When it comes to securing bolted joints, the choice between lock nuts and jam nuts can be crucial. While both types of nuts serve the purpose of preventing loosening, they achieve this in different ways. So, what exactly sets them apart? How do jam nuts combat the persistent problem of vibration-induced loosening? In this article, we dive deep into the structural and functional differences between lock nuts and jam nuts, offering a comparative analysis that is both insightful and practical. Whether you’re a seasoned professional or an intermediate enthusiast, understanding these nuances can make all the difference in ensuring the stability and longevity of your projects. Ready to unravel the mysteries of lock nuts and jam nuts? Let’s get started!

Overview of Bolted Joints

Definition and Importance

Bolted joints are essential components in many engineering and construction projects, consisting of a bolt and a nut that secure multiple parts together. These joints are crucial due to their ability to provide strong, reliable connections that can be easily assembled and disassembled. The use of bolted joints is prevalent in industries such as automotive, aerospace, machinery, and civil engineering, where robust and maintainable connections are vital.

Common Uses and Applications

Bolted joints are versatile and can be found in numerous applications, such as structural connections in construction, machine assembly, automotive industry, and aerospace. In construction, they connect steel beams and columns, ensuring stability. In machinery, they assemble components like gears and shafts, allowing easy maintenance. In vehicles, bolted joints connect parts like engine components and suspension systems. In aerospace, they are critical for assembling aircraft structures with precision and reliability.

Importance of Vibration Resistance

Vibration resistance is crucial for bolted joints because vibrations can cause bolts to loosen and joints to fail. Maintaining preload under dynamic conditions is essential, and techniques like using lock nuts can help keep joints secure.

Key Components of Bolted Joints

Bolt and Nut

The bolt and nut are the primary components of a bolted joint. The bolt is tightened to create a preload that compresses the joint, ensuring stability. Proper tightening methods, such as torque control or tensioning, are essential for maintaining preload and joint security.

Joint Stiffness

Joint stiffness refers to the rigidity of the connection, which is usually greater than the stiffness of the bolt. When an axial load is applied, the joint’s compression decreases more than the bolt’s extension increases, helping to maintain the joint’s integrity.

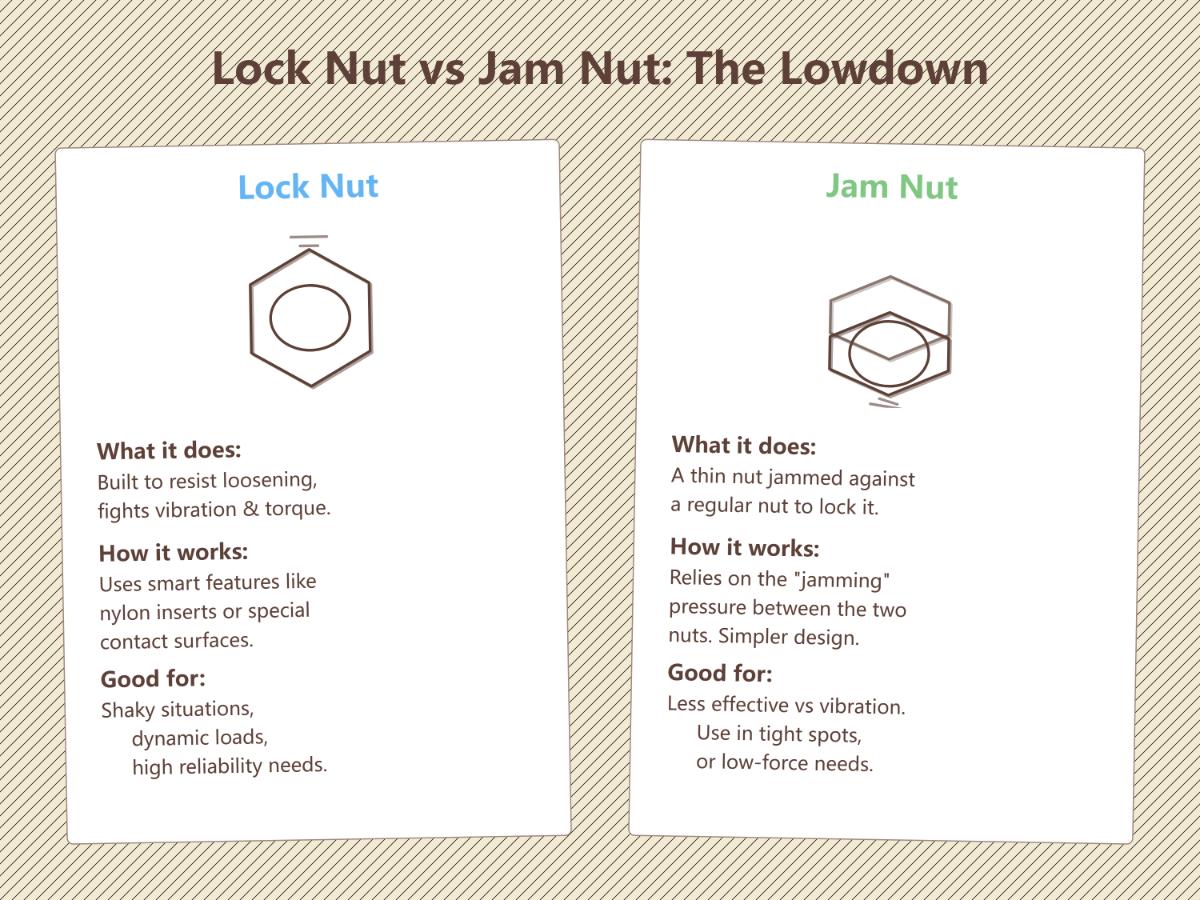

Comparative Analysis: Lock Nut vs. Jam Nut

Understanding the differences between lock nuts and jam nuts is essential for optimizing bolted joint performance. Each type of nut serves specific purposes and can significantly impact the reliability and efficiency of the joint in different environments. Lock nuts are designed to prevent loosening due to vibration, while jam nuts secure the main nut without adding significant thickness. The choice between these nuts depends on factors like space constraints, vibration resistance, and the need for maintaining preload over time.

Understanding Lock Nuts and Jam Nuts

Definition of Lock Nut

A lock nut is a specialized type of nut designed to resist loosening under vibration and dynamic loads. Lock nuts use different mechanisms to prevent loosening, such as nylon inserts, deformed threads, or metal-to-metal friction. The purpose of a lock nut is to maintain the integrity of bolted joints by preventing the nut from rotating and loosening over time. The most common types of lock nuts include:

- Nylon Insert Lock Nuts: Some lock nuts use a nylon collar to create friction against the bolt threads, while others have intentionally deformed threads to ensure a tight fit and increased friction.

- Distorted Thread Lock Nuts: These nuts have threads that are intentionally deformed to create a tight fit on the bolt, increasing friction and preventing movement.

- Metal Lock Nuts: Utilizing features such as serrated faces or conical designs, these nuts enhance metal-to-metal friction to resist loosening.

Definition of Jam Nut

A jam nut is a thinner hex nut used in conjunction with a standard nut to lock the main nut in place through axial tension. Unlike lock nuts, jam nuts do not have integrated locking features; instead, they rely on the mechanical principle of thread wedging. Tightening the jam nut against the standard nut compresses the threads, creating resistance to rotation. Jam nuts are typically half the height of regular nuts, making them suitable for applications where space is limited. Key characteristics include:

- Low Profile: Due to their reduced height, jam nuts are ideal for applications with spatial constraints.

- Dual Nut System: Jam nuts require pairing with a standard nut to function effectively.

- Thread Compression: The wedging action created by tightening two nuts together prevents loosening.

Common Uses and Applications

Lock Nuts

Lock nuts are widely used in industries where vibration resistance is crucial, such as automotive, aerospace, and heavy machinery. Some typical applications include:

- Automotive: Used in engine components, suspension systems, and other parts subject to constant vibration.

- Aerospace: Essential in aircraft assembly, where maintaining joint integrity under dynamic conditions is critical.

- Machinery: Employed in equipment subject to frequent movement and vibration, ensuring secure connections.

Jam Nuts

Jam nuts are ideal for adjustable assemblies and precise positioning, commonly used in threaded rods, belt tensioners, and machine components. Common uses include:

- Threaded Rods: Utilized in scenarios where threaded rods need secure locking without additional thickness.

- Belt Tensioners: Employed in adjustable belt tensioner systems, such as those in agricultural equipment.

- Machinery: Used in adjustable machine components to lock settings in place.

Comparative Analysis: Lock Nut vs. Jam Nut

Structural Differences

- Lock Nuts: Feature integrated locking mechanisms such as nylon inserts or deformed threads. They are designed as single units, eliminating the need for a secondary nut.

- Jam Nuts: Require a standard nut to create a locking mechanism. They are always low-profile and depend on axial tension for locking.

Functional Differences

- Lock Nuts: Provide direct threading with integrated locking features, suitable for high-vibration environments.

- Jam Nuts: Function through the wedging action of two nuts, ideal for adjustable systems where precise positioning is necessary.

Advantages and Disadvantages

Lock Nut Pros and Cons

Advantages:

- Effective in high-vibration environments.

- Simple installation without the need for additional nuts.

- Available in various designs to suit different applications.

Disadvantages:

- Nylon inserts may degrade with reuse.

- Metal lock nuts may require higher torque for installation.

Jam Nut Pros and Cons

Advantages:

- Fully reusable if undamaged.

- Ideal for adjustable assemblies requiring frequent maintenance.

- Low profile suitable for space-constrained applications.

Disadvantages:

- Requires pairing with a standard nut.

- Installation sequence is critical to ensure effectiveness.

Knowing the differences between lock nuts and jam nuts helps in choosing the right fastener for specific needs. Each type offers unique benefits and is suited to particular environments and requirements.

Comparative Analysis: Lock Nut vs. Jam Nut

When choosing between lock nuts and jam nuts, it’s important to understand their distinct designs, functions, and uses to make the right selection.

Structural Differences

Lock Nuts

Lock nuts are designed with integrated locking mechanisms that provide resistance to loosening under vibration and dynamic loads. Lock nuts may use nylon inserts, altered threads, or friction-based designs. The structural integrity of lock nuts allows them to maintain their position without the need for additional components.

Jam Nuts

Jam nuts are thin hex nuts that work with a secondary nut to create a wedging action, compressing threads to prevent loosening. Their low-profile design makes them suitable for applications where space is limited.

Functional Differences

Lock Nuts

Lock nuts offer several functional advantages due to their built-in locking features. These nuts are particularly effective in high-vibration environments, such as automotive and aerospace applications. The integrated mechanisms, such as nylon inserts or deformed threads, ensure that the nut remains secure without additional hardware.

Jam Nuts

Jam nuts rely on the mechanical principle of thread wedging to prevent loosening. They are particularly useful in adjustable assemblies where precise positioning is required. However, their effectiveness is highly dependent on the proper installation and the use of a primary nut to create the necessary axial tension.

Lock Nut Types

There are several types of lock nuts, each tailored for specific uses:

- Nylon Insert Lock Nuts: These nuts use a nylon collar that creates friction against the bolt threads. They are commonly used in automotive and machinery applications where vibration resistance is crucial.

- Distorted Thread Lock Nuts: These nuts have intentionally deformed threads that increase friction and prevent loosening. They are suitable for high-stress environments.

- Metal Lock Nuts: Utilizing serrated faces or conical designs, these nuts enhance metal-to-metal friction, making them ideal for heavy-duty applications.

Jam Nut Applications

Jam nuts are used in a variety of applications where space constraints and the need for adjustability are significant factors:

- Threaded Rods: Jam nuts are commonly used to secure threaded rods in construction and machinery.

- Belt Tensioners: In adjustable belt tensioner systems, jam nuts help maintain the desired tension settings.

- Machine Components: They are used to lock adjustable components in place, ensuring that settings remain consistent.

Advantages and Disadvantages

Lock Nut Pros and Cons

Advantages:

- Provide effective vibration resistance.

- Easy to install without additional hardware.

- Available in various designs to meet specific application needs.

Disadvantages:

- Nylon inserts may degrade with reuse, affecting performance.

- Metal lock nuts may require higher torque for installation, potentially complicating the process.

Jam Nut Pros and Cons

Advantages:

- Fully reusable if undamaged.

- Ideal for applications requiring frequent adjustments and maintenance.

- Low profile suitable for space-constrained environments.

Disadvantages:

- Requires pairing with a standard nut, increasing installation complexity.

- Effectiveness depends on proper installation and torque application.

Knowing the differences between lock nuts and jam nuts helps you choose the right fastener for your engineering or construction project.

Locking Mechanisms in Bolted Joints

Ensuring that bolted joints stay secure, especially in environments with vibrations or dynamic forces, is essential. Two commonly employed mechanisms to achieve this are lock nuts and jam nuts. Each mechanism has unique characteristics and specific applications, making them suitable for different scenarios.

Lock Nut

Definition and Types

A lock nut is designed to prevent loosening due to vibration or dynamic loads. Various types of lock nuts include nylon insert lock nuts, serrated flange nuts, and distorted thread lock nuts. These nuts utilize friction or mechanical interference to secure the nut on the bolt thread.

Functionality

Lock nuts secure the bolt by gripping it tightly. For instance, nylon insert lock nuts have a nylon ring that presses against the threads, creating friction to prevent loosening. This locking mechanism is effective without needing additional components.

Advantages

- Ease of Installation: Lock nuts are simple to install and remove.

- Space Efficiency: They can be used in most applications without requiring extra space.

- Variety: Available in multiple types to meet various requirements.

Jam Nut

Definition and Function

A jam nut, also known as a “thin nut,” is a small hex nut used with a standard nut to lock them both in place.

Functionality

Jam nuts work by wedging the threads of the two nuts against each other and the bolt. This wedging action creates a secure lock, which is particularly effective in preventing loosening due to vibrations.

Advantages

- Vibration Resistance: Provides excellent resistance to vibration-induced loosening.

- Space Efficiency: Suitable for tight spaces where additional locking mechanisms might not fit.

- Cost-Effectiveness: Generally more economical compared to specialized lock nuts.

Comparative Analysis

Locking Mechanism

| Feature | Lock Nut | Jam Nut |

|---|---|---|

| Locking Mechanism | Relies on friction or interference to lock. | Locks by tightening two nuts against each other and the bolt. |

| Application | Suitable for most applications requiring a secure lock. | Ideal for vibration-prone environments and tight spaces. |

| Installation | Easy to install and remove individually. | Requires a second nut for the locking effect. |

| Space Requirements | Can be compact, depending on the type. | Needs space for two nuts, but can fit in tight spaces due to low profile. |

| Effectiveness | Generally effective but may require additional safety measures in extreme vibration conditions. | Highly effective against vibration-induced loosening. |

Anti-Loosening Solutions

Preventing bolts from loosening due to vibration and dynamic loads is essential for maintaining structural integrity and safety. Several anti-loosening techniques are employed to ensure that joints remain secure under varying conditions.

Mechanical Locking Methods

Mechanical locking methods, such as lock nuts, jam nuts, and split ring lock washers, use physical interference to prevent the rotation of the nut or bolt.

- Lock Nuts: These nuts have built-in features such as nylon inserts, serrated flanges, or deformed threads to create friction and resist loosening.

- Jam Nuts: By using two nuts, with the jam nut tightened against a standard nut, thread wedging creates resistance to vibration-induced loosening.

- Split Ring Lock Washers: These washers exert tension on the bolted joint, pressing against the nut and the joint surface to prevent rotation.

Chemical Locking Methods

Chemical locking methods use adhesives or compounds that harden to secure the threads. Examples include thread-locking adhesives and epoxy resins.

- Thread Locking Adhesives: These liquid adhesives, such as anaerobic adhesives, cure in the absence of air and lock the threads together, providing strong resistance to loosening.

- Epoxy Resins: Applied to the threads before assembly, these resins cure to form a solid bond that holds the components together.

Comparison with Other Solutions

When comparing anti-loosening solutions, it’s essential to consider factors such as ease of installation, effectiveness, reusability, and cost.

Mechanical vs. Chemical Locking

- Ease of Installation:

- Mechanical methods like lock nuts and jam nuts are relatively straightforward to install with standard tools.

- Chemical methods require careful application and curing time, making them more time-consuming.

- Effectiveness:

- Mechanical methods offer immediate, reliable resistance to loosening, especially in high-vibration environments.

- Chemical methods create strong, permanent bonds but are less suitable for applications needing frequent disassembly.

- Reusability:

- Mechanical methods, particularly jam nuts, are generally reusable if undamaged.

- Chemical methods often require the application of new adhesive for each reassembly, limiting reusability.

- Cost:

- Mechanical methods can be cost-effective, especially in bulk applications.

- Chemical methods may incur higher costs due to the need for specific adhesives and application tools.

Innovations in Anti-Loosening Technology

Recent advancements in anti-loosening technology have focused on enhancing the performance and ease of use of both mechanical and chemical solutions.

Smart Fasteners

Smart fasteners use sensors and wireless technology to monitor the tension and integrity of bolted joints in real-time. These systems provide alerts for maintenance or adjustment, greatly enhancing safety and reliability in critical applications.

Advanced Coatings

New coatings for fasteners, such as self-healing polymers and advanced anti-corrosion layers, enhance the longevity and performance of bolted joints. These coatings can also provide additional frictional properties to improve anti-loosening characteristics.

Hybrid Solutions

Combining mechanical and chemical methods, hybrid solutions offer enhanced security and flexibility. For instance, applying thread locking adhesive to a lock nut can provide dual-layer protection against loosening.

By understanding the various anti-loosening techniques and their comparative advantages, engineers can select the most suitable method for their specific applications, ensuring the long-term reliability and safety of bolted joints.

Choosing the Right Nut for Anti-Loosening Applications

Factors to Consider When Selecting a Nut

When choosing the right nut for anti-loosening applications, it’s essential to consider various factors that influence the performance and reliability of bolted joints. The selection criteria should be based on the specific requirements of the application, including load conditions, environmental factors, maintenance needs, and the nature of the dynamic forces involved.

Load Requirements

The load requirements of the bolted joint play a crucial role in determining the appropriate nut type. High-stress environments like heavy machinery and structural applications require nuts that can endure substantial forces without compromising the joint’s integrity.

- Lock Nuts: Ideal for high-load applications due to their robust design and integrated locking mechanisms. For example, serrated flange nuts provide enhanced metal-to-metal friction, making them suitable for structural connections.

- Jam Nuts: Suitable for moderate load applications where the dual-nut system can effectively distribute the load and resist loosening through thread wedging.

Environmental Conditions

The operating environment can greatly impact the performance of nuts in bolted joints. Consider factors like temperature changes, chemical exposure, and moisture levels.

- Lock Nuts: Nylon insert lock nuts are effective in environments with moderate temperature variations but may degrade under extreme conditions. Metal lock nuts, such as those with serrated flanges, offer better resistance to harsh environments and are less susceptible to chemical degradation.

- Jam Nuts: Jam nuts are generally more versatile and can be used in various environments. Their low-profile design makes them suitable for applications with spatial constraints.

Maintenance Needs

Maintenance needs are another crucial factor in choosing the right nut. Some applications may necessitate frequent adjustments or disassembly, impacting the choice between reusable and single-use nuts.

- Lock Nuts: Nylon insert lock nuts often require replacement after disassembly due to wear on the nylon insert. Serrated flange nuts and other metal lock nuts can be reused if undamaged, making them more suitable for applications with infrequent maintenance.

- Jam Nuts: Fully reusable if undamaged, jam nuts are ideal for applications requiring frequent adjustments, such as belt tensioners and threaded rod assemblies.

Case Studies and Practical Examples

Understanding real-world applications and success stories can provide valuable insights into selecting the right nut for specific scenarios, such as in the following real-world applications.

Real-World Applications

- Automotive Industry: Lock nuts, particularly nylon insert types, are commonly used in engine components and suspension systems due to their vibration resistance and ease of installation.

- Agricultural Machinery: Jam nuts are preferred for belt tensioning systems in agricultural equipment, where adjustability and vibration resistance are critical.

- Aerospace Industry: Lock nuts with specialized designs, such as distorted thread lock nuts, are essential in aerospace applications to maintain joint integrity under dynamic loads.

Success Stories and Failures

- Success: In the construction of a high-rise building, serrated flange lock nuts were used to secure steel beams, providing reliable vibration resistance and maintaining joint stability over time.

- Failure: An automotive assembly line faced issues with bolts loosening because nylon insert lock nuts were reused beyond their lifespan, highlighting the importance of following single-use recommendations in critical applications.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is the difference between lock nuts and jam nuts?

Lock nuts and jam nuts serve different purposes in securing bolts, primarily distinguished by their design and application. A lock nut is specifically designed to prevent loosening under torque or vibration, using various mechanisms like nylon inserts or bearing surfaces. These features make lock nuts highly reliable for maintaining secure fastenings in environments subject to movement or load changes.

In contrast, a jam nut is a thinner hex nut, typically half the height of a standard nut, used by being tightened against another nut. This “jamming” action creates a locking effect, but it is generally less effective under significant loads and vibrations compared to lock nuts. Jam nuts are often utilized in situations where space is constrained or when additional force should not be applied to the fastened item.

How do jam nuts prevent loosening due to vibration?

Jam nuts prevent loosening due to vibration by using a technique known as thread jamming. This method involves tightening a thinner jam nut against a standard nut on the same bolt. The jamming action occurs because the threads of the two nuts press against each other, creating tension that pulls in opposite directions. This tension minimizes the relative movement between the bolt and the nut threads, which is essential for preventing self-loosening under vibrational forces.

In practice, the bolt thread contacts the top flank of the bottom nut and the bottom flank of the top nut, effectively locking them in place. This mechanical lock is particularly effective in high-vibration environments such as automotive and industrial applications, where maintaining bolt security is critical. Unlike some lock nuts that rely on friction or mechanical barriers, jam nuts provide a more robust solution by physically restricting thread movement, ensuring the assembly remains secure despite continuous vibration.

When should I use a lock nut instead of a jam nut?

You should use a lock nut instead of a jam nut in situations where a single, self-contained locking mechanism is necessary, particularly in high-stress environments where extreme vibration or movement is expected. Lock nuts, which include types like nylon insert lock nuts and bearing lock nuts, are designed to maintain their grip under such conditions without the need for a two-nut system. They offer reliability and ease of installation, making them suitable for quick and straightforward setups where minimal adjustment is required. Conversely, jam nuts are better suited for applications with space constraints, frequent adjustment needs, or tighter budget considerations.

Are there any industry standards for using lock nuts and jam nuts?

Industry standards for lock nuts and jam nuts are not as rigidly defined as they are for other fasteners. However, general standards related to material grades and thread specifications apply to both. Lock nuts typically adhere to these general standards but may also follow specific application guidelines depending on the type, such as nylon insert or bearing lock nuts. These guidelines ensure compatibility with the equipment and environmental conditions where they are used.

Jam nuts, on the other hand, do not have specific industry standards but rely heavily on proper installation techniques for effectiveness. They are used in conjunction with another nut to prevent loosening, especially in high-vibration applications. Their effectiveness is determined by how well they are installed and how tightly they are wedged against the primary nut. Therefore, while general nut standards apply, the successful use of jam nuts is largely governed by best practices and application requirements rather than strict standards.

Can lock nuts and jam nuts be used together for enhanced security?

Yes, lock nuts and jam nuts can be used together for enhanced security. Combining these two types of nuts can provide an additional layer of protection against loosening due to vibration. Lock nuts, such as those with nylon inserts, create friction that prevents rotation, while jam nuts secure the standard nut by tightening against it, locking the threads in place.

However, using both may be redundant as each type independently offers effective anti-loosening mechanisms. It might also add unnecessary bulk and complexity, especially in confined spaces. Therefore, while feasible, the combination is usually reserved for applications demanding maximum security, such as environments with extreme vibrations or critical safety requirements.