I. Advantages and Disadvantages of Hydraulic Transmission

1. Main Advantages

Compared with mechanical transmission, electric transmission, and pneumatic transmission, hydraulic transmission has the following advantages:

- Hydraulic transmission can achieve stepless speed regulation during operation, with convenient speed adjustment and a relatively large speed range, reaching 100:1 to 2000:1.

- Under the same power conditions, hydraulic transmission devices are small in size, light in weight, have low inertia, and a compact structure (for example, the weight of a hydraulic motor is only 10% to 20% of the weight of an electric motor with the same power), and can transmit large forces or torques.

- Hydraulic transmission operates relatively smoothly, responds quickly, has small impact, and can start, brake, and reverse at high speeds. The reversing frequency of hydraulic transmission devices can reach 500 times per minute for rotary motion and 400 to 1000 times for reciprocating linear motion.

- The control and adjustment of hydraulic transmission devices are relatively simple, operation is convenient and labor-saving, and it is easy to achieve automation and coordination with electrical control, thereby realizing complex sequential actions and remote control.

- Hydraulic transmission devices are easy to achieve overload protection. If the system is overloaded, the oil returns to the tank through the overflow valve. Since oil is used as the working medium, it can lubricate itself, thus having a long service life.

- Hydraulic transmission is easy to standardize, generalize, and serialize, making it easy to design, manufacture, and promote.

- Hydraulic transmission is easy to achieve both rotary and linear motion, and the arrangement and layout of components are flexible.

- In hydraulic transmission, the heat generated by power loss can be carried away by the flowing oil, thus avoiding excessive temperature rise in certain local areas of the system.

2. Main Disadvantages

- The working medium is liquid, which is prone to leakage, and the oil can be compressed, so it cannot be used in situations where an accurate transmission ratio is required.

- Hydraulic transmission has mechanical losses, pressure losses, and leakage losses, resulting in lower efficiency, so it is not suitable for long-distance transmission.

- Hydraulic transmission is sensitive to changes in oil temperature and load, making it unsuitable for use in low or high temperatures, and it is also sensitive to contamination.

- Hydraulic transmission requires a separate power source (such as a hydraulic pump station), and hydraulic energy cannot be transmitted from a distance like electrical energy.

- Hydraulic components require high manufacturing precision and are expensive, so specialized production must be organized.

- When a fault occurs in a hydraulic transmission device, it is not easy to trace the cause and quickly eliminate it.

Overall, hydraulic transmission has many advantages, and its disadvantages are gradually being overcome with the development of production technology. Therefore, hydraulic transmission has broad development prospects in modern production.

II. Applications of Hydraulic Transmission

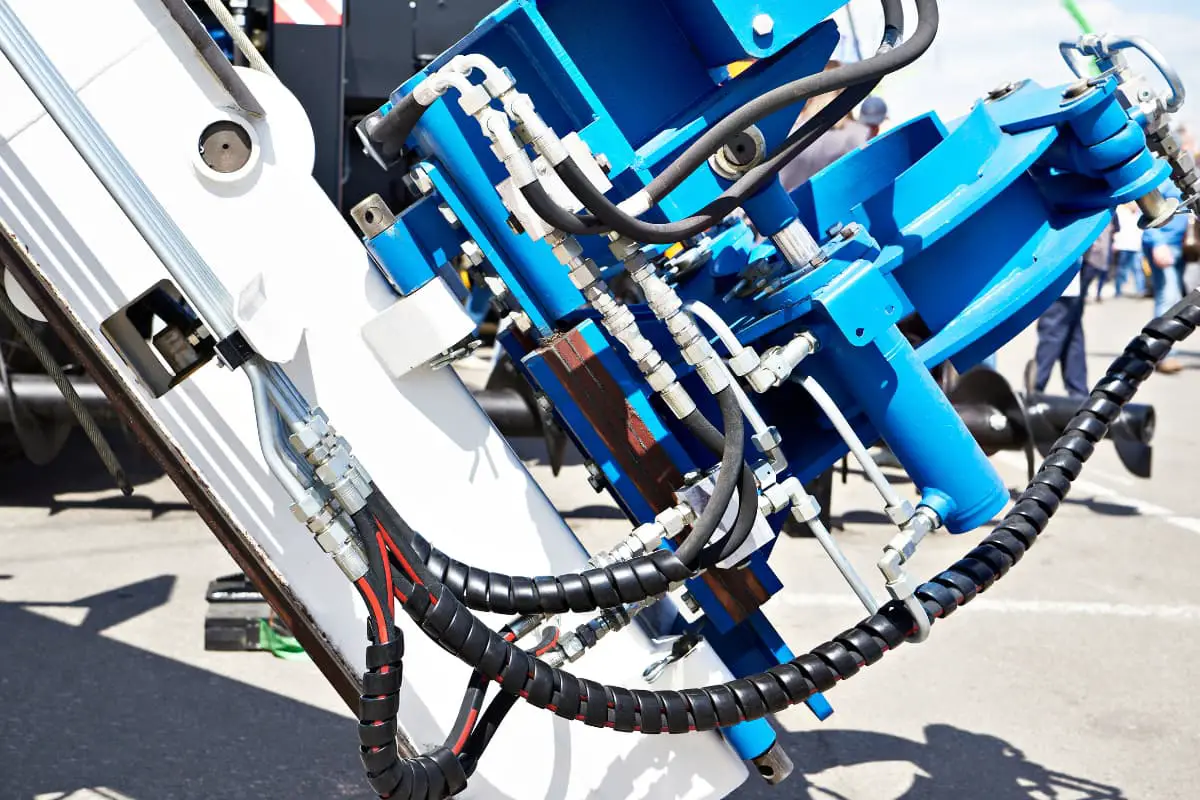

Due to the many advantages of hydraulic transmission, it has been widely used in various sectors of the national economy. However, the reasons for using hydraulic transmission vary across different sectors. For example, engineering machinery and pressure machinery use it because of its simple structure and large output force, while the aviation industry uses it because of its light weight and small size.

In machine tools, hydraulic transmission is mainly used because it can achieve stepless speed change, is easy to automate, and can achieve frequent reversing movements. Therefore, hydraulic transmission is commonly used in the following devices of machine tools.

1. Feed Motion Transmission Device

This application is most widely used in machine tools: the wheelhead of grinding machines; the tool post or turret of horizontal lathes, turret lathes, and automatic lathes; the worktable or headstock of grinding machines, drilling machines, milling machines, and planers; the power head and slide of combination machines, etc., can all use hydraulic transmission. Some of these components require fast movement, some require slow movement (2mm/min), and some require both fast and slow movement.

Most of these components require a large speed regulation range and stepless speed regulation during operation; some require continuous feed, some require intermittent feed; some require constant speed under varying loads, and some require good reversing performance. For all these requirements, hydraulic transmission is the most suitable.

2. Reciprocating Main Motion Transmission Device

The worktable of a gantry planer and the ram of a shaper or slotter can use hydraulic transmission to achieve the required high-speed reciprocating motion. The former can reach a speed of 60 to 90 m/min, while the latter two can reach 30 to 50 m/min. In these cases, using hydraulic transmission is beneficial in reducing reversing impact, lowering energy consumption, and shortening reversing time.

3. Rotary Main Motion Transmission Device

The spindle of a lathe can use hydraulic transmission to achieve stepless speed change for rotary main motion, but this application is not yet common.

4. Profiling Device

The profiling machining of lathes, milling machines, and planers can be achieved using a hydraulic servo system, with an accuracy of 0.01 to 0.02mm. In addition, the forming wheel correction device and the standard lead screw correction device on grinding machines can also use this system.

5. Auxiliary Devices

Clamping devices, speed change control devices, lead screw nut clearance elimination devices, balancing devices for vertical moving parts, indexing devices, and loading, unloading, conveying, and storage devices for workpieces and tools on machine tools can all be implemented using hydraulic transmission. This approach helps simplify the machine tool structure and improve the automation level of the machine tool.

6. Stepping Transmission Device

The linear or rotary stepping motion of the worktable on CNC machine tools can be quickly and accurately achieved by an electro-hydraulic servo system based on electrical signals. Open-loop systems have lower positioning accuracy (<0.01mm) but are cost-effective; closed-loop systems have higher positioning accuracy and cost.

7. Hydrostatic Bearing

Bearings, guide rails, and lead screw nut mechanisms on heavy-duty, high-speed, and high-precision machine tools can achieve high operational stability and motion accuracy if a hydraulic system is used for hydrostatic bearing.

The application of hydraulic transmission in various industries is shown in Table 1.

Table 1 Application of Hydraulic Transmission in Various Industries

| Industry Name | Examples of Application Scenarios |

| Machine Tools | Grinding machines, milling machines, planers, broaching machines, presses, automatic machine tools, combination machine tools, CNC machine tools, machining centers, etc. |

| Construction Machinery | Excavators, loaders, bulldozers, etc. |

| Automobile | Dump trucks, etc. |

| Agricultural Machinery | Control systems for combine harvesters, suspension devices for tractors, etc. |

| Light Industry Machinery | Packing machines, injection molding machines, straightening machines, rubber vulcanizing machines, paper machines, etc. |

| Metallurgical Machinery | Electric furnace control systems, rolling mill control systems, etc. |

| Lifting and Transport Machinery | Cranes, forklifts, loading and unloading machinery, hydraulic jacks, etc. |

| Mining Machinery | Mining machines, hoists, hydraulic supports, coal mining machines, etc. |

| Construction Machinery | Pile drivers, graders, etc. |

| Ship and Port Machinery | Cargo winch, anchor winch, rudder machine, etc. |

| Casting machinery | Sand compactor, feeder, die casting machine, etc. |