Lasers can be classified in various ways, typically by active medium, excitation method, output mode, and wavelength range.

Classification by active medium divides lasers into solid-state, gas, liquid, and semiconductor lasers.

Furthermore, lasers can be categorized by their output as either continuous wave or pulsed.

(1) Solid-State Lasers

Solid-state lasers use materials such as ruby, neodymium glass, and yttrium aluminum garnet (YAG), where a small amount of ions are uniformly doped into the host crystal or glass. The doped ions, known as active ions, are responsible for the laser emissions. Transition metal ions like chromium (Cr3+) and rare-earth metal ions such as neodymium (Nd3+) and erbium can serve as active ions.

These lasers are typically excited by light, with common pulsed light sources including xenon flash lamps, and continuous sources like krypton arc lamps, iodine tungsten lamps, and potassium rubidium lamps. In small, long-life lasers, light-emitting diodes or solar light can be used as the excitation source. Some new solid-state lasers are also excited by other lasers.

Solid-state lasers boast compact size, robustness, ease of use, and high output power. Their continuous power can exceed 100W, while pulse peak power can reach up to 109W. However, due to the complex preparation of the active medium, they tend to be expensive.

(2) Gas Lasers

Gas lasers utilize gases or metal vapors as the active medium, typically contained within a discharge tube to generate active ions. Their main excitation methods include electrical, aerodynamic, photonic, and chemical, with electrical being the most common.

Under appropriate discharge conditions, gas particles are selectively excited to a higher energy level, creating an inversion of particle number between this and a lower energy level, leading to stimulated emission transitions. Gas lasers can be atomic, ionic, molecular, or excimer.

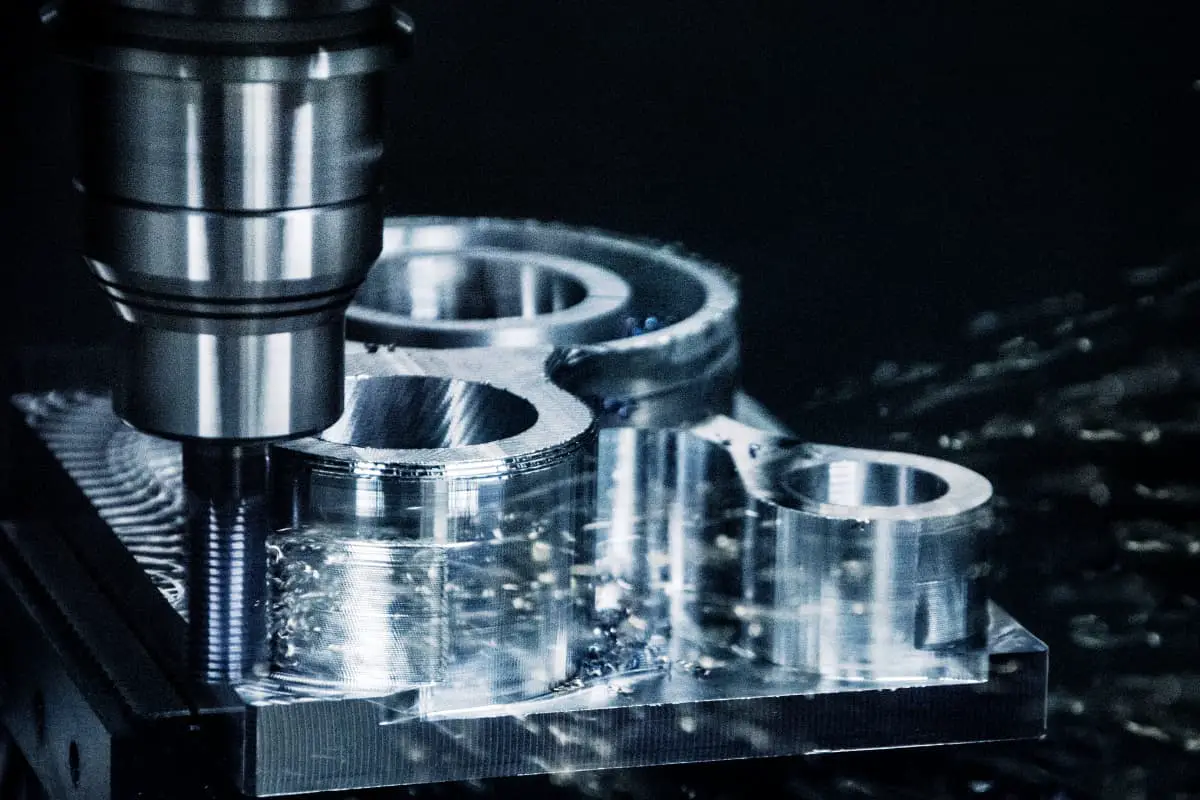

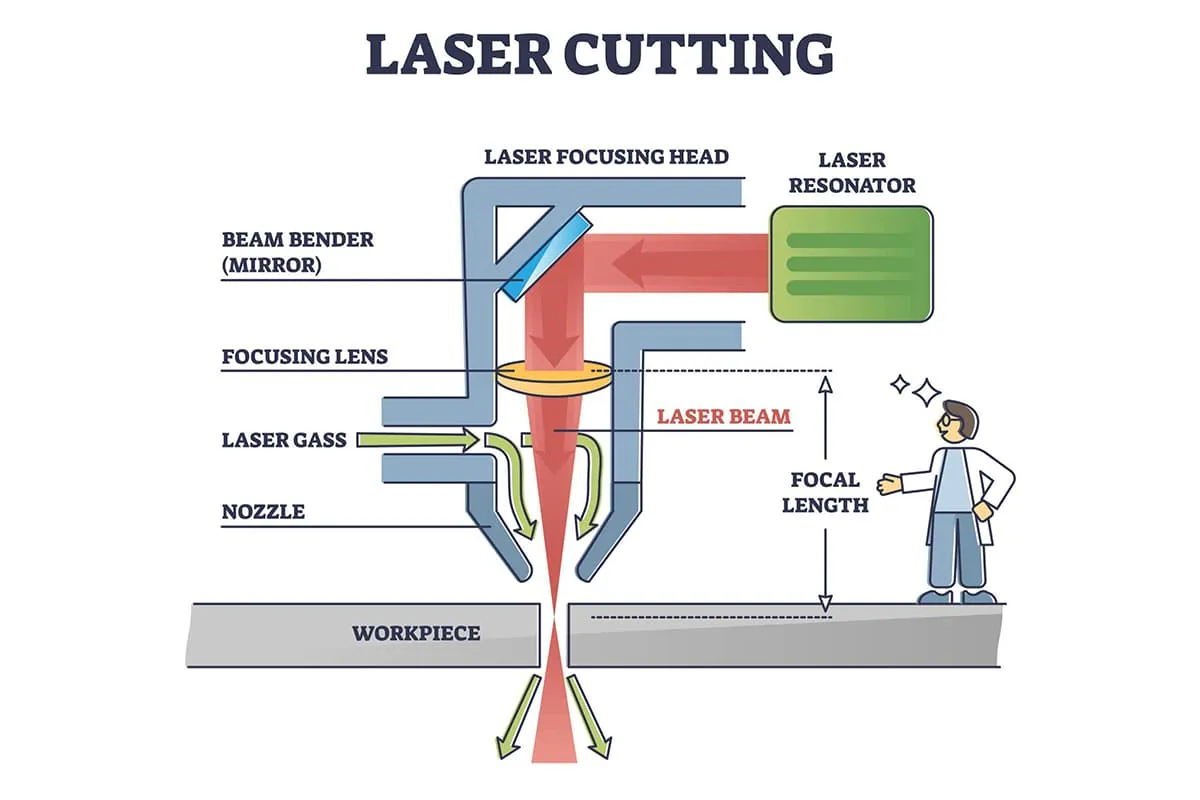

Molecular gas lasers often use CO2 as the medium, predominantly emitting infrared wavelengths, which due to their high thermal effect, are commonly used in laser cutting, medical applications, and mechanical processing, as well as for ranging and communication. Excimer lasers emit in the ultraviolet range and are used in fine machining, photolithography, and medicine.

Gas lasers are characterized by their simple construction, low cost, convenience, good beam quality, and the ability to operate continuously and stably for long periods. They are the most diverse and widely used type of laser.

(3) Liquid Lasers

Liquid lasers, also known as dye lasers, use organic dyes as the active medium dissolved in solvents like ethanol, acetone, or water, but can also operate in vapor form. Common organic dyes include rhodamine, coumarin, and phthalocyanine, which enable the generation of different laser wavelengths within the visible range. Liquid lasers are often optically pumped, either by lasers or flash lamps.

Their wavelength coverage ranges from ultraviolet to infrared (321nm to 1.168μm), which can be extended into the vacuum ultraviolet range using frequency doubling techniques. The advantages of liquid lasers include tunable continuous output across a wide range and are primarily used in scientific research and medicine, such as laser spectroscopy, photochemistry, isotope separation, and photobiology.

(4) Semiconductor Lasers

Semiconductor lasers, also known as laser diodes, utilize semiconductor materials as the active medium. Due to structural differences, the process of laser generation is quite unique for various types of semiconductor materials. Common active materials include gallium arsenide (GaAs), cadmium sulfide (CdS), indium phosphide (InP), and zinc sulfide (ZnS).

There are three main excitation methods: electrical injection, electron beam excitation, and optical pumping. Semiconductor lasers are categorized into homojunction, single heterojunction, and double heterojunction types. Homojunction and single heterojunction lasers generally operate as pulsed devices at room temperature, while double heterojunction lasers can operate continuously at room temperature.

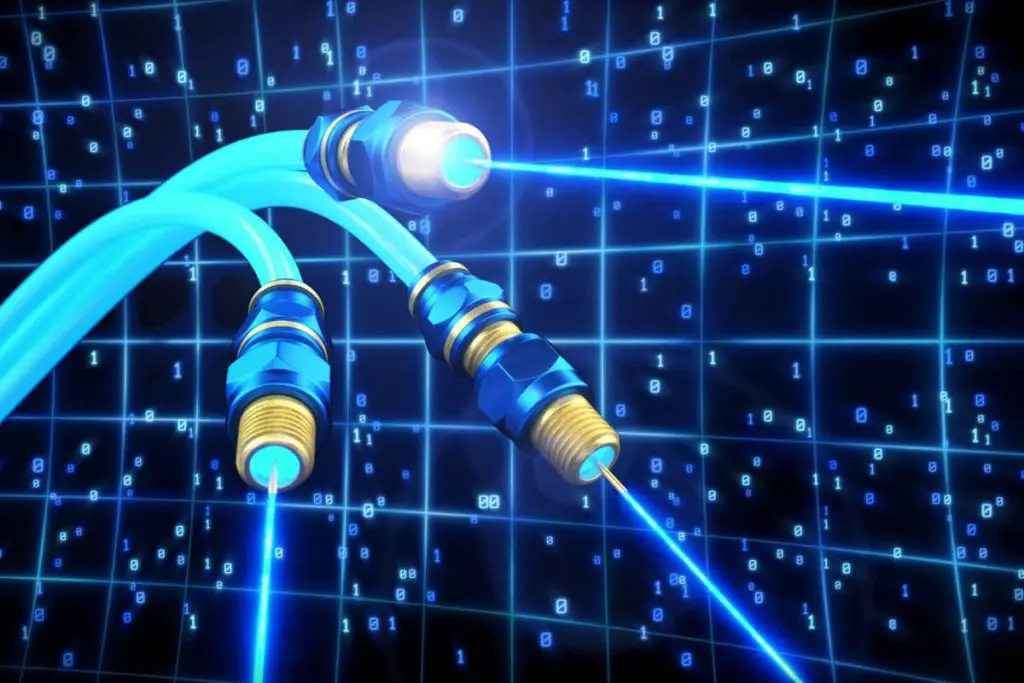

Semiconductor lasers are compact, have a long lifespan, and can be easily pumped through a simple injection of current. Their operating voltage and current are compatible with integrated circuits, enabling monolithic integration. Furthermore, they can be modulated directly at frequencies up to 50-100 GHz for high-speed laser output.

Owing to these advantages, semiconductor lasers are widely used in laser communication, optical storage, optical gyroscopes, laser printing, range finding, and radar applications.

(5) Fiber Lasers

Fiber lasers are a type of solid-state laser with rare-earth-doped fiber as the active medium. The pump source of a fiber laser consists of one or more high-power laser diode arrays. The pump light emitted is coupled into the rare-earth-doped fiber through a specialized pumping structure. Photons at the pump wavelength are absorbed by the doped fiber medium, creating a population inversion that leads to stimulated emission.

The light waves emitted are reflected by the resonator mirrors, oscillating to produce laser output. Fiber lasers have high coupling efficiency, can easily achieve high power density, and have excellent heat dissipation, eliminating the need for bulky cooling systems. They boast high conversion efficiency, low thresholds, superior beam quality, and narrow linewidths.

Additionally, fiber lasers have a resonator cavity free of optical lenses, resulting in maintenance-free operation, high stability, and extremely long service lives exceeding 100,000 hours. As a result, fiber lasers are gradually replacing other types of lasers in industrial applications such as cutting, marking, and welding.