I. Requirements for grinding fluids

Grinding fluids are mainly used to reduce grinding temperature, improve machining surface quality, increase grinding efficiency, extend wheel life, and avoid workpiece burning, cracking, and thermal deformation. From the perspective of improving grinding effects, grinding fluids should serve the following functions:

1. Cooling effect

The cooling effect of grinding fluids mainly removes grinding heat from the grinding zone, reducing the grinding temperature.

2. Lubrication effect

Grinding fluids can penetrate between abrasive grains and the workpiece surface, adhering to the metal surface to form a lubricating film, reducing friction between abrasive grains and the workpiece surface, improving the cutting performance of the wheel to obtain a smaller surface roughness value.

3. Cleaning and chip flushing effect

Grinding fluids have high fluidity and can promptly wash away chips and fallen abrasive grains through the chip removal groove.

4. Rust prevention effect

Adding rust inhibitors to grinding fluids can form a protective film on the metal surface, protecting the workpiece and machine from rusting for a certain period.

In addition to the above effects, grinding fluids are also required to be non-toxic, odorless, non-irritating to the skin, non-corrosive, chemically stable, resistant to spoilage and deterioration, not prone to foaming, easy to treat and recycle waste fluids, and avoid environmental pollution.

Additives are commonly used to improve the performance of grinding fluids, including oiliness additives, extreme pressure additives, rust inhibitors, antifoam additives, and emulsifiers.

Some common fluid supply methods include: pouring method, high-pressure cooling method, internal cooling supply method, ultrasonic supply method, and wheel impregnation method.

II. Types and applications of grinding fluids

There are many types of grinding fluids, generally divided into two main categories: water-soluble grinding fluids and oil-soluble grinding fluids. Water-soluble grinding fluids can be further divided into: emulsions, transparent aqueous solutions, and electrolyte aqueous solutions.

The main component of water-soluble grinding fluids is water, with other additives added. They have excellent cooling effects, are easy to prepare, cost-effective, and less likely to cause pollution.

The main components of oil-soluble grinding fluids are mostly mineral oils. Common mineral oils are low or medium viscosity mineral oils with rust inhibitors added. For example, fatty acids are added to machine oil, light diesel oil, or kerosene to enhance lubrication.

Additionally, extreme pressure additives containing elements such as sulfur, chlorine, and phosphorus are added to grinding fluids to form extreme pressure oils, which have better penetration and lubrication abilities, suitable for processes requiring small surface roughness values.

Oil-soluble grinding fluids have good adhesion, can isolate air, and prevent undesirable chemical reactions such as oxidation and hydrolysis in the grinding zone. For example, CBN wheels are prone to react with water at high temperatures, so oil-soluble grinding fluids should be used for high-speed grinding with CBN wheels.

Oil-soluble grinding fluids are used to increase grinding speed and rate, particularly suitable for CBN wheel grinding. Oil-soluble grinding fluids made from residual mineral oils are typically used as coolants and lubricants, which age quickly under hot conditions. With proper wheel quality selection, oil-soluble grinding fluids can adapt to most grinding operations.

Synthetic oil-soluble grinding fluids have good characteristics and aging stability, with higher flash points at low viscosities, suitable for high-productivity grinding processes. Compared to conventional oil-soluble grinding fluids, the cost of synthetic grinding fluids is about doubled.

1. Advantages of oil-soluble grinding fluids

- Due to good lubrication performance, they require less power.

- Double the grinding rate at the same power.

- Less wheel wear, extended dressing intervals.

- High surface quality.

- Can be kept clean regularly with proper machine treatment.

- Essentially maintenance-free.

- Does not contain biocides, not susceptible to bacterial or fungal invasion.

2. Disadvantages of oil-soluble grinding fluids

- Flammable and explosive (if mixed with air in volume fractions between 0.6% and 7%).

- Machines must be completely enclosed.

- Must have oil mist extraction devices and explosion-proof doors.

- Must be equipped with carbon dioxide fire extinguishing systems.

- Due to low heat dissipation, double the amount of coolant-lubricant is required.

- Seals, pipes, and cables must be oil-resistant.

Table 1 provides a performance comparison of various grinding fluids; Table 2 shows the composition, properties, and usage instructions of common grinding fluids for reference when selecting.

Table 1 Performance comparison of various grinding fluids

| Item | Mineral oil | Extreme pressure oil | Emulsion oil | Synthetic fluid |

| Lubricity | Excellent | Excellent | Good | Poor |

| Cooling ability | Poor | Poor | Good | Excellent |

| Stability | Excellent | Excellent | Medium | Good |

| Cleaning ability | Poor | Poor | Medium | Good |

| Rust prevention | Excellent | Excellent | Medium | Good |

| Cutting ability | Good | Excellent | Medium | Good |

| Surface roughness value | Small | Smallest | Small | Small |

| Corrosion resistance | Good | Excellent | Poor | Good |

| Fire resistance | Poor | Poor | Good | Good |

| Defoaming ability | Good | Good | Medium | Poor |

| Visibility | Poor | Poor | Medium | Good |

| Usage cycle | Longer | Long | Short | Longer |

| Post-processing cost | Less | Less | Average | More |

Table 2 Composition, performance and instructions for common grinding fluids

| Category | Type | Serial number | Name | Composition (volume fraction, %) | Performance in use | |

| Oil-soluble grinding fluid | Non-active | 1 | Mineral oil | Barium petroleum sulfonate Kerosene | 2 98 | Good cleaning performance, used for grinding and super-finishing For grinding carbide, adding 0.5% by mass of sodium nitrite can increase rust prevention |

| 2 | Compound oil | Kerosene L-AN15 total loss system oil | 80-90 10-20 | Used for grinding cast iron, non-ferrous metals and polishing optical glass | ||

| 3 | Compound oil | Kerosene Oleic acid Turpentine | 55 40 5 | Used for grinding steel, cast iron, bronze, aluminum alloy and other materials | ||

| Active | 4 | Extreme pressure oil | Barium petroleum sulfonate Lead naphthenic acid Chlorinated paraffin L-AN10 high-speed total loss system oil L-AN32 high-speed total loss system oil | 0.5-2 6 10 10 Remainder | Good lubrication performance, non-corrosive, used for super-finishing, can replace sulfurized oil | |

| 5 | F43 extreme pressure oil | Chlorinated petroleum grease barium soap Zinc dialkyl dithiophosphate Molybdenum disulfide Barium petroleum sulfonate Calcium petroleum sulfonate L-AN7 high-speed total loss system oil | 4 4 0.5 4 4 83.5 | Used for grinding stainless steel, heat-resistant steel and corrosion-resistant steel | ||

| 6 | Grinding oil | Barium petroleum sulfonate 6411 Chlorinated paraffin Oleic acid L-AN32 turbine oil | 4 5 10 7 74 | Used for high-speed grinding, good extreme pressure performance, effective in preventing local burning and annealing | ||

| Water-soluble grinding fluid | Emulsion | 7 | 69-1 emulsion | Barium petroleum sulfonate Sulfonated castor oil Oleic acid Triethanolamine Potassium hydroxide L-AN7-10 high-speed total loss system oil | 10 10 2.4 10 0.6 Remainder | Used for grinding steel and cast iron parts, good cleaning performance with rust prevention properties Mix ratio 2% to 5% (volume fraction, same below) |

| 8 | F74-8 emulsion | Polyoxyethylene ether alkylphenol Phosphorus pentoxide Triethanolamine Sodium petroleum sulfonate L-AN7-10 high-speed total loss system oil | 4.5 0.5 5 15 75 | Used for grinding inner and outer circles of bearings Mix ratio 1% to 2% | ||

| 9 | F25D-73 rust-proof emulsion oil | Sodium petroleum sulfonate High carbonate sodium soap L-AN30 total loss system oil | 13 4 Remainder | Used for grinding and milling processes Mix ratio 3% to 5% | ||

| 10 | NL emulsion | Sodium petroleum sulfonate Sodium castor oil soap Triethanolamine Benzotriazole L-AN15 high-speed total loss system oil | 36 19 6 0.2 Remainder | High emulsifier content, low concentration, light-colored transparent liquid, good rust prevention performance, used for metal grinding Mix ratio 2% to 3% | ||

| 11 | Rust-proof emulsion | Sodium petroleum sulfonate Barium petroleum sulfonate Sodium naphthenic acid Triethanolamine L-AN15 Total Loss System Oil | 11-12 8-9 12 1 Remainder | Used for grinding ferrous metals and optical glass, add 0.3% mass fraction of sodium nitrite and 0.5% mass fraction of sodium carbonate to the already proportioned solution to further improve rust prevention performance Proportion 2% to 5% | ||

| 12 | Translucent emulsion | Sodium petroleum sulfonate Triethanolamine Oleic acid Ethanol L-AN15 Total Loss System Oil | 39.4 8.7 16.7 4.9 34.9 | Used for fine grinding, when preparing, add a mass fraction of 0.2% phenylethylamine Proportion 2% to 3% | ||

| 13 | Extreme pressure emulsion oil | Rust-proof glycerol complex (62 parts boric acid, 92 parts glycerol, 65 parts 45% sodium hydroxide) Sodium thiosulfate Sodium nitrite Triethanolamine Polyethylene glycol (relative molecular mass 400) Sodium carbonate Water | 22.4 9.4 11.7 7 2.5 5 Remainder | Has good lubrication and rust prevention properties, widely used for ferrous metal grinding Proportion 5% to 10% | ||

| Chemical synthetic fluid | 14 | No. 420 Grinding Fluid | Glycerol Triethanolamine Sodium benzoate Sodium nitrite Water | 0.5 0.4 0.5 0.8-1 Remainder | Used for high-speed grinding and slow-feed grinding, and grinding high temperature alloys, sometimes requires adding a foaming agent. Replacing glycerol with sulfurized oleic acid polyoxyethylene ether can improve grinding effect. Replacing with chlorinated stearic acid sulfurized oleic acid polyoxyethylene ether is suitable for grinding In-738 blades | |

| 15 | High-speed high-load grinding fluid | Chlorinated stearic acid Sulfur-containing additive Tx-10 non-ionic surfactant Boric acid Triethanolamine 742 defoaming agent Water | 0.4 0.6 0.1 0.1 0.2 1.6 Remainder | Diluted to 2% mass fraction solution for use, used for high-speed grinding and high-load grinding | ||

| 16 | M-2 Grinding Fluid | Oleic acid butanedioic acid monoalcohol amide Lauric acid monoalcohol amide Sodium benzoate | Used for general grinding (does not contain sodium nitrite) | |||

| 17 | No. 3 High-load Grinding Fluid | Sulfurized oleic acid Triethanolamine Non-ionic surfactant Borate Defoaming agent (organosilicon) added separately (0.25% mass fraction) Water | 30 23.3 16.7 5 25 | Has good cleaning and cooling properties, with relatively high extreme pressure value (pk value greater than 2500N) | ||

| 18 | H-1 Fine Grinding Oil | Castor oil maleic anhydride Diethanolamine Triethanolamine Lauric acid Boric acid | Used for precision grinding, also suitable for general grinding, can replace emulsions and soda water | |||

| 19 | GMY-2 High-speed Grinding Fluid | Sodium nitrite Sodium oleate 2010 (surfactant) Triethanolamine Water | 16 4 15 18 Remainder | Used for high-speed grinding, precision grinding Proportion: General grinding 2% to 3%, high-speed and special grinding 3% to 5% | ||

| 20 | SM-2 Grinding Fluid | EP-SS extreme pressure additive Surfactant Rust inhibitor additive | Used for grinding bearing steel, ferrous metals, etc. Proportion 3% to 5% | |||

| 21 | NY-802 Grinding Fluid | Sodium oleate Anionic surfactant Polyethylene glycol Sodium nitrite Preservative Auxiliary lubricant, etc. | Used for general and precision grinding Proportion 1% to 2% | |||

| 22 | 10° Strong Grinding Fluid | Synthetic chlorinated stearic acid polyoxyethylene ether Sodium benzoate Triethanolamine Sodium nitrite Defoaming agent Water | 0.5 0.3 0.4 1.0 0.1 97.7 | Used for creep grinding, no dilution, use directly | ||

| 23 | QM powerful grinding fluid | Used for high-speed, powerful, and creep grinding. QM176 and QM189 are used for grinding steel, QM186 is used for grinding chilled cast iron Mixing ratio: 2% to 3% for normal grinding, 3% to 4% for powerful grinding | ||||

| 24 | Grinding fluid | Sulfated castor oil (neutral) Trisodium phosphate Sodium nitrite Borax Water | 0.5 0.6 0.25 0.25 Balance | Has good cooling and cleaning properties, re- places kerosene grinding, or uses sodium carbonate instead of sulfated castor oil | ||

| 25 | Grinding fluid | Cleaner 6503 (coconut oil alkyl alcohol amide phosphate ester) Sodium nitrite OP-10 Water | 10 0.5 0.5 Balance | Good cleaning performance, used for grinding | ||

| 26 | Grinding fluid | Polyethylene glycol Castor acid diethanolamine salt Potassium tripolyphosphate Sodium nitrite Anti-rust complex (50 parts sorbitol, 30 parts triethanolamine, 8 parts benzoic acid, 12 parts boric acid) Water | 10 4 3 5 30 Balance | Brown transparent aqueous solution, used for grinding, good rust prevention performance, poor lubrication Mixing ratio 4% | ||

| 27 | Fine grinding fluid | Sodium petroleum sulfonate High carbonate triethanolamine Water (adjusted to pH=7.5 with triethanolamine) | 0.3-0.5 0.3-0.5 Balance | Used for fine grinding | ||

| 28 | QTS-1 grinding fluid | Chlorinated fatty acid Polyoxyethylene ether Trisodium phosphate Sodium nitrite Triethanolamine Water | 0.25 0.50 0.8 1.0 0.5-1 Balance | Used for fine grinding and other cutting processes | ||

| 29 | Grinding fluid | Naphthenic soap Trisodium phosphate Sodium nitrite Water | 0.6 0.6 0.25 Balance | Used for grinding | ||

| 30 | Bearing steel grinding fluid | Triethanolamine Oleic acid Sebacic acid Emulsifier Water | 0.4~0.6 0.3~0.4 0.1~0.2 0.2~0.3 Balance | Used for grinding bearing steel | ||

| 31 | Grinding fluid | Sulfur-containing additive Polyethylene glycol (relative molecular mass 400) TX-10 surfactant 6503 cleaner Boric acid Triethanolamine Sodium nitrite 742 defoamer Water | 0.4~0.9 0.5 0.1 0.1~0.2 0.1 0.2 0.5 0.4~0.6 Balance | Used for high and medium composite grinding | ||

| 32 | Grinding fluid | Triethanolamine Sebacic acid Polyethylene glycol (relative molecular mass 400) Benzotriazole Water | 17.5 10 10 2 Balance | Used for grinding metals, benzotriazole can be omitted when not grinding steel parts Benzotriazole Mixing ratio 1% to 2% | ||

| 33 | Transparent aqueous solution | Sodium carbonate Sodium nitrite Glycerol Polyethylene glycol (relative molecular mass 400 Water | 0.15 0.8 0.8~1.0 0.3~0.5 Balance | Used for centerless grinding machines and cylindrical grinding machines Mixing ratio 2% to 3% | ||

| 34 | 101 Grinding Fluid | High Molecular Compound (PAM) Rust Inhibitor Preservative Surfactant | Can replace oils and emulsions | |||

| 35 | Soda Water (I) | Sodium Carbonate Sodium Nitrite Water | 0.8~1.0 0.15~0.25 Remainder | Used for metal grinding, suitable for grinding nodular cast iron, During rainy seasons, add an appropriate amount of triethanolamine; when water hardness is high, add some sodium carbonate | ||

| 36 | Soda Water (II) | Sodium Carbonate Sodium Nitrite Glycerin Water | 0.5 0.15~0.25 0.5~1 Remainder | Used for metal grinding, suitable for diamond wheel grinding (not for resin bonded wheels) | ||

| 37 | Borax Triethanolamine Water | 1.6 0.2 Remainder | Used for diamond wheel grinding and general wheel grinding but not suitable for cubic boron nitride wheels | |||

III. Solid Grinding Agents

In addition to the above grinding fluids, solid grinding agents are sometimes used as supplements for grinding difficult-to-machine materials. Solid grinding agents mainly serve as fillers for grinding wheels. For example, using cryolite as a filler for grinding wheels produces good results when grinding stainless steel. Graphite, tungsten disulfide, and molybdenum disulfide can also be used as solid grinding agents.

For instance, when grinding tool steels with high alloy content, grinding becomes more difficult, especially dry grinding, where the workpiece is prone to burns and cracks. To address this, a mixture of molybdenum disulfide and alcohol can be used to soak the grinding wheel before dry grinding. This can improve the surface quality of the machined part and increase grinding efficiency by 2 times. Generally, the soaking process is simple, low-cost, and easy to promote.

Molybdenum disulfide can also be used as an additive in cutting to enhance the lubricating ability of grinding fluids. It can be added to machine oil or kerosene at a mass fraction of 10% molybdenum disulfide and 4% to 5% neutral soap.

IV. Correct Use of Grinding Fluids

- Grinding fluid should be poured directly onto the contact area between the grinding wheel and the workpiece.

- The flow of grinding fluid should be sufficient and evenly sprayed across the entire grinding width of the wheel to achieve a cooling effect.

- Grinding fluid should be injected into the grinding area with adequate pressure to achieve good cleaning action and prevent grinding debris from clogging the wheel surface in the grinding area.

- Properly configure splash guards to prevent grinding fluid from splashing out of the grinding machine.

- Maintain a certain fluid level in the cutting fluid tank.

- Grinding fluid should be kept clean regularly, minimizing the content of grinding debris and abrasive particles in the cutting fluid. Deteriorated cutting fluid should be replaced promptly. For ultra-precision grinding, specialized filtration devices can be used.

- Ensure smooth flow of grinding fluid and prevent blockages in the fluid passages caused by grinding debris. Remove any clogged debris promptly.

- Do not introduce other foreign objects into the fluid tank.

- In summer, pay special attention to prevent emulsion from corroding workpieces and machine table surfaces. The concentration of emulsion can be higher.

- Prevent grinding fluid from splashing into eyes, and especially avoid ingestion or inhalation of sodium nitrite from the cutting fluid. Take care to protect your health.

- Cultivate environmental awareness.

V. Methods of Supplying Grinding Fluid

During grinding, grinding fluid often has difficulty entering the grinding zone. The main reason is that when the grinding wheel rotates, it also produces a rotating airflow around the wheel. The higher the speed, the greater the airflow influence. Moreover, the obstruction of the wheel guard increases the dynamic pressure of the airflow.

1) The general method of supplying grinding fluid is by pouring. To improve the effectiveness of the pouring method, the following measures are often taken:

- Position the nozzle as close as possible to the grinding zone.

- Install a wheel guard or airflow deflectors on the nozzle.

- Increase the flow rate of grinding fluid. Generally, the flow rate should not be less than 0.5L/min per 1mm width. For high-speed grinding, as the wheel speed increases, the supply should also increase accordingly, and should not be less than 2-3L/min.

- Wheel guards often reduce the effectiveness of fluid supply, so the nozzle position should be as far away from the guard opening as possible, or the guard structure should be improved.

2) During high-speed grinding, the airflow around the wheel also increases. To improve fluid supply effectiveness, the following measures are often taken:

- Increase the grinding fluid supply volume and spray pressure.

- Reduce the contact area of the nozzle outlet while appropriately increasing the outlet width. This can improve spray speed and cooling range, and also reduce fluid splashing caused by high-speed airflow.

- Adjust the spray direction.

VI. Filtering Methods for Grinding Fluids

Grinding fluids need to be kept clean regularly. Impurities such as chips and loose abrasive particles produced during the grinding process cause the grinding fluid to deteriorate, not only affecting workpiece quality and scratching the machined surface but also impacting environmental hygiene.

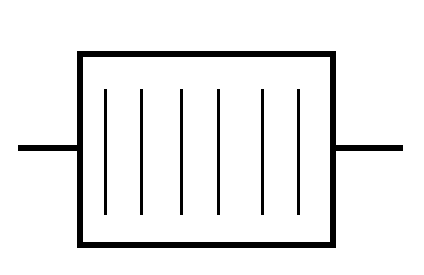

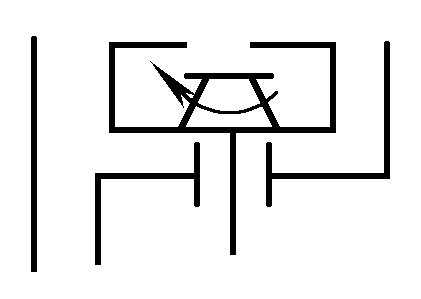

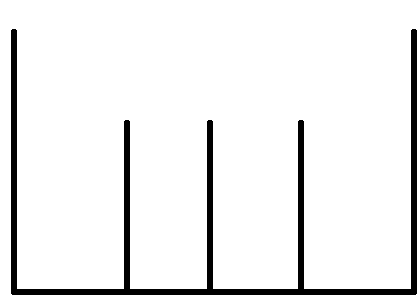

Especially for grinding that requires high precision and low surface roughness, the requirements for filtering and purifying grinding fluids are becoming increasingly stringent. Common filtering and purification devices include metal mesh sedimentation filters, centrifugal filters, magnetic filters, paper filters, and cyclone separators. Various grinding fluid purification devices are shown in Table 3.

Table 3 Various Grinding Fluid Purification Devices

| Filter Type | Cyclone Separator | Magnetic Filter | Paper Filter | Centrifugal Filter | Metal Mesh Sedimentation Filter | |

|  |  |  |  | ||

| Purification Performance | Purification Capacity/(L/min) | 12.5~100 | 25~100 | <25 | <50 | |

| Purification Rate (%) | 95 | Agitated 99, Not agitated 87 | ||||

| Particle Size/μm | 3~40 | <74 | 2~10 | >100 | ||

| Economic Effect | Power Consumption/kW | 0.6~1.1 | 0.12 | 0.12 | 0.17 | |

| Cutting Fluid Usage Duration | Long | Relatively Long | Long | Short | Shortest | |

| Filter Material | No Consumption | High Consumption | ||||

| Equipment Cost | Relatively Low | Relatively High | Relatively High | Relatively High | Low | |

| Floor Space | No Space Required | No Space Required | Relatively Little | Relatively Little | Relatively Little | |

| Noise | None | Slight | None | Relatively High | None | |

| Possibility of Filtering Non-magnetic Impurities | Possible | Not possible | Possible | Possible | ||

| Possibility of filtration when the medium viscosity is extremely high | Not possible | Possible | Possible | Possible | ||

| Continuity | Possible | Possible | Not possible | Clean once per shift | Clean once per shift | |

| Structural complexity | Simple | Complex | Relatively complex | Complex | ||

| Flow loss | Relatively large | Relatively large | Large | Relatively small | ||

VII. Problems encountered in the use of grinding fluids and their solutions

During the use of grinding fluids, expected results are often not achieved or unexpected problems occur, such as high surface roughness values, short wheel life, low processing efficiency, etc.; there are also management issues with grinding fluids, such as corrosion of grinding fluids, rust on workpieces and machines, etc.; there are also safety and health issues, such as operators developing dermatitis. When these problems occur, refer to Table 4 to analyze the causes and take corresponding measures.

Table 4 Problems encountered in the use of grinding fluids and corresponding measures

| Serial number | Problem | Cause | Corresponding measures |

| 1 | The surface roughness value of the ground surface is relatively high | Insufficient lubrication performance of the grinding fluid | 1. For oil-based grinding fluids, switch to grinding fluids with higher content of oily agents and extreme pressure additives; for water-based grinding fluids, switch to synthetic grinding fluids with good lubrication performance 2. Increase the viscosity of oil-based grinding fluids or the concentration of water-based fluids 3. Improve the filtration device 4. Increase the supply volume and pressure of the fluid |

| 2 | Dimensional accuracy is difficult to guarantee | Insufficient cooling performance of the grinding fluid, workpiece expands due to heat | 1. Increase the supply volume and pressure of the fluid 2. Lower the temperature of the grinding fluid itself, ensure the container is large enough, increase circulation for heat dissipation |

| 3 | Burn marks and cracks appear on the workpiece surface | Poor penetration of grinding fluid, unable to reach the grinding zone, resulting in high grinding temperature | 1. For oil-based grinding fluids, reduce their viscosity; for water-based grinding fluids, choose grinding fluids with good penetration 2. Increase the supply volume and pressure of the fluid 3. Improve the pouring method |

| 4 | Residual stress on the workpiece surface, reduced hardness | Insufficient lubrication and cooling performance of the grinding fluid, generating a large amount of grinding heat in the grinding zone | 1. Increase viscosity for oil-based grinding fluids; for water-based, choose synthetic cutting fluids with good lubrication or high-concentration emulsions 2. Increase fluid supply flow and pressure 3. Choose grinding fluids with high content of extreme pressure additives |

| 5 | Grinding wheel clogging | Poor penetration and cleaning performance of the grinding fluid, causing chips to clog the pores | 1. Reduce the viscosity of oil-based grinding fluids; or switch to water-based grinding fluids with good penetration and cleaning performance 2. Increase fluid supply flow and pressure 3. Choose synthetic grinding fluids that easily promote abrasive self-sharpening |

| 6 | Grinding wheel dulling | Poor lubrication performance of the grinding fluid, abrasive cutting edges wear quickly | Switch to grinding fluids with high content of oily agents and extreme pressure additives; for water-based solutions, choose emulsions with good lubrication or high-concentration synthetic fluids |

| 7 | Low lifespan of resin grinding wheels | Alkaline grinding fluids cause dissolution of resin binders | Switch to grinding fluids with weak alkalinity (pH around 8.5) |

| 8 | As usage period increases, grinding wheel lifespan decreases, grinding fluid performance deteriorates | 1. Oil leakage reduces grinding fluid performance 2. Increase in chips and fine abrasive particles in the grinding fluid 3. Decreased concentration of water-based grinding fluids 4. Grinding fluid deterioration and corruption | 1. Take measures to prevent oil leakage 2. Improve filtration devices 3. Add preservatives and pH value increasers to water-based grinding fluids to restore the original liquid to normal state 4. Replace with new grinding fluid |

| 9 | Machine or workpiece rusting (water-based grinding fluids) | 1. Decreased concentration of the fluid in use 2. Decreased pH value 3. Insufficient or consumed rust inhibitors 4. Grinding fluid deterioration and corruption | 1. Measure concentration and maintain at a certain level 2. Add alkaline liquid to maintain pH around 9 3. Supplement rust inhibitors 4. Replace with new fluid when grinding fluid is severely deteriorated and corrupted |

| 10 | Workpiece rusting between processes (water-based grinding fluids) | 1. Excessive idle time 2. Corrosion from acidic gases from nearby pickling tanks 3. Storage under abnormal climate conditions such as rainy seasons | 1. Apply rust-preventive oil or grease 2. Under the influence of surrounding environmental conditions, apply rust-preventive oil or grease in advance 3. Supplement rust inhibitors, appropriately increase the concentration of water-based fluids |

| 11 | Stains appear on machine bed surfaces, etc. (oil-based grinding fluids) | Caused by reactions between the metal surface and certain components in the grinding fluid | 1. Clean thoroughly immediately after operation 2. Check if water has mixed into the grinding fluid 3. Check if extreme pressure additives in the grinding fluid have chemically reacted with it 4. Promptly replace deteriorated grinding fluid |

| 12 | Emulsion separation, phase inversion, and formation of insoluble substances | 1. Improper dilution method 2. Oil leakage mixing into the fluid 3. Deterioration 4. When the workpiece is aluminum alloy, aluminum hydroxide causes the formation of metal alkali | 1. Fill the tank with water and stir, then add the original emulsion liquid 2. Prevent oil leakage, install oil leakage recovery device 3. Add preservatives, pH value enhancers or increase the original liquid 4. Replace with new liquid |

| 13 | Coating peeling (water-based grinding fluid) | The effect of alkali and surfactants in grinding fluid | Phosphoric acid phthalate coatings are prone to peeling, so baked vinyl resin or polyurethane coatings should be used |

| 14 | Excessive bubbles in water-based grinding fluid | Too much surfactant (dilution concentration too high) | 1. Add water to dilute when concentration is too high 2. Add defoaming agent 3. Change the type of grinding fluid |

| 15 | Water-based grinding fluid easily deteriorates, requiring frequent replacement | 1. Poor management 2. Poor preservative performance in the fluid 3. Excessive oil leakage and chips mixing in 4. Long-term disuse, insufficient air injection 5. Use of vitrified grinding wheels | 1. Manage pH value and concentration 2. Add bactericides regularly 3. Set up anti-leakage and filtering devices 4. Regularly inject air into grinding fluid during holiday periods 5. Switch to grinding fluid suitable for vitrified grinding wheels |

| 16 | Water-based grinding fluid turns red | 1. Amine in grinding fluid reacts with chips (iron) 2. Formation of iron hydroxide | 1. Increase filtering devices, remove chips from grinding fluid 2. Add preservatives, pH value enhancers |

| 17 | When using oil-based grinding fluid, splashing chips smoke and catch fire in the liquid tank | Low flash point of grinding fluid | 1. Switch to water-based grinding fluid 2. Switch to grinding fluid with higher flash point |

| 18 | Operators experience skin dryness, cracking, rash, erythema, ulceration | 1. Solvents or low-viscosity petroleum products cause degreasing 2. Oil allergy 3. Degreasing and irritation caused by alkali and surfactants | 1. Choose grinding fluids with less skin irritation 2. Install devices to prevent grinding fluid splashing, reducing skin contact opportunities 3. Operators should maintain clean hands, wrists, and work clothes, wash thoroughly after work and apply protective grease 4. Manage the use of fluids to prevent deterioration 5. Reassign work for operators with allergic conditions |

| 19 | Odd smell around the machine | 1. Water-based fluid deterioration, leaked grinding oil in oil pans and floor areas deteriorates 2. High grinding temperature causes oil-based fluid components to vaporize and decompose, generating smoke | 1. Replace with new fluid, add bactericides and preservatives 2. Increase fluid supply volume and pressure, lower grinding temperature, reduce smoke generation 3. Regularly clean oil pans and floor |

| 20 | Oil-based grinding fluid smokes, workshop fills with mist | Low flash point of cutting fluid | 1. Supply cutting fluid with higher flash point 2. Switch to water-based grinding fluid |