Imagine transforming a simple block of material into a complex, precisely crafted piece of machinery. The secret lies in understanding the lathe’s axes. If you’re an intermediate machinist seeking to elevate your CNC skills, grasping the intricacies of lathe axes is essential. This guide will demystify the X, Y, and Z axes, explain how the Y-axis enhances off-center milling, and introduce the rotational axes—A, B, and C—that revolutionize machining possibilities. Discover how these axes function and why they are pivotal in CNC operations. Ready to unlock the full potential of your lathe? Let’s delve into the world of lathe axes step-by-step.

Understanding the Primary Axes in a Lathe

Introduction to Lathe Axes

Lathes are crucial machining tools used to shape cylindrical, conical, and complex geometric workpieces. The precision and versatility of a lathe are primarily determined by its axis configuration, which defines the range of movements and machining capabilities. Understanding the primary axes in a lathe is essential for effective machining operations.

Linear Axes: X, Y, Z

The primary axes in a lathe are the linear axes, designated as X, Y, and Z. These axes facilitate the movement of the cutting tool in three-dimensional space.

X Axis

The X-axis controls the movement of the tool or workpiece forward and backward, typically along the cross-slide. In most lathes, the X-axis moves perpendicular to the spindle axis. This axis is crucial for controlling the depth of cut, which determines the diameter of the workpiece being machined.

Y Axis

The Y-axis allows movement perpendicular to both the X and Z axes, enabling off-center machining and more complex geometries. While not always present in basic lathes, the Y-axis is essential for creating intricate shapes and features. In many simpler models, the Y-axis is omitted, and movement is primarily along the X and Z axes. However, in advanced CNC lathes, the Y-axis significantly enhances the machine’s versatility.

Z Axis

The Z-axis provides longitudinal movement along the workpiece, parallel to the spindle, and is essential for turning and facing operations. This axis allows the cutting tool to machine along the length of the workpiece, making it fundamental for shaping and finishing tasks.

Importance in CNC Machining

In CNC (Computer Numerical Control) machining, the precision and control of the X, Y, and Z axes are paramount. These axes enable automated, precise movements of the cutting tool, leading to high-accuracy machining processes. CNC lathes utilize these axes to perform various operations, including:

- Turning: Removing material from the outer diameter.

- Facing: Creating a flat surface at the end.

- Boring: Enlarging a hole or cylindrical cavity.

- Threading: Cutting threads for screws or bolts.

- Knurling: Creating a patterned texture on the workpiece surface.

The integration of X, Y, and Z axes in CNC lathes allows for complex and precise machining tasks that are difficult to achieve with manual lathes. Advanced CNC systems can simultaneously control multiple axes, enabling the production of complex parts with high precision and repeatability.

Expanding Lathe Capabilities with the Y-axis

Enhancing Capabilities with the Y-Axis

Adding the Y-axis to CNC lathes marks a major leap forward in machining technology. This additional axis allows for a greater range of movements and more complex machining tasks that go beyond the capabilities of traditional X and Z-axis configurations.

The Y-axis introduces movement perpendicular to both the X-axis (which handles diameter changes) and the Z-axis (which controls length changes). This perpendicular movement is critical for off-center operations, such as drilling holes that are not aligned with the center of the workpiece or milling features that extend beyond the central axis. Traditional lathes, restricted to X and Z-axis movements, require additional setups or secondary operations on different machines to handle off-center tasks. The Y-axis enables:

- Off-Center Drilling: Creating holes or cavities at various positions around the workpiece, not limited to its centerline.

- Slot Milling: Cutting slots and grooves along the surface of the workpiece, which would otherwise be challenging without the Y-axis.

These capabilities streamline the manufacturing process, reducing the need for multiple setups and thus saving time and improving precision.

The Y-axis enhances the ability to machine complex geometries. By allowing the tool to approach the workpiece from different angles and positions, it is possible to create complex shapes and features that were difficult to create with traditional setups. This includes:

- Keyways and Splines: Machining detailed keyways and splines directly on the lathe without transferring the workpiece to a milling machine.

- Complex Contours: Producing complex, multi-faceted contours and surfaces in a single setup.

Y-axis CNC lathes combine several machining tasks in a single setup. This integration significantly reduces setup times, enhances precision by minimizing repositioning errors, and boosts overall productivity. Tasks that can be consolidated include:

- Turning and Milling: Performing turning operations alongside milling tasks without removing the workpiece.

- Drilling and Boring: Executing precise drilling and boring operations in conjunction with turning and facing.

There are various types of Y-axis CNC lathes available, each with different capabilities:

- True Y-Axis Lathes: These machines offer comprehensive Y-axis movement, providing full versatility for a wide range of machining tasks, including angled drilling and intricate geometries.

- Wedge-Type Y-Axis Lathes: Although not as versatile as true Y-axis lathes, wedge-type lathes still offer enhanced capabilities compared to traditional two-axis lathes, making them suitable for less complex off-center operations.

Several models exemplify the capabilities of Y-axis CNC lathes:

- Haas ST-10Y: A compact model featuring a 6″ hydraulic chuck and a 12-position tool turret, ideal for smaller spaces yet offering versatile 4-axis capability with high-torque live tooling and a servo-driven C-axis.

- Force One’s Y-Axis Lathes: Engineered for industries such as aerospace and automotive, these lathes focus on reliability, precision, and efficiency, particularly in producing complex parts.

When selecting a Y-axis lathe, consider factors like:

- Complexity of Parts: Ensure the machine can handle the intricate geometries and off-center operations required by your production needs.

- Production Volume: Assess whether the machine meets the required production capacity.

- Space and Budget: Evaluate the physical footprint and cost, ensuring it fits within your operational constraints.

- Vendor Support: Consider the availability of comprehensive service and support from the manufacturer or vendor.

By integrating Y-axis CNC lathes into their manufacturing processes, industries can significantly enhance their productivity, reduce costs, and improve product quality. The versatility and precision offered by these advanced machines make them a valuable asset in modern machining operations.

Introduction to Rotational Axes in CNC Lathes

Overview of CNC Lathe Axes

CNC lathes are high-tech machines that use both linear and rotational movements to perform precise and intricate tasks. The integration of these axes allows for a wide range of movements, enhancing the machine’s versatility and capability.

Linear Axes in CNC Lathes

- X-Axis: Controls the lateral movement (left and right) of the tool. It is essential for determining the diameter of the workpiece.

- Z-Axis: Governs the longitudinal movement (forward and backward) of the tool. It is crucial for controlling the length of the cut and the depth of features along the workpiece.

Rotary Axes: Expanding Machining Capabilities

Rotary axes, or rotational axes, add another dimension of movement to CNC lathes, enabling the machining of more complex geometries. These axes, designated as A, B, and C, include the A-Axis, which rotates around the X-axis and allows for angular machining, providing access to additional sides of the workpiece.

- B-Axis: Represents rotation around the Y-axis. This axis enables the tool or workpiece to tilt in a different plane, increasing the machine’s versatility.

- C-Axis: Represents rotation around the Z-axis. In advanced CNC lathes, the C-axis allows for precise angular positioning of the workpiece, making it possible to perform milling operations and create complex features on the circumference of a part.

The Role of Rotary Axes in Modern CNC Lathes

Adding rotary axes turns a simple 2-axis lathe into a versatile multi-axis machine:

- 3-Axis CNC Lathes: Typically include X, Z, and C axes. The C-axis enables milling and drilling operations on the face or periphery of the workpiece while it is stationary or rotating.

- 4-Axis CNC Lathes: Incorporate an A-axis (rotation around X), allowing for angular machining and access to features on additional sides of the part.

- 5-Axis CNC Lathes: Add a B-axis (rotation around Y), enabling the most complex geometries and simultaneous multi-sided machining.

Benefits of Rotary Axes

- Increased Flexibility: Rotary axes allow the tool or workpiece to be positioned at various angles, enabling the machining of complex contours and undercuts that would be impossible with linear axes alone.

- Improved Accuracy: Rotary axes improve precision and repeatability by minimizing the need for multiple setups and manual adjustments.

- Reduced Cycle Times: Complex parts can be completed in fewer operations, streamlining production and reducing lead times.

Practical Applications

- Milling on a Lathe: With a C-axis, CNC lathes can perform milling operations, such as drilling holes or cutting slots at precise angular positions.

- Multi-Sided Machining: The A and B axes enable machining on multiple sides of a workpiece in one setup, reducing errors from repositioning.

- Complex Geometries: Rotary axes enable the creation of intricate parts with complex curves, angles, and undercuts, which are common in aerospace, automotive, and medical industries.

| Axis | Direction/Motion | Function |

|---|---|---|

| X | Horizontal (left/right) | Controls diameter; lateral tool movement |

| Z | Longitudinal (forward/backward) | Controls length; longitudinal tool movement |

| C | Rotation around Z | Angular positioning; milling operations |

| A | Rotation around X | Tilt axis; angular machining |

| B | Rotation around Y | Additional tilt for complex geometries |

Comparing Different Axis Lathes

Differences Between 2-Axis, 3-Axis, and Multi-Axis Lathes

Understanding the specific capabilities and limitations of different axis lathes is crucial for selecting the right machine for your needs. This section details the differences between 2-axis, 3-axis, and multi-axis lathes and their applications in CNC machining.

2-Axis CNC Lathes

2-axis CNC lathes are the most basic type of CNC lathe. These lathes function using two main axes: the X-axis and the Z-axis.

- X-Axis: Controls the lateral movement of the cutting tool, allowing it to move left and right across the workpiece.

- Z-Axis: Governs the longitudinal movement of the cutting tool, enabling it to move forward and backward along the length of the workpiece.

Applications and Limitations:

- Applications: Ideal for simple turning operations, such as creating cylindrical shapes, facing, and basic threading.

- Limitations: Best for cylindrical shapes; cannot perform milling. Limited to simple geometries.

3-Axis CNC Lathes

3-axis CNC lathes add a third axis, significantly enhancing their capabilities.

- X-Axis and Z-Axis: Same as in 2-axis lathes.

- C-Axis: Allows for rotational movement around the Z-axis, enabling the workpiece to be positioned at precise angles.

Enhanced Capabilities:

- Live Tooling: Adding live tooling allows 3-axis CNC lathes to perform milling, drilling, and tapping operations. This enables more complex parts to be machined without needing to move the workpiece to a different machine.

- Flexibility: Suitable for parts requiring both turning and secondary operations like milling or drilling, providing more versatility than 2-axis lathes.

Multi-Axis CNC Lathes

Multi-axis CNC lathes, which include 4-axis and 5-axis lathes, offer even greater flexibility and precision.

- 4-Axis CNC Lathes: Introduce an A-axis, allowing for rotation around the X-axis. This enables angular machining and access to additional sides of the workpiece.

- 5-Axis CNC Lathes: They add a B-axis, which rotates around the Y-axis, enabling the machining of complex geometries and multi-sided parts simultaneously.

Advanced Capabilities:

- Complex Geometries: Multi-axis lathes can machine intricate parts with complex curves, angles, and undercuts.

- Simultaneous Operations: Capable of performing multiple machining operations in a single setup, reducing the need for multiple setups and increasing efficiency.

- High Precision: Achieve high precision and repeatability, essential for industries such as aerospace, automotive, and medical device manufacturing.

Comparison and Applications

Different axis lathes are suited for various applications based on their capabilities:

| Axis Type | Capabilities | Limitations |

|---|---|---|

| 2-Axis | Basic turning operations | Best for cylindrical shapes; cannot perform milling |

| 3-Axis | Turning, milling, drilling with live tooling | More complex operations may require additional setups |

| 4-Axis | Angular machining, access to additional sides | Increased complexity and cost |

| 5-Axis | Multi-sided machining, intricate geometries | High complexity and cost; requires advanced programming |

Real-World Examples

- 2-Axis Lathe Example: A machine shop producing simple shafts and bushings may use a 2-axis lathe for its efficiency and cost-effectiveness.

- 3-Axis Lathe Example: A manufacturer making parts needing both turning and milling, like flanges with bolt patterns, would benefit from a 3-axis lathe with live tooling.

- 4-Axis Lathe Example: Producing components with angled features, such as turbine blades, would be more feasible with a 4-axis lathe.

- 5-Axis Lathe Example: Complex aerospace parts with intricate geometries and high precision requirements are best suited for 5-axis lathes.

Understanding the differences between these lathes allows manufacturers to select the appropriate machine for their specific needs, balancing complexity, cost, and production requirements.

Practical Applications of Lathe Axes

Understanding Lathe Axes

Lathes function by rotating a workpiece around an axis, allowing for various machining tasks such as cutting, drilling, and threading. The practical applications of lathe axes are fundamental to mastering lathe operations. Below is a step-by-step guide to understanding and applying lathe axes in real-world machining.

Z-Axis and X-Axis

The Z-axis runs parallel to the spindle and workpiece rotation, controlling the tool’s position along the length of the workpiece, while the X-axis is perpendicular to the spindle axis and manages the radial position of the tool, determining the diameter of the cut. These axes are essential for basic lathe operations.

- Turning (Using Z and X Axes)

- Process: The tool moves along the Z-axis to cut lengthwise and along the X-axis to control diameter.

- Application: Creating cylindrical shapes such as shafts and pins. For example, turning a metal stock into a functional screw jack involves shaping the stock by controlling the tool position along these axes, threading the screw, and finishing the surface.

- Thread Cutting (Primarily Z and X Axes)

- Process: Synchronizing the tool movement along the Z-axis with the spindle rotation to cut precise threads.

- Application: Cutting threads onto a workpiece, with the X-axis controlling the depth of the cut.

- Facing and Boring (Z and X Axes)

- Facing: Moving the tool radially (X-axis) across the end of the rotating workpiece to create a flat surface.

- Boring: Enlarging a hole by moving the tool along the Z-axis inside the workpiece.

Y-Axis and C-Axis

Advanced CNC lathes include additional axes such as the Y-axis and C-axis. The Y-axis moves the tool perpendicular to both the X and Z axes, while the C-axis controls the rotation of the spindle in precise angular increments.

- Milling Flats or Keyways (Using Y and C Axes in CNC Lathes)

- Process: Using the Y-axis to move the tool perpendicular to the X and Z axes, allowing direct milling on cylindrical parts.

- Application: Machining flats or keyways without removing the part from the lathe. The C-axis enables precise angular positioning for milling features at specific rotational locations.

Specialized Reducing Lathes

Specialized reducing lathes use a mechanism to “read” an original model and simultaneously cut a scaled-down replica on a blank.

- Copying and Reducing

- Process: Synchronizing movement between the model and the cutting tool to produce scaled-down replicas.

- Application: Coin-making and manufacturing master dies where precise reduction ratios are required.

Multi-axis Machining and Live Tooling

Advanced multi-axis lathes integrate live tooling and additional axes beyond X and Z, enabling milling, drilling, and turning in one setup.

- Live Tooling and Multi-Axis Machining

- Process: Utilizing live tooling to perform multiple operations such as milling, drilling, and turning in a single setup.

- Application: Reducing handling time and increasing accuracy for complex parts, enhancing machining efficiency.

| Axis | Movement Direction | Typical Use Cases |

|---|---|---|

| Z | Along spindle axis | Turning, threading, boring |

| X | Radial to spindle | Diameter control, facing |

| Y | Perpendicular to X and Z | Milling flats, keyways on round parts |

| C | Spindle rotation control | Indexing for milling/drilling operations |

| U, V, W | Incremental tool adjustments | Fine positioning and complex tool paths |

Understanding and effectively utilizing the various axes of a lathe, from the fundamental X and Z to the more advanced Y and C axes, is crucial for optimizing machining processes and expanding the capabilities of lathe operations.

Multi-axis Machining: Benefits and Limitations

Benefits of Multi-Axis Machining

Enhanced Accuracy and Precision

Multi-axis machining enhances part accuracy and precision by allowing the workpiece to be machined in a single setup, eliminating errors associated with transferring workpieces between machines. This consolidated approach ensures geometric consistency and tighter tolerances, which are critical for high-precision components.

Capability to Produce Complex Geometries

The additional axes, such as the Y-axis and rotational axes (C-axis and B-axis), enable the creation of intricate angles, arcs, and 3D contours, which is particularly valuable in industries like aerospace and automotive. Multi-axis lathes facilitate the machining of complex part geometries that would be challenging or impossible with traditional 2-axis lathes.

Superior Surface Finish

Multi-axis machining offers the ability to achieve superior surface finishes. Continuous movement along multiple axes allows for the use of shorter cutting tools, reducing tool deflection and vibrations. As a result, machined surfaces exhibit fewer machining marks and a smoother finish, enhancing the overall quality of the parts.

Reduced Setup and Cycle Times

Multi-axis lathes can perform multiple machining operations in a single setup, significantly reducing setup and cycle times. This integration minimizes the need for repositioning and multiple fixtures, streamlining the production process and leading to faster turnaround times and increased productivity.

Lower Labor Costs

The automation and reduced manual intervention associated with multi-axis machining contribute to lower labor costs. Since these machines can handle complex tasks with minimal human oversight, the reliance on skilled operators is reduced, allowing manufacturers to allocate labor resources more effectively and focus on other critical areas of production.

Prolonged Tool Life

Dynamic adjustment of tool angles in multi-axis machining helps reduce tool wear, extending tool life. By optimizing cutting conditions and minimizing excessive stress on the tools, multi-axis lathes ensure more consistent and durable performance of cutting tools, translating to cost savings on tooling expenses.

Mass Production Capabilities

Multi-axis lathes are particularly suited for high-volume, repeatable production of precision parts. Their ability to maintain consistent quality and accuracy across multiple production runs makes them ideal for mass production scenarios. Industries that require large quantities of uniform parts, such as medical device manufacturing, benefit greatly from the reliability and efficiency of multi-axis machining.

Limitations of Multi-Axis Machining

High Initial and Operational Costs

Multi-axis CNC lathes require substantial investment not only for the equipment but also for advanced tooling, maintenance, and energy consumption. These costs can be a significant barrier for smaller manufacturing operations.

Complex Setup and Programming

Multi-axis machining involves complex setup and programming requirements. The advanced capabilities of these machines necessitate sophisticated software and skilled programmers who can handle intricate tool paths and machining strategies, increasing the time and resources needed for initial setup and programming.

Training Requirements

Operators and programmers need extensive training to effectively use multi-axis CNC lathes, given their advanced functionalities and additional axes. Investing in training programs is essential to maximize the potential of multi-axis machining.

Limited Cost-Effectiveness for Simple Parts

For simple, low-complexity parts, the advanced capabilities of multi-axis lathes may be unnecessary and cost-ineffective. Traditional 2-axis lathes or simpler CNC machines can adequately handle basic turning and milling operations at a lower cost. Therefore, manufacturers must carefully evaluate the complexity of their parts and production needs before investing in multi-axis technology.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the primary axes in a lathe and what do they do?

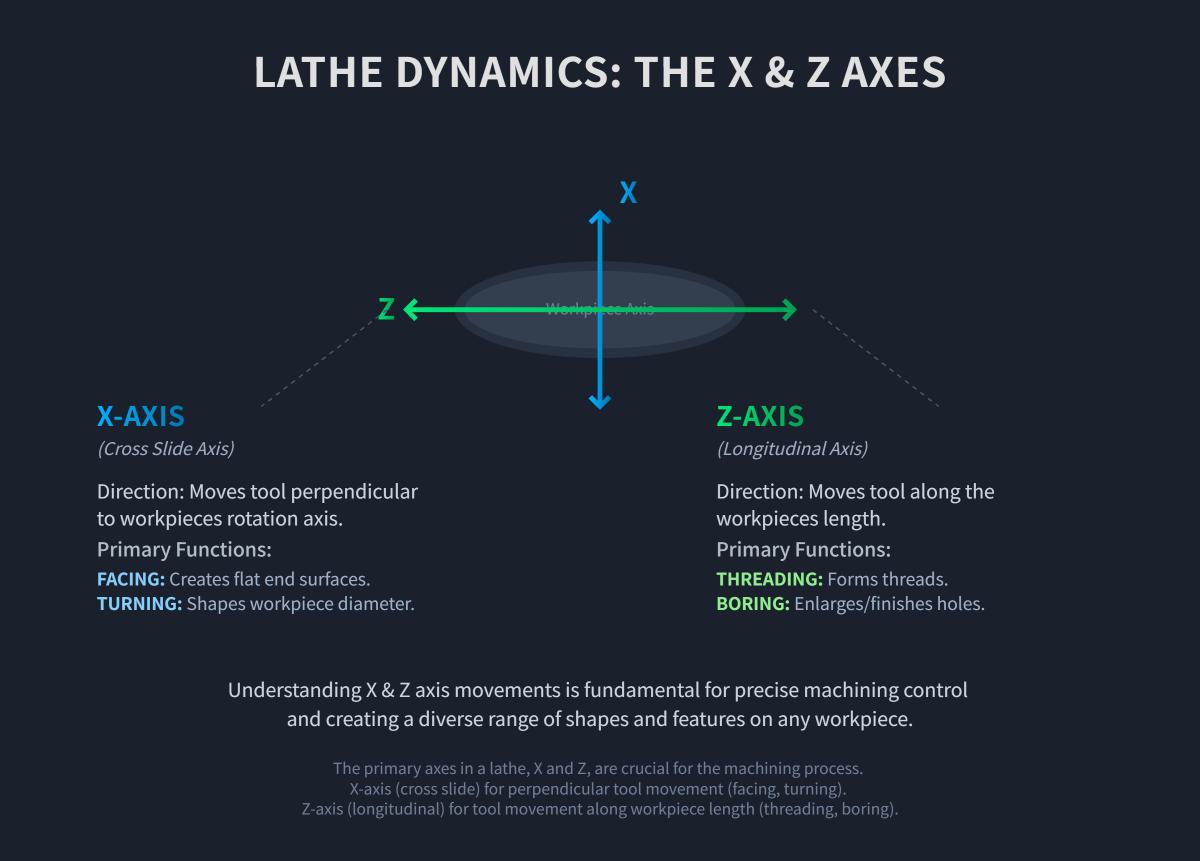

The primary axes in a lathe are the X-axis and the Z-axis, each playing a crucial role in the machining process. The X-axis, also known as the cross slide axis, moves the cutting tool perpendicular to the workpiece’s axis of rotation. This movement is essential for operations such as facing, where flat surfaces are created at the ends of the workpiece, and turning operations, which involve shaping the diameter of the workpiece. The Z-axis, or longitudinal axis, controls the movement of the cutting tool along the length of the workpiece. This axis is vital for operations like threading and boring, where precise control over the tool’s movement along the workpiece is necessary. Understanding these axes is fundamental for effectively using a lathe, ensuring precise control over the machining process and enabling the creation of a wide range of shapes and features on the workpiece.

How does the Y-axis expand lathe capabilities?

The Y-axis in a CNC lathe significantly expands its capabilities by allowing for off-center milling, drilling, and turning operations, which were previously not possible without repositioning the workpiece multiple times. This additional axis enables the performance of complex machining tasks, such as creating keyways, slots, and intricate geometries directly on the lathe. This versatility reduces setup times, enhances precision by minimizing the need for multiple machine setups, and increases productivity. The Y-axis also allows for the use of multiple tools in each tool station, further enhancing the machine’s flexibility and efficiency. This makes Y-axis lathes particularly valuable in industries requiring high precision and complex component production, such as aerospace, automotive, and medical devices.

What are the rotational axes in a CNC lathe and what are their functions?

Rotational axes in a CNC lathe are crucial for expanding machining capabilities beyond simple linear movements. These axes, known as A-axis, B-axis, and C-axis, allow rotation around the main linear axes (X, Y, Z).

- A-axis (Roll): This axis enables rotation around the X-axis. It is primarily used for tilting the tool or workpiece, facilitating complex sculpting and contouring operations.

- B-axis (Pitch): This axis allows rotation around the Y-axis. It is beneficial for multi-angle machining and is particularly useful for creating cylindrical or conical shapes.

- C-axis (Yaw): This axis rotates around the Z-axis. It is used for indexing the workpiece or tool, which is essential for helical or spiral cuts and live tooling operations.

These rotational axes enhance a CNC lathe’s versatility, enabling multi-sided machining without manual repositioning, improving efficiency, precision, and allowing intricate part designs that would be challenging on standard 2- or 3-axis machines.

What are the differences between 2-axis, 3-axis, and multi-axis lathes?

A 2-axis CNC lathe utilizes the X and Z axes, enabling basic turning operations such as outer and inner diameter machining, facing, drilling, and tapping. This configuration is suitable for producing simple cylindrical parts and is commonly used in general machining and small workshops.

A 3-axis CNC lathe includes the X, Z, and C axes. The addition of the C-axis allows for rotary motion and live tooling capabilities, enabling more complex operations like milling and intricate drilling. This setup is prevalent in industries like aerospace, automotive, and medical, where parts require more detailed machining.

Multi-axis CNC lathes, such as 4-axis, 5-axis, and 6-axis machines, incorporate additional axes like Y, A, and B, providing enhanced capabilities for machining complex geometries. These lathes can perform simultaneous operations on multiple sides of a workpiece, reducing cycle time and increasing precision. They are ideal for high-precision industries, such as aerospace, where intricate designs and high-volume production are necessary.

What are the benefits and limitations of multi-axis machining?

Multi-axis machining offers numerous benefits and some limitations that are crucial to consider.

Benefits:

- Increased Accuracy and Precision: Multi-axis machining allows for the production of complex parts in a single setup, reducing errors from manual repositioning.

- Complex Part Production: It enables the creation of intricate 3D shapes, contours, and undercuts that are challenging with traditional methods.

- Enhanced Surface Finish: The continuous movement along multiple axes minimizes tool marks, resulting in superior surface finishes.

- Reduced Labor and Production Time: Fewer setups and manual interventions lower labor costs and shorten production times.

- Extended Tool Lifespan: Optimal cutting angles reduce tool wear, extending tool life and lowering maintenance costs.

- Reduced Fixture Needs: Secure positioning of the workpiece throughout the process reduces the need for multiple fixtures.

- Mass Production Capability: Consistent quality in high-volume manufacturing makes it ideal for mass production.

Limitations:

- High Costs: The initial purchase and operational costs, including maintenance and tooling, are significantly higher than conventional machines.

- Complex Setup and Programming: Advanced skills and specialized software are required for programming, which can be a barrier for less experienced operators.

- Limited Application Scope: It may not be cost-effective for simpler components or low production volumes, limiting its use in some industries.

How are lathe axes applied in real-world CNC operations?

In real-world CNC operations, lathe axes are fundamental for precisely controlling the movement and positioning of the cutting tool and workpiece. The X and Z axes are the primary directions, with the X-axis managing the tool’s radial movement towards or away from the workpiece’s centerline, and the Z-axis controlling the longitudinal movement along the workpiece. This configuration allows for essential operations like turning, facing, and boring, which are crucial for creating cylindrical parts such as shafts and bushings.

Multi-axis lathes, including 3-, 4-, and 5-axis machines, expand capabilities by adding additional linear and rotational axes. These advanced lathes enable the machining of complex geometries and intricate designs with high precision. For example, 4- and 5-axis lathes are vital in aerospace and medical industries for producing turbine blades and surgical instruments, respectively, due to their ability to perform simultaneous multi-directional cuts.

The application of lathe axes in CNC operations ensures efficient, high-quality production across various industries, from automotive to consumer electronics, by enabling a wide range of machining processes, from simple turning to complex contouring and engraving.