In today’s technology-driven world, choosing the right type of cable for your network infrastructure can make all the difference. Copper and fiber optic cables each offer distinct advantages and disadvantages that can impact performance, cost, and long-term efficiency. But how do you decide which one is best suited for your needs? This article delves into the technical comparison between copper and fiber optic cables, exploring their unique properties, applications, and potential drawbacks. From signal transmission capabilities to installation costs and durability, we’ll provide a comprehensive analysis to help you make an informed decision. Ready to unravel the key differences between these two pivotal technologies? Let’s dive in.

Understanding Copper Cables

Copper cables are electrical conductors primarily made from copper, a metal known for its excellent electrical and thermal properties. These cables consist of one or more copper wires, each insulated with a layer of plastic or other dielectric material to prevent short-circuiting and ensure safe and efficient transmission of electrical signals.

Types of Copper Cables

Copper cables come in various types, each suited for specific applications and performance requirements, such as twisted pair cables, which consist of pairs of copper wires twisted together to reduce electromagnetic interference (EMI). Other types include:

- Coaxial Cables: Feature a single copper conductor at the core, surrounded by a dielectric insulator, metallic shield, and outer insulating layer. Used for television signals, internet connections, and other high-frequency applications.

- Shielded and Unshielded Cables: Shielded cables have an additional layer of shielding to protect against EMI, while unshielded cables rely on the twisting of pairs to minimize interference.

Advantages of Copper Cables

Electrical Conductivity

Copper is an excellent conductor of electricity, second only to silver, making it ideal for efficient signal transmission with minimal energy loss. This high conductivity ensures that copper cables can carry electrical currents effectively over various distances and applications.

Malleability and Ductility

Copper’s malleability and ductility make it easy to shape and bend without breaking. This property is crucial for cable installation, as it enables the cables to be routed through tight spaces and around obstacles without compromising their structural integrity.

Corrosion Resistance

Copper has a natural resistance to corrosion, which helps maintain its electrical properties over time. This resistance reduces the need for frequent replacements and ensures long-term reliability in various environmental conditions.

Cost-Effectiveness and Installation

Copper is relatively inexpensive compared to materials like silver or gold, making it a cost-effective choice for electrical and telecommunications infrastructure. Additionally, copper cables are easier to install and require less specialized equipment and training compared to fiber optic cables.

Limitations of Copper Cables

Electromagnetic Interference (EMI)

Copper cables are susceptible to electromagnetic interference, which can degrade signal quality, especially over long distances. This limitation requires additional shielding or the use of twisted pair designs to mitigate the effects of EMI.

Signal Attenuation

Over long distances, copper cables experience signal attenuation, where the strength of the signal diminishes. This attenuation limits the effective transmission range of copper cables and necessitates the use of repeaters or signal boosters in long-distance applications.

Bandwidth Constraints

Copper cables have lower bandwidth compared to fiber optic cables. While they are sufficient for many standard applications, they may not meet the demands of high-speed data transmission and large-scale network infrastructures.

Typical Applications

Telecommunications

Copper cables are widely used in telecommunications for voice and data transmission. Twisted pair cables, such as those used in Ethernet networks, are a common example, providing reliable connectivity for residential, commercial, and industrial applications.

Electrical Wiring

Copper cables are a standard choice for electrical wiring in buildings, machinery, and equipment. Their excellent conductivity and durability make them suitable for carrying electrical currents safely and efficiently.

Power Distribution

In power distribution systems, copper cables are used to transmit electricity from power plants to substations and ultimately to end consumers. Copper is favored for its excellent electrical conductivity, durability, and flexibility, which make it an ideal material for electrical wiring. The efficiency of copper cables helps minimize energy losses during transmission, ensuring that a higher percentage of generated power reaches its destination.

Key Technical Specifications

- Conductivity: Copper has a conductivity of approximately 5.8 x 10^7 S/m, making it highly efficient for electrical transmission.

- Tensile Strength: Copper cables typically have a tensile strength of around 200-250 MPa, providing sufficient mechanical strength for various applications.

- Operating Temperature: Copper cables can operate effectively in a wide temperature range, from -65°C to 200°C, depending on the insulation material used.

Fiber Optic Cables: An Overview

Structure and Components

The core is the central part of a fiber optic cable where light signals travel, made of ultra-pure glass or plastic. Surrounding the core is the cladding, a layer of glass that reflects light back into the core, utilizing total internal reflection to prevent signal loss. This design ensures efficient data transmission with minimal signal degradation.

The primary coating is a layer of plastic applied to the cladding to protect the fiber from physical damage and environmental factors. Additionally, strength members such as Kevlar provide mechanical support and protect the delicate fibers during installation and use.

The outer jacket is the external layer of the fiber optic cable, offering additional protection against environmental hazards and physical damage. It is often color-coded to distinguish between different types of fibers, such as yellow for single-mode fibers and orange for multimode fibers.

Advantages of Fiber Optic Cables

Fiber optic cables offer significantly higher bandwidth and data transmission speeds compared to copper cables. This makes them ideal for applications requiring the transfer of large amounts of data quickly and efficiently, such as internet backbones and high-speed networks.

Fiber optic cables excel at transmitting data over long distances with minimal signal loss, unlike copper cables which suffer from attenuation. This makes them ideal for maintaining signal integrity and quality across vast distances.

Fiber optic cables are immune to electromagnetic interference (EMI), which can disrupt data transmission in copper cables. This makes fiber optics suitable for use in environments with high levels of electrical noise, such as industrial settings and areas with heavy machinery.

Light signals in fiber optic cables make them hard to tap without being noticed, offering enhanced data security. This is particularly important for sensitive communications and secure networks.

Fiber optic cables are non-metallic, which means they are resistant to corrosion and can be used in harsh environmental conditions. Additionally, they do not carry electrical currents, reducing the risk of fire hazards and making them safer for use in various applications.

Disadvantages of Fiber Optic Cables

The installation of fiber optic cables requires specialized equipment and trained personnel, leading to higher initial costs compared to copper cables. However, the long-term benefits of reduced maintenance and higher performance can offset these initial expenses.

Fiber optic cables, especially those made of glass, are more fragile than copper cables and need careful handling during installation to avoid damage. This adds complexity to the installation process.

Connecting fiber optic cables requires precision splicing and the use of specialized tools to ensure proper alignment and minimal signal loss. This complexity can increase installation time and costs.

Applications of Fiber Optic Cables

Fiber optic cables are the backbone of modern telecommunications networks, enabling high-speed internet, cable television, and telephone services. Their ability to handle large amounts of data with minimal latency makes them essential for global communications infrastructure.

In medicine, fiber optic cables are used in imaging equipment and minimally invasive surgeries because they transmit clear images and data. In industrial applications, they are used for data transmission in environments with high EMI and for monitoring and control systems.

Data centers rely on fiber optic cables to connect servers and storage systems, ensuring fast and reliable data transfer. The high bandwidth and low latency of fiber optics are crucial for the efficient operation of large-scale computing environments.

Comparative Analysis: Copper Cables vs Fiber Optic Cables

Electrical Conductivity and Signal Transmission

Copper cables and fiber optic cables differ significantly in their methods of signal transmission and electrical conductivity.

Copper Cables

Copper cables transmit data through electrical signals. Copper is an excellent conductor of electricity, second only to silver, making it highly effective for signal transmission. However, electrical signals in copper cables can be distorted by electromagnetic interference (EMI), particularly in noisy electrical environments. Copper cables also experience signal attenuation over long distances, limiting their effective range to about 100 meters for high-speed data applications.

Fiber Optic Cables

Fiber optic cables use light to carry data. This method involves light pulses traveling through the core of the fiber, which is typically made of glass or plastic. Since fiber optic cables do not rely on electrical signals, they are immune to EMI, ensuring clear and uninterrupted data transmission even in electrically noisy environments. Fiber optics also have a much longer effective range, capable of transmitting data over several kilometers without significant signal loss.

Cost and Durability

The cost and durability of copper and fiber optic cables are important factors to consider when choosing between the two.

Copper Cables

Copper cables are more cost-effective and easier to install for short-distance applications due to the widespread availability of copper infrastructure. Copper cables are also durable and resistant to physical damage, making them suitable for various environments. However, they are prone to corrosion over time, which can affect their performance and longevity.

Fiber Optic Cables

Fiber optic cables have a higher initial cost due to the materials and specialized installation required. Despite this, they offer long-term cost benefits through lower maintenance requirements and longer lifespans. Fiber optics are resistant to corrosion and environmental factors, making them durable and reliable for long-term use. However, they are more fragile than copper cables and require careful handling during installation.

Applications in Telecommunications and Electrical Systems

The choice between copper and fiber optic cables can significantly impact their effectiveness in different applications.

Telecommunications

In telecommunications, fiber optic cables are preferred for high-speed internet, cable television, and other data-intensive applications. Their high bandwidth and ability to transmit data over long distances make them ideal for these applications. Copper cables, while still used for telephony and Ethernet connections, are gradually being replaced by fiber optics in many new installations due to the latter’s superior performance.

Electrical Systems

For electrical systems, copper cables remain the standard due to their excellent conductivity and ability to carry electrical power. They are widely used in building wiring, power distribution, and other electrical applications where their flexibility and durability are advantageous. Fiber optic cables are not suitable for these applications as they do not conduct electricity.

Initial Costs, Installation, and Long-Term Cost Efficiency

The financial implications of choosing between copper and fiber optic cables include initial costs, installation complexity, and long-term cost efficiency.

Copper Cables

Copper cables have lower initial costs and are easier to install. They do not require specialized equipment or extensive training, making them a cost-effective choice for many projects. However, the long-term costs can be higher due to maintenance, susceptibility to EMI, and the need for repeaters in long-distance applications.

Fiber Optic Cables

Installing fiber optic cables is initially more expensive and complex. Specialized tools and trained personnel are required to install and splice these cables correctly. Despite the higher upfront investment, fiber optics offer significant long-term cost savings through reduced maintenance, lower power consumption, and longer lifespans. Their superior performance and reliability can also lead to cost savings in high-bandwidth and long-distance applications.

Advantages and Disadvantages of Using Copper Cables

Advantages of Copper Cables

Conductivity and Heat Resistance

Copper cables are highly valued for their excellent electrical conductivity, surpassed only by silver. This high conductivity ensures efficient signal transmission with minimal energy loss, while also aiding in heat dissipation, enhancing the overall performance and longevity of the cables.

Malleability and Ductility

One of the standout properties of copper is its malleability and ductility. Copper can be easily shaped and stretched into thin wires without breaking, which is essential for manufacturing and installing cables. This flexibility makes copper cables ideal for routing through tight spaces and around obstacles, perfect for complex installations.

Cost-Effectiveness

Copper cables are usually cheaper to install than fiber optic cables. The materials and installation processes for copper cables are less expensive, which can be particularly advantageous for short-distance applications where the advanced capabilities of fiber optics are not necessary. This cost-effectiveness makes copper cables an attractive option for many projects, especially those with budget constraints.

Durability

Copper cables are physically robust and can withstand bending, twisting, and pulling, making them suitable for harsh industrial environments. Although copper cables are not as resistant to signal degradation as fiber optic cables, their physical toughness is a notable advantage.

Disadvantages of Copper Cables

Electromagnetic Interference (EMI)

One of the major drawbacks of copper cables is their susceptibility to electromagnetic interference (EMI). Electrical signals in copper cables can be distorted by external electromagnetic fields, leading to signal degradation and potential data loss. This interference can be particularly problematic in environments with high electrical noise, necessitating additional shielding or the use of twisted pair designs to mitigate the effects.

Signal Attenuation

Copper cables experience significant signal loss over long distances, a phenomenon known as signal attenuation. This limitation restricts their effectiveness in high-speed, long-distance data transmission applications. To maintain signal integrity over extended distances, repeaters or signal boosters are often required, which can increase the complexity and cost of the installation.

Security Vulnerability

Copper cables are more vulnerable to security breaches compared to fiber optic cables. Since they transmit data as electrical signals, it is easier to tap into copper cables and intercept the transmitted information. This security vulnerability makes copper cables less suitable for applications where data security is paramount, such as in sensitive communications and secure networks.

Weight and Bulk

Copper cables are heavier and bulkier than fiber optic cables, which can pose challenges during installation and maintenance. Their larger size and weight can make it more difficult to maneuver and install them in tight spaces, and they require more physical support structures. This bulkiness can be a disadvantage in applications where space is limited or where weight is a critical factor.

CCA Cables: A Brief Overview

Introduction to CCA Cables

Copper-Clad Aluminum (CCA) cables combine copper’s conductivity with aluminum’s lightweight and affordability. These cables feature an aluminum core coated with a thin layer of copper, aiming to provide a balance between performance and cost-effectiveness.

Advantages of CCA Cables

Cost Efficiency

Using aluminum reduces material costs compared to pure copper cables, making CCA cables budget-friendly, especially for large-scale projects or installations with tight budgets.

Lightweight

CCA cables are significantly lighter than their pure copper counterparts, simplifying handling, transportation, and installation processes. This reduced weight is particularly advantageous in scenarios where cable weight is a critical factor, such as in aerial installations or when routing through confined spaces.

Flexibility

The combination of aluminum and copper in CCA cables results in improved flexibility. This flexibility makes it easier to maneuver the cables during installation, reducing the risk of physical damage and simplifying the routing process through complex pathways or tight spaces.

Disadvantages of CCA Cables

Performance Limitations

Although CCA cables are cost-effective, they have performance limitations. The aluminum core has higher electrical resistance compared to pure copper, leading to increased signal attenuation and potential data loss over longer distances. This limitation makes CCA cables less suitable for high-performance applications that require consistent and reliable data transmission.

Mechanical Weakness

CCA cables are more prone to mechanical fatigue and breakage compared to pure copper cables. The aluminum core is less durable and can be damaged more easily during installation or in environments with frequent physical stress. This mechanical weakness can result in higher maintenance costs and reduced lifespan for the cables.

Regulatory Compliance Issues

CCA cables do not always meet the stringent industry standards required for Ethernet cabling. This non-compliance can pose legal and safety risks, particularly if the cables are misrepresented as meeting certain specifications. As a result, using CCA cables in applications that require strict adherence to standards may not be advisable.

Comparison with Pure Copper Cables

Conductivity and Signal Transmission

Pure copper cables offer superior electrical conductivity and lower resistance compared to CCA cables. This results in better signal transmission, lower attenuation, and higher data integrity over longer distances. For applications that demand high-performance and reliable data transmission, pure copper cables are generally the preferred choice.

Durability and Mechanical Strength

Copper cables are more robust and durable, withstanding greater mechanical stress and being less susceptible to damage during installation and use. This durability translates to lower maintenance requirements and a longer service life, making copper cables a more reliable option in demanding environments.

Cost Considerations

While CCA cables are more cost-effective in terms of material and initial purchase price, pure copper cables offer long-term cost benefits through enhanced performance, durability, and lower maintenance needs. The higher upfront cost of copper cables can be justified by their superior performance and reliability over the cable’s lifespan.

Applications and Limitations

Suitable Applications

CCA cables are best suited for static or low-performance environments, such as home networking, basic telecommunications, and certain industrial settings with minimal cable demands.

Unsuitable Applications

CCA cables are not recommended for high-performance or critical applications, such as data centers, high-speed Ethernet networks, and environments with high electrical noise. In these scenarios, the limitations in conductivity, signal transmission, and mechanical strength of CCA cables can lead to performance issues and potential data loss.

Technical Specifications and Standards Compliance

CCA cables typically fall short of the technical specifications required for high-performance Ethernet cabling. The higher resistance and lower conductivity of the aluminum core, combined with potential non-compliance with industry standards, make them a less reliable choice for applications where adherence to specific technical standards is crucial. It is essential to carefully evaluate the requirements of the application and the compliance of the cables with relevant standards before selecting CCA cables for any project.

Technical Specifications and Standards Compliance

International Electrical Standards for Copper and Fiber Optic Cables

It’s essential to understand international standards for copper and fiber optic cables to ensure compliance, safety, and optimal performance across various applications. These standards provide guidelines on specifications, performance metrics, and testing methods.

Copper Cable Standards

Copper cables are regulated by several international standards, including:

- IEC 60228: This standard defines the nominal cross-sectional areas of conductors, ensuring consistency in electrical performance.

- ANSI/TIA-568: It specifies commercial building cabling for telecommunications products and services. Categories such as Cat5e, Cat6, and Cat6a fall under this standard.

- IEEE 802.3: This standard encompasses Ethernet technologies, including the specifications for copper cabling in Ethernet networks up to 10GBASE-T.

These standards ensure copper cables meet requirements for conductivity, signal strength, and durability.

Fiber Optic Cable Standards

Fiber optic cables are governed by standards such as:

- ITU-T G.652: This standard specifies characteristics of single-mode optical fiber cables, widely used in telecommunications.

- ANSI/TIA-568: Similar to copper, this standard also applies to fiber optics, including specifications for multimode and single-mode fibers.

- ISO/IEC 11801: This international standard specifies generic cabling for customer premises, ensuring fiber optic cables meet global performance criteria.

These standards cover aspects such as core diameter, attenuation, bandwidth, and environmental resilience.

Technical Specifications for Copper Cables

Copper cables have specific technical specifications that ensure their suitability for various applications:

- Conductivity: Copper cables usually have a conductivity of about 5.8 x 10^7 S/m, which ensures efficient signal transmission.

- Attenuation: Signal loss in copper cables is a critical factor, with attenuation rates varying based on the cable category and length. For instance, Cat6 cables exhibit lower attenuation compared to Cat5e.

- Impedance: The characteristic impedance for most Ethernet copper cables is standardized at 100 ohms, ensuring compatibility with networking equipment.

- Frequency Range: Copper cables support various frequencies, with Cat5e supporting up to 100 MHz and Cat6a up to 500 MHz.

These specifications are essential for ensuring copper cables perform reliably in their intended applications.

Technical Specifications for Fiber Optic Cables

Fiber optic cables have unique technical advantages and specifications:

- Bandwidth: Fiber optic cables can support extremely high bandwidths, with single-mode fibers capable of transmitting data at speeds up to 60 terabits per second.

- Attenuation: Signal loss in fiber optic cables is minimal, with single-mode fibers exhibiting attenuation rates as low as 0.35 dB/km at 1310 nm wavelength.

- Core and Cladding Diameter: Single-mode fibers typically have a core diameter of 8-10 microns, while multimode fibers have core diameters of 50 or 62.5 microns.

- Numerical Aperture: This specification determines the light-gathering ability of the fiber, with typical values around 0.14 for single-mode and 0.275 for multimode fibers.

These specifications highlight the superior performance characteristics of fiber optic cables, particularly for high-speed and long-distance data transmission.

Compliance and Testing

Both copper and fiber optic cables undergo rigorous testing to ensure compliance with international standards. These tests include:

- Insertion Loss (Attenuation): Measures the loss of signal power as it travels through the cable.

- Return Loss: Evaluates the amount of signal reflected back towards the source, indicating impedance mismatches.

- Crosstalk: Assesses the level of interference between adjacent cables, critical for maintaining signal integrity in high-density installations.

- Environmental Testing: Ensures cables can withstand various environmental conditions, including temperature fluctuations, moisture, and mechanical stress.

Following these standards ensures copper and fiber optic cables perform reliably and efficiently in their applications.

Case Studies and Real-World Applications

High-Speed Internet Infrastructure

In the telecommunications sector, fiber optic cables are integral to high-speed internet infrastructure. They enable rapid data transfer rates, crucial for activities like streaming, gaming, and using cloud services. For instance, Google Fiber uses fiber optic cables to deliver gigabit internet speeds to residential and commercial customers, significantly enhancing user experience with minimal latency and buffering.

Long-Distance Communication

Telecommunications companies like AT&T and Verizon employ fiber optic cables for long-distance communication networks. These cables enable clear data transmission over long distances with minimal signal loss, making them ideal for connecting cities and countries. Submarine fiber optic cables, such as the transatlantic cables, are critical for international data transfer, supporting global internet traffic and connectivity.

Power Distribution Networks

Copper cables are extensively used in power distribution networks due to their excellent electrical conductivity and durability. Utilities rely on copper cables to transmit electricity from power plants to substations and end-users. The reliability of copper ensures consistent power delivery and minimizes energy losses during transmission. For example, the New York Power Authority utilizes copper cables in its extensive power grid, ensuring efficient and reliable electricity distribution across the state.

Building Wiring

In building wiring, copper cables are preferred for their mechanical strength and ease of installation. They are used in residential, commercial, and industrial buildings for electrical wiring, ensuring reliable power delivery to devices and systems. The Empire State Building, for instance, underwent a significant electrical upgrade where copper wiring was used to enhance the building’s energy efficiency and electrical capacity.

Data Centers

Data centers often employ a hybrid approach, using both copper and fiber optic cables to optimize performance and cost. Fiber optic cables are used for high-speed data transfer between servers and storage systems, ensuring low latency and high bandwidth. Copper cables, on the other hand, are used for Power over Ethernet (PoE) applications, delivering both data and electrical power to devices like wireless access points, security cameras, and IP phones. Companies like Facebook and Google implement such hybrid cabling solutions in their data centers to balance performance with cost-effectiveness.

Industrial Automation

In industrial automation, both copper and fiber optic cables play crucial roles. Fiber optic cables are used for data communication between control systems and machinery, where immunity to electromagnetic interference (EMI) is essential. Copper cables are used for powering equipment and for control signals in environments where mechanical durability and ease of installation are critical. For example, automotive manufacturing plants use fiber optics for precise data communication in automated assembly lines, while copper cables are used for powering robotic arms and other machinery.

Public Safety and Security

Emergency Communication Networks

Fiber optic cables are deployed in emergency communication networks to ensure reliable and secure data transmission. These networks are vital for first responders, enabling clear and uninterrupted communication during emergencies. The Department of Homeland Security in the United States, for example, uses fiber optic cables in its Integrated Public Alert and Warning System (IPAWS) to disseminate emergency alerts and warnings efficiently.

Surveillance Systems

Copper cables are commonly used in surveillance systems for their ability to transmit both power and data through PoE technology. This simplifies installation and reduces the need for separate power sources. Airports, such as those managed by the Port Authority of New York and New Jersey, utilize copper cabling for their extensive network of security cameras, ensuring continuous monitoring and safety.

Smart City Infrastructure

Intelligent Transportation Systems

Fiber optic cables are integral to intelligent transportation systems (ITS) in smart cities. They support real-time data communication between traffic control centers, sensors, and traffic lights, optimizing traffic flow and reducing congestion. Cities like Singapore have implemented fiber optic-based ITS to enhance urban mobility and reduce travel times.

Smart Grids

Copper cables are essential in the development of smart grids, which integrate renewable energy sources, energy storage, and advanced metering infrastructure. Copper’s durability and conductivity ensure reliable power distribution and efficient energy management. The Smart Grid Pilot Project in Boulder, Colorado, for instance, uses copper cabling to connect various components of the grid, facilitating efficient energy distribution and real-time monitoring.

Frequently Asked Questions

Below are answers to some frequently asked questions:

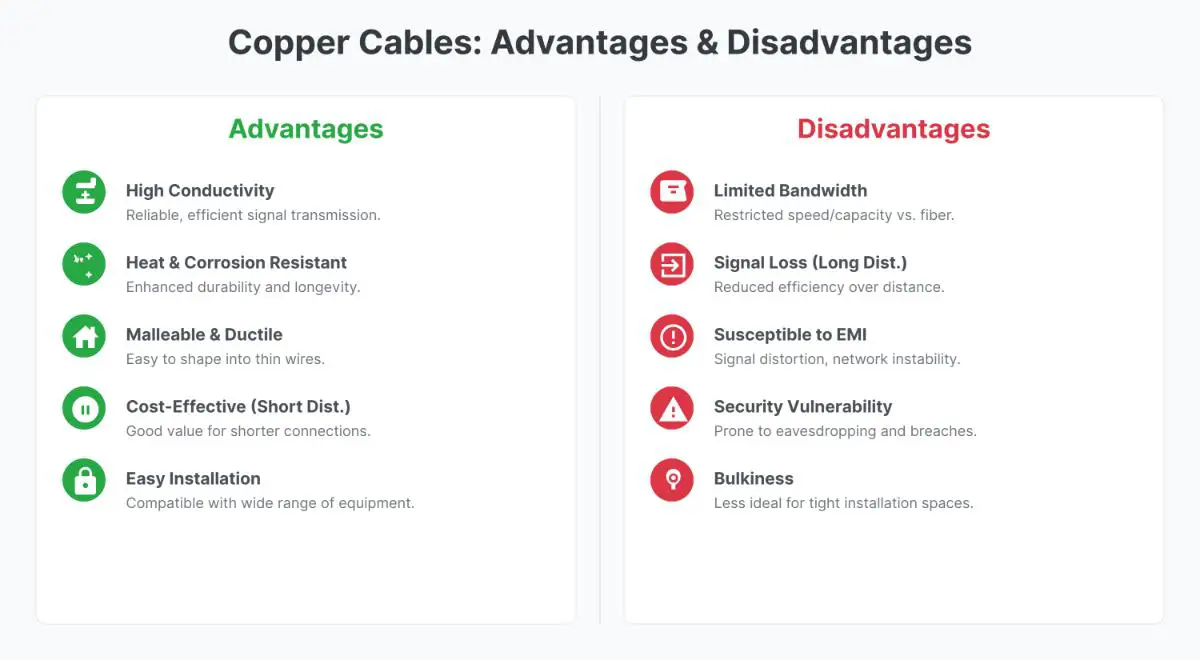

What are the advantages and disadvantages of using copper cables?

Copper cables offer several advantages, including high electrical conductivity, which ensures reliable and efficient signal transmission. They are also heat-resistant and corrosion-resistant, enhancing their durability and longevity. The malleability and ductility of copper make it easy to work with, allowing it to be shaped into thin wires suitable for various applications. Additionally, copper cables are cost-effective for short-distance data connections and are relatively easy to install, being compatible with a wide range of network equipment.

However, copper cables have some notable disadvantages. They have limited bandwidth compared to fiber optic cables, which restricts their data transmission speed and capacity. Copper cables are also prone to signal loss and degradation over long distances, leading to reduced efficiency. They are susceptible to electromagnetic interference (EMI), which can distort signals and impact network stability. Furthermore, copper cables are more vulnerable to eavesdropping and security breaches. Their bulkiness makes them less ideal for installation in tight spaces compared to the more flexible fiber optic cables.

How do copper cables compare to fiber optic cables?

Copper cables and fiber optic cables each have distinct advantages and disadvantages, making them suitable for different applications. Copper cables use electrical signals to transmit data and are typically used in localized networks due to their limited bandwidth and transmission distance. They are cost-effective for short distances and small-scale installations, supporting speeds up to 10 Gbps over about 100 meters. However, they are susceptible to electromagnetic interference (EMI) and signal degradation over longer distances.

In contrast, fiber optic cables use light signals, offering significantly higher bandwidth and the ability to transmit data over much longer distances without significant signal loss. They can achieve speeds of 100 Gbps or more, making them ideal for high-speed internet and large data transmissions. Although the initial installation cost of fiber optic cables is higher, they provide long-term savings due to lower maintenance and power consumption. Additionally, fiber optic cables are more secure and resistant to environmental factors, offering greater reliability and durability compared to copper cables.

What are the typical applications of copper cables in modern industries?

Copper cables are widely used across various modern industries due to their excellent electrical conductivity, flexibility, and durability. In the electrical and electronics industry, copper cables are essential for household wiring, power transmission lines, circuit boards, and electronic devices. In telecommunications, they serve as the backbone for telephone lines and DSL connections, ensuring stable and efficient data transmission. The automotive industry relies on copper wires for engine wiring, battery connectors, and in-car communication systems, which are increasingly important with the rise of electric vehicles. Additionally, copper cables play a crucial role in renewable energy systems, facilitating efficient energy transmission in solar panels, wind turbines, and battery storage systems. The construction industry also benefits from copper cables for electrical wiring, grounding systems, and lightning protection due to their strength and conductivity.

How does the cost of copper cables compare to that of fiber optic cables?

Copper cables are generally less expensive than fiber optic cables on a per linear foot basis. However, the

On the other hand, fiber optic cables, though initially more expensive, offer superior bandwidth and longer transmission distances, which can reduce the need for additional components. They are also immune to EMI, which can save on shielding and protective conduit costs. Over time, fiber optic cables tend to be more cost-effective due to their durability, lower maintenance needs, and fewer replacements. Thus, while copper might be a viable option for shorter distances and specific applications like Power Over Ethernet (PoE), fiber optics generally provide better long-term value for high-speed data transmission over longer distances.

What are the technical standards for copper cables?

The technical standards for copper cables are defined by organizations such as the Telecommunications Industry Association (TIA) and the International Organization for Standardization (ISO). These standards ensure copper cables meet specific performance criteria crucial for reliable data transmission.

The TIA-568.2-D standard specifies requirements for 4-pair twisted pair copper cabling, including parameters such as wiremap, DC loop resistance, insertion loss, return loss, NEXT, and PSNEXT. This standard is commonly used in North America.

Internationally, the ISO/IEC 11801-1 standard covers similar specifications for generic cabling in customer premises, including parameters like NEXT, PSNEXT, and ACRN. This standard applies to both shielded and unshielded cables.

Copper cables are categorized into different performance levels, such as Cat 5e, Cat 6, Cat 6A, and Cat 8, each corresponding to specific bandwidth capabilities. The termination of copper cables is standardized through the T568A and T568B standards, which define the pinout configurations for RJ45 connectors.

These standards ensure that copper cables are suitable for various applications in telecommunications and data transmission, maintaining consistency and reliability in network performance.

What are the technical standards for CCA cables?

Copper-Clad Aluminum (CCA) cables, composed of an aluminum core with a copper coating, offer a cost-effective alternative to pure copper cables. However, they come with specific technical standards and compliance requirements. The National Electrical Code (NEC) permits CCA conductors for certain applications, but they are unsuitable for environments requiring high fire safety ratings. CCA cables are listed under UL 83 for sizes ranging from 12 AWG to 1,000 kcmil, provided they comply with specific wiring methods. Despite their cost benefits, CCA cables do not meet the standards for high-performance applications such as Category 5e, 6, 6A, 7, and 8 cables, due to their inferior electrical properties, making them less suitable for professional networks or high-speed data transmission.