When it comes to choosing the right piping material for construction and industrial applications, mild steel pipes often emerge as a popular choice, but what makes them stand out? Known for their remarkable strength and cost-effectiveness, mild steel pipes are versatile enough to fit a wide range of applications—from plumbing systems to automotive manufacturing. However, they are not without their drawbacks, such as susceptibility to corrosion and the need for regular maintenance. This article delves into the properties, advantages, and disadvantages of mild steel pipes, offering a comprehensive comparison with other materials like ductile iron, stainless steel, and PVC. By the end, you’ll gain a clearer understanding of when mild steel pipes are the optimal choice for your project. Are they the right fit for your needs, or is another material better suited? Let’s explore the possibilities.

Understanding Mild Steel Pipes

Definition and Basic Properties of Mild Steel Pipes

Mild steel pipes, also known as low-carbon steel pipes, primarily consist of iron with a small amount of carbon, typically around 0.05% to 0.25%. This low carbon content gives mild steel its characteristic properties, including moderate strength, good ductility, and excellent weldability. These attributes make mild steel pipes ideal for a variety of applications, from structural frameworks to fluid conveyance systems.

Chemical Composition and Manufacturing Process

The chemical composition of mild steel pipes includes iron as the primary element, with carbon content between 0.05% to 0.25%, and small amounts of manganese, silicon, sulfur, and phosphorus to enhance various properties.

The manufacturing process involves several key steps:

- Melting and Refining: Raw materials like iron ore, coke, and limestone are melted in a blast furnace. The molten iron is refined to reduce impurities and adjust the carbon content.

- Casting: The refined molten steel is cast into billets, blooms, or slabs, which serve as the starting material for pipe production.

- Forming: Seamless pipes are created by extruding a steel billet through a die, while welded pipes are made by rolling steel plates or strips into cylinders and welding the seam.

- Finishing: Pipes undergo finishing processes such as heat treatment, surface treatment (e.g., galvanization), and inspection to ensure they meet required standards.

Properties of Mild Steel Pipes

Strength and Durability

Mild steel pipes possess moderate tensile strength, suitable for applications where extreme strength is not essential. The strength can be enhanced through heat treatment and alloying with other elements. Seamless mild steel pipes offer higher tensile strength than welded pipes due to the absence of a welded seam.

Weldability

A key property of mild steel pipes is their excellent weldability. The low carbon content allows for easy and effective welding using various techniques, making these pipes highly suitable for fabrication and construction projects. This also facilitates repairs and modifications in the field.

Corrosion Resistance

Although mild steel pipes can corrode when exposed to moisture, their resistance can be improved with surface treatments like galvanization or protective coatings, extending their lifespan in harsh environments.

Ductility

The ductility of mild steel pipes allows them to be drawn into wires, bent, and shaped without breaking. This is particularly valuable in construction and engineering, where pipes need to be formed into various shapes and sizes to meet specific design requirements.

Machinability

Mild steel has good machinability, meaning it can be easily cut, drilled, and machined using standard tools. This simplifies the fabrication process, allowing for precise and efficient production of components.

Uses of Mild Steel Pipes

Mild steel pipes are used across a wide range of industries due to their versatility and cost-effectiveness:

- Construction: Used in building structures, frameworks, and scaffolding due to their strength and ease of fabrication.

- Plumbing Systems: Commonly found in residential and commercial plumbing systems for water supply and drainage.

- Industrial Applications: Utilized in HVAC systems, gas pipelines, and various manufacturing processes where moderate strength and durability are required.

Comparisons with Other Materials

Compared to ductile iron, stainless steel, PVC, and copper pipes, mild steel pipes offer a balance of cost-effectiveness, strength, and versatility, making them suitable for various applications.

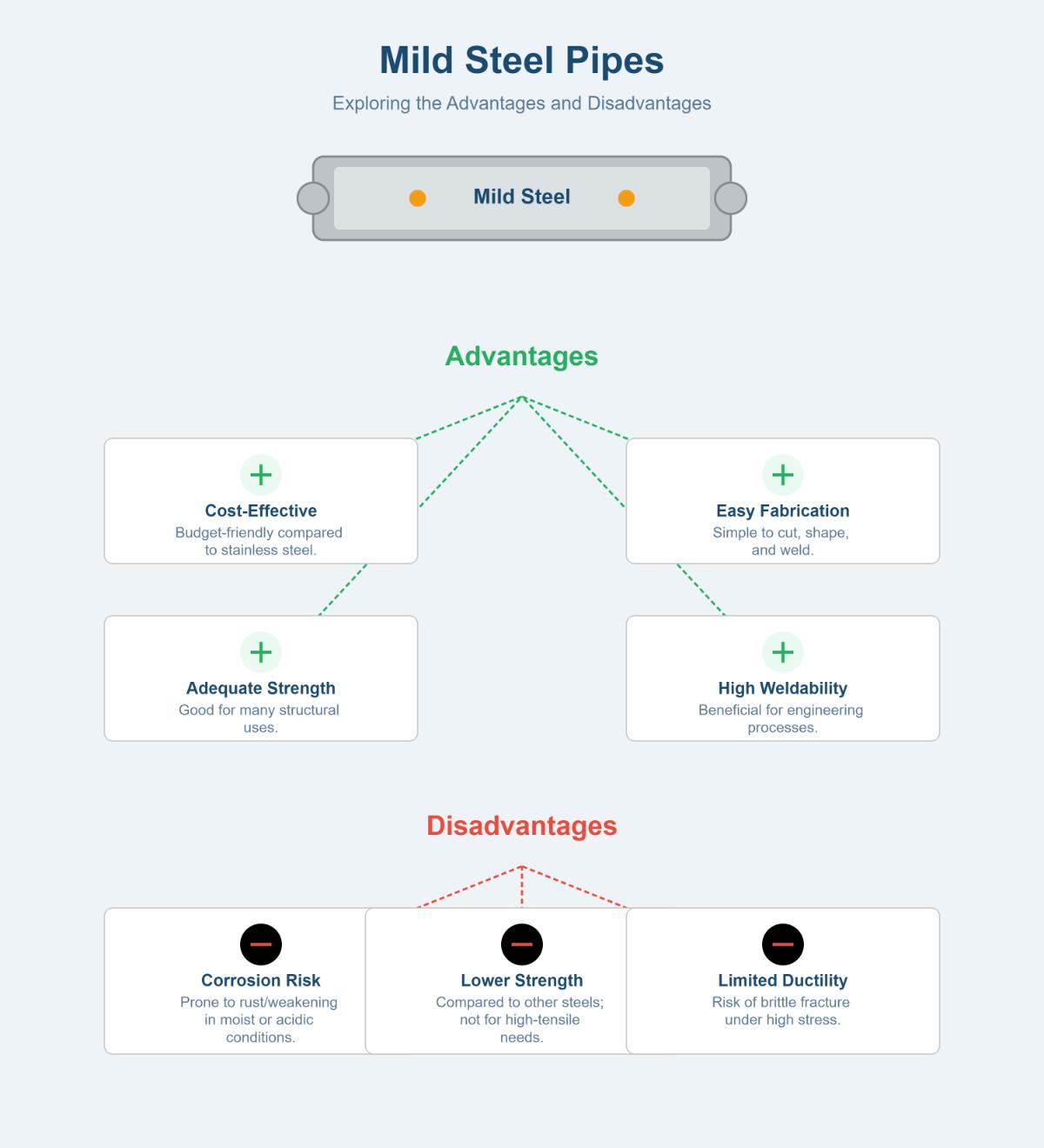

Advantages and Disadvantages of Mild Steel Pipes

Mild steel pipes are popular in various industries due to their many benefits.

Cost-Effectiveness

Mild steel pipes are highly cost-effective compared to materials like stainless steel and copper, offering a lower initial cost while providing satisfactory performance in non-corrosive environments. This makes them an attractive option for budget-conscious projects.

Fabrication Flexibility

Mild steel pipes are easy to weld and machine. Their low carbon content allows for easy welding using various techniques, which is essential for custom fabrication and structural applications. Additionally, they can be machined with standard tools, facilitating the production of precise components.

Temperature Resistance

Mild steel pipes can withstand high temperatures without significant deformation, making them ideal for boilers, outdoor pipelines, and other high-temperature environments. This temperature resilience extends their usability across a range of industrial applications.

Durability

With proper maintenance, mild steel pipes can have a long service life, particularly in dry or controlled environments. Their durability is enhanced when protective coatings are applied, helping to prevent corrosion and wear.

Corrosion Vulnerability

Mild steel pipes are prone to rust and oxidation in moist or chemically corrosive environments, necessitating protective coatings or frequent maintenance to prevent corrosion. This susceptibility adds to the overall cost and effort required for upkeep.

Strength Limitations

Compared to materials like ductile iron or alloy steels, mild steel pipes have lower tensile strength. This limits their use in high-pressure or seismic zones where higher strength is required to prevent brittle fractures and ensure structural integrity.

Weight Considerations

Mild steel pipes are heavier than alternatives such as aluminum and PVC. This added weight can complicate transportation and installation processes, requiring more effort and potentially increasing labor costs.

Environmental Sensitivity

Mild steel pipes are unsuitable for prolonged exposure to acidic or marine environments without additional treatments such as galvanization or epoxy coatings. These treatments are necessary to protect the pipes from the harsh effects of such environments, but they also increase the overall cost and complexity of the project.

Key Properties of Mild Steel Pipes

Corrosion Resistance

Mild steel pipes have moderate resistance to corrosion due to their low carbon content and lack of alloying elements. While the inherent corrosion resistance of mild steel is limited, it can be significantly improved through surface treatments such as galvanization or the application of epoxy and paint coatings. These treatments create a protective barrier that prevents moisture and corrosive elements from contacting the steel, thereby extending the pipe’s lifespan.

Ductility

One of the standout properties of mild steel pipes is their high ductility. This property allows the pipes to be bent or shaped without breaking, which is essential in construction and engineering. The ductility of mild steel pipes is largely due to their low carbon content, which enhances their ability to absorb energy and undergo plastic deformation. This property is particularly valuable in construction and engineering, where pipes often need to be shaped to fit specific design requirements or to accommodate structural changes.

Strength

Mild steel pipes offer a good balance of strength and flexibility, making them suitable for various applications. The tensile strength of mild steel pipes typically ranges from 400 to 600 N/mm², with a yield strength of 205 to 240 MPa. While these values are moderate compared to high-carbon or alloy steels, they are adequate for many structural and fluid transport applications. The strength of mild steel pipes can be further enhanced through heat treatment processes, such as quenching and tempering, which increase their hardness and load-bearing capacity.

Weldability

Mild steel pipes are known for their excellent weldability. The low carbon content reduces the risk of cracking and other defects during the welding process, allowing for strong and reliable joints. Various welding techniques, including arc welding, gas welding, and resistance welding, can be effectively used with mild steel pipes. This property is particularly advantageous in construction and industrial applications, where pipes need to be joined together to form complex structures or systems.

Durability

The durability of mild steel pipes is another key property that contributes to their widespread use. With proper maintenance and protective coatings, mild steel pipes can have a service life of up to 100 years. Their weather resistance makes them suitable for outdoor applications, provided they are adequately protected against corrosion. Regular inspections and maintenance, such as reapplying protective coatings and checking for signs of wear or damage, are essential to ensure the longevity of mild steel pipes in harsh environments.

Other Material Properties

Mild steel pipes possess several other material properties that enhance their utility in various applications:

- Machinability: Mild steel can be easily cut, drilled, and machined using standard tools, facilitating the fabrication process.

- Magnetic Properties: Due to the predominance of ferrite, mild steel pipes exhibit magnetic properties, which can be advantageous in certain industrial applications.

- Cost Efficiency: Mild steel pipes are cost-effective compared to other materials like stainless steel or copper, making them an economical choice for many projects. The low procurement cost and high output manufacturing capabilities contribute to their affordability.

Applications of Mild Steel Pipes

Construction

Mild steel pipes are widely used in the construction industry due to their high strength, durability, and versatility. They serve as essential components in various structural applications, including building frameworks, scaffolding, and support structures for bridges and high-rise buildings. Their ability to withstand substantial loads without deformation makes them ideal for creating robust and stable constructions. Additionally, mild steel pipes are often used in the fabrication of handrails, guardrails, and other safety features in buildings and infrastructure projects.

Plumbing Systems

In both residential and commercial plumbing systems, mild steel pipes are commonly employed for water supply and drainage. They are particularly valued for their strength and ability to handle high-pressure water flow. Mild steel pipes are also used in HVAC (Heating, Ventilation, and Air Conditioning) systems to transport hot and cold water, as well as high-pressure gases. Their cost-effectiveness and easy installation make them a popular choice, ensuring reliable performance.

Oil and Gas Industry

The oil and gas industry relies heavily on mild steel pipes for the transportation of oil, gas, and other petrochemical products. These pipes are preferred for their ability to handle high pressures and resist corrosion when treated. Mild steel pipes are used in both large-scale pipelines and smaller distribution networks, providing a safe and efficient means of transporting energy resources over long distances. Their robustness and adaptability to different environmental conditions make them indispensable in this sector.

Agriculture

In the agricultural sector, mild steel pipes are utilized for a variety of purposes, including irrigation systems, fencing, and animal enclosures. They offer a durable and cost-effective solution for irrigating crops and livestock, ensuring efficient and reliable water delivery. Mild steel pipes are also used to construct sturdy and long-lasting fences and enclosures, protecting livestock and crops from external threats. Their versatility and strength make them a valuable asset in modern farming practices.

Automotive and Aerospace Industry

Mild steel pipes play a crucial role in the automotive and aerospace industries, where they are used in the manufacturing of engine exhaust systems, gas delivery systems, and ignition chambers. These pipes are favored for their ability to withstand high temperatures and pressures, ensuring the safe and efficient operation of engines and other critical components. The high strength-to-weight ratio of mild steel pipes makes them suitable for applications where performance and reliability are paramount.

Furniture Industry

The furniture industry utilizes mild steel pipes to create durable and stylish pieces, such as chairs, tables, and shelving units. Mild steel’s ease of fabrication and versatility enable the creation of functional and attractive furniture. The strength and durability of mild steel pipes ensure that furniture pieces can withstand daily use and maintain their structural integrity over time.

Manufacturing Industry

In the manufacturing industry, mild steel pipes are applied in various processes and equipment, including conveyor systems, storage racks, and material handling equipment. Their strength and durability make them ideal for constructing components that can endure the rigors of industrial environments. Mild steel pipes are also used in the production of machinery and tools, providing reliable performance and longevity in demanding applications.

Comparing Mild Steel Pipes with Other Materials

When comparing mild steel pipes to ductile iron pipes, key factors such as strength, durability, and cost need to be considered. Mild steel pipes offer a balance of strength and flexibility, making them suitable for applications that require bending and shaping. Ductile iron pipes, on the other hand, provide higher tensile strength and greater resistance to impact, making them ideal for high-pressure water and sewer systems.

Strength and Durability

Mild steel pipes offer a balance of strength and flexibility, making them suitable for applications that require bending and shaping. Ductile iron pipes, however, have higher tensile strength and are more resistant to impact, making them ideal for high-pressure water and sewer systems.

Cost Analysis

In terms of cost, mild steel pipes are generally more economical than ductile iron pipes. The production processes and raw material costs for mild steel are lower, which can significantly impact large-scale projects.

Corrosion Resistance and Maintenance

Mild steel pipes require protective coatings to enhance their corrosion resistance, whereas ductile iron pipes are naturally more resistant to corrosion due to their material properties. This means that ductile iron pipes often have lower maintenance costs over time, despite a higher initial investment.

Mild Steel vs. Stainless Steel Pipes

The comparison between mild steel and stainless steel pipes focuses on their applications, cost, and long-term benefits.

Applications and Suitability

Mild steel pipes are widely used in construction and general engineering applications due to their cost-effectiveness and ease of fabrication. Stainless steel pipes, known for their excellent corrosion resistance and aesthetic appeal, are preferred in environments where hygiene and appearance are critical, such as in the food processing and chemical industries.

Cost and Long-term Benefits

While stainless steel pipes have a higher upfront cost, they offer long-term benefits due to their durability and resistance to corrosion without the need for additional coatings. Mild steel pipes, although cheaper initially, may incur higher maintenance costs due to the necessity of protective treatments to prevent corrosion.

Mild Steel vs. PVC Pipes

Comparing mild steel pipes to PVC pipes involves examining flexibility, weight, and cost.

Flexibility and Weight Comparison

Mild steel pipes are much heavier and more rigid than PVC pipes, which can be beneficial in applications requiring structural support. However, PVC pipes offer superior flexibility and are lightweight, making them easier to handle and install, especially in residential plumbing systems.

Cost and Usage Scenarios

PVC pipes are generally less expensive than mild steel pipes and are often used in low-pressure applications such as drainage and waste lines. Mild steel pipes, while more costly, provide the necessary strength and durability for high-pressure applications.

Mild Steel vs. Copper Pipes

The comparison between mild steel and copper pipes is centered on thermal conductivity, price, and longevity.

Conductivity and Application

Copper pipes excel in thermal conductivity, making them ideal for heating and cooling systems. Mild steel pipes, with moderate thermal conductivity, are more commonly used in structural and industrial applications where thermal properties are less critical.

Price and Longevity

Copper pipes are typically more expensive than mild steel pipes but offer a longer lifespan due to their natural corrosion resistance. Mild steel pipes, while cheaper initially, may require more frequent maintenance and replacement if not adequately protected against corrosion.

Selecting the Right Material for Your Project

Mechanical Properties

The mechanical properties of a material, such as tensile strength, ductility, and hardness, are crucial for determining its suitability for specific applications. For instance, mild steel pipes, known for their moderate tensile strength and excellent ductility, are ideal for structural applications that require a balance of strength and flexibility. In contrast, materials like stainless steel offer higher tensile strength and better resistance to deformation under stress, which can be crucial for high-pressure environments.

Environmental Resistance

Environmental factors, such as exposure to moisture, chemicals, and extreme temperatures, play a significant role in material selection. Stainless steel provides inherent corrosion resistance, making it a better choice for environments with high humidity or chemical exposure. For applications in marine or corrosive environments, materials with superior corrosion resistance are essential to ensure longevity and reduce maintenance costs.

Cost Considerations

The cost of materials is an important factor in project planning and budgeting. Mild steel pipes are generally more affordable than stainless steel, copper, or specialized alloys, making them a popular choice for large-scale projects where budget constraints are a concern. However, the initial cost savings must be weighed against the potential long-term expenses associated with maintenance and protective treatments. In some cases, investing in a more expensive material with lower maintenance requirements, such as stainless steel, can be more cost-effective over the lifespan of the project.

Application Requirements

Different applications have specific requirements that influence material selection. For example, in plumbing systems, materials must be able to handle the pressure and flow of water or gases. Mild steel pipes are often used for their strength and ability to withstand high-pressure conditions. In contrast, copper pipes are favored for their excellent thermal conductivity and corrosion resistance, making them ideal for heating and cooling systems. In structural applications, the material’s load-bearing capacity and ease of fabrication are critical considerations. Mild steel’s versatility and weldability make it a suitable choice for constructing frameworks and support structures.

Case Studies and Examples

Examining case studies and real-world examples can provide valuable insights into the practical application of different materials. For instance, a construction project that utilized mild steel pipes for its structural framework might highlight the material’s ease of welding and fabrication, contributing to efficient project completion. Conversely, a plumbing system that employed stainless steel pipes could demonstrate the long-term benefits of reduced maintenance and superior corrosion resistance in a high-humidity environment.

Pipe Installation and Maintenance

Proper installation and maintenance are vital to the performance and longevity of any piping system. Best practices for installation include ensuring proper alignment and secure fittings to prevent leaks and structural weaknesses. Regular maintenance, such as inspecting for signs of corrosion or wear and reapplying protective coatings as needed, can significantly extend the service life of mild steel pipes. Utilizing advanced techniques like cathodic protection can further enhance corrosion resistance and minimize maintenance requirements.

Corrosion Prevention Techniques

Corrosion prevention is a key consideration when selecting materials for piping systems, especially for mild steel pipes. Various methods can be employed to protect against corrosion, including:

- Protective Coatings: Applying coatings such as epoxy, paint, or galvanization can create a barrier that shields the steel from moisture and corrosive elements.

- Galvanization: This process involves coating the steel with a layer of zinc, which provides sacrificial protection by corroding in place of the steel.

- Cathodic Protection: This electrochemical technique involves applying a small electrical current to the pipe, preventing the oxidation reactions that cause corrosion.

By implementing these corrosion prevention techniques, the durability and service life of mild steel pipes can be significantly enhanced, making them a viable option for a wide range of applications.

Sustainability and Cost-Effectiveness

Environmental Impact

Mild steel pipes are known for their durability and long lifespan, which help reduce their environmental footprint over time. The production of mild steel involves processes that can be energy-intensive and produce greenhouse gas emissions. However, advancements in manufacturing techniques and the implementation of more efficient technologies are helping to reduce these emissions. Moreover, the long service life of mild steel pipes means that they do not need to be replaced frequently, which minimizes waste and the environmental impact associated with production and disposal.

Recyclability

One of the most significant sustainability benefits of mild steel pipes is their high recyclability. Mild steel can be melted down and reformed into new products without significant degradation of its properties. This recycling process not only conserves natural resources but also uses less energy than producing new steel from raw materials. As a result, recycling mild steel pipes helps to reduce both the environmental impact and the demand for virgin materials. The steel industry has established robust recycling programs, making it easy to incorporate recycled steel into new products, thus promoting a circular economy.

Lifecycle Cost Analysis

When considering the cost-effectiveness of mild steel pipes, it is essential to look at the entire lifecycle, from production to disposal. While the initial cost of mild steel pipes is relatively low compared to other materials like stainless steel or copper, the long-term savings are where they truly shine. Their durability and strength mean they need less frequent replacement and have lower maintenance costs. Protective coatings and galvanization can further extend their lifespan, reducing the need for costly repairs and replacements. Additionally, the recyclability of mild steel contributes to lower end-of-life disposal costs, making it a financially prudent choice for many applications.

Case Studies of Cost-Effective Applications

Several real-world examples highlight the cost-effectiveness of mild steel pipes:

- Construction Projects: In large-scale construction projects, using mild steel pipes for structural frameworks and plumbing systems is both economical and efficient. The low initial cost and ease of fabrication help keep project budgets under control, while the durability of mild steel ensures long-term performance.

- Industrial Applications: Factories and manufacturing facilities often choose mild steel pipes for their fluid and gas transportation systems. The ability to withstand high pressures and temperatures without significant degradation makes mild steel a reliable and cost-effective option.

- Infrastructure Development: In infrastructure projects like bridges and highways, mild steel pipes are used for support structures and drainage systems. Their strength and resistance to environmental factors, when properly coated, provide a cost-effective solution that requires minimal maintenance over the years.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the advantages and disadvantages of using mild steel pipes?

Mild steel pipes offer several advantages and disadvantages, making them suitable for a variety of applications but also posing some limitations.

Advantages include cost-effectiveness, as they are significantly cheaper than stainless steel pipes, making them a budget-friendly option for many projects. Their ease of fabrication is notable; mild steel pipes are highly versatile and can be easily cut, shaped, and welded, which is beneficial in construction and manufacturing. They also provide adequate strength and durability for many structural applications, and their high weldability is an asset in various engineering processes.

However, mild steel pipes are susceptible to corrosion, especially when exposed to moisture or acidic environments, leading to potential rusting and weakening over time. They have relatively low strength compared to other steel types, limiting their use in high-tensile applications. Additionally, they may not be suitable for high-stress environments due to limited ductility, which can result in brittle fractures.

How do mild steel pipes compare to ductile iron pipes?

Mild steel pipes and ductile iron pipes are often compared due to their prevalent use in various industries. Mild steel pipes are made from low-carbon steel, providing flexibility, moderate strength, and excellent weldability, making them suitable for a wide range of applications such as construction, plumbing, and the automotive industry. They are cost-effective but may require coatings or galvanization to enhance their corrosion resistance.

On the other hand, ductile iron pipes are known for their high strength, toughness, and superior resistance to corrosion, which makes them ideal for high-pressure applications and harsh environments, such as water and sewage systems. While ductile iron pipes are generally more expensive than mild steel pipes, they often require less maintenance due to their inherent durability and corrosion resistance.

What are the common applications of mild steel pipes?

Mild steel pipes are commonly used across various industries due to their strength, durability, and cost-effectiveness. In the construction industry, they are utilized for structural frameworks, scaffolding, and bridge construction because of their robustness and ability to support heavy loads. In plumbing and HVAC systems, mild steel pipes are employed for water supply lines, gas lines, and heating, ventilation, and air conditioning systems due to their pressure and stress resistance. The oil and gas industry relies on mild steel pipes for transporting oil and gas over long distances, leveraging their strength and durability. Additionally, in the automotive and aerospace industries, these pipes are used in exhaust systems and engine components owing to their high-temperature tolerance. In agriculture, mild steel pipes are applied in irrigation systems and for creating durable fencing and enclosures. These diverse applications highlight the versatility and practicality of mild steel pipes across multiple sectors.

How can the corrosion resistance of mild steel pipes be improved?

Improving the corrosion resistance of mild steel pipes is essential for enhancing their lifespan and maintaining their structural integrity in various applications. Several methods can be employed to achieve this:

- Protective Coatings: Applying protective layers such as zinc galvanization, epoxy, or paint coatings can create a barrier against corrosive elements. Zinc galvanization, for example, offers sacrificial protection where the zinc layer corrodes instead of the steel. Powder coating is another effective method that provides a durable and wear-resistant surface.

- Environmental Control: Managing the environment around the pipes by reducing humidity, maintaining dry conditions, and preventing exposure to corrosive substances can significantly minimize corrosion.

- Alloying and Material Selection: Using low-carbon steel or incorporating corrosion-resistant alloys like stainless steel can enhance the corrosion resistance of the pipes.

- Cathodic Protection: This technique involves attaching a more reactive metal, such as zinc or magnesium, to the mild steel pipe. The attached metal corrodes preferentially, thus protecting the steel pipe.

- Corrosion Inhibitors: Adding chemical inhibitors to the fluids inside the pipes can reduce the corrosive effects of the environment.

- Regular Inspection and Maintenance: Routine cleaning and inspection can help detect early signs of corrosion, allowing for timely maintenance and intervention to prevent further damage.

By implementing these methods, the corrosion resistance of mild steel pipes can be significantly improved, ensuring their durability and reliability in various industrial and construction applications.

What factors should be considered when selecting pipe materials for construction projects?

When selecting pipe materials for construction projects, several key factors must be considered to ensure optimal performance and cost-effectiveness. Firstly, material properties such as strength, durability, and weldability are crucial. Mild steel pipes offer moderate tensile strength and are highly weldable, making them suitable for various applications. However, they may require protective coatings to enhance corrosion resistance.

Environmental and operational conditions also play a significant role. Mild steel’s susceptibility to corrosion necessitates protective measures like galvanization or cathodic protection, especially in chemically aggressive or coastal environments. Additionally, soil conditions and the type of fluid being transported must be considered to prevent degradation.

Cost and maintenance are important factors as well. While mild steel is cost-effective initially, it may incur higher maintenance costs over time due to its tendency to rust. Availability and procurement ease can further influence material choice, with mild steel being widely accessible.

Sustainability and compliance with industry standards are increasingly relevant. Mild steel’s recyclability supports environmental goals, and adherence to certifications ensures quality and safety.

How do mild steel pipes compare to PVC and copper pipes in terms of cost and application?

Mild steel pipes, PVC pipes, and copper pipes each have distinct advantages and applications, particularly when considering cost and usage. Mild steel pipes are generally more durable and can withstand higher pressures compared to PVC, making them suitable for structural applications, gas lines, and water supply systems. They are cost-effective relative to copper but more expensive than PVC. However, mild steel requires treatment to improve corrosion resistance, which can add to maintenance costs.

PVC pipes are the most cost-effective option and are easy to install, ideal for drainage systems and non-potable water supply lines. They are lightweight but less suitable for high-pressure applications or environments with extreme temperatures, as they can become brittle.

Copper pipes, while the most expensive of the three, offer excellent durability and natural corrosion resistance, making them suitable for indoor water supply, HVAC systems, and fuel lines. Despite the higher initial cost, their longevity and minimal maintenance requirements can be beneficial in long-term installations. When selecting pipe materials, consider the specific needs of the project, such as pressure requirements, installation ease, and budget constraints.