Imagine machinery that hums with precision, powered by components that ensure seamless operation under immense pressure—these are the unsung heroes known as dynamic seals. Integral to a multitude of industries, dynamic seals prevent leaks and maintain efficiency in systems ranging from automotive engines to industrial pumps. But how do you choose the right seal for your specific needs? This article delves into the fascinating world of dynamic seals, exploring their types, materials, and applications. Discover the key differences between rotary, reciprocating, and oscillating seals, and learn about the materials like Polytetrafluoroethylene (PTFE), Polyurethane (PU), and Nitrile Rubber (NBR) that make these seals reliable and durable. Whether you’re looking to enhance performance in hydraulic systems or tackle extreme environments, this comparative analysis will guide you through the options. Ready to uncover which dynamic seal solution best fits your requirements? Let’s dive in.

Overview of Dynamic Seals

Dynamic seals are essential parts of mechanical systems where surfaces move against each other. These seals create a barrier to retain fluids or gases, prevent contamination, and maintain system pressure, ensuring the integrity and efficiency of machinery, particularly in applications involving linear, oscillating, or rotary motions.

Dynamic seals come in various types, including rotary seals, reciprocating seals, and oscillating seals. Rotary seals contain fluids in rotating shafts, such as in pumps and engines. Rotary seals need to handle high speeds and changing pressures, so choosing the right materials is crucial for their performance and durability. Reciprocating seals handle back-and-forth motions found in pistons and hydraulic cylinders. These seals must cope with repeated motion and pressure changes, minimizing wear and ensuring long-term reliability. Oscillating seals manage arc movements in equipment like robotic arms. They need to handle continuous movement while maintaining their sealing capabilities.

Dynamic seals are employed across various industries due to their ability to maintain system integrity while allowing motion. They are essential in automotive for engines and transmissions, aerospace for hydraulic pumps and fuel systems, oil and gas for pumps and compressors, and manufacturing for robotic arms and machinery.

Dynamic seals effectively contain fluids, reduce friction, and offer high durability. They are compatible with various chemicals and can withstand extreme temperatures, ensuring machinery runs smoothly and lasts longer.

Types of Dynamic Seals

Rotary seals are essential components in systems with rotating parts, such as pumps and motors, where they prevent fluid leakage and ensure smooth operation. These seals are designed to withstand high speeds and varying pressures, making material selection crucial for effective performance.

Types of Rotary Seals

- Lip Seals: These seals use a flexible lip to create a barrier against the shaft, ideal for applications with moderate pressure.

- Mechanical Face Seals: Comprising two flat surfaces that rotate against each other, they are suited for high-pressure environments.

- Labyrinth Seals: Featuring a series of grooves to minimize leakage, these are perfect for high-speed applications.

Reciprocating seals are employed in systems with components that move back and forth, such as hydraulic cylinders and piston pumps. They are vital for preventing fluid escape and ensuring efficient system operation.

Types of Reciprocating Seals

- Piston and Rod Seals: These seals are crucial in hydraulic and pneumatic systems, where they prevent fluid from passing the piston and seal the rod during movement. They work together to maintain system integrity and support high performance.

Oscillating seals are used in systems where components move in an arc, like robotic arms and certain automotive parts. These seals must handle continuous movement while maintaining their sealing capabilities, ensuring precision and reliability.

Types of Oscillating Seals

- O-Rings: Known for their versatility, O-Rings can effectively manage oscillating motion, often used in robotic arms for their simplicity and effectiveness.

- V-Rings: These provide a dynamic seal that adapts to oscillating movements, commonly used in automotive parts to prevent debris ingress.

- Cup Seals: Offering enhanced sealing for applications with high pressure, cup seals are ideal for oscillating systems requiring robust performance.

Dynamic seals are crucial in maintaining system reliability and efficiency by preventing fluid leakage, reducing friction, and protecting against contaminants. They contribute to the prolonged lifespan of equipment and are indispensable in industries such as automotive, aerospace, and manufacturing. Understanding the types and applications of these seals is essential for selecting the right seal to ensure optimal performance and longevity in industrial systems.

Materials Used in Dynamic Seals

Polytetrafluoroethylene (PTFE)

PTFE, or polytetrafluoroethylene, is a highly versatile polymer widely used in dynamic seals due to its exceptional properties. Known for its remarkably low friction coefficient and chemical inertness, PTFE performs effectively across a broad temperature range, from -200°C to +260°C. These attributes make it self-lubricating and suitable for systems with minimal lubrication.

PTFE seals are particularly beneficial in industries such as chemical processing and aerospace, where high-speed rotation and exposure to aggressive chemicals are common. Its ability to maintain integrity under extreme temperatures and chemical exposure makes PTFE a preferred choice for critical applications.

Polyurethane (PU)

Polyurethane, or PU, is renowned for its mechanical strength and durability in dynamic seals. It excels in abrasion resistance, making it a top choice for heavy-duty applications in hydraulic systems. PU operates efficiently within temperatures ranging from -40°C to +100°C, ensuring reliable performance in high-pressure environments.

This material is commonly used in hydraulic cylinders, construction machinery, and pneumatic systems, thanks to its robustness and flexibility under pressure. PU’s durability and ability to withstand repeated motion make it ideal for applications where reliability is essential.

Nitrile Rubber (NBR)

Nitrile Rubber, or NBR, is a cost-effective material widely employed for dynamic seals in various industries. It is particularly noted for its oil and fuel resistance, which makes it ideal for automotive engines, fuel systems, and industrial hydraulics. NBR can function effectively between -40°C and +120°C, accommodating diverse conditions.

NBR’s versatility and affordability make it a popular choice for seals in both standard and demanding applications, especially where exposure to oils, fuels, and other hydrocarbons is prevalent.

Comparative Analysis of Seal Materials

Here is a simplified comparison of the key attributes of PTFE, PU, and NBR:

-

PTFE

-

Temperature Range: -200°C to +260°C

-

Key Features: Low friction, chemical inertness

-

Common Applications: Chemical processing, aerospace

-

PU

-

Temperature Range: -40°C to +100°C

-

Key Features: High abrasion resistance, mechanical strength

-

Common Applications: Hydraulic systems, construction machinery

-

NBR

-

Temperature Range: -40°C to +120°C

-

Key Features: Oil and fuel resistance, cost-effectiveness

-

Common Applications: Automotive engines, industrial hydraulics

Each material is selected based on specific application requirements such as temperature range, chemical exposure, and mechanical stress. PTFE is favored for high-speed and chemically aggressive environments, PU for high-pressure systems, and NBR for applications involving oil and fuel resistance. This careful selection ensures optimal performance and longevity of dynamic seals across various industries.

Comparative Analysis of Seal Materials

When choosing dynamic seals, it’s important to compare PTFE, PU, and NBR based on their unique properties and applications.

PTFE (Polytetrafluoroethylene)

Durability: PTFE is highly durable due to its chemical inertness and resistance to extreme temperatures, ranging from -200°C to 260°C. It maintains structural integrity and functionality even in the harshest environments.

Friction: PTFE’s low friction makes it great for high-speed applications and helps reduce wear on moving parts.

Industry Standards Compliance: PTFE complies with standards for chemical processing and aerospace applications due to its chemical resistance and high-temperature tolerance.

Polyurethane (PU)

Durability: PU is known for its high abrasion resistance and flexibility, making it suitable for applications involving heavy mechanical stress. It operates effectively within -40°C to 100°C.

Friction: PU has more friction than PTFE, but its wear resistance is ideal for parts that move often and face pressure changes.

Industry Standards Compliance: PU meets standards for hydraulic and pneumatic systems, particularly in construction and automotive industries, where abrasion resistance and mechanical strength are crucial.

Nitrile Rubber (NBR)

Durability: NBR offers good mechanical durability and is resistant to oils and fuels, with an operational temperature range of -40°C to 120°C. This makes it versatile for various industrial applications.

Friction: NBR has moderate friction properties, which are suitable for many general-purpose sealing applications, but it is less effective in high-speed scenarios compared to PTFE.

Industry Standards Compliance: NBR adheres to standards for automotive and industrial machinery, especially in applications involving exposure to oils and fuels.

Selecting the Right Material for Specific Applications

Selecting the right seal material depends on the specific needs of your application, like temperature, chemical exposure, and stress.

High-Speed and Chemical Exposure:

- PTFE is the preferred choice due to its low friction and chemical inertness. It is widely used in chemical processing, aerospace, and high-speed machinery.

Heavy-Duty and Abrasive Environments:

- PU is ideal for applications requiring high abrasion resistance and mechanical strength. It is commonly used in hydraulic systems, construction equipment, and automotive components.

Oil and Fuel Resistance:

- NBR excels in applications involving exposure to oils and fuels, such as automotive engines, fuel systems, and industrial machinery.

Advanced Materials for Extreme Environments

Key High-Performance Polymers

PTFE (Polytetrafluoroethylene)

PTFE’s excellent chemical resistance and low friction make it perfect for dynamic sealing in harsh conditions. It can withstand temperatures ranging from -328°F to 500°F, making it suitable for cryogenic applications and aerospace seals. This material is often used in systems requiring minimal resistance and high reliability under severe conditions.

PEEK (Polyether Ether Ketone)

PEEK, especially the Ketron™ CR-D variant, is engineered for cryogenic sealing applications, enduring temperatures down to -320°F. Its superior mechanical properties and chemical resistance make it ideal for dynamic uses in LNG systems and aerospace.

PFA (Perfluoroalkoxy)

PFA works well up to 500°F and has non-stick qualities that lower friction in dynamic seals. It is widely used in the aerospace industry, where low resistance and high-temperature tolerance are essential. PFA’s ability to function in aggressive chemical environments further enhances its suitability for high-performance sealing applications.

VESPEL®

VESPEL® is a high-performance polymer crucial for spacecraft components, maintaining its structure during extreme thermal cycles and rapid temperature changes, ensuring reliable sealing in critical aerospace applications.

Ultra-High-Temperature Composites

Luna Labs’ ultra-high-temperature composites exhibit glass transition temperatures exceeding 900°F, targeting solid rocket motor seals. These composites offer exceptional compressibility and thermal resistance, addressing the stringent demands of propulsion systems and enhancing thrust and burn duration.

Biomimetic and Advanced Polymers

Biomimetic Materials

Biomimetic materials, inspired by natural structures, offer greater durability in harsh environments like subsea drilling. These advanced polymers leverage the inherent strengths found in biological systems to offer superior performance in challenging conditions.

PCTFE (Polychlorotrifluoroethylene)

PCTFE combines cryogenic performance with gas impermeability, making it crucial for aerospace fuel systems. This polymer is designed to withstand ultra-low temperatures while preventing gas leakage, ensuring the integrity of fuel lines and storage systems.

Seal Types and Applications

Rotary Shaft Seals

Rotary shaft seals are used in high-pressure oil and gas systems, as well as wind turbines, where they are designed to manage dynamic motion and abrasive conditions. These seals are essential for maintaining system integrity and preventing fluid leakage in rotating machinery.

Cryogenic Seals

Cryogenic seals employ materials like PTFE and PEEK to ensure leakage prevention at ultra-low temperatures. They are critical in spacecraft fuel lines and cryogenic storage systems, where maintaining seal integrity under extreme cold is paramount.

High-Temperature Dynamic Seals

High-temperature dynamic seals, such as those made from Luna Labs’ composites, are designed to address extreme thermal demands in propulsion systems. These seals enhance the performance of propulsion components by providing reliable sealing under high-temperature conditions.

Industry-Specific Solutions

Aerospace

In the aerospace industry, PTFE and VESPEL® seals are employed to endure rapid thermal shifts and vacuum conditions. These materials ensure reliable performance in spacecraft components, where maintaining seal integrity is crucial for mission success.

Oil and Gas

Advanced EMC’s seals are tailored to handle subsea pressures and corrosive fluids, making them ideal for oil and gas applications. These seals provide durability and reliability in harsh underwater environments, ensuring the efficient operation of subsea equipment.

Renewable Energy

Durable seals are essential for wind turbine hydraulic systems, reducing maintenance requirements in harsh weather conditions. These seals contribute to the longevity and reliability of renewable energy systems, ensuring consistent performance under variable environmental stresses.

Innovation Trends (2024–2025)

Material Hybridization

Material hybridization involves combining polymers, such as PTFE-PEEK blends, to optimize thermal and mechanical properties. This approach aims to enhance the performance and durability of dynamic seals in extreme environments.

R&D Focus

Advanced EMC prioritizes cost-effective, application-specific designs through partnerships with testing facilities. These collaborations drive innovation in seal materials and designs, ensuring tailored solutions for diverse industrial applications.

Military/Aerospace Demands

Luna Labs’ Phase II developments focus on improving compressibility for missile defense systems. These advancements aim to enhance the reliability and performance of seals in military and aerospace applications, addressing the stringent requirements of defense systems.

Performance Metrics

| Material | Temp Range | Key Strengths | Primary Use Cases |

|---|---|---|---|

| PTFE | -328°F to 500°F | Chemical inertness, low friction | Aerospace, cryogenics |

| PEEK (CR-D) | -320°F to 300°F | Cryogenic dynamic sealing | LNG systems, space |

| Luna Labs Composite | >900°F | Ultra-high Tg, compressibility | Solid rocket motors |

Recent advancements in material science focus on tailored polymers and composites for extreme thermal and mechanical stresses. PTFE and PEEK dominate cryogenic applications, while novel composites address propulsion challenges. Cross-industry collaboration drives cost-effective, high-reliability solutions, ensuring the continued innovation and application of advanced materials in dynamic sealing for extreme environments.

Applications and Benefits

Dynamic seals are crucial in many industries because they keep systems secure while allowing movement. In aerospace, these seals ensure the safety and efficiency of aircraft and spacecraft by managing pressure differences and preventing fluid leaks in engines, hydraulic pumps, and fuel systems. In the automotive sector, dynamic seals are essential for preventing fluid leakage in engines, transmissions, and braking systems, which is vital for vehicle safety and performance. They also help optimize fuel efficiency and reduce emissions by maintaining the integrity of fuel systems.

Advanced dynamic seals work reliably even under extreme conditions, like high temperatures and pressures, which helps maintain safety in critical areas such as aerospace and automotive industries. Because dynamic seals are built to endure tough conditions, they reduce wear on important parts. This durability means less maintenance, longer machinery life, cost savings, and higher productivity.

Dynamic seals enhance the efficiency of mechanical systems by minimizing fluid leakage and maintaining optimal pressure levels, improving system performance and reducing operational costs. In hydraulic and pneumatic systems, they ensure smooth operation and reduce the risk of downtime caused by seal failure. Additionally, dynamic seals contribute to weight reduction in applications using lightweight materials, such as ceramic matrix composites (CMCs), offering an advantage in industries focused on minimizing environmental impact and improving energy efficiency.

Recent advances in dynamic seal technology, especially for high temperatures in demanding environments like aerospace, have improved efficiency, safety, and versatility. These innovations make dynamic seals useful for more applications, thanks to the use of high-performance polymers and composites that offer superior resistance to extreme temperatures and pressures, ensuring reliable operation even in the most challenging conditions.

Interactive Tools for Seal Selection

Trelleborg’s Variseal® Oil & Gas Seal Selector is a web-based configurator designed to assist in choosing dynamic seals for the oil and gas sector. Launched in July 2022, this tool provides an intuitive interface that helps generate precise seal specifications based on user inputs. Users can specify application-specific parameters, including the type of media, temperature range, pressure limits, groove dimensions, and motion type. Motion types such as radial rod/piston and axial seals are catered for; radial seals are used around shafts, while axial seals handle pressure from either side of a component. The tool outputs detailed reports in PDF format, offering design suggestions and material compatibility data, ensuring users can adjust dimensions in real-time without restarting the process. It is particularly useful for high-pressure applications, such as downhole tools and valves.

The Trelleborg Rotary Seal Selector focuses on rotary motion applications, providing a specialized tool for complex rotary systems. After logging in, users can tailor seal selection by inputting parameters such as shaft size, RPM, lubrication type, and installation constraints. The tool guides users in choosing suitable materials, recommending elastomers like FKM and HNBR based on chemical exposure and thermal limits. For more intricate systems requiring multiple seals, direct consultation with rotary seal specialists is advised.

Freudenberg Sealing Technologies (FST) offers configurators that optimize material selection across various dynamic motions and environmental factors. These tools match compounds like PTFE and polyurethane to specific requirements for abrasion resistance and temperature thresholds, providing industry-specific solutions for sectors such as manufacturing, energy, and hydraulics.

Each tool addresses industry needs through distinct functionalities. Trelleborg’s Variseal® Selector is specialized for the demanding conditions of oil and gas applications, offering high-pressure sealing solutions. The Rotary Seal Selector is tailored for general rotary systems, ensuring optimal performance by advising on material and installation specifics. Meanwhile, FST configurators are designed to cross industry boundaries, providing versatile solutions that cater to the specific demands of each field.

To maximize the effectiveness of these tools, it is crucial to ensure input tolerances are accurate within ±5% of actual operating conditions to prevent seal failure. Hybrid validation, combining tool outputs with laboratory testing, is recommended for critical applications, such as subsea valves. When prioritizing material selection, consider chemical resistance as a key factor, especially in aggressive media environments. These practices help ensure that the chosen seals will perform reliably in their intended applications.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the different types of dynamic seals?

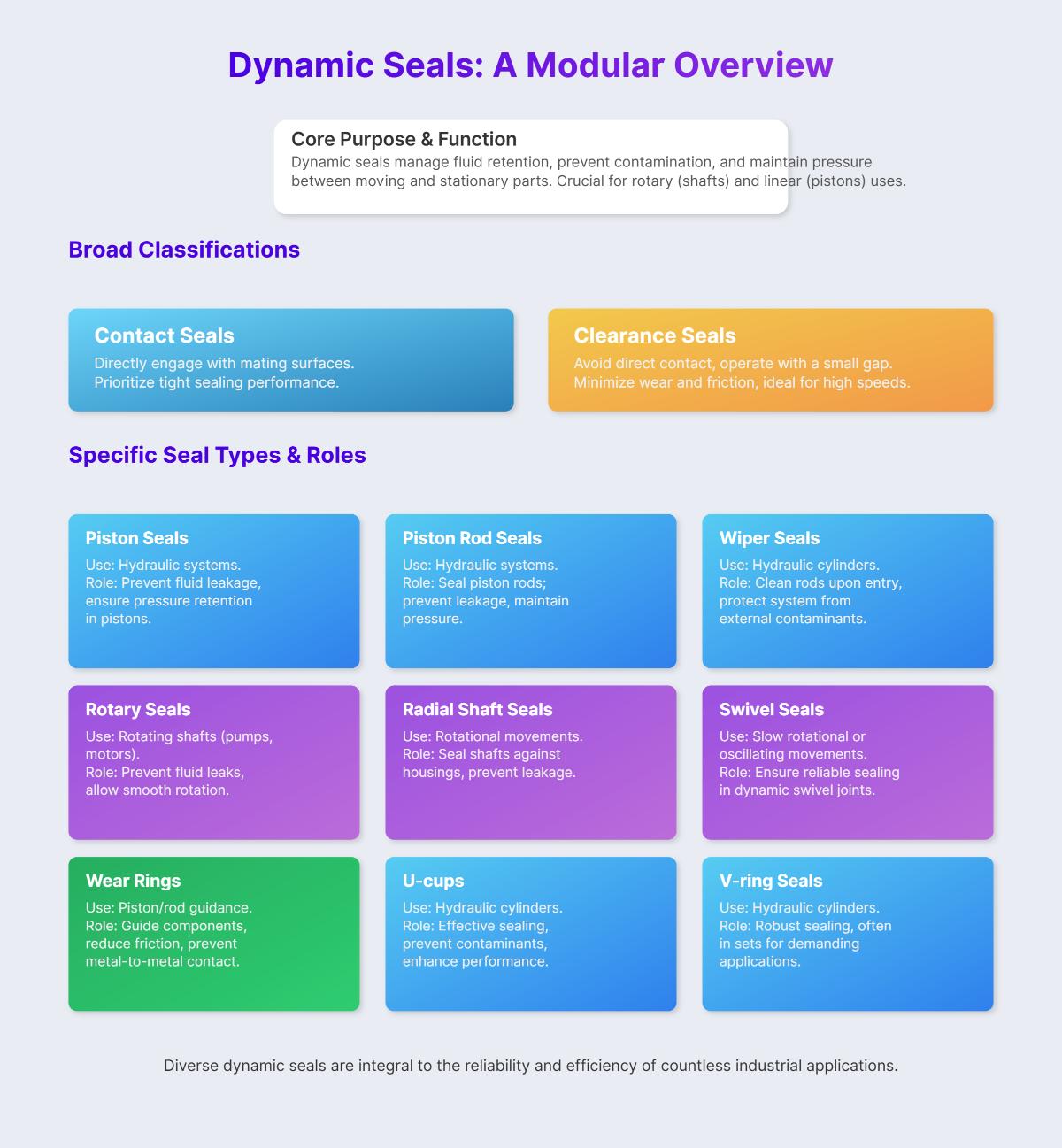

Dynamic seals are essential components in mechanical systems, designed to manage fluid retention, prevent contamination, and maintain pressure between moving and stationary parts. They are widely used in rotary and linear applications such as rotating shafts and pistons. Broadly, dynamic seals can be divided into contact seals, which directly engage with mating surfaces, and clearance seals, which avoid direct contact to minimize wear.

Specific types of dynamic seals include piston seals and piston rod seals, which are used in hydraulic systems to prevent fluid leakage and ensure pressure retention. Wiper seals clean rods entering hydraulic cylinders, protecting against contamination. Rotary seals are employed in applications involving rotating shafts, like pumps and motors, to prevent fluid leaks while allowing smooth rotation. Radial shaft seals and swivel seals cater to rotational movements, while wear rings guide pistons or rods, reducing friction. U-cups and V-ring seals offer effective sealing in hydraulic cylinders, often enhancing performance by preventing contaminants. These diverse types ensure dynamic seals fulfill their critical roles in various industrial applications.

Which materials are most effective for dynamic seals?

Dynamic seals are essential in applications involving rotary, reciprocating, and oscillating motions, ensuring effective sealing in various mechanical systems. The most effective materials for dynamic seals include Polytetrafluoroethylene (PTFE), Polyurethane (PU), and Nitrile Rubber (NBR).

PTFE is highly valued for its excellent chemical resistance, low friction coefficient, and wide temperature tolerance. It is self-lubricating, making it ideal for chemical processing and high-temperature applications where external lubrication is not feasible.

Polyurethane (PU) offers high abrasion resistance, mechanical strength, and excellent oil resistance. It performs well under high pressures and fast sliding speeds, making it suitable for hydraulic and pneumatic systems, commonly found in construction equipment and automotive components.

Nitrile Rubber (NBR) is renowned for its resistance to oils, fuels, and hydraulic fluids. It performs reliably in moderate temperature ranges and is commonly used in engines, pumps, and other applications involving petroleum products.

Each material’s unique properties cater to different requirements, ensuring optimal performance and longevity in their respective applications.

How can I select the appropriate dynamic seal for my needs?

Selecting the appropriate dynamic seal for your needs involves a careful evaluation of several key factors. First, consider the type of motion involved—whether it is rotary, reciprocating, or oscillating—as different motions require specific seal designs and materials. For instance, rotary seals are ideal for rotating shafts, while reciprocating seals work well with piston movements.

Next, assess the operating conditions, including speed, pressure, and temperature. Ensure the seal material can handle the maximum speed without excessive wear and withstand the operating pressure to prevent extrusion. The temperature range is also crucial, as extreme temperatures can affect seal material performance.

Material compatibility is another critical factor. Identify the medium being sealed and ensure the seal material is chemically compatible to prevent degradation. Additionally, consider environmental factors such as vibration and potential contaminants that could impact seal longevity.

What standards should I consider when choosing seal materials?

When choosing seal materials for dynamic seals, consider several key standards to ensure optimal performance and compatibility with your application.

First, assess the operational environment standards, including the temperature range and chemical resistance of the materials. For instance, PTFE excels in extreme temperatures and harsh chemical environments, while Nitrile Rubber (NBR) and Polyurethane (PU) are suitable for moderate temperatures and specific fluids.

Next, evaluate the mechanical performance criteria such as friction, speed, and pressure resistance. Low-friction materials like PTFE are ideal for high-speed applications, and reinforced PU can handle higher pressures compared to standard NBR.

Material durability and compatibility are also crucial. PTFE offers excellent fatigue resistance and minimal debris accumulation, whereas PU is highly elastic but may degrade under cyclic thermal stress.

Additionally, consider industry-specific certifications such as vacuum compatibility and sanitary standards for pharmaceutical and food-grade applications.

By carefully evaluating these standards, you can select the most appropriate seal material for your specific needs.

What are the advantages of using low friction materials in dynamic seals?

Using low friction materials in dynamic seals offers several advantages, which are crucial for enhancing the performance and longevity of various mechanical systems. Firstly, they significantly reduce friction and energy loss. Materials like PTFE-based composites or specific polyurethanes minimize contact resistance between moving parts, leading to lower energy consumption and reduced heat generation. This is particularly beneficial in high-speed applications such as automotive transmissions and hydraulic systems.

Secondly, low friction materials enhance wear resistance and durability. By minimizing direct surface contact, these materials decrease wear rates, extending the lifespan of the seals in demanding environments. This is particularly important in applications that experience high pressure or high-speed conditions.

Additionally, low friction materials improve efficiency in high-performance applications. For instance, in transmissions, they optimize fluid dynamics and reduce component weight, thus enhancing overall system efficiency. These materials are also advantageous in applications requiring bidirectional motion as they eliminate orientation-dependent installation issues.

Moreover, these materials offer broad compatibility with existing systems, allowing for easier integration without the need for costly modifications. This ensures that systems can be upgraded with minimal disruption.

Lastly, low friction materials provide excellent temperature and chemical resistance, making them suitable for use in extreme environments such as automotive, aerospace, and industrial systems. Overall, the use of low friction materials in dynamic seals results in more efficient, durable, and versatile sealing solutions.

How do advanced materials benefit extreme environment applications?

Advanced materials significantly enhance the performance of dynamic seals in extreme environments by improving their thermal stability, mechanical strength, and resistance to wear and corrosion. Innovations such as nanocomposites, incorporating materials like carbon nanotubes and ceramic nanoparticles, offer superior thermal resistance, making them ideal for applications in aerospace propulsion and nuclear reactors. Additionally, the use of refractory alloys and self-healing polymers reduces wear in corrosive environments, such as chemical processing plants, ensuring longer seal life and reliability.

These materials also allow for the development of seals that can withstand high pressures and temperatures, essential for applications like deep-sea drilling and high-pressure turbine shafts. Furthermore, manufacturing advancements, including additive manufacturing and machine learning-driven modeling, enable precise control over seal characteristics, ensuring they meet the specific demands of extreme operational conditions. Overall, advanced materials play a crucial role in expanding the capabilities and durability of dynamic seals in challenging environments, as discussed earlier in the article.