Imagine a material that blends remarkable strength with unparalleled corrosion resistance, suitable for everything from skyscrapers to kitchen utensils. Stainless steel is that versatile alloy, and understanding its properties, grades, and applications is crucial for anyone involved in engineering, manufacturing, or construction. In this comprehensive guide, we will delve deep into the technical aspects that make stainless steel an indispensable choice across various industries. You’ll discover the key properties that define its performance, compare different grades to pinpoint the right fit for your needs, and explore the wide-ranging applications that leverage its durability and resilience. Ready to uncover the secrets behind stainless steel’s enduring popularity? Let’s dive in.

Introduction to Stainless Steel

Stainless steel is a versatile and widely used alloy, known for its exceptional resistance to corrosion, impressive strength, and attractive appearance. This unique material is not a single type of metal but a family of corrosion-resistant steels containing a minimum of 10.5% chromium. The addition of chromium forms a protective oxide layer on the surface, significantly enhancing the steel’s durability and resistance to rust and staining.

Composition of Stainless Steel

The primary components of stainless steel include iron, chromium, nickel, and carbon. These elements are combined in various proportions to create different types of stainless steel, each with its unique properties. All stainless steels form a protective layer of chromium oxide, which prevents corrosion. This passive layer is self-healing, meaning that if the surface is damaged, it can repair itself in the presence of oxygen.

Key Alloying Elements

- Chromium: Essential for corrosion resistance, chromium content in stainless steel typically ranges from 10.5% to 30%.

- Nickel: Added to enhance formability and increase corrosion resistance, especially in acidic environments.

- Carbon: Used to increase strength and hardness. However, higher carbon content can reduce corrosion resistance.

- Molybdenum: Often added to improve resistance to pitting and crevice corrosion in chloride environments.

Properties of Stainless Steel

Stainless steel is renowned for several key properties that make it suitable for a wide range of applications. These properties include:

Corrosion Resistance

The most notable feature of stainless steel is its excellent resistance to corrosion. The chromium in the alloy reacts with oxygen to form a thin, stable film of chromium oxide on the surface. This oxide layer prevents further surface corrosion and blocks corrosion from spreading into the metal’s internal structure.

Tensile Strength

Stainless steel exhibits high tensile strength, making it an ideal material for applications requiring durability and the ability to withstand high stress. The strength of stainless steel can vary significantly depending on its composition and heat treatment, with some grades offering among the highest tensile and yield strengths of all metals.

Durability

Stainless steel is highly durable, maintaining its integrity and appearance even in harsh conditions. Its durability makes it a preferred choice for infrastructure, industrial equipment, and other applications where long-term performance is critical.

Types of Stainless Steel

Stainless steel is categorized into several types based on its microstructure, which affects its mechanical properties and applications. The three main types are:

Austenitic Stainless Steel

Austenitic stainless steels are the most common type, known for their excellent corrosion resistance and high ductility. They are non-magnetic and can be easily welded. Common grades include 304 and 316 stainless steel.

Ferritic Stainless Steel

Ferritic stainless steels contain high chromium levels and are magnetic. They offer good corrosion resistance and are typically less expensive than austenitic steels. However, they are less ductile and cannot be hardened by heat treatment.

Martensitic Stainless Steel

Martensitic stainless steels are known for their high strength and hardness, achieved through heat treatment. They are magnetic and generally used in applications requiring high wear resistance, such as cutlery and surgical instruments.

Applications of Stainless Steel

Thanks to its unique properties, stainless steel is utilized across many industries and applications. Some of the most common uses include:

- Engineering and Manufacturing: Stainless steel is used in the production of machinery, tools, and equipment that require high strength and resistance to corrosion.

- Construction: It is widely used in building facades, roofing, and structural components due to its aesthetic appeal and durability.

- Aerospace: The material’s strength and corrosion resistance make it suitable for aircraft and spacecraft components.

- Food Processing: Stainless steel is ideal for food processing equipment because it is non-reactive, easy to clean, and resistant to corrosion.

Properties of Stainless Steel

Corrosion Resistance

Stainless steel is highly valued for its exceptional resistance to corrosion. This characteristic is primarily due to the presence of chromium, which constitutes at least 10.5% of the alloy. When exposed to oxygen, chromium forms a thin, stable oxide layer on the surface, known as the passive layer. This layer acts as a barrier, preventing further oxidation and protecting the underlying metal from corrosive elements such as moisture, acids, and salts. This makes stainless steel an ideal choice for applications in harsh environments, including marine, chemical processing, and food processing industries.

Tensile Strength

Stainless steel is renowned for its high tensile strength, which varies among different grades but generally surpasses many other materials. For example, austenitic stainless steels, such as grade 304, exhibit excellent tensile strength combined with good ductility, making them suitable for structural applications, pressure vessels, and automotive components. The ability to withstand substantial stress without deformation is crucial in maintaining the structural integrity and longevity of stainless steel products.

Durability

Durability is another important property of stainless steel, meaning it can withstand wear, pressure, and damage over time. The combination of corrosion resistance and tensile strength contributes significantly to its durability. Stainless steel maintains its mechanical properties and appearance even under extreme conditions, including high temperatures and heavy loads. This makes it an excellent material for use in construction, infrastructure, and industrial machinery where long-term performance is essential. Additionally, stainless steel’s resistance to impact and abrasion extends its service life, reducing the need for frequent replacements and maintenance.

Thermal Properties

Stainless steel exhibits favorable thermal properties, making it suitable for applications involving high temperatures. Different grades of stainless steel can withstand varying degrees of heat. For instance, certain austenitic grades can operate at temperatures up to 760°C (1400°F) intermittently. The material’s low thermal conductivity compared to other metals also makes it useful in environments where thermal insulation is required. Furthermore, its ability to retain strength and resist oxidation at high temperatures makes stainless steel ideal for furnace parts, heat exchangers, and exhaust systems.

Hygiene and Maintenance

The hygiene and maintenance properties of stainless steel are particularly important in industries such as food processing, pharmaceuticals, and medical equipment manufacturing. Stainless steel is non-porous, which means it does not harbor bacteria or other pathogens, making it easy to clean and sanitize. This property, combined with its corrosion resistance, ensures that stainless steel surfaces remain free of contaminants and do not degrade over time. The ease of maintenance reduces operational costs and enhances the safety and quality of products in hygiene-critical applications.

Aesthetic Appeal

In addition to its functional properties, stainless steel is also valued for its aesthetic appeal. Its bright, reflective surface provides a modern and clean look, making it a popular choice in architectural and decorative applications. Stainless steel can be polished to various finishes, from matte to mirror-like, offering design versatility. Its ability to maintain a pristine appearance with minimal effort further enhances its desirability in both commercial and residential settings.

Magnetic Properties

The magnetic properties of stainless steel vary depending on its microstructure. Austenitic stainless steels, such as grades 304 and 316, are generally non-magnetic due to their face-centered cubic (FCC) crystal structure. In contrast, ferritic and martensitic stainless steels, which have body-centered cubic (BCC) crystal structures, are magnetic. Understanding these magnetic properties is essential for applications where magnetism is a factor, such as in electrical appliances and certain industrial processes.

By integrating these properties, stainless steel offers a unique combination of performance, durability, and versatility, making it an indispensable material across numerous industries and applications.

Stainless Steel Grades

Stainless steel grades are classified based on their chemical composition and properties, which help determine their suitability for various applications. Understanding these grades is essential for selecting the right type of stainless steel for specific needs.

Austenitic Stainless Steel

Austenitic stainless steels, such as 304 and 316, are the most widely used types known for their excellent corrosion resistance and high ductility. Grade 304 contains approximately 18% chromium and 8% nickel, offering high corrosion resistance and good formability, making it ideal for kitchen sinks and food processing equipment. Grade 316, which includes 16% chromium, 10% nickel, and 2-3% molybdenum, provides superior resistance against chlorides and is perfect for marine environments and medical implants.

Ferritic Stainless Steel

Ferritic stainless steels are magnetic and offer good corrosion resistance, particularly for indoor applications. Grade 430 contains 16-18% chromium, making it suitable for automotive trim and kitchen appliances. Grade 409, with 10.5-11.75% chromium, is commonly used in automotive exhaust systems and heat exchangers due to its good formability.

Martensitic Stainless Steel

Martensitic stainless steels, such as grades 410 and 420, are magnetic and known for their high strength and hardness achieved through heat treatment. Grade 410, containing 12-13% chromium and 0.15% carbon, is used in cutlery and aerospace components. Grade 420, with higher carbon content and 12-14% chromium, is ideal for surgical tools and cutlery due to its excellent hardness and wear resistance.

Duplex Stainless Steel

Duplex stainless steels are a blend of austenitic and ferritic phases, offering a balance of high strength and excellent corrosion resistance. They have a mixed crystal structure and are used in demanding environments. Common grades include:

- 2205 Duplex Stainless Steel: Contains 21-23% chromium, 4.5-6.5% nickel, and 2.5-3.5% molybdenum. It offers high strength, good corrosion resistance, and lower nickel content, making it suitable for chemical processing, marine environments, and pulp and paper industries.

- 2507 Super Duplex Stainless Steel: Contains 24-26% chromium, 6-8% nickel, and 3-5% molybdenum. It provides exceptional strength and corrosion resistance, used in the oil and gas industry, seawater desalination plants, and high-pressure applications.

Precipitation Hardening Stainless Steel

Precipitation hardening stainless steels are designed to achieve high strength through heat treatment. Grade 17-4PH, containing 15-17.5% chromium, 3-5% nickel, and 3-5% copper, offers high strength and good corrosion resistance, making it suitable for aerospace and defense applications. Grade 17-7PH, with 16-18% chromium, 6.5-7.75% nickel, and 1-1.5% aluminum, is ideal for springs and fasteners due to its high strength and corrosion resistance.

Applications of Stainless Steel

Engineering and Manufacturing

Stainless steel is vital to engineering and manufacturing due to its corrosion resistance, strength, and durability. It is used to produce machinery, tools, and equipment that must withstand harsh environments and heavy use. Common applications include:

- Machinery Components: Bearings, gears, and shafts made from stainless steel offer long-lasting performance with minimal maintenance.

- Fasteners: Bolts, nuts, and screws manufactured from stainless steel ensure secure and durable connections.

- Industrial Equipment: Stainless steel is used in the fabrication of tanks, reactors, and processing equipment, particularly in chemical and petrochemical industries.

Construction

Stainless steel plays a crucial role in construction, providing both structural integrity and aesthetic appeal. Its resistance to corrosion and ability to maintain its appearance over time make it ideal for structural components like beams and columns, as well as architectural elements such as facades and handrails.

Aerospace

The aerospace industry requires materials that can endure extreme conditions, such as high temperatures and stress. Stainless steel meets these requirements, making it suitable for:

- Aircraft Components: Structural parts, landing gear, and fasteners benefit from stainless steel’s strength and corrosion resistance.

- Engine Parts: Stainless steel is used in turbine blades, exhaust systems, and other engine components that must endure high temperatures.

- Spacecraft: The durability and reliability of stainless steel make it a preferred choice for various spacecraft parts, ensuring mission success.

Food Processing

Stainless steel is essential in food processing due to its hygienic properties and corrosion resistance. It is used extensively in:

- Processing Equipment: Mixers, conveyors, and storage tanks made from stainless steel ensure contamination-free processing.

- Kitchen Utensils: Cutlery, pots, and pans benefit from stainless steel’s ease of cleaning and durability.

- Packaging: Stainless steel machines used in packaging maintain product integrity and comply with hygiene standards.

Medical Field

In the medical field, stainless steel is valued for its sterility, durability, and biocompatibility, making it ideal for surgical instruments, implants, and hospital equipment. It is used in:

- Surgical Instruments: Scalpels, forceps, and other tools are made from stainless steel due to their ability to be sterilized and maintain sharpness.

- Implants: Orthopedic implants, such as joint replacements, utilize stainless steel for its strength and compatibility with the human body.

- Hospital Equipment: Stainless steel is used in beds, cabinets, and trolleys, ensuring durability and ease of sanitation.

Chemical and Petrochemical Industries

Stainless steel is essential in chemical and petrochemical industries where resistance to corrosion and chemical reactions is critical. Applications include:

- Pipelines: Stainless steel pipes transport corrosive substances safely and efficiently.

- Reactors and Vessels: Stainless steel containers withstand aggressive chemical processes.

- Heat Exchangers: The material’s thermal properties make it ideal for heat exchanger components.

Transportation

The transportation sector benefits from stainless steel’s strength, durability, and resistance to corrosion, making it suitable for:

- Automotive: Exhaust systems, trim, and structural components in vehicles utilize stainless steel.

- Railway: Train carriages and tracks benefit from stainless steel’s robustness and longevity.

- Marine: Stainless steel is used in shipbuilding for hulls, decks, and fittings due to its resistance to saltwater corrosion.

Stainless steel’s versatility and superior properties make it a valuable material across diverse industries and applications, ensuring performance and longevity in demanding environments.

Impact of Sustainability Trends on Stainless Steel Production

Sustainable Manufacturing Practices

The stainless steel industry is increasingly adopting sustainable manufacturing practices to meet stringent environmental regulations and cater to the growing consumer demand for eco-friendly products. Leading manufacturers are integrating renewable energy sources, such as wind, hydro, and solar power, into their production processes. Additionally, comprehensive waste recycling systems are being implemented to minimize resource depletion and reduce environmental impact. These initiatives enhance the sustainability of stainless steel production and offer a competitive advantage by aligning with global sustainability goals.

Reduction of Carbon and Environmental Footprint

Reducing the carbon and environmental footprint is a key focus in the industry’s sustainability strategies. Advances in production technologies, such as preheating scrap charges with hot exhaust gases and using liquid ferrochrome from in-house plants, have resulted in significant energy savings and lower CO2 emissions. European manufacturers, for example, now use over 90% recyclable raw materials, further reducing the environmental impact. The adoption of carbon capture technologies and automated production planning systems has also improved efficiency and consistency, contributing to a reduced carbon profile.

Product Longevity and Lifecycle Management

Stainless steel’s exceptional corrosion resistance and durability contribute to its long product lifecycle, which can exceed 100 years. This inherent sustainability is further enhanced by industry practices focusing on product longevity and lifecycle management. Manufacturers are designing products with minimal maintenance requirements and maximizing recycled content, supporting resource efficiency and sustainability. By creating durable and long-lasting products, the stainless steel industry aligns with global efforts to reduce waste and conserve resources.

Advanced Alloys and Specialized Applications

The trend of developing advanced stainless steel alloys for specific applications is growing, offering improved performance, durability, and environmental benefits for sectors like construction, automotive, and medical fields. New manufacturing techniques and high-quality materials ensure stainless steel stays versatile and continues to grow in use. By continuously improving alloy compositions, manufacturers can provide solutions that meet stringent performance criteria while minimizing environmental impact.

Industry Challenges and Opportunities

Sustainable stainless steel production offers great opportunities but also brings challenges that need addressing. Issues such as pricing, transparency, and global competition are critical to ensuring the long-term viability of low-emission steel. However, with strong partnerships and a clear focus on sustainability, the industry is well-positioned to lead the green industrial revolution. Working together, manufacturers, regulators, and consumers can overcome these challenges and make low-emission stainless steel the standard.

Key Data and Innovations

Innovations in stainless steel production are driving sustainability forward. Notable advancements include:

- Recyclability: European stainless steel production now incorporates over 90% recyclable raw materials, significantly reducing resource depletion.

- Carbon Footprint Reduction: Products like Outokumpu’s Circle Green® offer up to 93% lower carbon footprint compared to traditional stainless steel.

- Energy Efficiency: Techniques such as preheating scrap and integrating liquid ferrochrome have drastically reduced energy consumption and CO2 emissions.

- Product Lifecycle: Stainless steel’s corrosion resistance supports a lifecycle exceeding 100 years, contributing to long-term sustainability.

| Trend/Innovation | Description | Impact/Outcome |

|---|---|---|

| Renewable Energy Adoption | Use of wind, hydro, solar in production | Lower carbon emissions |

| Waste Recycling | Comprehensive scrap and byproduct recycling | Reduced resource depletion |

| Advanced Alloys | Development of specialized, high-performance alloys | Expanded application range |

| Carbon Capture Technologies | Integration of CO2 capture systems | Further emission reduction |

| Product Longevity | Design for durability and minimal maintenance | Extended lifecycle, less waste |

| Automated Production Planning | IT-driven, automated systems for efficiency | Consistent quality, energy savings |

Sustainability trends are reshaping the stainless steel industry, driving innovation in manufacturing, materials, and lifecycle management. As environmental regulations tighten and consumer preferences shift, the adoption of cleaner technologies, advanced alloys, and resource-efficient practices will continue to define the future of stainless steel production.

Frequently Asked Questions

Below are answers to some frequently asked questions:

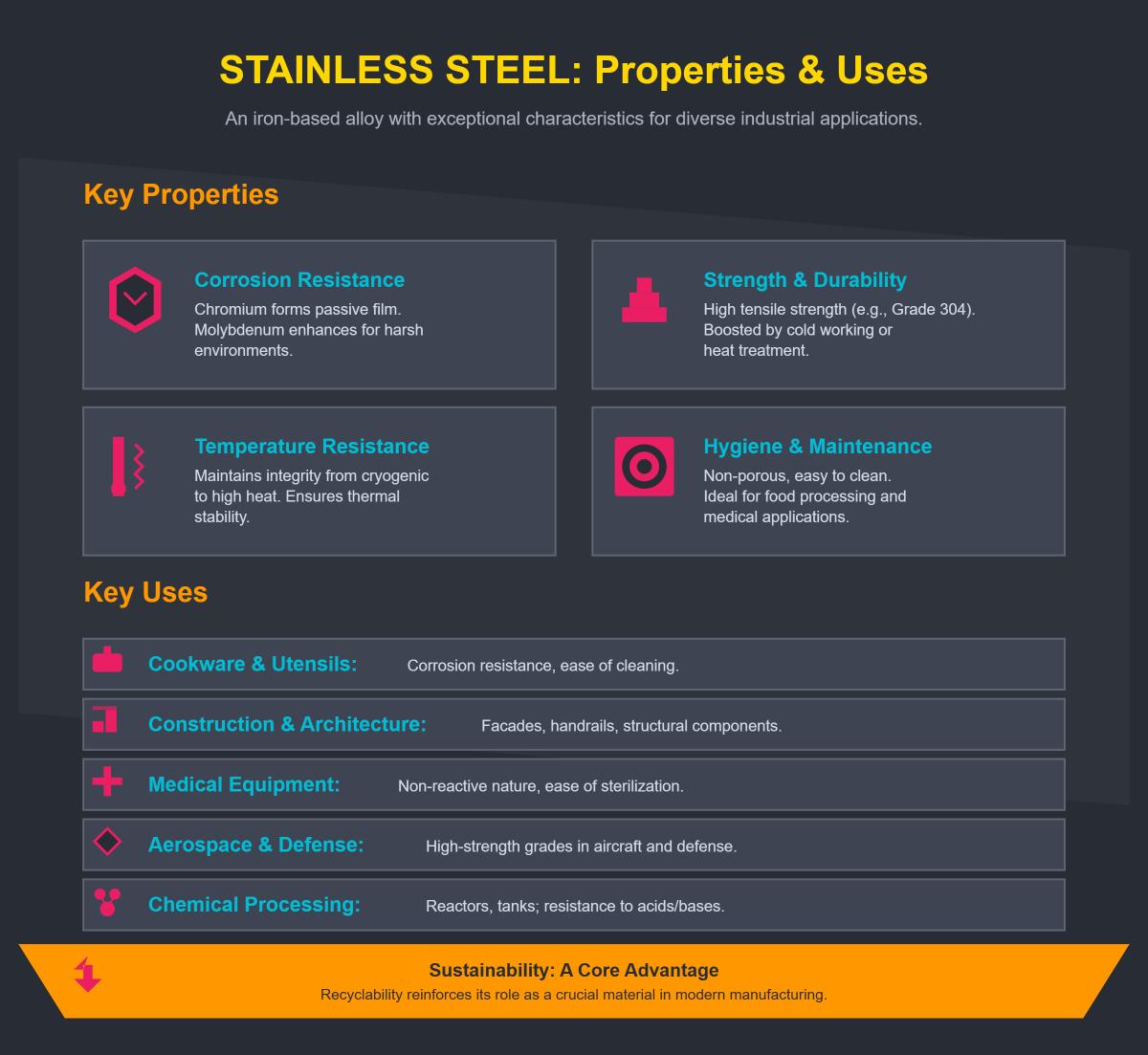

What are the key properties and uses of stainless steel?

Stainless steel is an iron-based alloy renowned for its exceptional properties, making it indispensable across various industries. Its key properties include:

- Corrosion Resistance: Stainless steel’s primary advantage is its high resistance to corrosion, attributed to its chromium content. This forms a passive film that protects against rust and stains. Adding elements like molybdenum enhances resistance to pitting and crevice corrosion, particularly in harsh environments.

- Strength and Durability: Stainless steel offers high tensile strength and durability. Common grades, such as 304, exhibit substantial tensile yield strength, which can be further increased through processes like cold working or heat treatment.

- Temperature Resistance: It maintains structural integrity across a wide temperature range, from cryogenic to high heat applications, making it suitable for environments requiring thermal stability.

- Hygiene and Maintenance: Its non-porous surface makes stainless steel easy to clean and maintain, ideal for food processing and medical applications where hygiene is critical.

Stainless steel’s versatility leads to its use in various applications:

- Cookware and Utensils: Due to its corrosion resistance and ease of cleaning.

- Construction and Architecture: For building facades, handrails, and structural components.

- Medical Equipment: Thanks to its non-reactive nature and ease of sterilization.

- Aerospace and Defense: High-strength grades are used in aircraft and defense applications.

- Chemical Processing: For reactors and tanks, given its resistance to acids and bases.

Its recyclability further contributes to its sustainability, reinforcing its role as a crucial material in modern manufacturing and construction.

How does stainless steel compare to other materials in terms of strength and corrosion resistance?

Stainless steel is known for its exceptional strength and corrosion resistance, making it superior to many other materials in these aspects. Its high chromium content, typically at least 10.5%, forms a protective layer of chromium oxide, which prevents rust and corrosion. Some grades, like 316 stainless steel, also include molybdenum, further enhancing their resistance to harsh environments, such as those with chloride exposure.

In terms of strength, stainless steel generally surpasses conventional steel, offering both durability and resistance to environmental damage. While conventional steel may corrode quickly, stainless steel is ideal for applications requiring long-term durability and hygiene, such as food processing and medical equipment.

Compared to other corrosion-resistant materials like copper and aluminum, stainless steel is stronger and more durable, especially in demanding environments. Although materials like titanium and duplex stainless steel may offer higher performance in specific applications, their higher cost and less versatile nature make stainless steel a more practical choice for many industries.

What are the different grades of stainless steel and their specific applications?

Stainless steel is categorized into several grades, each with unique properties and specific applications.

Austenitic stainless steels, such as grades 304 and 316, are known for their excellent corrosion resistance and high levels of chromium and nickel. Grade 304 is common in kitchen utensils and construction, while grade 316, with added molybdenum, is better suited for marine environments due to its enhanced resistance to chloride corrosion.

Ferritic stainless steels, like grades 409 and 430, contain lower nickel content and are more cost-effective. Grade 409 is often used in automotive exhaust systems, whereas grade 430 is used in decorative trim and appliances due to its good corrosion resistance.

Martensitic stainless steels, such as grade 420, are characterized by their high hardness and strength, making them ideal for cutlery and surgical instruments.

Precipitation hardening (PH) stainless steels, including grade 17-4 PH, offer a balance of strength and corrosion resistance and are used in aerospace and chemical processing.

Duplex stainless steels, such as grade 2205, combine the properties of austenitic and ferritic steels, providing high strength and excellent corrosion resistance, making them suitable for chemical processing and marine applications.

Each grade is selected based on its specific properties and the requirements of the intended application, including factors like corrosion resistance, strength, and cost.

What standards are relevant for stainless steel in various industries?

Stainless steel standards are crucial for ensuring the quality, safety, and performance of stainless steel products across various industries. Key standards include:

- ASTM Standards:

- ASTM A240: Specifies requirements for stainless steel sheets, plates, and strips, covering commonly used grades like SS304 and SS316.

- ASTM A276: Focuses on stainless steel bars and shapes, detailing their mechanical properties and chemical composition.

- EN Standards:

- EN 10088: A European standard that classifies stainless steel grades by their chemical composition and mechanical properties, such as 1.4401 for SS316.

- ISO Standards:

- ISO 15510: Provides globally accepted specifications for stainless steel, similar to EN standards.

- Industry-Specific Standards:

- AISC Specifications: Covers stainless steel plate, sheet, and strips for pressure vessels and structural applications.

- Cleanroom Standards: Ensure materials meet high cleanliness requirements for specialized environments.

These standards help maintain consistency and reliability in stainless steel applications, from marine environments to food processing and construction, as discussed earlier in the article.

How is stainless steel contributing to sustainability in manufacturing and construction?

Stainless steel significantly contributes to sustainability in manufacturing and construction due to its inherent properties and the industry’s ongoing commitment to reducing environmental impact. Firstly, stainless steel’s durability and longevity mean that structures built with it require fewer replacements and repairs, minimizing waste over time. Additionally, stainless steel is 100% recyclable, which greatly reduces the demand for new raw materials and lowers the carbon footprint associated with its production.

In manufacturing, leading producers are implementing technologies to reduce carbon emissions during production. Stainless steel’s recyclability also plays a crucial role, with increased recycled content reducing the need for virgin materials. Advanced monitoring systems and certifications for architectural grades further optimize resource use.

In construction, stainless steel’s versatility supports prefabrication and modular construction methods, which reduce on-site energy consumption and waste. Lightweight stainless steel systems also minimize material usage without compromising structural integrity, supporting sustainable building practices.