Imagine transforming the sleek, modern look of stainless steel into a luxurious, gold-plated masterpiece. Whether you’re a beginner looking to add a touch of elegance to your DIY projects or someone eager to explore new techniques, learning how to color stainless steel gold can open up a world of possibilities. This tutorial is designed to guide you through the entire process, from understanding the basics of stainless steel to mastering gold plating techniques like electroplating and Physical Vapor Deposition (PVD). By the end, you’ll not only know how to achieve that coveted golden hue but also understand the benefits of using gold-plated stainless steel, such as enhanced durability and corrosion resistance. Ready to add some shine to your creations? Let’s dive in!

Introduction to Stainless Steel

What is Stainless Steel?

Stainless steel is an alloy, a mixture of different metals. It mainly consists of iron and carbon at its base. The key addition is chromium. For a metal to be classified as stainless steel, it must contain at least 11% chromium. This chromium forms a thin, protective oxide layer on the steel’s surface. The layer acts like a shield. It prevents rust and corrosion. So, stainless steel can maintain its appearance and functionality in various environments.

Properties and Benefits of Stainless Steel

- Corrosion Resistance: As mentioned, the chromium oxide layer prevents rust formation. This makes stainless steel suitable for items exposed to water, chemicals, or harsh weather, such as outdoor sculptures and kitchen sinks.

- Strength and Durability: Stainless steel is strong and resists wear and tear well. It doesn’t break or deform easily, so it’s used in construction and industrial equipment.

- Hygiene: It’s easy to clean and doesn’t harbor bacteria. That’s why it’s commonly used in hospitals, food processing plants, and kitchens.

- Aesthetic Appeal: It has a sleek, modern look that can enhance the appearance of any product, whether it’s jewelry or a building facade.

Common Uses in Various Industries

- Kitchenware: Stainless steel is commonly used in pots, pans, cutlery, and kitchen appliances. Its corrosion resistance and ease of cleaning make it ideal for food preparation.

- Construction: It’s used in buildings for structural support and decorative elements like handrails and facades.

- Automotive: Many car parts, such as exhaust systems and trim, are made from stainless steel due to its durability and corrosion resistance.

- Medical: In hospitals, stainless steel is used for surgical instruments, medical equipment, and implants because of its hygiene and strength.

- Jewelry: It’s a popular choice for making rings, necklaces, and bracelets due to its appealing look and lower cost than precious metals.

Coloring Stainless Steel

Overview of Coloring Techniques

Coloring stainless steel enhances both its aesthetic appeal and functionality. Achieving a gold color on stainless steel can be done through several methods, each with its unique procedures and benefits.

Importance and Popularity of Gold Coloring

Gold-colored stainless steel is highly valued for its luxurious appearance and enhanced durability. This finish is often seen in high-end products such as the iconic Apple Watch, which combines elegance with superior wear resistance.

Safety Precautions

Before starting any coloring process, it’s crucial to ensure safety:

- Protective Gear: Wear safety goggles, gloves, and aprons to protect against chemicals and heat.

- Ventilation: Work in a well-ventilated area to avoid inhaling fumes.

- Cleaning Supplies: Use acetone, mineral spirits, or soap and water to clean the stainless steel surface.

Brass Deposition Method

This method involves applying a brass coating to achieve a golden appearance.

Materials Needed:

- Stainless Steel (preferably 304-grade)

- Brass Wire Brush

- Jeweler’s Torch or Heat Source

- Locking Plier

- Drill

Steps:

- Prepare the Surface: Clean the stainless steel with acetone or mineral spirits to remove any oils and contaminants.

- Heat the Stainless Steel: Use a jeweler’s torch to heat the metal until it reaches a light pale color.

- Apply Brass Coating:

- Secure the brass wire brush in a drill.

- As the stainless steel heats up, gently rub the brush against the surface to deposit brass.

- Continue brushing until you achieve an even golden tone.

- Cooling and Finishing: Allow the piece to cool naturally. This method typically results in a matte finish.

High-Temperature Oxidation Method

This technique creates a gold color by forming an oxide layer on the stainless steel through controlled heating.

Why Austenitic Grades Like 304 Are Preferred:

Austenitic grades, such as 304 stainless steel, are favored for their excellent heat resistance and ability to form uniform oxide layers, making them ideal for this coloring process.

Materials Needed:

- Stainless Steel (Austenitic grades like 304)

- Heat Source (heat treating oven or controlled torch setup)

- Temperature Control Equipment

Steps:

- Prepare the Surface: Clean the stainless steel with soap and water, then dry thoroughly.

- Heat Treatment:

- Preheat the oven to a temperature range of 620°F to 750°F (325°C to 399°C).

- Place the stainless steel in the oven.

- Monitor the color formation closely to achieve a subtle gold tint.

- Cooling and Inspection: Remove the piece once the desired color is achieved and let it cool naturally.

Safety Considerations and Tips

- Even Heating: Use a heat source that provides uniform heat distribution to prevent uneven color. For larger pieces, consider rotating the item or using multiple heat sources.

- Temperature Control: Carefully monitor and adjust the temperature to avoid overheating. Using a digital thermometer can help maintain precise control.

- Clean Surface: Always start with a clean surface to ensure consistent and high-quality finishes.

Coloring stainless steel gold involves selecting the appropriate method and following safety protocols to achieve the desired appearance and durability.

Methods of Gold Plating

Overview of Gold Plating Processes

Gold plating involves applying a thin layer of gold onto the surface of another metal, like stainless steel. Various methods achieve this, each with its own unique steps and benefits.

Electroplating

Electroplating is a popular technique for gold plating stainless steel due to its efficiency and effectiveness.

Definition and Process

Electroplating uses an electrical current to create a metal coating on an electrode. Here’s how the process works:

- Preparation:

- Thoroughly clean the stainless steel using methods like ultrasonic cleaning, solvent cleaners, or soap and water to remove any dirt, oil, or contaminants.

- Cleaning and Rinsing:

- Conduct a second deep cleaning using electrocleaning or steaming.

- Rinse the item with distilled water.

- Strike Layer Application:

- Apply a thin layer of nickel (strike layer) to improve gold adhesion and prevent tarnish.

- Rinse the item again with distilled water.

- Gold Plating:

- Submerge the negatively charged item into the gold plating solution, and use an electrical supply to attract positively charged gold ions to the surface.

- Adjust the voltage and temperature according to the type of gold being used.

- The duration of submersion affects the thickness of the gold layer.

- Final Rinse and Drying:

- Rinse the gold-plated item with distilled water to remove any impurities.

- Hang the item to dry completely.

Pros and Cons

- Pros:

- Provides a uniform and durable gold coating.

- Suitable for various sizes and shapes of stainless steel items.

- Cost-effective for small-scale and large-scale applications.

- Cons:

- Requires careful control of the plating conditions.

- Involves the use of potentially hazardous chemicals.

PVD (Physical Vapor Deposition)

PVD is another method used for gold plating, known for its ability to create a high-quality, thin gold layer.

Definition and Process

Physical Vapor Deposition (PVD) is a vacuum deposition method used to produce thin films and coatings. Here’s the step-by-step process:

- Preparation:

- Clean the stainless steel surface to remove any contaminants.

- Use methods like ultrasonic cleaning or solvent cleaning.

- Preparing the PVD Chamber:

- Place the cleaned stainless steel item in the PVD chamber.

- Evacuate the chamber to create a high vacuum environment.

- Depositing the Gold Layer:

- Introduce the gold source material into the chamber.

- Use a heat source or electron beam to vaporize the gold.

- The vaporized gold atoms condense on the stainless steel surface, forming a thin, uniform layer.

- Final Finishing Steps:

- Allow the item to cool down and remove it from the chamber.

- Inspect the item for coating consistency and quality.

Pros and Cons

- Pros:

- Produces a high-quality, durable, and wear-resistant coating.

- Environmentally friendly as it doesn’t use harmful chemicals.

- Can be used for complex shapes and large surfaces.

- Cons:

- Requires specialized equipment and expertise.

- Higher initial setup cost compared to electroplating.

Comparative Analysis: PVD vs Electroplating

Both PVD and electroplating have their own advantages and are suitable for different applications.

- Durability: PVD coatings tend to be more durable and wear-resistant compared to electroplated coatings.

- Cost: Electroplating is generally more cost-effective, especially for small-scale projects.

- Environmental Impact: PVD is more environmentally friendly as it avoids the use of hazardous chemicals.

- Application: Electroplating is more versatile for a variety of shapes and sizes, while PVD is ideal for high-quality, thin coatings on complex surfaces.

Choosing the Right Method for Your Project

When deciding between PVD and electroplating for gold plating stainless steel, consider the following factors:

- Project Scale: For large-scale projects, PVD might be more cost-effective in the long run despite higher initial costs.

- Durability Requirements: If the item requires a highly durable and wear-resistant coating, PVD is the better option.

- Budget: For budget-conscious projects, electroplating offers a more affordable solution.

- Environmental Concerns: PVD is preferable for projects where environmental impact is a significant consideration.

Advantages of Gold-Plated Stainless Steel

Durability

Stainless steel is known for its excellent resistance to corrosion and wear. The durability of stainless steel ensures that the gold-plated layer stays intact for a long time, unlike other base metals like brass where the gold tends to fade or peel off quickly.

Hypoallergenic Properties

Its hypoallergenic nature makes gold-plated stainless steel suitable for a wide range of products, including earrings and bracelets, that many people can wear. Stainless steel contains very little nickel, a common cause of allergic reactions, making gold-plated stainless steel a great option for those with sensitive skin.

Affordability

Gold plating stainless steel is a more affordable option than using precious metals like silver or solid gold. The process requires less gold, reducing the cost and allowing consumers to enjoy the look of gold without the high price of pure gold jewelry.

Aesthetic Appeal

Gold plating gives stainless steel a sleek and polished finish. This modern appearance is perfect for contemporary jewelry designs and other decorative items. The gold layer often results in a more subdued, lighter gold color, preferred by many for its unique charm.

Low Maintenance

Gold-plated stainless steel is easier to maintain than brass or silver; simply clean it with soap and water to keep its shine. It can resist the effects of many chemicals, making it suitable for wear in various conditions without significant worry about damage or maintenance.

Step-by-Step Tutorial for Coloring Stainless Steel Gold

Preparation

Before starting the process of coloring stainless steel gold, it’s essential to prepare the stainless steel surface and gather the necessary safety equipment.

Cleaning the Stainless Steel Surface

- Degreasing: Use a degreaser or a mild detergent to remove any grease, oil, or contaminants from the surface of the stainless steel. This ensures the surface is thoroughly clean and prepared for plating.

- Rinsing: After degreasing, thoroughly rinse the stainless steel with distilled water to remove any residual cleaning agents.

- Drying: Dry the stainless steel completely using a lint – free cloth or air dryer to prevent any water spots or residues.

Safety Precautions and Equipment Needed

- Protective Gear: Wear safety goggles, gloves, and a lab coat or apron to protect yourself from chemicals and heat.

- Ventilation: Work in a well – ventilated area or use a fume hood to avoid inhaling chemical fumes.

- Equipment:

- Gold plating solution

- Rectifier (for electroplating)

- Electrodes (carbon or platinum)

- PVD chamber (for PVD process)

- Cleaning solutions (acetone, distilled water)

Electroplating Process

Electroplating is a common method for applying a gold layer onto stainless steel. Follow these steps to achieve a gold finish through electroplating.

Setting Up the Electroplating Bath

- Prepare the Electroplating Bath: Mix the gold plating solution according to the manufacturer’s instructions. Ensure the solution is at the correct concentration and temperature.

- Connect the Electrodes: Attach the stainless steel item to the negative terminal (cathode) of the rectifier. Attach the positive terminal (anode) to a carbon or platinum electrode.

Applying the Gold Plating

- Submerge the stainless steel item in the electroplating bath, then turn on the rectifier and set it to the recommended voltage (around 4.5 volts). The current will cause gold ions to deposit onto the stainless steel surface.

- Move the Electrode: Gently move the electrode around the surface of the stainless steel to ensure an even coating. Continue this process for 10 – 15 minutes for a thicker gold layer.

Post – Plating Procedures

- Rinse: After plating, rinse the gold – plated stainless steel with distilled water to remove any excess plating solution.

- Dry: Thoroughly dry the piece with a lint – free cloth or air dryer to avoid water spots.

PVD Process

Physical Vapor Deposition (PVD) is another method for achieving a gold finish on stainless steel. This process involves depositing a thin gold layer in a vacuum chamber.

Preparing the PVD Chamber

- Clean the Stainless Steel: Clean the stainless steel surface thoroughly using ultrasonic cleaning or solvent cleaning to remove any contaminants.

- Load the Chamber: Place the cleaned stainless steel item into the PVD chamber. Ensure it is securely positioned.

Depositing the Gold Layer

- Create a Vacuum: Evacuate the PVD chamber to create a high vacuum environment.

- Introduce Gold Source: Introduce the gold source material into the chamber. This can be in the form of gold pellets or a gold target.

- Vaporize the Gold: Use a heat source or electron beam to vaporize the gold. The vaporized gold atoms will condense on the stainless steel surface, forming a thin, uniform layer.

Final Finishing Steps

- Cool Down: Allow the item to cool down naturally within the chamber.

- Inspect: Remove the item from the chamber and inspect it for coating consistency and quality.

Quality Checks

After completing the coloring process, it’s crucial to perform quality checks to ensure the gold plating is durable and aesthetically pleasing.

Inspecting the Plated Surface

- Visual Inspection: Check the surface for inconsistencies, uneven areas, or defects in the gold layer.

- Thickness Measurement: Use a thickness gauge to measure the gold layer’s thickness, ensuring it meets the desired specifications.

Conducting Durability Tests

- Adhesion Test: Perform an adhesion test to check if the gold layer adheres properly to the stainless steel surface.

- Wear Resistance Test: Conduct a wear resistance test to ensure the gold plating can withstand regular use without significant wear or damage.

By following these steps, you can achieve a high – quality gold finish on stainless steel, enhancing its appearance and durability.

Frequently Asked Questions

Below are answers to some frequently asked questions:

How do I color stainless steel gold?

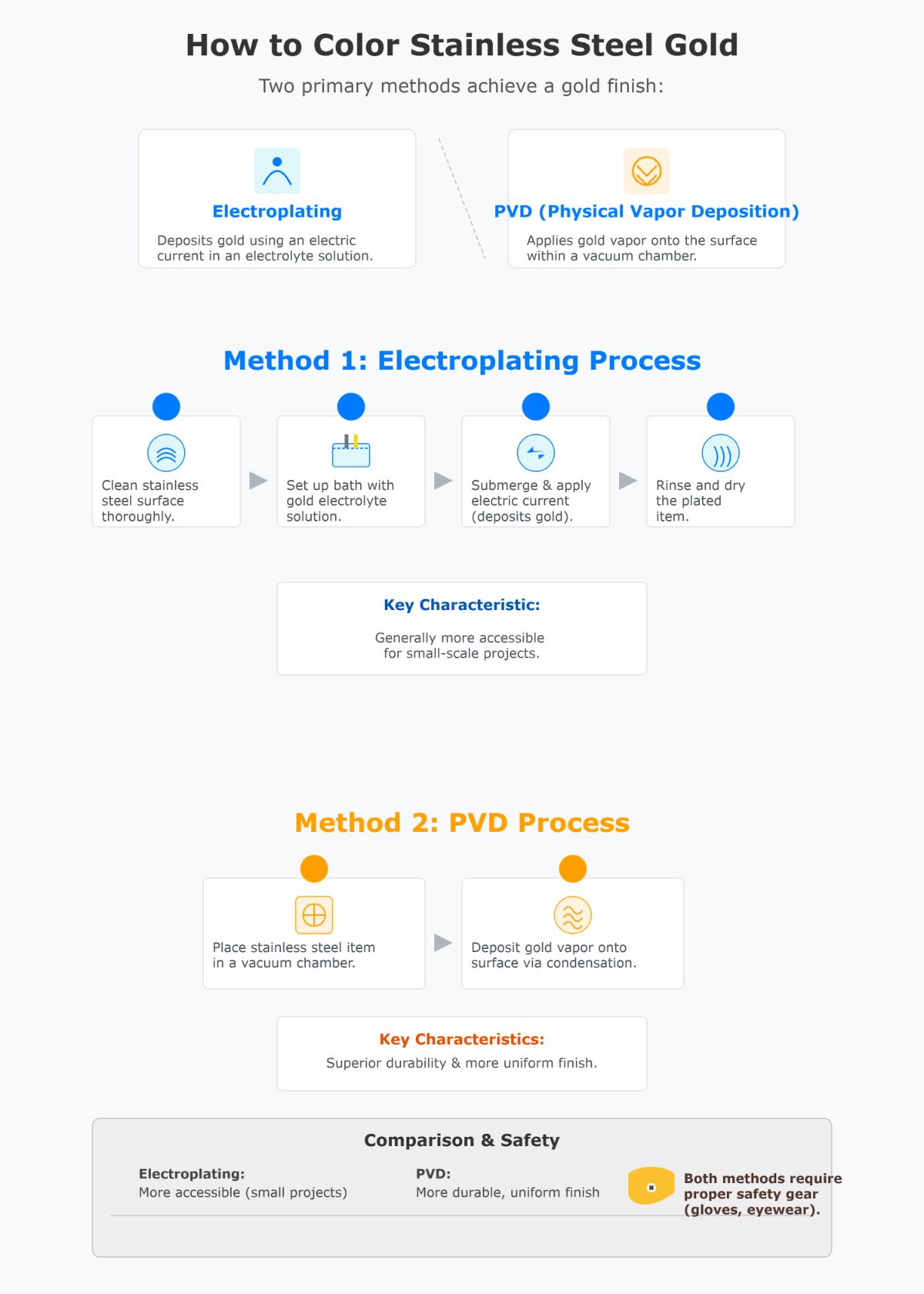

To color stainless steel gold, you can use two main methods: electroplating and PVD (Physical Vapor Deposition).

For electroplating, start by thoroughly cleaning the stainless steel surface to remove any contaminants. Set up an electroplating bath with a gold electrolyte solution. Submerge the stainless steel piece and apply an electric current, which will deposit a thin layer of gold onto the surface. After plating, rinse and dry the item to complete the process.

Alternatively, PVD involves placing the stainless steel in a vacuum chamber. Gold vapor is then deposited onto the surface through a process of condensation. This method produces a durable and even coating.

Both methods require proper safety precautions and equipment, such as gloves and protective eyewear. Electroplating is generally more accessible for small projects, while PVD offers superior durability and a more uniform finish.

What are the advantages of using gold-plated stainless steel?

Gold-plated stainless steel offers numerous advantages, making it a popular choice for jewelry, accessories, and decorative items. Firstly, its durability and corrosion resistance are notable, as the stainless steel base is highly resistant to rust and tarnishing, ensuring a long-lasting golden appearance. This makes it suitable for items exposed to moisture or harsh conditions.

Additionally, gold-plated stainless steel is generally hypoallergenic, making it a safe option for those with sensitive skin, unlike some other metals that may contain nickel. It also requires low maintenance; simple cleaning with soap and water is often sufficient to maintain its shine.

Aesthetically, gold-plated stainless steel provides a sleek, modern look that is versatile in design. It is also cost-effective, offering better value over time compared to gold-plated brass due to its enhanced durability. These qualities make it ideal for everyday wear and a practical choice for various applications.

What is the difference between PVD and Electroplating?

When coloring stainless steel gold, Electroplating and Physical Vapor Deposition (PVD) are two popular methods with distinct differences. Electroplating involves immersing the stainless steel in a solution with metal ions and applying an electrical current to bond the ions to the substrate. It’s cost – effective, can create thicker coatings (0.1 – 100 microns), and is versatile in color. However, it has a porous structure, limited material compatibility, and is less durable. PVD vaporizes the coating material in a vacuum chamber for molecular – level bonding. It offers superior durability, can coat various materials, is hypoallergenic, and is environmentally friendly. Yet, it’s more expensive and produces thinner coatings (0.01 – 5 microns).

How long does gold plating last on stainless steel?

The durability of gold plating on stainless steel largely depends on several factors, including the quality of the gold layer, its thickness, and how well the item is maintained. Typically, gold plating can last several years with proper care. High-quality gold plating, often achieved through techniques such as electroplating or Physical Vapor Deposition (PVD), can significantly enhance the adhesion and uniformity of the gold layer.

The thickness of the gold plating is crucial; it usually ranges from 0.5 to 5 microns. Thicker layers provide better resistance to wear and tarnishing. Additionally, the grade of the stainless steel, such as 316L, affects

To extend the lifespan of gold-plated stainless steel, it is important to avoid harsh chemicals, clean the item regularly with mild soap, and store it in a dry place. With proper care, gold-plated stainless steel can maintain its appearance for over five years, and high-quality plating with thicker gold layers can last even longer.

Can I gold plate stainless steel at home?

Yes, you can gold plate stainless steel at home with the right tools and knowledge. First, you will need a gold plating kit, which typically includes a gold solution, an electrolyte, and a power source. Make sure to clean the stainless steel item thoroughly using an electrocleaning solution to remove any dirt and oils. Next, apply a thin layer of nickel using a nickel strike solution to enhance adhesion. Rinse the item after each step to remove any residues.

For the gold plating process, prepare the 24-karat gold solution and submerge the stainless steel item, using a voltage of 2.7 to 2.8 volts. The item should remain in the solution for 5 to 15 minutes, depending on the desired thickness of the gold layer. After plating, rinse the item in water and dry it thoroughly to prevent water spots. Always wear protective gear when handling chemicals and electrical equipment. By following these steps, you can achieve a high-quality gold-plated finish on stainless steel at home.

What maintenance is required for gold-plated stainless steel?

To maintain gold-plated stainless steel, start with gentle cleaning. Use a soft, non-abrasive cloth dampened with water to wipe away dirt and oils; avoid harsh chemicals. For a deeper clean, soak in mild soap solution for 15 minutes. Limit water exposure by removing the item before showering or swimming. Keep it away from chemicals like perfumes and lotions. Store it separately in a cool, dry place to prevent scratching and fading. Regularly inspect for wear and consider professional replating if needed. Applying a clear lacquer can also enhance durability.