Imagine a world without the gleaming skyscrapers that define our cityscapes or the robust infrastructure that powers our daily lives. These modern marvels owe their existence to the ancient and ever-evolving science of metallurgy. As an intermediate learner, you’re stepping into a realm where the properties and behaviors of metals can be manipulated to create everything from delicate jewelry to massive bridges. But what exactly is metallurgy, and how are these versatile metal alloys crafted? This comprehensive guide will delve deep into the fascinating processes that transform raw ores into essential components of our industrial world. Get ready to explore the intricacies of metallurgical techniques, discover the secrets behind alloy creation, and understand the pivotal role these materials play in advancing technology and sustainability. Are you prepared to unlock the mysteries of metals and their boundless potential? Let’s embark on this technical deep dive together.

Introduction to Metallurgy

What is Metallurgy?

Metallurgy is the study and application of the properties and processes involving metals. It involves understanding the physical and chemical behavior of metallic elements and their mixtures, known as alloys. This field encompasses various processes such as extraction, refining, and processing of metals to create materials with specific properties for diverse applications.

Historical Background of Metallurgy

Metallurgy has a rich history dating back thousands of years. Early civilizations, such as the Egyptians and Sumerians, began using metals like copper and gold for tools, weapons, and ornaments. The discovery of smelting techniques allowed ancient metallurgists to extract metals from ores, leading to the development of bronze and iron. The Iron Age marked significant advancements as iron became the primary material for construction and warfare, laying the foundation for modern metallurgical practices.

Importance and Applications in Modern Industries

Metallurgy plays a pivotal role in modern industries. It is essential for the production of various metal products used in construction, automotive, aerospace, electronics, and healthcare. The ability to design and produce metals with specific properties, such as strength, flexibility, resistance to rust, and ability to conduct electricity, is vital for meeting the demands of these industries.

For example, in the automotive industry, the use of aluminum in car frames helps reduce the vehicle’s weight, improving fuel efficiency and performance. In construction, steel and aluminum are widely used in building structures and infrastructure due to their strength and durability. In aerospace, advanced alloys with high strength-to-weight ratios are critical for aircraft and spacecraft components. In electronics, copper and gold are used in electrical wiring and components for their excellent conductivity. In healthcare, biocompatible metals, like titanium, are used in medical implants and devices.

Metallurgy also contributes to advancements in sustainable practices, such as recycling and the development of eco-friendly materials. Additionally, the field continues to evolve with innovations in additive manufacturing (3D printing) and the design of new alloys for emerging technologies.

Metallurgy Basics

Fundamental Concepts in Metallurgy

Metallurgy is the science and technology of metals, focusing on their extraction, processing, and properties. This section explores the fundamental concepts that underpin metallurgical science.

Metallurgical Principles

Metallurgy is grounded in several core principles that define how metals behave and how they can be manipulated:

- Crystallography: The study of crystal structures and their influence on metal properties. Metals are typically crystalline solids, and their mechanical properties are influenced by the arrangement of atoms within the crystal lattice.

- Phase Diagrams: Graphical representations showing the stability of different phases (solid, liquid, and gas) of a metal or alloy at various temperatures and pressures, which are crucial for controlling the microstructure and properties of metals during processing.

- Thermodynamics: The study of energy and its transformations. In metallurgy, thermodynamics helps predict the feasibility of reactions and the energy required for processes such as smelting and refining.

- Kinetics: Kinetics studies the rates of reactions, which is important in metallurgy for understanding the speed of processes like alloying and heat treatment.

Key Metallurgical Terms and Definitions

Several key terms are essential for understanding metallurgy:

- Alloy: A mixture of two or more elements, with at least one being a metal, designed to enhance properties such as strength or corrosion resistance.

- Smelting: Extracting metal from ore by heating and melting, a fundamental step in metal production.

- Annealing: A heat treatment process that alters the microstructure of a metal to improve its ductility and reduce hardness. Annealing involves heating the metal to a specific temperature and then cooling it slowly.

- Quenching: Rapid cooling of a metal from a high temperature to achieve desired properties, such as increased hardness. Quenching is often followed by tempering to balance hardness and toughness.

- Tempering: A heat treatment process applied to quenched metals to improve their toughness. Tempering involves reheating the metal to a lower temperature and then cooling it.

Introduction to Metallurgical Processes

Metallurgical processes are techniques used to extract, refine, and shape metals, essential for producing metals with specific properties for various applications.

Extraction and Refining

- Mining: The process of extracting ores from the earth. Mining is the first step in obtaining metals.

- Ore Dressing: The process of separating valuable minerals from the gangue (worthless material). Techniques such as flotation and magnetic separation are used.

- Smelting: Extracting metal from ore often involves reduction reactions where the ore is heated with a reducing agent, such as carbon, to produce the metal.

- Electrolysis: A refining process where an electric current is passed through a solution containing the metal ions, causing the metal to deposit onto an electrode.

Forming and Shaping

- Casting: Pouring molten metal into a mold to create a desired shape, commonly used for complex forms.

- Forging: Shaping metal using compressive forces, usually with a hammer or press, improving mechanical properties by refining the grain structure.

- Rolling: Passing metal through rollers to reduce its thickness and make it uniform, used to produce sheets and plates.

- Extrusion: Forcing metal through a die to create long objects with a fixed cross-sectional profile, such as rods and tubes.

Heat Treatment

Heat treatment processes are used to alter the microstructure of metals to achieve desired mechanical properties:

- Annealing: Enhances ductility and reduces hardness.

- Quenching: Increases hardness by rapid cooling.

- Tempering: Balances hardness and toughness after quenching.

Understanding these fundamental concepts and processes is crucial for anyone involved in metallurgy, whether in academic research or industrial applications.

Understanding Metal Alloys

Definition and Composition of Metal Alloys

Metal alloys are made by combining two or more elements, where at least one element is a metal. The primary purpose of creating alloys is to enhance the properties of pure metals, making them more suitable for various applications. The base metal, typically the predominant element, is mixed with other metals or non-metals to form an alloy. For example, aluminum alloys are made by adding elements such as copper, magnesium, and zinc to aluminum. These elements mix with aluminum to form a uniform material when it cools.

Properties of Metal Alloys

Alloys are designed to have better properties than pure metals. These key properties include:

Hardness

Alloys tend to be harder than pure metals due to the disruption of the metal’s crystalline structure by different-sized atoms. This disruption makes it more difficult for the atoms to slide past each other, increasing the material’s hardness and wear resistance.

Strength

The addition of other elements can significantly increase the strength of the base metal. This enhancement allows the alloy to withstand greater stress and load without deforming. For example, steel, an alloy of iron and carbon, is much stronger than pure iron.

Corrosion Resistance

Some alloys are specifically created to resist corrosion. Stainless steel, for instance, contains chromium, which forms a passive oxide layer on the surface, preventing further oxidation and corrosion. This property is crucial for applications exposed to harsh environments.

Ductility and Malleability

Alloys can also be designed to improve ductility and malleability, allowing them to be shaped and formed more easily without breaking. This is essential for manufacturing processes that require extensive deformation of the material.

Common Types of Metal Alloys

Various alloys are tailored for specific applications based on their unique properties. Some of the most common types include:

Stainless Steel

Stainless steel is an alloy of iron, chromium, and sometimes nickel and molybdenum. It is renowned for its excellent corrosion resistance, strength, and aesthetic appearance. Stainless steel is widely used in construction, medical devices, and kitchenware.

Aluminum Alloys

Aluminum alloys are lightweight, strong, and highly resistant to corrosion. They are commonly used in the aerospace and automotive industries to reduce weight and improve fuel efficiency. Key elements added to aluminum include copper, magnesium, and silicon.

Nickel-Base Alloys

Nickel-base alloys are known for their exceptional resistance to high temperatures and corrosion. They are used in demanding environments such as gas turbines, jet engines, and chemical processing equipment.

How Metal Alloys are Made

Making metal alloys involves several steps to get the right properties:

Melting and Mixing

The base metal and additional elements are melted together in a furnace. This step ensures thorough mixing and homogenization of the components. The temperature and atmosphere within the furnace are carefully controlled to prevent contamination and achieve the desired chemical composition.

Casting

The molten alloy is then poured into molds to form ingots or other desired shapes. This process solidifies the alloy, and the cooling rate can affect the microstructure and properties of the final product.

Heat Treatment

Heat treatment processes such as annealing, quenching, and tempering are often applied to modify the microstructure and enhance the mechanical properties of the alloy. For example, quenching and tempering can increase the hardness and toughness of steel alloys.

Applications of Metal Alloys

Metal alloys are integral to numerous industries due to their enhanced properties. Some notable applications include:

Construction and Architecture

Alloys like stainless steel and structural steel are essential for constructing buildings, bridges, and infrastructure due to their strength and durability.

Transportation

Aluminum alloys are used extensively in the automotive and aerospace industries to manufacture lightweight, high-strength components, improving fuel efficiency and performance.

Industrial Equipment

Nickel-base alloys are used in high-temperature and corrosive environments, such as chemical plants and power generation facilities, due to their superior resistance to degradation.

Manufacturing Processes in Metallurgy

Metallurgical manufacturing processes convert raw metals into usable products with specific properties. These processes involve various techniques, each suited for specific applications and metal types. The primary manufacturing processes in metallurgy include smelting and refining, casting, forming, machining, and powder metallurgy.

Smelting and Refining Techniques

Smelting and refining are fundamental metallurgical processes used to extract and purify metals from their ores.

- Smelting: This process involves several key steps:

- Roasting: Heating the ore in the presence of oxygen to remove sulfur or other volatile impurities.

- Reduction: Using a reducing agent, such as carbon, to convert metal oxides into pure metal.

- Fluxing: Adding substances to remove impurities by forming a slag that can be easily separated from the molten metal.

- Refining: Once the metal is extracted, it is further purified through various refining techniques:

- Electrolysis: An electrochemical process where metal ions are reduced to pure metal at the cathode, while impurities are left behind or oxidized at the anode.

- Zone Refining: A method used to purify metals with high melting points, such as silicon, by moving a molten zone through a solid metal rod to segregate impurities.

Casting and Forming Methods

Casting

Casting involves pouring molten metal into a mold where it solidifies into the desired shape. Key casting techniques include:

- Sand Casting: A versatile and cost-effective method using sand molds, suitable for large and complex shapes.

- Die Casting: Injecting molten metal into steel molds under high pressure, ideal for high-volume production of precise components.

- Investment Casting: Creating intricate parts by encasing wax patterns in ceramic molds, then melting the wax and pouring metal into the cavity.

Forming

Forming processes shape metal through plastic deformation. Major forming techniques include:

- Forging: Using compressive forces to shape metal and improve its mechanical properties. Types include open-die, closed-die, and drop forging.

- Rolling: Passing metal through rollers to reduce thickness and achieve uniformity, commonly used for making sheets and plates.

- Extrusion: Forcing metal through a die to produce long objects with a fixed cross-sectional profile, such as rods and tubes.

Heat Treatment Processes

Heat treatment processes alter the microstructure of metals to achieve specific mechanical properties. Key heat treatment techniques include:

- Annealing: Heating metal to a specific temperature and then cooling it slowly to improve ductility and reduce hardness.

- Quenching: Quenching involves cooling metal quickly from a high temperature to make it harder. This is usually followed by tempering to balance hardness and toughness.

- Tempering: Reheating quenched metal to a lower temperature to balance hardness and toughness.

Advanced Manufacturing Techniques

Additive Manufacturing

Additive manufacturing, also known as 3D printing, builds metal parts layer by layer using technologies such as selective laser melting (SLM) and electron beam melting (EBM). This method allows for the creation of complex geometries that are difficult to achieve with traditional methods.

Powder Metallurgy

Powder metallurgy involves compacting metal powders into a desired shape and then sintering them to form a solid part. This technique is efficient for producing components with complex shapes and controlled porosity. Key processes include:

- Powder Compaction: Pressing metal powders in a die to form a compacted shape.

- Sintering: Heating the compacted powder below its melting point to bond the particles together.

Standards and Safety Compliance in Metallurgy

Adhering to standards and safety regulations is crucial in metallurgical manufacturing to ensure product quality and worker safety. Key standards include:

- Material Safety Standards: Guidelines for handling and processing metals safely.

- Quality Assurance Standards: Protocols for maintaining consistent product quality, such as ISO 9001.

- Environmental Regulations: Compliance with environmental laws to minimize the impact of metallurgical processes on the environment.

Innovative and Sustainable Practices in Metallurgy

Innovative applications of metal alloys are revolutionizing industries by enhancing performance, sustainability, and efficiency. These advancements are driven by the need to meet stringent environmental regulations and the demand for high-performance materials.

Single-step metallurgy, pioneered by the Max Planck Institute, integrates metal extraction, alloying, and processing into a single reactor. This breakthrough reduces energy use by 40% and eliminates CO₂ emissions, significantly contributing to climate-neutral production. By using hydrogen as a reducing agent instead of carbon, critical alloys like Invar can be produced at lower temperatures (around 700°C). This method streamlines the manufacturing process, bypassing intermediate steps and directly converting oxides to alloys, enhancing energy efficiency and reducing environmental impact.

Magnum’s Green High Purity Pig Iron exemplifies sustainable metallurgy. This process uses renewable energy sources like solar and wind power instead of fossil fuels, aligning with global sustainability goals. Biochar replaces coke coal, significantly reducing CO₂ emissions and promoting resource reuse. The HIsmelt technology operates at lower temperatures and pressures, reducing harmful gas emissions while maintaining high purity levels, showcasing a scalable model for eco-friendly iron production.

Metamaterials are engineered with unique properties that enable advancements in lightweight alloys and thermal management. These materials are designed at the molecular level to achieve specific performance characteristics, such as enhanced strength-to-weight ratios and improved thermal conductivity, crucial for aerospace and automotive applications. Additionally, integrating circular economy principles in metallurgy focuses on scrap metal recycling and closed-loop systems, minimizing dependency on raw ore and promoting material reuse, reducing waste, and conserving resources.

The shift towards innovative and sustainable practices in metallurgy is creating new career opportunities. Professionals with expertise in green technologies, advanced manufacturing techniques, and sustainable material science are increasingly in demand. Intermediate learners can benefit from case studies and hands-on experiences that illustrate these practices, such as studying the lifecycle analysis of traditional versus green pig iron methods or simulating hydrogen reduction experiments and biochar-based smelting in lab settings.

Saudi Arabia’s Green Steel Initiative, supported by Magnum’s engineering studies, demonstrates the scalability of renewable-powered metallurgy. This initiative includes logistical optimization and resource mapping to ensure efficient and sustainable production processes. Such efforts highlight the importance of international cooperation in setting sustainable metallurgy standards and promoting energy-efficient smelting and material reuse.

The SMAM 2025 proceedings emphasize the need for international collaboration to establish sustainable metallurgy standards. Focus areas include energy-efficient smelting techniques and material reuse practices, ensuring that the industry aligns with global environmental goals.

Hands-on learning and critical analysis are essential for understanding the trade-offs between process complexity, cost, and emission savings in emerging metallurgical methods. Engaging in practical experiments and evaluating case studies can enhance comprehension and foster innovation in sustainable metallurgy practices.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is metallurgy?

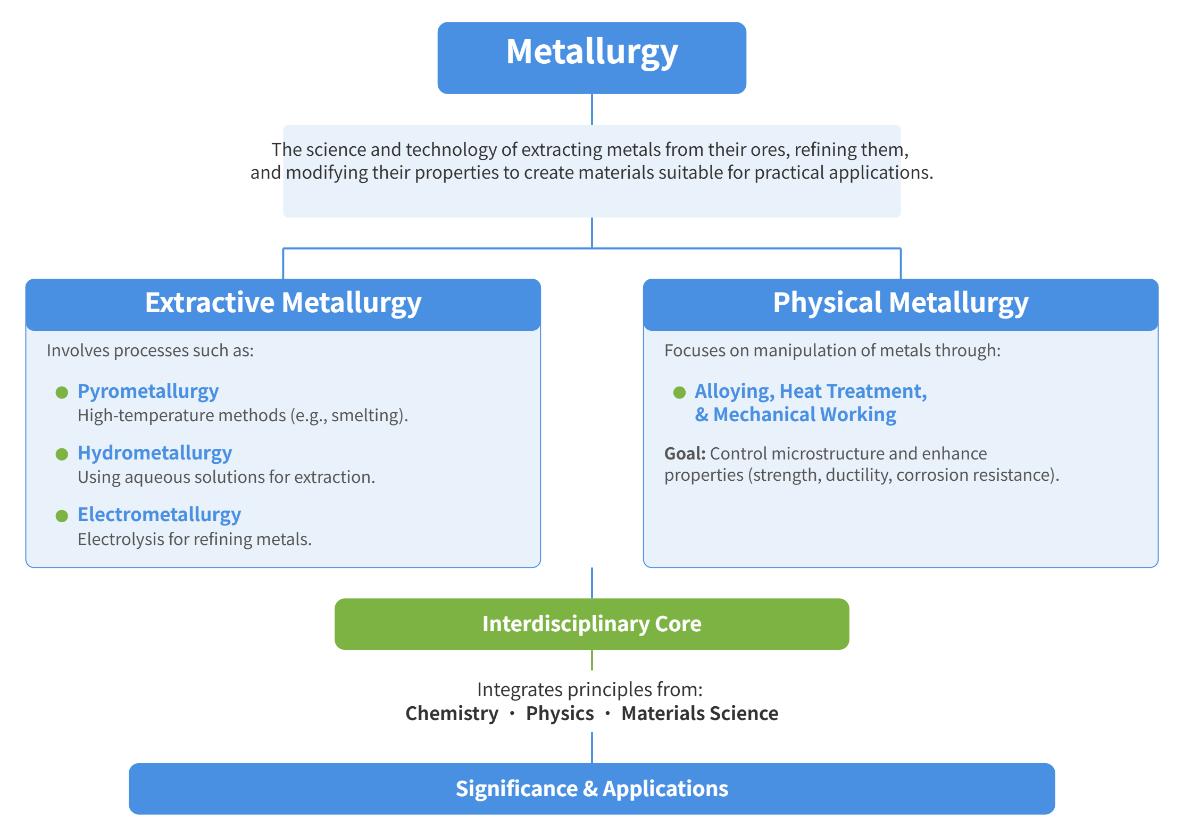

Metallurgy is the science and technology of extracting metals from their ores, refining them, and modifying their properties to create materials suitable for practical applications. It encompasses several key branches:

- Extractive Metallurgy: This involves processes such as pyrometallurgy (high-temperature methods like smelting), hydrometallurgy (using aqueous solutions for extraction), and electrometallurgy (electrolysis for refining metals).

- Physical Metallurgy: Focuses on the manipulation of metals through alloying, heat treatment, and mechanical working to control their microstructure and enhance properties like strength, ductility, and corrosion resistance.

Metallurgy integrates principles from chemistry, physics, and materials science to optimize metal performance in various industries, including aerospace, healthcare, and manufacturing. Understanding metallurgy is crucial for developing advanced materials, improving manufacturing processes, and innovating sustainable practices.

How are metal alloys made?

Metal alloys are made through a series of controlled processes that involve combining different elements to achieve specific material properties. The primary method involves melting the base metal until it reaches a liquid state, allowing for the addition of other elements (solutes) to the molten metal. This ensures uniform mixing and composition. Heating methods such as induction or arc melting are commonly used to achieve the precise temperatures needed.

Once the elements are thoroughly mixed, the molten alloy is shaped through processes like casting, where the liquid metal is poured into molds, or forging, which involves heating and hammering to form the desired shape and improve strength. Rolling and extrusion are other common techniques used to refine the alloy’s form and enhance its mechanical properties.

Quality control measures, including chemical analysis, mechanical testing, and microstructure examination, are crucial to ensure the alloy meets the required specifications. Advanced manufacturing techniques may involve multiple stages of melting, remelting, annealing, and reduction to fine-tune the alloy’s properties.

What are the common types of metal alloys?

Common types of metal alloys include ferrous and non-ferrous alloys. Ferrous alloys, which are iron-based, include steel and cast iron. Steel, composed primarily of iron and carbon, is widely used in construction and manufacturing due to its strength and versatility. Stainless steel, which includes chromium and nickel, is known for its corrosion resistance and is used in medical instruments and kitchenware. Cast iron, containing higher carbon content, is utilized in engine blocks and pipes for its durability.

Non-ferrous alloys do not contain iron and include aluminum and copper-based alloys. Aluminum alloys, such as duralumin (aluminum with copper and manganese), are valued for their lightweight and are used in the aerospace and automotive industries. Copper alloys like brass (copper and zinc) are used in musical instruments and plumbing, while bronze (copper and tin) is employed in bearings and sculptures. Cupronickel, a copper-nickel alloy, is resistant to seawater corrosion and used in marine applications.

Each type of alloy is chosen based on its specific properties and the requirements of its application, making them essential in various industries.

What are the main manufacturing processes in metallurgy?

The main manufacturing processes in metallurgy involve several key methods, each with its unique applications and advantages.

- Casting: This process involves pouring molten metal into molds where it solidifies into the desired shape. It is suitable for producing complex geometries and large volumes, such as engine blocks and pipes.

- Forging: In forging, metal is shaped by compressive forces, often through hammering or pressing. This method enhances the grain structure and mechanical properties of the metal, making it ideal for high-strength components like gears and shafts.

- Machining: Machining involves the removal of material from a workpiece using tools like CNC machines, drills, or grinders. It is used for producing precision components with tight tolerances, such as those required in the aerospace industry.

- Extrusion: This process forces metal through a die to create continuous cross-sectional profiles, such as structural beams and tubing. It is efficient with minimal waste and can be performed hot or cold depending on the metal type.

- Powder Metallurgy (PM): PM includes steps like powder production, mixing, compacting, and sintering to create near-net-shape parts with minimal waste. It is commonly used for automotive bushings and self-lubricating bearings.

- Metal Injection Molding (MIM): MIM combines metal powder with a polymer binder to form complex shapes through injection molding, followed by debinding and sintering. This process is suited for small, intricate parts like medical devices and firearm components.

Each of these processes plays a crucial role in shaping and forming metals for various industrial applications, providing a range of mechanical properties and design possibilities.

How does heat treatment affect metal properties?

Heat treatment significantly affects the properties of metals by altering their atomic arrangements and grain structures through controlled heating and cooling cycles. Key processes such as annealing, quenching, and tempering induce phase transformations, modify dislocation densities, and refine grain structures, which directly impact mechanical performance.

Quenching involves rapid cooling, typically in water or oil, which traps carbon atoms in a hard, brittle microstructure called martensite, increasing hardness and strength. Tempering, which follows quenching, reheats the metal to reduce brittleness while retaining strength by allowing controlled carbide precipitation.

Annealing involves slow cooling after heating above the critical temperature, which softens metals and enhances ductility, making them easier to machine. Normalizing, another process, air-cools the metal to refine grain size, balancing strength and toughness.

Heat treatment processes like case hardening create wear-resistant surface layers while maintaining a tough core, and stress relieving reduces residual stresses from machining, improving fatigue life.

These processes are essential for tailoring metal properties to meet specific industrial applications, ensuring optimal performance in sectors such as aerospace, automotive, and tooling.

What are the latest trends in metallurgical engineering?

Metallurgical engineering is evolving rapidly with several key trends shaping the future of the field. Automation and robotics are increasingly integrated into metallurgical processes, enhancing precision and productivity while reducing labor shortages. This is particularly beneficial in sectors like aerospace and medical devices. Additive manufacturing, especially 3D printing, allows for the creation of complex geometries using metal powders, which is ideal for prototyping and specialized parts. This technology is gaining traction in industries such as healthcare for patient-specific implants.

Advanced materials development focuses on metamaterials with tailored electromagnetic or thermal properties, nanostructured alloys, and composite materials, driving innovation in consumer electronics and energy storage. Sustainable practices are also a priority, with efforts to produce low-carbon steel and recycle aluminum to meet decarbonization goals.

Laser cutting technologies are improving precision and speed, supporting on-demand manufacturing and rapid prototyping. Smart manufacturing and digital twins optimize production processes through real-time monitoring and predictive maintenance. IoT and augmented reality tools further enhance workflow accuracy and equipment maintenance.

These trends highlight the growing importance of interdisciplinary skills, material innovation, and proficiency in Industry 4.0 tools for metallurgical engineers.