When it comes to anchoring heavy loads or securing structural components, choosing the right bolt can make all the difference. Among the myriad options available, J-bolts and L-bolts stand out as two of the most commonly used anchor bolts in construction and engineering. But what sets them apart? How do their unique designs influence their applications and performance?

In this article, we will delve into the specifics of J-bolts and L-bolts, comparing their physical characteristics, load capacities, and typical uses. Whether you’re an intermediate-level professional seeking to deepen your understanding or simply curious about which bolt is better suited for heavy-duty tasks, this comprehensive guide will provide the insights you need. Join us as we explore the key differences and practical applications of these essential fasteners—helping you make an informed decision for your next project.

Understanding Anchor Bolts

Definition of Anchor Bolts

Anchor bolts are essential components in construction and engineering, designed to secure structural and non-structural elements to concrete foundations. These bolts are embedded into the concrete to provide a stable connection point for various structural elements such as steel columns, beams, and machinery.

Importance of Anchor Bolts in Construction and Engineering

Anchor bolts are crucial for transferring loads from the structure to the foundation, ensuring stability against forces like wind, seismic activity, and heavy operational loads. By securely anchoring structural components, anchor bolts play a vital role in maintaining the integrity and safety of buildings, bridges, and other infrastructure. They are indispensable in applications where reliable load transfer and structural stability are critical.

Overview of Different Types of Anchor Bolts

Anchor bolts come in various shapes and sizes, each designed to meet specific structural requirements and load conditions. The two most common types are J-bolts and L-bolts:

J-bolts feature a curved end resembling the letter ‘J’, providing a strong mechanical interlock with the concrete and reducing the risk of pull-out under high-stress conditions. They are often used in heavy-duty applications such as securing steel columns, bridge components, and heavy machinery. L-bolts, on the other hand, have a right-angle bend resembling the letter ‘L’. This design offers adequate anchorage for many standard applications but may not provide the same level of mechanical interlock as J-bolts. L-bolts are typically used in lighter structural applications, such as securing machinery bases, architectural features, and residential construction.

Mechanical Interlock and Load Resistance

The effectiveness of an anchor bolt in resisting pull-out forces largely depends on its design. J-bolts create a mechanical interlock within the concrete, distributing stress more evenly and enhancing resistance against vertical and lateral loads. This makes them ideal for critical structural applications requiring high load resistance and stability. On the other hand, L-bolts rely on their 90-degree bend for anchorage. While this design provides sufficient resistance for many applications, it may not offer the same degree of mechanical interlock as J-bolts. Therefore, L-bolts are often chosen for less demanding uses where loads are moderate.

Applications of Anchor Bolts

Anchor bolts are used across various industries to ensure the stability and safety of structures, including construction, bridges, precast concrete, heavy equipment, and the energy sector. Some key applications include:

- Construction: Securing structural steel beams and columns to concrete foundations, providing stability against wind, seismic, and operational loads.

- Bridges: Anchoring bridge decks and support beams to foundations, maintaining integrity under heavy traffic and environmental forces.

- Precast Concrete: Connecting precast panels to foundations, ensuring proper alignment and load distribution.

- Heavy Equipment: Providing stable mounting points for HVAC systems, generators, and storage tanks, essential for operational safety.

- Energy Sector: Supporting wind turbines with specially designed anchor bolts to withstand high wind speeds and rotational forces.

J-Bolt: Design and Applications

J-bolts are anchor bolts with a distinctive J-shaped hook at one end. This unique design allows them to securely anchor into concrete or masonry structures by wrapping around embedded rebar or other structural components. The hook shape provides a strong mechanical interlock, enhancing the bolt’s pull-out resistance and load distribution capabilities.

Common Materials and Sizes for J-Bolts

J-bolts are typically made from durable materials such as carbon steel, stainless steel, and galvanized steel to ensure longevity and performance under various conditions. Standard diameters range from 1/2 inch to 1 inch, with lengths varying based on the application needs.

Structural Applications for J-Bolts

Construction

In the construction industry, J-bolts are widely used to anchor steel columns, beams, and roofing systems to concrete foundations. Their design ensures a secure connection that can withstand high winds and seismic activity, providing stability and safety to the structure.

Infrastructure

J-bolts are essential in infrastructure projects, such as securing bridge supports, utility poles, and pipelines. Their high resistance to changing loads makes them ideal for these critical applications, ensuring the integrity and durability of the infrastructure.

Renewable Energy

In the renewable energy sector, J-bolts anchor solar panel mounts and wind turbine bases. These applications demand precision and stability, which J-bolts provide through their strong mechanical interlock and load distribution properties.

Industrial

J-bolts are used in various industrial settings to fasten heavy machinery, conveyor systems, and storage tanks. Their ability to withstand significant loads and harsh environments makes them indispensable in manufacturing and oil/gas sectors.

Automotive

In the automotive industry, J-bolts are utilized to stabilize exhaust systems and suspension components. Their robust design ensures that these critical parts remain securely anchored, contributing to the vehicle’s overall performance and safety.

Case Studies or Practical Examples Showing J-Bolt Performance

Example 1: Bridge Construction

In a recent bridge construction project, J-bolts were used to anchor the support beams to the concrete foundations. The J-shaped hook provided a strong mechanical interlock with the embedded rebar, distributing the loads effectively and ensuring the bridge’s stability under heavy traffic and environmental forces.

Example 2: Wind Turbine Installation

During the installation of wind turbines, J-bolts were employed to secure the turbine bases to the concrete foundations. The precision and stability offered by J-bolts were critical in maintaining the turbines’ alignment and structural integrity, even under high wind conditions.

Installation Process for J-Bolts

- Preparation: Clean the surface and determine the installation spot.

- Drilling: Drill a hole slightly larger than the bolt diameter.

- Setting the Bolt: Insert the J-bolt, ensuring proper engagement with the rebar.

- Grouting: Fill the hole with high-strength grout or epoxy.

- Curing: Allow the grout to cure as per instructions.

- Inspection: Ensure the bolt is correctly positioned and secure.

J-bolts are an essential component in various structural applications due to their unique design and robust performance. Their ability to provide secure anchorage and distribute loads effectively makes them a preferred choice in construction, infrastructure, renewable energy, industrial, and automotive sectors. Proper installation and material selection are critical to maximizing their performance and ensuring the safety and stability of the structures they anchor.

L-Bolt: Design and Applications

Design of L-Bolt

L-bolts are a specific type of anchor bolt that feature a 90-degree bend at one end, forming an “L” shape. The L-bolt’s design features a threaded section at the end opposite the bend, allowing for the attachment of nuts and plates. The L-shaped bend enables the bolt to be deeply embedded into concrete or masonry, thereby creating a mechanical interlock that significantly enhances its resistance to being pulled out under heavy loads. The straight leg of the L-bolt extends vertically or at a slight angle from the embedded bent leg, providing a secure anchoring point for various structural components.

Common Materials and Sizes for L-Bolts

L-bolts are typically manufactured from high-strength materials such as carbon steel, stainless steel, and galvanized steel to ensure durability and performance in demanding conditions. These materials provide excellent resistance to corrosion and wear, which is essential for maintaining structural integrity over time. Standard diameters for L-bolts range from 1/2 inch to 1 inch, with lengths varying based on specific application requirements. The choice of material and size depends on the load conditions and environmental factors of the installation site.

Structural Applications for L-Bolts

Construction

L-bolts are widely utilized in the construction industry to secure structural beams, sill plates, and heavy machinery to concrete foundations. Their robust design ensures stable connections, which are critical for the overall integrity and safety of buildings. The mechanical interlock created by the L-shaped bend provides superior pull-out resistance, making L-bolts ideal for applications where high stability is required.

Industrial Equipment

In industrial settings, L-bolts anchor heavy machinery to concrete floors. This prevents movement and vibration during operation, which is essential for both equipment safety and worker protection. The heavy-duty nature of L-bolts makes them suitable for anchoring large, high-stress machinery in manufacturing and processing plants.

Infrastructure Projects

L-bolts play a crucial role in infrastructure projects by anchoring light poles, traffic signals, highway signs, and bridge components to concrete bases. Their ability to withstand environmental stresses and traffic loads ensures the resilience and longevity of these critical infrastructure elements. The reliability of L-bolts in such applications helps maintain public safety and operational efficiency.

Specialized Uses

Beyond typical construction and industrial applications, L-bolts are also employed in securing wind turbine bases, playground equipment, fences, and other outdoor structures that demand high strength and durability. Their versatility allows them to be used in a wide range of settings, ensuring reliable performance across diverse applications.

Installation Process for L-Bolts

The installation of L-bolts requires careful preparation to ensure proper placement and embedment. Typically, templates made from plywood or cardboard with precisely drilled holes are used to maintain accurate spacing and alignment before concrete is poured or when embedding the bolts into hardened concrete. The steps include:

- Preparation: Clean the installation site and prepare the template.

- Drilling: Drill holes in the concrete according to the template specifications.

- Setting the Bolt: Insert the L-bolts into the drilled holes. Ensure they are positioned correctly.

- Concrete Pouring: If embedding into freshly poured concrete, ensure the bolts remain aligned during the pour.

- Curing: Allow the concrete to cure fully before applying any load to the bolts.

- Inspection: Check the alignment and embedment depth to ensure proper installation.

Case Studies or Practical Examples Showing L-Bolt Performance

Example 1: Building Construction

In a recent high-rise building project, L-bolts were used to anchor structural beams to the concrete foundation. The L-shaped bend’s mechanical interlock kept the beams secure under heavy wind and seismic loads, enhancing the building’s stability and safety.

Example 2: Industrial Equipment Installation

During the installation of heavy machinery in a manufacturing plant, L-bolts were chosen for their superior load-bearing capacity. The bolts successfully prevented movement and vibration, ensuring the machinery operated smoothly and safely, thereby reducing maintenance costs and enhancing operational efficiency.

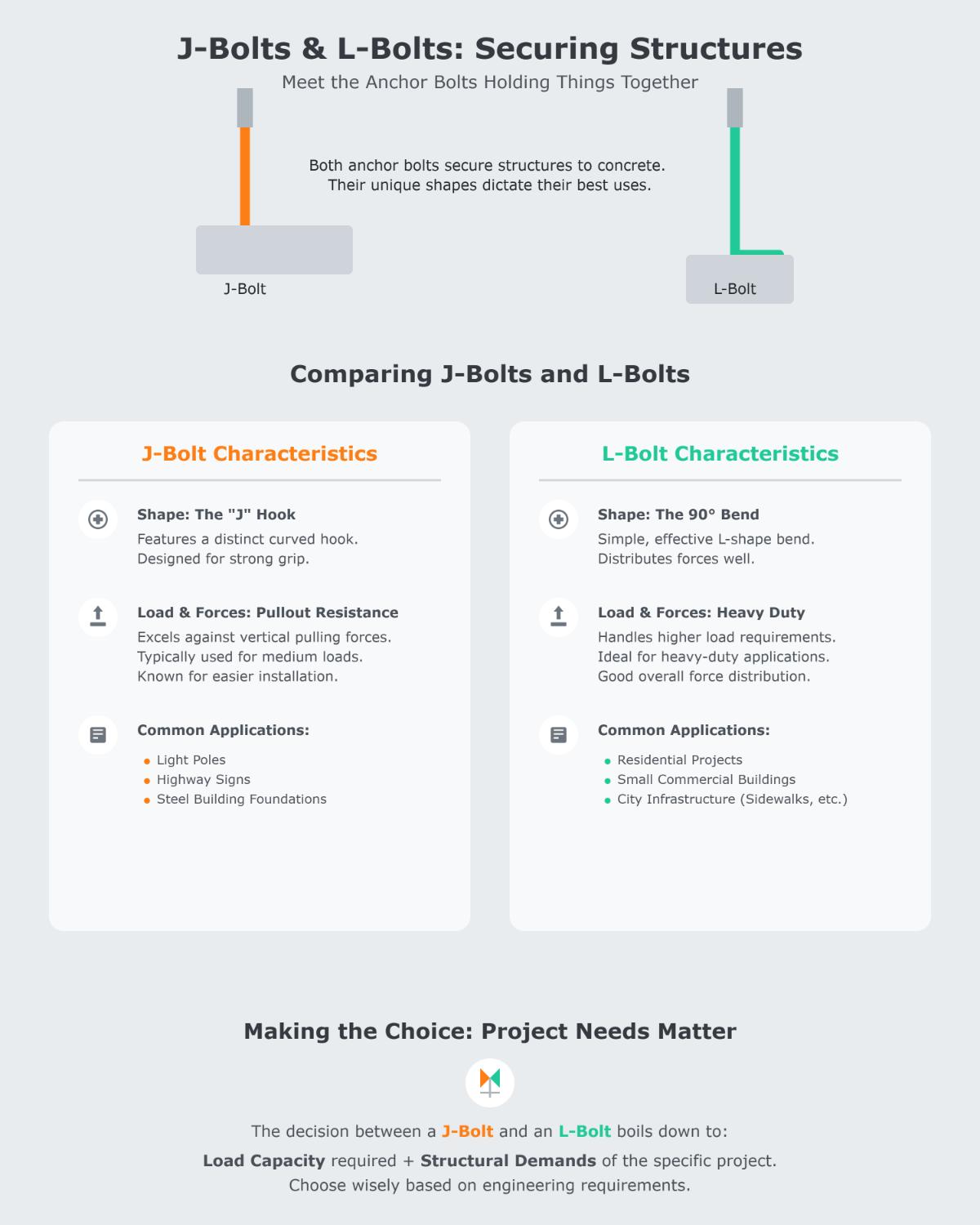

Comparative Analysis: J-Bolt vs L-Bolt

In construction and engineering, J-bolts and L-bolts are essential for anchoring structures to concrete. While both bolts perform similar roles, their designs, load capacities, installation methods, and applications distinguish them from one another.

Key Differences

Shape

The primary distinction between J-bolts and L-bolts lies in their shape: J-bolts have a hook-like 180-degree bend, while L-bolts feature a 90-degree bend resembling the letter “L”.

Load Capacity

- J-Bolts: Typically used for medium to light load applications, J-bolts offer good resistance to pullout forces due to their hook design. They are suitable for securing smaller structures and components.

- L-Bolts: Designed for heavy-duty applications, L-bolts provide stronger anchoring capabilities. Their L-shape ensures that they can handle higher loads and resist pull-out forces more effectively than J-bolts.

Installation Method

J-bolts are usually placed into wet concrete before it sets, making installation easier. L-bolts require drilling into hardened concrete, providing maximum strength but requiring more effort.

Applications

J-bolts are ideal for securing light poles, fences, and smaller steel structures. L-bolts are best suited for heavy-duty applications, such as anchoring structural beams and industrial machinery.

Choosing the Right Bolt

When deciding between J-bolts and L-bolts, consider the load capacity, installation flexibility, and the type of application. J-bolts are perfect for lighter loads and easier installation in wet concrete, while L-bolts are preferred for heavier loads and hardened concrete.

Visual Comparison of J-Bolts and L-Bolts

Shape and Design

J-Bolt Design

J-bolts feature a curved hook resembling the letter “J,” with a rounded bend on one end and threading on the other. This distinctive design allows J-bolts to anchor firmly in concrete, providing substantial resistance against pullout forces. The curved hook is particularly effective in creating a mechanical interlock within the concrete, enhancing the bolt’s ability to handle vertical and lateral loads.

L-Bolt Design

L-bolts are characterized by a sharp 90-degree bend at one end, forming the letter “L.” This design includes threading on the opposite side of the bend, which facilitates the attachment of nuts and plates. The right-angle bend enables deeper embedment into concrete, significantly increasing anchoring strength and preventing bolt pull-out under heavy loads. This makes L-bolts particularly suited for applications requiring robust structural integrity.

Load Capacity and Structural Performance

J-Bolt Load Capacity

J-bolts are generally suited for light to medium load applications. The curved hook design provides significant pullout resistance but is less effective under very heavy loads. This makes J-bolts perfect for smaller structures and components that need moderate anchoring strength.

L-Bolt Load Capacity

L-bolts are engineered for heavy-duty applications. The 90-degree bend ensures stronger anchorage and effectively prevents bolt pull-out. This design is ideal for high-stress, load-bearing structures such as industrial machinery and structural beams, where maximum holding power and durability are crucial.

Installation Methods

J-Bolt Installation

J-bolts are typically installed before concrete is poured. This method allows the curved hook to be securely embedded as the concrete sets, simplifying the installation process for lighter applications. The pre-pour installation ensures that the J-bolt is firmly anchored, providing reliable performance for various structural needs.

L-Bolt Installation

L-bolts tend to be embedded deeply into hardened concrete or set during the pour. Their installation requires precise placement to ensure the right-angle bend anchors firmly in place. This method offers superior holding power, making L-bolts suitable for demanding applications that require robust structural support.

Common Applications

| Bolt Type | Typical Uses | Structural Load | Installation Context |

|---|---|---|---|

| J-Bolt | Securing light poles, fences, smaller steel structures | Light to medium loads | They are installed before pouring concrete, making them suitable for applications requiring moderate anchoring strength |

| L-Bolt | Securing structural beams, heavy machinery, building foundations | Heavy-duty and high-stress loads | Installed in hardened concrete or during pour for deep anchorage |

In-Depth Insight

J-bolts provide excellent resistance to vertical pullout forces due to their curved hook, making them indispensable in scenarios where moderate anchoring strength is sufficient and installation simplicity is valued. They are commonly used in infrastructure elements such as streetlight poles and fencing, where load demands are not extreme but firm anchorage is necessary.

On the other hand, L-bolts excel in environments demanding robust anchorage, such as foundations for buildings and heavy industrial equipment. The 90-degree bend allows deep embedding, distributing forces evenly within the concrete. This feature prevents pullout even under heavy tension or shear stress, which is critical for maintaining structural safety in heavy-load applications.

While J-bolts are generally placed prior to concrete pouring for ease of installation, L-bolts may require more precise placement or embedding in hardened concrete to achieve their full anchoring potential.

Selecting the Right Bolt for Your Project

Choosing the right bolt for your project requires careful consideration of factors like load requirements, installation conditions, and the specific application.

Load Requirements

The load capacity of the bolt is a crucial factor in your decision-making process.

- J-Bolts: Suitable for medium to heavy loads and effective in applications where shear forces are significant, such as securing structural components in multi-story buildings, bridges, and industrial facilities.

- L-Bolts: Designed for heavy-duty applications, L-bolts excel in load-bearing structures due to their 90-degree bend, which offers superior pull-out resistance. They are typically used for securing structural beams, heavy machinery, and industrial equipment.

Installation Timing and Conditions

The timing and conditions of installation can influence the choice between J-bolts and L-bolts.

- J-Bolts: These bolts are typically installed before concrete is poured. This pre-installation allows for easy integration into new construction projects, ensuring the hook is embedded securely in the concrete as it sets.

- L-Bolts: L-Bolts are embedded into hardened concrete, making them ideal for post-construction anchorage. This method ensures high strength and resistance to both tension and shear forces.

Specific Application Scenarios

Consider the specific needs of your project when choosing between J-bolts and L-bolts.

- J-Bolts: Ideal for projects requiring resistance to shear forces, such as bridges and industrial facilities. Their design makes them suitable for fastening heavy machinery and large infrastructure work.

- L-Bolts: Best suited for applications involving heavy loads and requiring deep anchorage, such as structural beams, industrial machinery, and reinforcing masonry and concrete walls.

Expert Recommendations Based on Project Type

Different projects have different requirements, so choose the bolt that best meets those needs.

Residential and Small Commercial Projects

For residential or small commercial projects, L-bolts might be sufficient due to their robust anchoring capabilities and ease of installation in hardened concrete. These projects typically involve moderate to heavy loads where deep embedment and high pull-out resistance are beneficial.

Large Infrastructure and Industrial Projects

For large infrastructure or industrial projects, J-bolts are often more appropriate. Their ability to handle significant shear forces and provide strong mechanical interlocks makes them ideal for securing large structural components and heavy machinery in demanding environments.

Practical Tips for Bolt Selection

- Evaluate Load Conditions: Determine the load requirements of your project. For medium to heavy loads with significant shear forces, J-bolts are suitable. For heavy-duty applications with high tension and shear forces, L-bolts are preferred.

- Consider Installation Timing: If the bolts need to be installed before the concrete is poured, J-bolts are the better choice. For applications requiring installation in hardened concrete, L-bolts offer superior anchorage.

- Assess Project Type: Analyze the type of project you are working on. Residential and small commercial projects may benefit from the use of L-bolts, while large infrastructure and industrial projects might require the robust performance of J-bolts.

By carefully considering these factors, you can select the right bolt type to ensure the stability, safety, and integrity of your construction or engineering project.

Installation Techniques and Best Practices

Installation Techniques

Installing J-Bolts

Timing and Method

J-bolts are typically installed before concrete is poured. This allows the bolt to be securely set as the concrete hardens, ensuring a strong anchor point. The process begins by positioning the J-bolt in the desired location, ensuring the curved hook is correctly oriented. The concrete, as it is poured, encases the hook, providing a firm anchor. It’s essential to ensure the hook is fully embedded to maximize anchoring strength.

Best Practices

- Preparation: Clean the surface and ensure all necessary tools are ready.

- Placement: Position the J-bolt accurately before pouring concrete.

- Embedding: Ensure the hook is fully embedded in the concrete.

- Inspection: After the concrete has set, inspect the bolt for proper alignment and embedding.

Installing L-Bolts

Timing and Method

L-bolts are typically installed into hardened concrete, which is more complex than installing J-bolts. This involves drilling into the cured concrete and securing the bolt using adhesives or expansion mechanisms. The L-shape, featuring a 90-degree bend, ensures strong anchoring by preventing bolt pull-out. This method is particularly effective in heavy-duty applications where high strength is required.

Best Practices

- Preparation: Clean the surface and gather all necessary tools.

- Drilling: Drill holes in the hardened concrete to the required depth and diameter.

- Securing: Insert the L-bolt and secure it using appropriate adhesives or expansion mechanisms.

- Inspection: Ensure the bolt is correctly positioned and securely anchored.

Comparative Analysis

Shape and Load Capacity

- J-Bolts: The 180-degree bend provides a curved hook, making them suitable for light to medium load applications.

- L-Bolts: The 90-degree bend offers strong anchoring suitable for heavy-duty applications.

Installation Complexity

- J-Bolts: Easier installation, as they are embedded during the concrete pouring process, reducing the need for additional tools and labor.

- L-Bolts: More complex installation, involving drilling into hardened concrete and using additional anchoring mechanisms.

Common Applications

- J-Bolts: Ideal for securing light poles, fences, and smaller steel structures.

- L-Bolts: Suitable for structural beams, industrial machinery, and heavy equipment due to their high load-bearing capacity.

Best Practices for Secure Installations

J-Bolts

- Ensure Proper Placement: Position J-bolts accurately before pouring concrete.

- Full Embedding: Make sure the hook is fully embedded in the concrete.

- Regular Inspection: Inspect the bolts periodically to ensure they remain securely anchored.

L-Bolts

- Accurate Drilling: Drill holes precisely in the hardened concrete.

- Secure Anchoring: Use appropriate adhesives or expansion mechanisms to secure the bolts.

- Regular Maintenance: Inspect the bolts regularly to ensure they maintain their structural integrity.

Common Challenges and Troubleshooting

- Misalignment and Embedding: Ensure accurate placement and full embedding during installation to prevent structural issues and maximize strength.

- Adhesive Failure: Use high-quality adhesives and follow manufacturer guidelines to avoid anchoring failures.

Alternatives and Substitutes for J-Bolts and L-Bolts

J-bolts feature a hook-like end that provides a strong mechanical interlock within concrete. This offers excellent resistance to vertical pull-out forces. They are commonly used for anchoring wooden frames and other structural elements to concrete foundations.

L-bolts have a 90-degree bend, forming an “L” shape. They are typically used in cast-in-place applications, offering secure anchorage within concrete. Precise placement is essential before the concrete sets.

Alternatives and Substitutes

Titen HD Anchors

Titen HD anchors are a modern alternative to traditional J-bolts, especially appreciated for their quick and easy installation. These anchors are designed for high-load applications and offer a reliable solution when installation time and simplicity are critical factors.

Wedge Anchors

Wedge anchors are suitable for applications requiring both vertical and lateral stability. They are effective in retrofit projects and provide immediate load-bearing capacity. This makes them ideal for securing heavy machinery or structural supports in industrial settings.

Epoxy Anchors

Epoxy anchors are versatile and useful for correcting misaligned or low-set anchor bolts. They allow for post-pour installation, addressing issues with misaligned holes or angled anchor bolts. These anchors are beneficial in scenarios without seismic or wind design loads but where additional stability is needed.

Removable Anchor Studs

Removable anchor studs offer flexibility in applications where anchors need to be adjusted or removed. Though less common, they provide a practical solution for temporary anchorage needs, allowing for easy adjustments or removal as project requirements change.

Applications and Considerations

J-bolts are best suited for foundational stability and vertical pull-out resistance. They are ideal for securing wooden frames and steel structures where long-term stability is essential.

L-bolts are often used in cast-in-place applications, providing secure anchorage. Proper planning is crucial to ensure accurate placement before the concrete sets.

When considering alternatives, factors such as load requirements, ease of installation, and the need for flexibility or resistance to lateral forces should be evaluated.

Comprehensive Analysis

| Anchor Type | Key Features | Applications |

|---|---|---|

| J-Bolts | Strong vertical pull-out resistance, foundational stability. | Wooden frames, industrial structures. |

| L-Bolts | Secure cast-in-place anchorage. | Residential and commercial foundations. |

| Titen HD Anchors | Fast installation, reduced aggravation. | General construction where ease of use is important. |

| Wedge Anchors | High load capacity, lateral stability, quick installation. | Industrial machinery, retrofit projects. |

| Epoxy Anchors | Post-pour installation, flexibility. | Misaligned or low-set anchor bolts. |

| Removable Anchor Studs | Flexibility, temporary anchorage. | Projects requiring adjustable anchors. |

Each option provides distinct advantages tailored to specific project needs, whether it’s foundational stability, flexibility, or ease of installation.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the main differences between J-bolts and L-bolts?

J-bolts and L-bolts are both types of anchor bolts used in construction to secure structures to concrete. The primary differences between them lie in their shape, load-bearing capacity, and applications.

J-bolts feature a curved hook at one end, resembling the letter “J,” with the other end threaded for fastening. This design provides strong pullout resistance, making J-bolts suitable for applications requiring significant vertical tensile forces, such as securing light poles, highway signs, and steel building foundations. They are commonly used in medium-load applications where ease of installation is also a factor.

In contrast, L-bolts have a simple 90-degree bend at the embedded end, forming an “L” shape. This design allows for better distribution of forces within the concrete, making L-bolts ideal for heavy-duty applications with higher load requirements. They are often used in residential projects, small commercial buildings, and city infrastructure projects like sidewalks and streetlight poles.

While both types of bolts are essential in construction, the choice between J-bolts and L-bolts depends on the specific load capacity and structural demands of the project.

Which bolt is better for heavy-duty applications, J-bolt or L-bolt?

For heavy-duty applications, J-bolts are generally better suited than L-bolts. The design of J-bolts, featuring a curved hook at one end, allows for superior load-bearing capacity and enhanced resistance to pulling forces when embedded in concrete. This makes J-bolts particularly effective in securing heavy machinery foundations, steel building supports, and large infrastructure projects where strong, durable anchorage is essential. In contrast, L-bolts, with their simpler 90-degree bend, are typically used for medium to light loads and are more common in residential construction and lighter commercial applications. Therefore, for projects demanding high structural stability and durability, J-bolts are the preferred choice.

What are typical applications for J-bolts and L-bolts in construction?

In construction, J-bolts and L-bolts serve different anchoring purposes based on their design and load requirements.

J-bolts, characterized by their J-shaped hook, are primarily used for vertical anchoring in concrete. They are embedded in wet concrete to secure structural elements such as sill plates, frames, and columns in building foundations. J-bolts are also crucial in infrastructure projects, anchoring bridge supports, utility poles, and pipelines to withstand dynamic loads like wind and seismic activity. Additionally, they are utilized in industrial settings to fasten heavy machinery, conveyor systems, and renewable energy installations, including solar panel mounts and wind turbine bases.

L-bolts, with their L-shaped end, offer lateral stability and are typically used for lighter loads or horizontal anchoring. Common applications include securing fencing, railing posts, and light structural members. They are also used in precast concrete construction to attach prefabricated panels or slabs and in temporary fixtures like formwork or scaffolding, where ease of removal is beneficial.

Both types of bolts are essential in construction, but their specific applications vary based on the required load capacity and installation method.

How does installation differ between J-bolts and L-bolts?

The installation of J-bolts and L-bolts differs primarily in their timing and method relative to concrete setting.

J-bolts are typically installed before the concrete is poured. They are embedded into the fresh concrete, allowing them to set securely as the concrete hardens. This method is straightforward and less labor-intensive, making it suitable for new construction projects where the concrete can be molded around the bolt for a secure hold.

L-bolts, in contrast, are designed to be installed after the concrete has fully set. Their L-shape provides a deep embedment within the hardened concrete, offering strong anchorage. This method can be more time-consuming as it requires drilling into the hardened concrete, but it ensures a robust connection ideal for heavy-duty applications.

Are there alternatives to J-bolts for anchoring?

Yes, there are several alternatives to J-bolts for anchoring, each suitable for different applications and installation conditions. Common alternatives include wedge anchors, expansion anchors (also known as sleeve anchors), mudsill anchors, removable anchor studs, and Titen HD anchors.

Wedge anchors and expansion anchors are installed into pre-drilled holes in cured concrete and provide strong pull-out resistance, making them ideal for retrofit projects and applications requiring both vertical and lateral load handling. Mudsill anchors are specialized for securing wood sill plates to concrete foundations and are typically used in wood framing projects. Removable anchor studs offer flexibility for temporary or adjustable anchoring needs, while Titen HD anchors allow for quick and strong installation post-concrete pour.

Each alternative has distinct advantages, such as immediate load-bearing capacity, ease of installation, and suitability for specific project requirements, making them viable options depending on the structural needs and timing constraints.

How do I ensure a secure installation of anchor bolts?

To ensure a secure installation of anchor bolts, particularly J-Bolts and L-Bolts, follow these key steps:

- Proper Planning and Layout: Accurately mark bolt positions according to structural requirements, ensuring correct spacing, embedment depth, and alignment.

- Selection and Preparation: Choose the appropriate bolt type (J-Bolt or L-Bolt) based on the load and concrete thickness. Inspect bolts for cleanliness and remove any protective coatings.

- Drilling and Preparing Holes: Use a hammer drill with the correct bit size to drill holes to the specified depth. Clear all dust and debris from the holes to ensure proper bonding.

- Inserting the Bolts: Insert bolts into the holes with slight pressure, ensuring they are perpendicular to the surface. For cast-in-place bolts, position them before concrete placement.

- Securing the Bolts: For post-installed anchors, expand the anchor inside the hole by tightening the nut. For cast-in-place bolts, ensure the concrete cures properly around the bolt. Tighten nuts evenly, avoiding over-tightening.

- Final Verification and Maintenance: Check the tightness of the nuts after initial installation and periodically. Inspect bolt alignment and ensure they remain secure and free of corrosion.

By following these steps, you can achieve a secure and reliable anchor bolt installation for your construction projects.