1. The principle of MIG welding

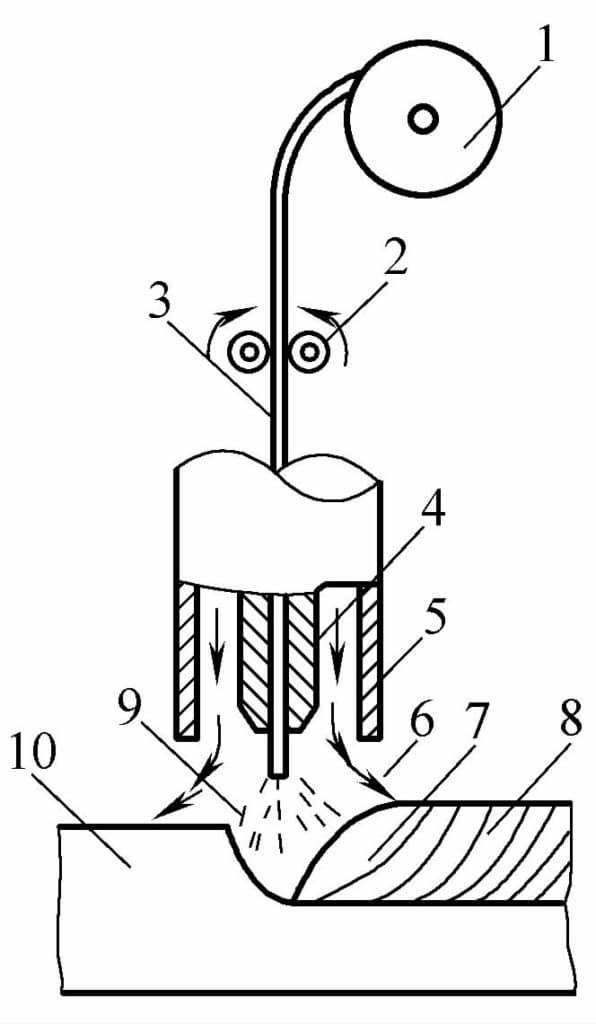

Gas shielded metal arc welding uses a filler wire as the electrode, with the protective gas flowing out of the nozzle at a certain speed to isolate the arc-melted welding wire, molten pool, and nearby metal of the weldment from the air, preventing its harmful effects to obtain a good quality weld seam. The welding principle is shown in Figure 5-70.

2. Characteristics of MIG Welding

(1) Advantages

1) Since the filler wire is used as the electrode, the welding current is increased, the heat is concentrated, the utilization rate is high, suitable for welding medium and thick plates.

2) When welding aluminum and its alloys, the use of DC reverse connection cathode atomization is significant, which can improve the quality of the weld.

3) In MIG welding sub-jet transition welding of aluminum and aluminum alloys, the inherent self-regulating action of the sub-jet arc is significant, making the process stable.

1—Wire reel 2—Wire feed roller 3—Welding wire 4—Conductive nozzle 5—Protective gas nozzle 6—Protective gas 7—Molten pool 8—Weld seam metal 9—Arc 10—Base material

4) Easy to automate. The arc in gas tungsten arc welding is a clear arc, and the welding process parameters are stable, easy to detect and control, thus facilitating automation. Currently, the vast majority of welding robots and mechanical arms around the world use this welding method.

(2) Disadvantages

1) Sensitive to oil and rust on the welding wire and workpiece, strict removal is required before welding.

2) High cost of inert gases, leading to high welding costs.

3. Application Range of MIG welding

MIG welding can be used for welding carbon steel, low alloy steel, stainless steel, heat-resistant alloys, magnesium and magnesium alloys, copper and copper alloys, titanium and titanium alloys, etc.

It is suitable for flat welding, horizontal welding, vertical welding, and all-position welding, with a minimum welding thickness of 1mm and no maximum thickness limit.