Ever wondered how to accurately determine the weight of a brass sheet for your next project? Whether you’re working on a DIY craft or managing inventory for a larger operation, knowing the precise weight is crucial. Brass, with its unique properties and versatile applications, requires a specific approach to calculate its weight. This guide breaks down the process into manageable steps, helping you navigate the calculations with ease. We’ll cover essential topics such as the density of brass, detailed calculation methods, and even explore advanced techniques for irregular shapes. Curious about how to use online tools for this task? We’ve got you covered. Ready to master the art of calculating brass sheet weight? Let’s dive in.

Understanding Brass Sheets

Introduction to Brass Sheets

Brass sheets are thin, flat pieces of metal primarily made from copper and zinc, and are widely used due to their excellent properties and attractive appearance. These sheets find applications in various industries thanks to their mechanical properties and aesthetic appeal. Understanding the characteristics and uses of brass sheets is essential for making informed decisions in engineering, manufacturing, and DIY projects.

Composition and Properties

Brass is an alloy typically consisting of 60-70% copper and 30-40% zinc. The varying composition results in different types of brass, each with unique properties. Some common types include:

- Cartridge Brass (70/30): Known for its ductility and formability, making it ideal for deep drawing and forming operations.

- Red Brass (85/15): Higher copper content provides excellent corrosion resistance and a reddish color, suitable for plumbing and decorative applications.

- Yellow Brass (65/35): Offers a balance of strength and malleability, commonly used in hardware and fittings.

Key Properties of Brass Sheets

- Corrosion Resistance: Brass resists tarnishing and corrosion, especially in marine and industrial environments.

- Workability: Brass sheets are easily cut, bent, and shaped with standard metalworking tools.

- Electrical Conductivity: Brass has good electrical conductivity, making it useful for electrical components.

- Aesthetic Appeal: The bright, gold-like appearance of brass adds visual appeal to decorative and architectural applications.

Common Applications

Brass sheets are used in various industries for applications such as:

- Architectural Elements: Brass sheets are used in the construction of doors, window frames, and decorative panels due to their aesthetic qualities.

- Electrical Components: The conductivity and durability of brass make it suitable for connectors, terminals, and other electrical hardware.

- Musical Instruments: Brass sheets are used in the manufacture of musical instruments like trumpets, trombones, and saxophones, owing to their acoustic properties.

- Plumbing and Hardware: The corrosion resistance and strength of brass make it an excellent choice for plumbing fixtures, valves, and fasteners.

Selecting the Right Brass Sheet

When selecting a brass sheet for a specific application, consider the following factors:

- Thickness: Brass sheets come in various thicknesses, typically measured in gauge or millimeters. The thickness required depends on the intended use and mechanical requirements.

- Type of Brass: Choose the appropriate type of brass based on the specific properties needed for your application, such as corrosion resistance, strength, or aesthetic appeal.

- Surface Finish: Brass sheets are available in different finishes, including polished, brushed, and patinated. The finish can affect both the appearance and performance of the sheet.

- Cost: Brass can be more expensive than other metals, so consider the budget and cost-effectiveness for your project.

Working with Brass Sheets

Working with brass sheets involves several common metalworking techniques:

- Cutting: Brass sheets can be cut using shears, saws, or laser cutting machines. Proper cutting techniques ensure clean edges and precise dimensions.

- Forming: Brass’s high malleability allows it to be bent, rolled, and formed into complex shapes without cracking.

- Joining: Brass sheets can be joined using soldering, brazing, or welding. Each method has its advantages depending on the application and required strength of the joint.

- Finishing: After forming and joining, brass sheets can be polished, coated, or treated to achieve the desired surface finish and protection.

What is the Density of Brass?

The density of brass, defined as the mass per unit volume, is a key property that affects its use in various industries.

Brass, an alloy of copper and zinc, typically has a density ranging from 8.4 to 8.7 g/cm³ due to varying proportions of these metals and other alloying elements. For instance, soft yellow brass (C26000) has a density of approximately 8.5 g/cm³, while yellow brass (C27000) is around 8.6 g/cm³.

Factors Influencing Brass Density

Several factors, including composition and the presence of additional alloying elements, affect the density of brass. Higher copper content increases the density, as copper itself has a density of about 8.96 g/cm³. Conversely, higher zinc content, with a density of around 7.14 g/cm³, reduces the

Additional alloying elements such as lead, aluminum, or tin also influence the density. Lead, often added to improve machinability, has a density of about 11.34 g/cm³ and can increase the

Manufacturing Processes

The method of production can also impact the density. Casting can create microvoids within the material, which may reduce its density. In contrast, extrusion and rolling processes typically produce a more uniform and compact microstructure, potentially increasing the density.

Practical Importance

Understanding the density of brass is essential for several reasons. Engineers and designers rely on accurate density values to ensure brass components meet their specific application requirements. Accurate density values are crucial for calculating the weight of brass components, which is vital for structural and manufacturing considerations.

Calculating Brass Density

To determine the density of a specific brass alloy, use the formula:

Where:

- Mass: The weight of the brass sample.

- Volume: The space occupied by the brass sample.

By measuring these properties precisely, you can calculate the density and ensure it aligns with the expected values for the type of brass being used. This knowledge helps in making informed decisions for engineering and manufacturing applications.

Step-by-Step Guide to Calculating the Weight of a Brass Sheet

Understanding Brass Density

Brass, an alloy of copper and zinc, has a density that varies based on its specific composition. The density of brass typically ranges from 8.44 to 8.75 g/cm³, or approximately 8440 to 8700 kg/m³. Knowing the specific density of the brass alloy you are working with is crucial for accurate weight calculations.

Measuring Dimensions

To calculate the weight of a brass sheet, you need to measure the following dimensions:

- Length (L): The total length of the brass sheet.

- Width (W): The total width of the brass sheet.

- Thickness (T): The thickness of the brass sheet.

Make sure all measurements are accurate and use the same units, such as meters or millimeters.

Weight Calculation Formula

Once you have the dimensions and the density, you can use the following formula to calculate the weight of the brass sheet:

Ensure that all dimensions are in the same unit system as the density to maintain consistency in your calculation. For example, if the density is in kg/m³, the dimensions should be in meters.

Example Calculation

Let’s consider an example to illustrate the weight calculation:

- Length (L): 2 meters

- Width (W): 1 meter

- Thickness (T): 0.005 meters (5 millimeters)

- Density (ρ): 8500 kg/m³ (a typical value for brass)

Using the formula:

Thus, the weight of the brass sheet is 722.5 kg.

Using Brass Sheet Weight Calculators

Online calculators are available to simplify the weight calculation process. These tools typically allow you to input the dimensions and density of the brass sheet, and they automatically compute the weight. This method is convenient and reduces the chance of manual calculation errors.

Considerations and Common Mistakes

Unit Consistency

Ensure that all dimensions and the density value are in the same unit system to avoid calculation errors. For example, if you use meters for length and width, ensure the thickness is also in meters.

Accurate Density

Use the correct density for the specific brass alloy you are working with. Different types of brass have slightly different densities, and using an incorrect value can lead to inaccurate weight calculations.

Coatings and Finishes

If the brass sheet has any coatings or finishes, these can add to the

Practical Tips

- Double-check measurements using appropriate tools to ensure accuracy.

- Refer to material standards such as ASTM for standardized values of brass densities.

- Consult manufacturer data for specific density values of their brass products, which can be more accurate than generic values.

Advanced Calculation Techniques for Complex Shapes

Complex shapes are geometric forms that go beyond basic categories like rectangles, triangles, or circles. They often have unique curves, edges, and combinations of simpler shapes, making them common in advanced engineering and architectural designs. Accurately calculating the weight of brass sheets with complex shapes is crucial for precise material planning and ensuring the structural integrity of projects.

Breaking Down Complex Shapes

To simplify the process of calculating the weight of complex shapes, break them down into simpler, more manageable components.

Step-by-Step Process

Start by visualizing and sketching the complex shape, noting all its components. Then, break it down into simpler geometric figures such as rectangles, triangles, and circles. Use known formulas to calculate the areas or volumes of these basic shapes, and sum the results to find the total area or volume of the complex shape.

Weight Calculation Formula

To find the weight of a brass sheet, multiply its volume by the density of brass. The volume can be calculated by multiplying the length, width, and thickness for simple shapes, or by breaking down complex shapes into simpler parts. Brass density varies between 8.44 and 8.75 g/cm³, depending on its alloy composition, so ensure you use the correct density for accurate calculations.

Advanced Techniques for Complex Brass Shapes

When dealing with complex brass shapes, consider the following advanced techniques to ensure precise calculations:

Additive and Subtractive Methods

- Additive Method: Calculate the volume by adding the volumes of simpler shapes that make up the complex shape.

- Subtractive Method: Determine the volume by subtracting the volumes of unnecessary parts from a larger, encompassing shape.

Geometric Modeling

Advanced geometric modeling techniques can be employed to handle complex 3D shapes, especially in applications requiring precise volume and surface area calculations. This involves using software tools to create detailed models of the shapes and accurately compute their volumes.

Practical Tools

Leverage specialized software tools or calculators designed for material weight calculations. These tools often include features for inputting complex shapes and automatically computing the weight based on the provided dimensions and material properties.

Practical Example

For instance, if you have a brass component made of a cylinder attached to a rectangular block, calculate the volumes separately. Use the formula (π×radius2×height) for the cylinder and (length×width×thickness) for the block. Add the volumes together and multiply by the density of brass to find the weight.

By following these advanced techniques, you can ensure accurate weight calculations for brass sheets with complex shapes, facilitating better material management and structural planning in engineering and manufacturing projects.

Using Online Brass Sheet Weight Calculators

Advantages of Using Online Calculators

Online brass sheet weight calculators offer several benefits, making them invaluable tools for engineers, manufacturers, and hobbyists. Here are some key advantages:

- Time-Saving: These tools quickly provide results, eliminating the need for manual calculations.

- Accuracy: By automatically handling unit conversions and complex formulas, online calculators minimize the risk of human error.

- User-Friendly: Most calculators feature intuitive interfaces that are easy to use, even for those with limited technical expertise.

- Convenience: Accessible from any device with an internet connection, online calculators can be used anytime and anywhere.

Steps to Use an Online Brass Sheet Weight Calculator

Selecting the Right Calculator

There are several online calculators available, each with unique features. Popular websites like MachineMFG and Calculator Academy offer reliable options. When selecting a calculator, consider the following:

- Reputation: Choose calculators from reputable websites to ensure reliability.

- Functionality: Look for calculators that allow input of various dimensions and units.

- Customization: Some calculators let you input specific densities, which is crucial for different brass alloys.

Inputting Dimensions

Once you’ve chosen a calculator, follow these steps:

- Enter the Length: Input the length of the brass sheet. Ensure the unit (e.g., meters, inches) matches your measurements.

- Enter the Width: Input the width of the sheet in the same unit as the length.

- Enter the Thickness: Input the thickness. Ensure all dimensions are in the same unit for consistency.

Selecting or Inputting Density

The density of brass varies based on its alloy composition. Most calculators provide a default density value, but you can manually input the correct density for your specific brass alloy if known:

- Default Density: Use the pre-set value if it aligns with your brass type.

- Custom Density: Input the specific density if you have precise data from material specifications.

Calculating the Weight

After entering all necessary data:

- Verify Inputs: Verify your dimensions and density entries for accuracy.

- Calculate: Click the “Calculate” button (or equivalent) on the calculator.

The tool will instantly provide the weight of the brass sheet based on your inputs.

Additional Features and Considerations

Conversion Tools

Many online calculators also offer unit conversion tools. This feature is helpful if your measurements are in different units (e.g., converting inches to meters).

Accounting for Coatings and Finishes

Some advanced calculators allow you to input additional weights for coatings and finishes. This is essential for achieving precise weight calculations in cases where the brass sheet has surface treatments.

Results Interpretation

Once the calculation is complete, the result will display the weight in the unit of your choice (e.g., kilograms, pounds). You can use this weight information for:

- Material Ordering: Ensure you order the correct amount of material for your project.

- Cost Estimation: Calculate the cost based on the weight and price per unit weight.

- Structural Analysis: Assess the suitability of the brass sheet for structural applications based on its weight.

By leveraging online brass sheet weight calculators, you can enhance the efficiency and accuracy of your weight calculations, ensuring better project outcomes and resource management.

Frequently Asked Questions

Below are answers to some frequently asked questions:

How do I calculate the weight of a brass sheet?

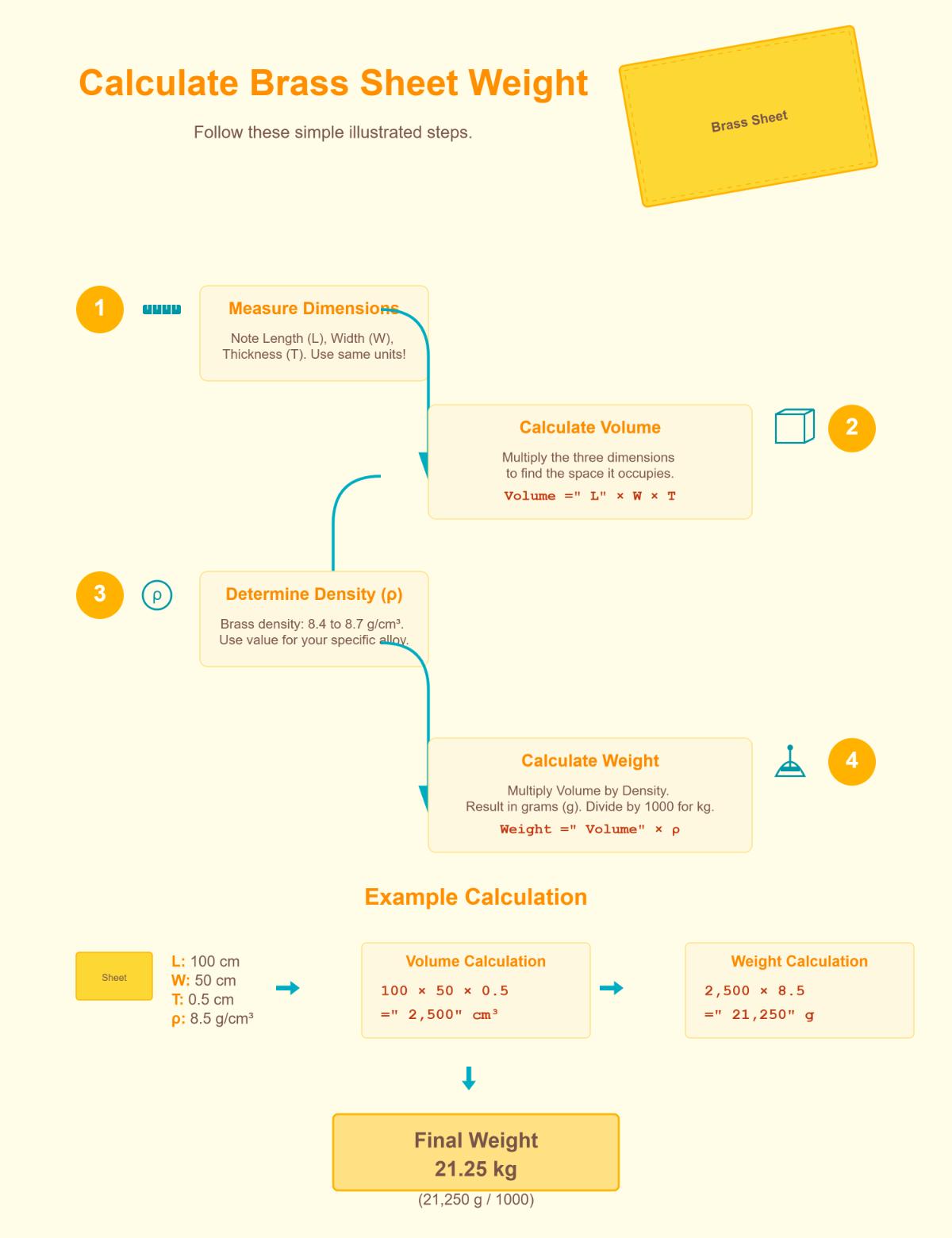

To calculate the weight of a brass sheet, follow these steps:

Measure the Dimensions: Obtain the length, width, and thickness of the brass sheet. Ensure all dimensions are in the same units (e.g., centimeters or inches).

Calculate the Volume: Use the formula for volume:

Volume=Length×Width×ThicknessDetermine the Density: The density of brass typically ranges from 8.4 to 8.7 g/cm³. Choose the appropriate density based on the specific alloy you are using.

Calculate the Weight: Multiply the volume by the density to find the weight:

Weight=Volume×Density

If the volume is in cubic centimeters and the density in g/cm³, the weight will be in grams. Convert to kilograms by dividing by 1,000 if needed.

For example, if a brass sheet measures 100 cm in length, 50 cm in width, and 0.5 cm in thickness, and the density is 8.5 g/cm³, the weight calculation would be:

Volume=100×50×0.5=2,500 cm3

Weight=2,500×8.5=21,250 grams=21.25 kilograms

This method ensures accurate weight calculations crucial for industrial applications.

What is the density of brass?

The density of brass, a key factor in calculating the weight of a brass sheet, typically ranges between 8.4 and 8.7 grams per cubic centimeter (g/cm³). This variation is influenced by the specific composition of the brass alloy, which primarily consists of copper and zinc. Additionally, the presence of other elements such as tin, lead, or aluminum, and the manufacturing process, can also affect the density. Accurate density measurement is crucial for determining the weight of brass components, ensuring they meet the required specifications for various applications.

Can I use the same method for different metal types?

Yes, you can use the same method for calculating the weight of different metal types. The fundamental formula remains Weight = Volume × Density. Volume is calculated by multiplying the dimensions of the metal piece (length, width, and thickness). However, the density is specific to each metal type and must be accurately used for precise calculations. For example, brass has a density ranging from 8.44 to 8.75 g/cm³, while aluminum is around 2.7 g/cm³, and mild steel is approximately 7.96 g/cm³. Ensure consistency in measurement units and consider any additional factors like coatings that might affect weight. Online calculators can simplify this process by providing quick and accurate results based on input dimensions and material densities.

Where can I find reliable online weight calculators for brass sheets?

Reliable online weight calculators for brass sheets can be found on various websites, including those of metal stockholders, specialized metal suppliers, and general online calculators. For example, Aalco in the UK provides an online metal weight calculator that allows you to input dimensions and material specifics for accurate results. Best Stainless offers calculators tailored to different materials, including brass, with customizable options for shape and size. Additionally, platforms like Omnicalculator and EasyCalculation offer versatile calculators where you can manually input the density and dimensions of the brass sheet. These tools simplify the calculation process and ensure accuracy when determining the weight of brass sheets.

What factors can affect the accuracy of my weight calculations?

Several factors can affect the accuracy of your weight calculations for a brass sheet. First, precise measurement of the sheet’s length, width, and thickness is crucial; even minor measurement errors can significantly impact the results. Additionally, manufacturing tolerances can lead to variations in these dimensions, so it’s essential to account for them.

The density of brass, which can vary between 8.44 and 9.7 g/cm³ depending on the alloy composition, also plays a critical role. Using an incorrect density value will lead to inaccurate weight calculations. Ensuring consistency in units across all measurements and density values is vital to avoid conversion errors.

Other factors include the presence of coatings or finishes on the brass sheet, which can add weight, and the use of appropriate formulas for different shapes. Utilizing reliable online calculators can also enhance accuracy by providing quick adjustments for dimensions and densities. By considering these factors, you can achieve more precise weight calculations for brass sheets.