Have you ever marveled at the seamless joints in metal structures and wondered how they were made? Spot welding, a fascinating and essential technique in metalworking and manufacturing, is the answer. This guide is tailored for beginners eager to dive into the world of spot welding and master its techniques step by step. From understanding what spot welding is and how it works, to learning the intricacies of the resistance welding process, this comprehensive resource will equip you with the knowledge and skills needed to excel. You’ll discover the tools and equipment required, detailed procedures for spot welding, and essential safety precautions. Ready to start your journey into spot welding? Let’s explore the basics and beyond, ensuring you gain the confidence to create strong and precise welds.

Introduction to Spot Welding

Spot Welding

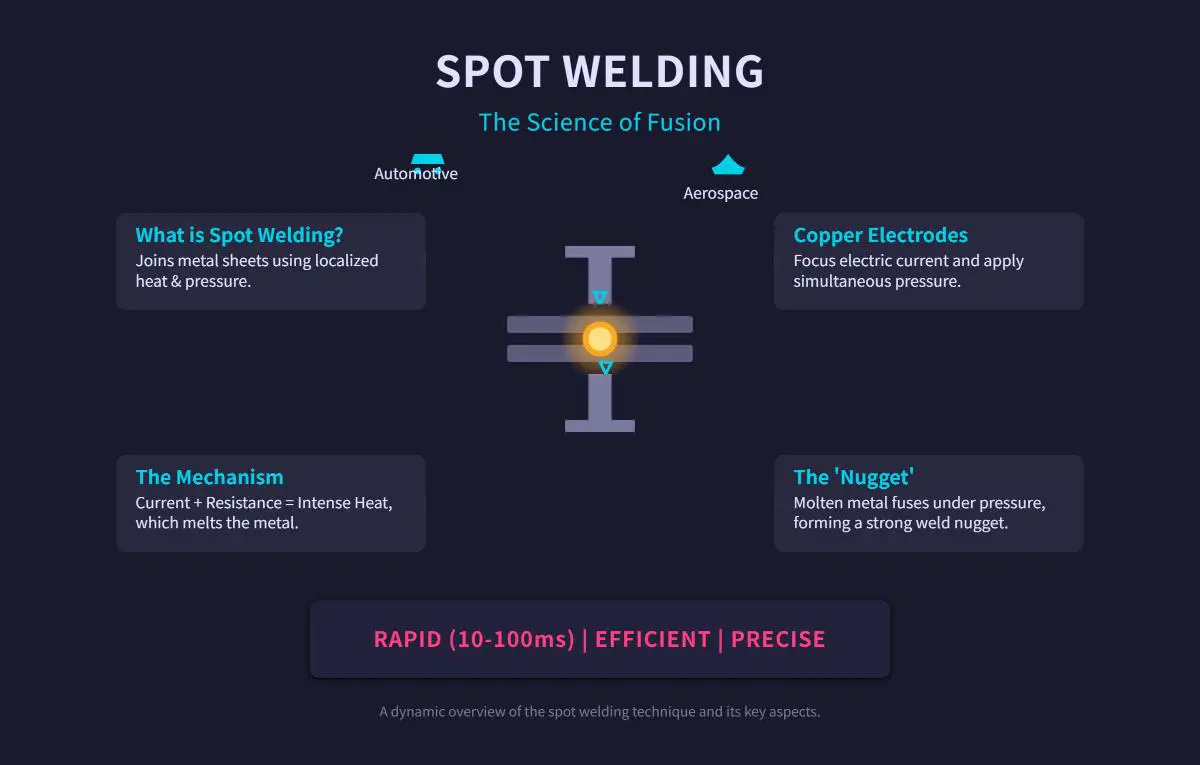

Spot welding is a technique used to join metal sheets by applying pressure and heat from an electric current. It is a type of resistance welding that is widely utilized in various industries due to its efficiency, speed, and cost-effectiveness.

How Does Spot Welding Work?

Spot welding works by passing an electric current through the metal sheets, which generates heat due to the metal’s resistance, causing it to melt and fuse at specific points called weld nuggets.

Key Components

- Electrodes: Electrodes, usually made from copper alloys, apply pressure and conduct the electric current through the metal sheets.

- Pressure: Pressure is adjusted based on the metal’s thickness and type to ensure the sheets are held firmly together during welding.

- Electric Current: A high current is passed through the electrodes, generating the necessary heat to melt the metal and form a strong weld nugget.

Importance of Spot Welding in Manufacturing and Metalworking

Spot welding is valued for its efficiency, cost-effectiveness, and strength. It is quick, can be automated for mass production, doesn’t require filler materials, and produces strong, reliable welds essential in industries like automotive and aerospace.

Understanding Resistance Welding

Resistance welding is a process used to join metal pieces using heat generated from electrical resistance, eliminating the need for additional materials. The process involves squeezing the metal pieces together between electrodes and passing a high electric current through the contact area. The electrical resistance at the interface generates intense heat, causing the metal to melt locally and form a fused joint known as a weld nugget.

Basic Principles of Resistance Welding

Heat Generation and Pressure Application

When an electric current flows through the metals, resistance to this current—particularly at the interface where the metals meet—creates heat. This heat raises the temperature enough to melt the metal locally, facilitating the welding process. Electrodes apply mechanical pressure to hold the metal pieces firmly together. This pressure ensures good electrical contact and controls the shape and size of the weld. The pressure must be carefully adjusted based on the type and thickness of the metals being welded.

Weld Nugget Formation

The molten metal flows together to create a weld nugget, which solidifies into a strong bond once cooled. When the current stops and the molten metal cools, a strong metallic bond is created. The solidified weld nugget ensures the durability and strength of the joint.

Differences Between Spot Welding and Other Types of Resistance Welding

Spot welding, a type of resistance welding, joins metal sheets at specific points rather than continuously. Unlike other types of resistance welding, such as seam welding or projection welding, spot welding focuses on creating weld nuggets at particular spots rather than continuous or patterned welds.

Role of Electric Current in Resistance Welding

The electric current plays a crucial role in resistance welding by generating the necessary heat through electrical resistance. The amount of current, along with the duration it flows, determines the quality and characteristics of the weld. Controlling these parameters ensures optimal welding results and minimizes defects.

Key Parameters in Resistance Welding

Weld Tip Force (Squeeze Force)

The pressure applied by the electrodes is known as weld tip force or squeeze force. It ensures tight contact between the metal pieces, and the duration of this pressure application, called squeeze time, is critical for preparing the metals before welding.

Weld Current

The weld current refers to the amount of electrical current passed through the workpieces. Higher current increases heat generation, but it must be balanced to avoid defects such as excessive melting or burn-through.

Weld Time

Weld time is the duration during which the current flows. This parameter controls the size of the weld nugget and the penetration depth. Optimizing weld time based on metal thickness and type is essential for achieving strong welds.

Hold Time

Hold time is the period after the current stops during which the electrodes maintain pressure on the weld nugget. This allows the molten metal to solidify and harden, ensuring joint strength and preventing cracks.

Weld Tip Size and Cooling

The size of the electrode tip affects the weld area, and water cooling keeps the electrodes from overheating. Proper cooling is necessary to maintain electrode efficiency and prolong their lifespan.

Advantages of Resistance Welding

Resistance welding is quick, clean, and energy-efficient, making it ideal for mass production without the need for filler materials or pre-drilled holes. The process can be automated for consistent and repeatable results, providing a reliable method for joining metals in various industrial applications.

Step-by-Step Spot Welding Process

Required Tools and Equipment

Make sure you have all the necessary tools and equipment before starting the spot welding process:

- Spot Welder: A machine equipped with copper alloy electrodes for conducting electrical current.

- Protective Gear: Safety glasses, welding gloves, and a helmet to shield yourself from sparks and electrical shock.

- Metal Sheets: The materials you intend to join, typically thin metal sheets.

- Cleaning Supplies: Wire brushes or sandpaper to clean the metal surfaces.

Preparing Metal Sheets for Spot Welding

Proper preparation of metal sheets is crucial for successful spot welding:

- Cleaning: Remove any dirt, oil, or coatings from the metal sheets using a wire brush or sandpaper. Clean surfaces ensure better electrical contact and weld quality.

- Alignment: Align the metal sheets precisely where the weld is to be made, ensuring they are flat and in close contact to avoid gaps.

Detailed Steps for Performing Spot Welding

Setting Up the Equipment

- Position the Electrodes: Place the metal sheets between the spot welder’s electrodes. Ensure the electrodes are aligned correctly to apply even pressure on the sheets.

- Adjust the Pressure: Set the pressure according to the thickness and type of metal. This ensures the sheets are held firmly during the welding process.

Applying the Electric Current

- Initiate the Weld: Activate the spot welder to send an electrical pulse through the electrodes to the weld area.

- Heat Generation: The resistance of the metal sheets to the electric current generates heat, melting the metal at the contact points.

- Weld Nugget Formation: The melted metal forms a weld nugget, creating a strong bond as it cools and solidifies.

Cooling and Solidification

- Maintain Pressure: Hold the electrodes in place briefly after stopping the current. This helps the weld nugget cool and solidify properly.

- Release the Pressure: Once the metal has cooled, release the pressure and remove the welded sheets from the machine.

Safety Precautions and Best Practices

- Wear Protective Gear: Always use safety glasses, gloves, and a welding helmet to protect yourself from sparks and heat.

- Work in a Ventilated Area: Ensure good ventilation to avoid inhaling fumes generated during the welding process.

- Regular Maintenance: Keep the electrodes clean and replace them when worn to maintain effective welding performance.

- Practice: Start with simple projects to gain experience and confidence in handling the spot welder.

Information on Metal Sheets and Metal Fusion

- Metal Types: Spot welding works best on thin metal sheets, such as steel and aluminum.

- Fusion Process: The welding process involves the fusion of metals at specific points, forming a robust joint without the need for additional filler materials.

Common Applications of Spot Welding

Automotive Industry Applications

The automotive industry extensively uses spot welding because it efficiently produces strong, reliable welds. It is the primary method for joining sheet metal parts in car bodies, doors, and truck bodies. The process is highly suitable for automation, allowing manufacturers to integrate spot welders into robotic assembly lines. This automation ensures consistent weld quality, structural integrity, and safety in vehicles.

Aerospace and Railcar Manufacturing

This technique is crucial for joining thin sheet metals and components that demand precision and strength in the aerospace and railcar industries. Spot welding is particularly valued for its ability to create strong, clean joints without adding excessive weight, which is vital for safety-critical parts in these sectors.

Manufacturing and Fabrication

General manufacturing and metal fabrication industries rely on spot welding for various products, including metal buckets, wire mesh, and custom assemblies. Spot welding is ideal for applications where repeated, consistent welds are needed on thin sheets or wire cloths.

Electronics Industry Applications

Spot welding is widely used in electronics manufacturing to assemble components such as circuit boards, gas sensors, and solar panels. The precision of spot welding enables it to join specific points without harming sensitive electrical components, making it suitable for intricate and compact assemblies.

Battery Production

A key application of spot welding is in battery manufacturing, especially for assembling nickel–cadmium, nickel–metal hydride, and lithium-ion batteries. Spot welding connects battery cells by attaching thin metal straps to their terminals, creating a reliable electrical connection without overheating the battery components, unlike traditional soldering.

Orthodontics and Medical Uses

Spot welding is also used in orthodontics for resizing metal molar bands and other dental appliances. This application requires precise, small welds that are strong yet minimally invasive, ensuring the functionality and comfort of dental devices.

Papermaking and Other Specialized Industries

Spot welding finds applications in papermaking machinery, screen cloth/wire cloth production, and truck body assembly. It adapts to the specific material and design requirements of each industry, providing strong and durable joints necessary for specialized equipment and products.

How to Master Spot Welding Techniques

Introduction to Mastering Spot Welding Techniques

Mastering spot welding involves understanding the fundamental principles, proper preparation, precise execution, and consistent practice. This guide will help beginners get started with essential tips and techniques to become proficient in spot welding.

Key Principles of Spot Welding

To master spot welding, it’s crucial to grasp the basic principles:

- Heat Generation: Welding heat is produced by the electrical resistance of the metal sheets when a high electric current passes through them.

- Pressure Application: Copper alloy electrodes apply pressure to the metal sheets, ensuring a solid joint.

- Weld Nugget Formation: The heat melts the metal at the point of contact, forming a weld nugget that solidifies into a strong bond.

Step-by-Step Guide to Spot Welding

Safety First

- Wear Protective Gear: Always wear a welding helmet, gloves, and safety glasses to protect yourself from heat, sparks, and UV radiation.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

Preparation of Materials

- Clean the Metal Surfaces: Use solvents, wire brushes, or sandpaper to remove rust, dirt, oil, or grease. Clean surfaces ensure better weld quality.

- Fit the Metal Sheets: Ensure the sheets fit tightly with no gaps in the overlap area for a solid joint.

Setup and Alignment

- Adjust the welder settings according to the metal type and thickness, and then position the metal sheets between the electrodes, clamping them securely.

- Align the Electrodes: Ensure the electrode tips are directly opposite each other and centered on the intended weld spot.

Welding Parameters

- Set the welding parameters, including current magnitude, weld time, and electrode pressure, based on the type and thickness of the metal.

- Perform Test Welds: Beginners should perform test welds to fine-tune the settings and ensure optimal weld quality.

Welding Process

- Apply Pressure: Press the electrodes onto the metal sheets.

- Activate the Weld: Trigger the welder to apply the current and maintain pressure until the weld cools and solidifies.

- Consistent Welds: Ensure each spot weld is consistent in size and spacing along the joint line.

Inspecting the Welds

- Visual Inspection: Check each weld for uniformity and the absence of defects.

- Strength Test: Gently pull the metal sheets to confirm a strong joint.

Electrode Maintenance

- Clean the Electrodes: Regularly clean the electrode tips to remove oxidation, dirt, and debris.

- Reshape the Tips: If the electrodes become deformed, reshape them to maintain consistent contact and pressure.

Expert Tips for Effective Spot Welding

- Consistent Pressure and Timing: Apply consistent pressure and timing for each weld to avoid weak spots.

- Avoid applying too much pressure, as it can deform the metal or electrodes.

- Maintain Equipment: Keep the welding machine and electrodes clean and well-maintained.

- Understand Metal Properties: Different metals require different settings; adjust accordingly.

- Practice on Scrap Pieces: Develop a feel for timing and pressure by practicing on scrap pieces before working on final parts.

Advanced Spot Welding Techniques

Pulse Spot Welding

Pulse spot welding uses short bursts of high electrical current to join materials effectively. This technique is particularly beneficial for high-strength steels, as it enhances joint strength without significantly increasing weld time. The short pulses help manage the heat input, reducing the risk of overheating and potential damage to the materials being welded.

Single-Sided Spot Welding

Single-sided spot welding allows for the creation of weld nuggets from just one side of the materials. This technique is especially useful for welding closed-section structures where access to both sides is limited, as it ensures stable and strong welds by carefully controlling the electrode force and the current. By managing these parameters effectively, it is ideal for applications where traditional two-sided welding is not feasible.

Temper Energization

Temper energization involves applying an additional current pulse after the initial welding and cooling phase. This technique improves the toughness and strength of the welded joints, especially in high-strength steels, by refining the microstructure of the weld nugget. The extra current helps create a more durable and resilient joint.

Staged Current Application

Staged current application is a method where the current values are gradually decreased during the pre-energization phase. This approach efficiently generates larger weld nuggets while minimizing the occurrence of spatter, particularly in zinc-coated steels. By controlling the current in stages, the heat input is managed more effectively, leading to cleaner and stronger welds.

Friction Spot Welding

Friction spot welding is a solid-state welding process that uses frictional heat generated by mechanical work to join materials. This technique is especially suitable for lightweight alloys like aluminum. The process involves rotating a tool against the workpieces, generating heat through friction, which softens the material and allows it to flow together, creating a strong joint without a keyhole.

Laser Impact Spot Welding

Laser impact spot welding utilizes laser-induced shockwaves to join materials. A laser pulse generates a shockwave that accelerates a flyer plate towards a base plate, creating a cold, low-energy spot weld, which is effective for joining similar or dissimilar metals with precision and minimal thermal distortion. Laser impact spot welding is ideal for applications requiring high precision and minimal heat-affected zones.

Medium Frequency Direct Current (MFDC) Spot Welding

MFDC spot welding combines medium frequency current (typically 1000 to 10000 Hz) with direct current to enhance welding efficiency and control. This technique provides better control over the welding parameters, such as current, time, and pressure, resulting in higher quality welds with reduced spatter. The use of advanced electrodes and welding tips further improves the precision and durability of the welds.

Applications and Advantages

Advanced spot welding techniques are widely used in various industries, including automotive, aerospace, and consumer goods manufacturing. These methods offer significant advantages, such as stronger and more durable joints, increased productivity, and cost-effectiveness compared to traditional welding methods. By employing these advanced techniques, manufacturers can achieve higher quality welds, ensuring the structural integrity and reliability of their products.

Safety and Best Practices

When working with advanced spot welding techniques, it is crucial to follow safety protocols. Always use appropriate protective gear, such as gloves, safety glasses, and a welding helmet, to prevent injuries. Ensure that the welding surfaces are clean and dry to enhance conductivity and weld quality. Regular maintenance of welding equipment is essential to maintain optimal performance and safety.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is spot welding and how does it work?

Spot welding, also known as resistance spot welding, is a method used to join two or more metal sheets by applying pressure and electric current to a specific area. The process involves using copper alloy electrodes to focus the electric current onto a small spot, creating heat due to the metal’s internal resistance. This heat melts the metal at the contact points, and the electrodes simultaneously apply pressure to hold the metal sheets together. As the molten metal solidifies under pressure, it forms a small, round weld known as a “nugget.” This quick and efficient process, typically taking between 10 to 100 milliseconds, is widely used in industries such as automotive and aerospace for its precision and efficiency in welding sheet metal products.

How to master spot welding techniques?

To master spot welding techniques, start by understanding the basics of spot welding, which involves using electrical resistance to generate heat and join metal sheets. Begin with acquiring the essential equipment, including a spot welder and safety gear such as a welding helmet, gloves, and safety glasses.

Next, prepare the metal surfaces by cleaning them thoroughly to remove any dirt, oil, or corrosion. Align and clamp the metal sheets together properly. Set up the spot welder by adjusting its settings based on the metal thickness.

When performing spot welds, position the electrodes correctly on the metal sheets, apply pressure using the welder’s handles, and trigger the welding process. Hold the pressure until the weld cools and solidifies.

Regular practice is crucial to improving your technique. Consider formal training to learn proper methods and safety protocols. Experiment with different materials to understand how variations in thickness and type affect weld quality. By following these steps and practicing consistently, you can master spot welding and achieve high-quality welds.

What tools and equipment are needed for spot welding?

For spot welding, the essential tools and equipment include:

- Spot Welding Machine: The main device used to perform spot welding, available in portable, bench, pedestal, and robotic types, each suited for different scales and precision of work.

- Spot Welding Gun: A hand-held tool that applies pressure and electrical current to the metal pieces, facilitating the weld. These guns often come with interchangeable welding bits for various applications.

- Welding Clamps: Used to hold metal sheets firmly in place during welding, ensuring accuracy and preventing movement.

- Welding Table or Cart: Provides a stable and clean surface for welding projects, aiding in the positioning and safety of the work.

- Welding Pliers: Multipurpose tools for cutting wire, removing weld splatter, installing tips and nozzles, and cleaning weld areas.

- Cleaning Tools: Includes a steel wire brush for cleaning metal surfaces, a chipping hammer for removing spatter and slag, and a metal file for smoothing rough edges.

- Consumables and Accessories: Such as welding tips and inserts that conduct current to the weld spot, weld checkers, and water chillers to monitor and maintain the welding process.

- Spot Weld Cutters and Drills: Specialized tools used to separate welded parts without causing damage, essential for repair and bodywork tasks.

These tools and equipment provide a solid foundation for beginners to effectively and safely learn and perform spot welding.

What are the safety precautions for spot welding?

Spot welding is a widely used technique in metalworking, but it involves several safety risks that must be managed to ensure a safe working environment. Key safety precautions include:

- Avoiding Pinch Point Hazards: Ensure operators keep their hands away from the moving electrodes to prevent injuries. Use tooling or hold parts securely to avoid direct contact.

- Protecting Against Sparks and Molten Metal: Wear protective clothing, including safety glasses with side shields, to guard against burns from expelled sparks or molten metal. Keep the work area free of flammable materials.

- Proper Machine Grounding: Regularly check and secure the grounding of the welding machine to prevent electrical shocks.

- Mitigating Electromagnetic Fields: Use shielding and position the machine to minimize exposure to strong electromagnetic fields.

- Using Proper Foot Switches: Install shrouds on foot switches to prevent accidental activation and potential injuries.

- Following Operational Instructions: Adhere to the safety precautions and instructions in the owner’s manual to avoid misuse and accidents.

By following these precautions, beginners can safely perform spot welding and minimize risks in their work environment.

What are the common applications of spot welding in various industries?

Spot welding is a versatile and widely used welding technique across various industries due to its efficiency and precision. In the automotive industry, it is crucial for assembling car and truck bodies, ensuring the structural integrity and durability of vehicles. The aerospace industry utilizes spot welding for creating lightweight yet strong structural components in aircraft, where precision is vital. In electronics and appliances, spot welding is essential for manufacturing batteries and metal casings, ensuring efficient energy transfer and durability.

In metal fabrication, spot welding is used to assemble various metal products, from furniture to machinery, providing reliable and efficient welds. The construction industry benefits from spot welding for automating the welding of lightweight structural elements, enhancing the speed and quality of construction projects. Additionally, the rail and defense industries rely on spot welding for assembling rail car components and manufacturing military equipment, where strength and reliability are critical.

How does resistance welding differ from other welding techniques?

Resistance welding is a process that involves applying force and electrical current to heat and melt metal workpieces. Unlike other welding techniques, such as arc welding, MIG welding, and stud welding, resistance welding relies on the electrical resistance of the metal to generate heat at the joint. This method typically uses electrodes to apply pressure and deliver the current, causing the metal to fuse together without the need for additional filler materials.

In comparison, arc welding creates an electrical arc between an electrode and the metal to melt and join workpieces, offering flexibility in material thickness and joint design. MIG welding uses a continuous wire feed and shielding gas for cleaner and more precise welds, while stud welding heats and joins materials in a single step without continuous current flow or pressure during the process.

Resistance welding is commonly used for joining sheet metals in applications like spot welding, which is essential for industries such as automotive manufacturing. Understanding these differences helps beginners grasp the unique aspects and applications of resistance welding in metalworking.