace, Chrome Vanadium Steel is ideal for fasteners, bolts, and landing gear components because of its high tensile strength, toughness, and resistance to corrosion. Components in this sector must meet stringent requirements for strength, durability, and resistance to harsh environments.

Comparison with Other Materials

Chromium-Molybdenum Steel

Chromium-Molybdenum steel, known as chromoly steel, is strengthened by adding chromium and molybdenum, which improve its resistance to mechanical and thermal stress. The presence of molybdenum enhances the steel’s strength and ability to withstand high temperatures, while chromium contributes to its corrosion resistance and hardness.

Chromium-Molybdenum steel is widely used in applications that require high strength and temperature resistance, such as in the construction of pressure vessels, oil and gas pipelines, and automotive components like gears and crankshafts. Its ability to maintain mechanical integrity under high thermal conditions makes it particularly suitable for engine parts and turbine components.

High Carbon Steel

High Carbon steel, with 0.60% to 1.00% carbon, is very hard and strong but can be brittle and less flexible. This increased carbon content significantly enhances the hardness and strength of the steel but also makes it more brittle and less ductile.

Due to its hardness, High Carbon steel is commonly used in the manufacture of cutting tools, such as knives, blades, and chisels, where edge retention is critical. It is also used in springs and high-strength wires, where its ability to withstand deformation under load is advantageous.

Stainless Steel

Stainless steel, with over 10.5% chromium, forms a protective oxide layer that resists corrosion. Depending on its composition and heat treatment, it can also be very strong and tough.

Stainless steel is extensively used in environments that require high corrosion resistance, such as in kitchen utensils, medical instruments, and architectural applications. Its aesthetic appeal and resistance to rust make it ideal for both functional and decorative purposes. Additionally, stainless steel is used in the chemical and food processing industries, where hygiene and corrosion resistance are paramount.

Tool Steel

Tool steel is essential in the manufacture of durable tools and dies. Its unique composition allows it to maintain sharp edges and resist wear under high-stress conditions. It typically contains varying amounts of carbon, chromium, vanadium, and other alloying elements.

Tool steel is primarily used in the manufacture of cutting and forming tools, molds for plastic injection, and die-casting molds. Its ability to maintain hardness and shape under high-stress conditions makes it indispensable in the tool-making industry.

Comparison Summary

- Chrome Vanadium Steel: Strong, wear-resistant, moderately corrosion-resistant; ideal for hand tools and automotive parts.

- Chromium-Molybdenum Steel: Excellent for high-temperature applications due to its strength and thermal stability.

- High Carbon Steel: Very hard and strong, primarily used in cutting tools and high-strength wires, though it is more brittle and lacks corrosion resistance.

- Stainless Steel: Renowned for its corrosion resistance and aesthetic qualities, widely used in kitchenware, medical instruments, and architectural applications.

- Tool Steel: Known for its hardness and wear resistance, essential for the production of cutting and forming tools, molds, and dies.

Standards Compliance

Relevant Industry Standards

Chrome Vanadium Steel (Cr-V) must comply with several industry standards to ensure its quality, performance, and safety in various applications. These standards are set by organizations such as ASTM and SAE, and they specify the chemical composition, mechanical properties, and testing procedures required for Cr-V steel.

ASTM Standards

- ASTM A231/A231M-18

This standard covers chromium-vanadium alloy steel springs. It specifies the chemical composition ranges, mechanical properties, and testing procedures such as cast or heat analysis. The focus is on controlling elements like carbon, manganese, phosphorus, and sulfur to optimize the toughness and durability of the springs. - ASTM A232/A232M

This standard is crucial for Cr-V steel components exposed to cyclic loads requiring high fatigue resistance, such as in tool manufacturing and automotive parts. It specifies the necessary chemical composition, tensile strength, and hardness criteria essential for ensuring the durability and performance of these components.

SAE and Other Industry Standards

Cr-V steel also aligns with standards set by the Society of Automotive Engineers (SAE) and other global industry organizations. These standards detail alloy compositions and mechanical properties to maintain consistency in automotive and industrial applications, ensuring that Cr-V steel parts can withstand heavy stresses and repeated impacts without failure.

Chemical Composition Compliance

To meet these standards, Chrome Vanadium Steel typically has the following composition ranges:

| Element | Typical Range (%) | Function/Effect |

|---|---|---|

| Carbon (C) | ~0.50 | Increases hardness and strength |

| Chromium (Cr) | 0.80 – 1.10 | Enhances hardness, wear resistance, corrosion resistance |

| Vanadium (V) | ~0.18 | Refines grain structure, improves toughness and fatigue resistance |

| Silicon (Si) | ~0.30 | Improves strength and elasticity |

| Manganese (Mn) | 0.70 – 0.90 | Aids in hardness and tensile strength |

| Phosphorus (P) | ≤ specified limits | Controlled to reduce brittleness |

| Sulfur (S) | ≤ specified limits | Controlled for machinability and toughness |

This precise alloying ensures properties such as high tensile strength, hardness, and resistance to wear and abrasion, making Cr-V steel suitable for demanding applications.

Mechanical Properties and Testing

Compliance with standards mandates rigorous testing to ensure that Cr-V steel meets specified mechanical properties:

- Tensile Strength and Hardness: Cr-V steel should have a tensile strength of 190-300 MPa and a hardness of 45-50 HRC after heat treatment. These properties are essential for tools and automotive components that endure high mechanical stresses.

- Impact and Fatigue Resistance: Vanadium’s grain refinement effect enhances the steel’s toughness, making it highly impact-resistant and suitable for cyclic loading conditions. Standards require rigorous fatigue tests to confirm this behavior, ensuring longevity in applications like springs and gears.

- Corrosion Resistance: Chromium content forms a passive oxide layer that improves resistance against rust and oxidation. Although not as corrosion-resistant as stainless steel, Cr-V steel meets the necessary criteria for general use and requires maintenance in highly corrosive environments.

Applications and Compliance Implications

- Hand Tools: Wrenches, sockets, pliers, and screwdrivers made from Cr-V steel benefit from compliance with ASTM and SAE standards that ensure durability, wear resistance, and toughness needed for repeated use under stress.

- Automotive Parts: Axles, crankshafts, and gears need materials that meet specific fatigue and strength standards to ensure reliable performance under dynamic loads.

- Industrial Machinery: Heavy machinery parts subjected to abrasion and high-load stresses are manufactured using Cr-V steel that meets chemical and mechanical property standards, assuring operational safety and lifespan.

By adhering to these standards, Chrome Vanadium Steel fulfills stringent demands across various industries, providing reliable and high-performance material quality for critical applications.

Trending Factors in the Industry

Growing Demand for High-Performance Alloys

The demand for high-performance alloys like chrome vanadium steel is rising due to their outstanding mechanical properties. This trend is driven by the need for materials that can withstand extreme conditions, including high stress, wear, and corrosion. Industries such as automotive, aerospace, and industrial machinery are particularly focused on leveraging these properties to enhance the durability and performance of their components.

Advanced Manufacturing Techniques

Innovations in manufacturing techniques are significantly impacting the use of chrome vanadium steel. Precision forging and advanced heat treatment processes are being adopted to optimize the alloy’s mechanical properties. These techniques allow manufacturers to create parts that are harder, stronger, and more resistant to fatigue, customized for specific uses. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) is also enhancing the precision and efficiency of producing chrome vanadium steel parts.

Integration into Electric Vehicles (EVs)

The rise of electric vehicles (EVs) is creating new opportunities for chrome vanadium steel. Its lightweight yet durable nature makes it ideal for various EV components, including battery casings, chassis parts, and fasteners. The alloy’s ability to maintain mechanical integrity under cyclic loads and high temperatures is crucial for the reliability and longevity of EVs. With the growth of the EV market, the need for chrome vanadium steel is anticipated to increase considerably.

Sustainability and Recycling

Sustainability is becoming a major focus in the industry, and chrome vanadium steel is playing a role in this shift. More recycling of the alloy is being done to lessen the environmental impact of production. Recycling not only conserves resources but also lowers the carbon footprint associated with manufacturing new steel. This trend aligns with global efforts to promote eco-friendly practices and achieve sustainability goals.

Enhanced Coating Technologies

Recent advancements in coating technologies are further enhancing the properties of chrome vanadium steel. Techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) are being used to apply protective coatings that improve corrosion resistance and wear properties. These coatings are especially useful for parts used in harsh conditions, like marine settings and industrial machines.

Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, is revolutionizing the production of chrome vanadium steel components. This technology allows for the creation of complex geometries that are difficult to achieve with traditional manufacturing methods. Additive manufacturing also enables rapid prototyping and customization, making it easier to develop specialized tools and parts. The flexibility and precision offered by this technology are driving its adoption across various sectors.

Material Comparisons and Preferences

Chrome vanadium steel is increasingly being compared with other high-performance alloys, such as chromium-molybdenum (Cr-Mo) steel. While Cr-Mo steel is favored for applications requiring higher stress tolerance, chrome vanadium steel is preferred for its elasticity and fatigue resistance. Understanding these material preferences helps industries select the most suitable alloy for specific applications, optimizing performance and cost-effectiveness.

Future Trends and Developments

Looking ahead, chrome vanadium steel is expected to play a critical role in emerging technologies and applications. The alloy’s integration into robotic machinery components highlights its suitability for automation and precision tasks. Additionally, ongoing research into new alloy compositions and processing techniques will continue to enhance its properties, ensuring that chrome vanadium steel remains a valuable material in the industry.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the mechanical properties of chrome vanadium steel?

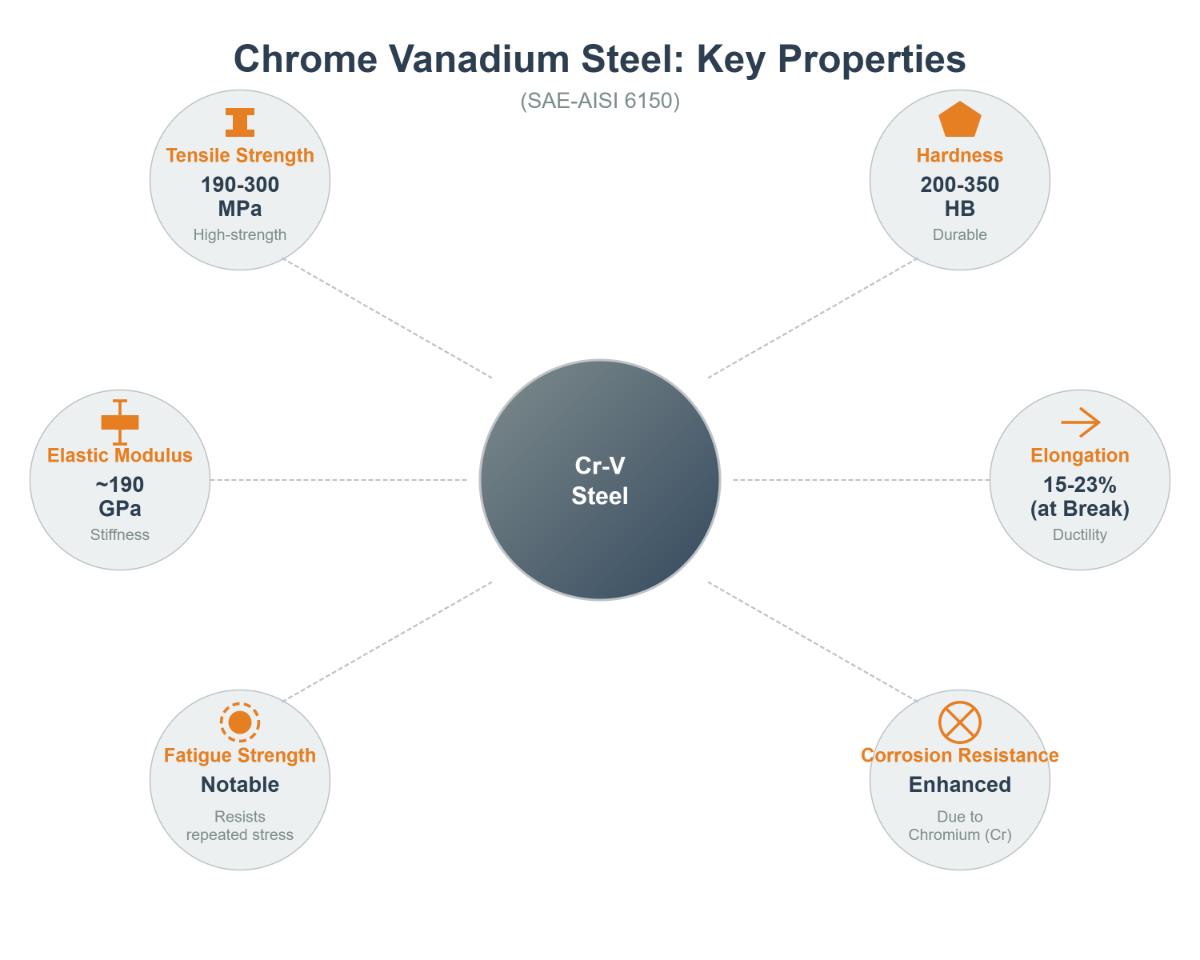

Chrome vanadium steel, specifically grades such as SAE-AISI 6150, exhibits several key mechanical properties that make it suitable for demanding applications. Its tensile strength typically falls within the range of high-strength alloys, varying from 190 to 300 MPa, depending on the specific treatment and composition. The hardness, measured on the Brinell scale, ranges from 200 to 350, contributing to its durability. The elastic modulus, which measures the material’s stiffness, is approximately 190 GPa, while elongation at break ranges from 15 to 23%, indicating good ductility. Additionally, chrome vanadium steel has notable fatigue strength, making it ideal for applications requiring repeated stress. Enhanced corrosion resistance due to chromium content further extends its usability in various environments.

How does the composition of chrome vanadium steel affect its properties?

The composition of chrome vanadium steel significantly affects its properties due to the specific elements involved. Carbon, typically around 0.50%, enhances hardness and strength. Manganese, ranging from 0.70% to 0.90%, improves hardenability and strength. Silicon, about 0.30%, contributes to strength and oxidation resistance. Chromium, between 0.80% and 1.10%, provides corrosion resistance and high hardness by forming a protective oxide layer. Vanadium, making up approximately 0.18%, increases wear resistance and hardness by forming hard carbides.

These elements collectively result in high strength and toughness, corrosion and oxidation resistance, wear and fatigue resistance, thermal stability, and good elasticity and flexibility. Consequently, chrome vanadium steel is suitable for demanding applications such as automotive components, aerospace fasteners, tools, springs, and bearings, where durability and resistance to harsh conditions are essential.

What are the common uses of chrome vanadium steel?

Chrome vanadium steel (Cr-V) is widely used in various applications due to its excellent mechanical properties, including high tensile strength, wear resistance, and durability. One of the most common uses of chrome vanadium steel is in the production of hand tools. This includes professional-grade tools such as wrenches, sockets, ratchets, pliers, and screwdrivers, which benefit from the alloy’s ability to resist rounding, cracking, and deformation under torque and repetitive use.

In the automotive industry, chrome vanadium steel is utilized for components that endure high loads and cyclic stresses, such as crankshafts, camshafts, gears, axles, and suspension springs. These components leverage the alloy’s fatigue resistance and ability to maintain structural integrity under dynamic conditions.

Additionally, chrome vanadium steel is employed in industrial machinery for high-stress fasteners, punch and die sets, and hydraulic system parts, where precision and resistance to deformation are crucial. This makes Cr-V steel a preferred material for applications requiring both strength and durability in demanding environments.

How does chrome vanadium steel compare to other materials?

Chrome Vanadium Steel (Cr-V) stands out compared to other materials due to its unique combination of properties derived from its composition. It contains iron, carbon, chromium, and vanadium, which together provide high hardness and strength. The vanadium forms hard carbides, significantly enhancing wear resistance, making it more durable under friction compared to regular carbon steel. Additionally, the chromium content provides a protective oxide layer, offering good corrosion resistance, although not as high as stainless steel, which contains more chromium.

Thermally, Cr-V steel maintains its mechanical integrity at high temperatures better than many other alloy steels, making it suitable for automotive and aerospace applications. Its elasticity and toughness, contributed by silicon and vanadium, allow it to flex and absorb shocks without permanent deformation, which is advantageous for hand tools and springs.

What standards does chrome vanadium steel comply with?

Chrome vanadium steel complies with several standards that ensure its quality and performance for various industrial applications. Key standards include:

- SAE-AISI 6000-Series Steel Grades: Chrome vanadium steel is typically categorized under the SAE 6000-series, with a common example being SAE-AISI 6150 (G61500). This standard specifies the chemical composition, including carbon (approx. 0.50%), chromium (0.80–1.10%), vanadium (approx. 0.18%), manganese (0.70–0.90%), and silicon (0.30%). It also defines mechanical properties such as Brinell hardness and elastic modulus.

- ASTM A231/A231M-18: This standard covers chromium-vanadium alloy steel spring wire used for springs operating at moderately elevated temperatures. It specifies requirements for chemical composition, mechanical properties (including tensile strength and wrap tests), and metallurgical quality (including surface condition and decarburization).

Compliance with these standards ensures that chrome vanadium steel maintains the necessary hardness, toughness, and corrosion resistance for demanding applications like hand tools and springs.

How is the market trend for chrome vanadium steel evolving?

The market trend for chrome vanadium steel is evolving positively, driven by several key factors. The automotive and aerospace industries, which require high-strength, corrosion-resistant materials, are significantly increasing their demand for CRV steel. Technological advancements in manufacturing processes have made CRV steel more accessible and cost-effective, further boosting its adoption across various applications. Additionally, sustainability concerns are favoring materials like CRV steel due to their durability and long lifespan, reducing the need for frequent replacements and minimizing waste. As discussed earlier, chrome vanadium steel’s balanced combination of strength, durability, and resistance properties makes it a crucial material in modern manufacturing, positioning it well for continued growth and market adoption.