Have you ever wondered why your toaster heats up so quickly while the electrical wiring in your home remains cool? The answer lies in the fascinating world of electrical resistance and the distinct properties of materials like nichrome and copper. While both are crucial in electrical engineering, they serve very different purposes due to their unique characteristics. In this article, we will explore the fundamental differences in electrical resistance between nichrome and copper, delve into why nichrome exhibits higher resistance, and uncover the reasons behind its suitability for heating elements as opposed to copper’s role in electrical wiring. Join us as we unravel the science behind these materials and their applications, providing a comparative analysis that will illuminate your understanding of their roles in our daily lives. Ready to discover the intriguing details that set nichrome and copper apart? Let’s dive in!

Electrical Resistivity and Conductivity of Nichrome vs Copper

Electrical Resistivity

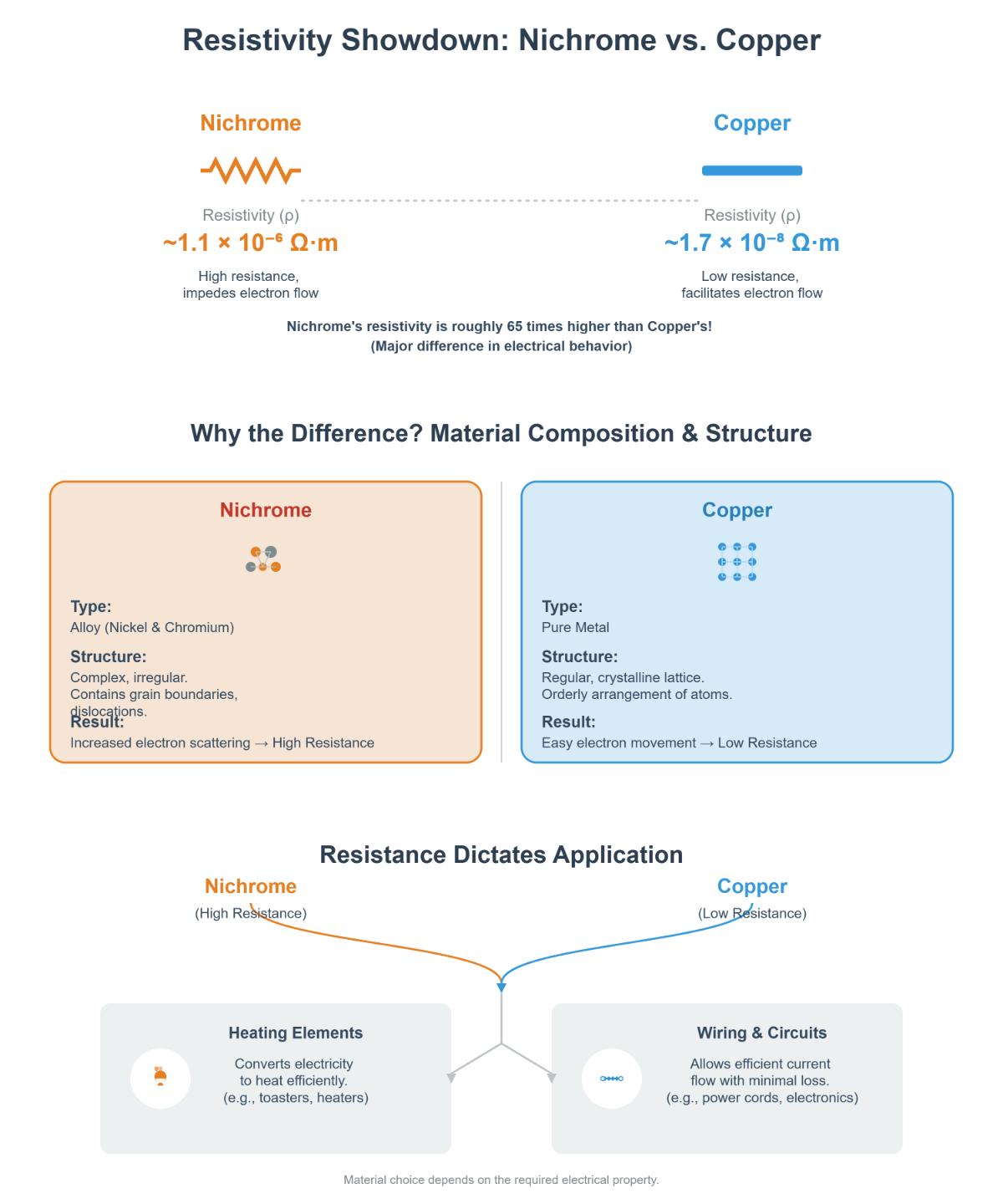

Electrical resistivity measures how strongly a material opposes the flow of electric current. It is measured in ohm meters (Ω·m) and is crucial in determining the suitability of materials for specific electrical applications.

Nichrome

Nichrome is an alloy made mostly of nickel and chromium, giving it a high resistivity of about (1.10×10−6) Ω·m. The alloy’s structure introduces atomic-scale irregularities that impede electron flow, thus increasing resistivity. This high resistivity makes nichrome ideal for applications requiring resistance, such as heating elements.

Copper

Copper, on the other hand, is known for its excellent conductivity due to its low resistivity of about (1.68 ×10−8) Ω·m. Its pure and regular atomic structure allows electrons to move freely with minimal resistance, making copper ideal for electrical wiring and circuits.

Electrical Conductivity

Electrical conductivity, the inverse of resistivity, measures how well a material conducts electricity and is expressed in siemens per meter (S/m). It is an essential factor in determining a material’s efficiency in conducting electric current.

Nichrome

With an electrical conductivity of around (1.03 ×106) S/m, nichrome is significantly less conductive than copper. The high resistivity of nichrome results in lower conductivity, making it less suitable for applications requiring efficient current flow but excellent for generating heat in heating elements.

Copper

Copper boasts an exceptionally high conductivity of approximately (5.96 ×107) S/m, second only to silver. This high conductivity makes copper ideal for electrical wiring and circuits, where efficient current flow is critical. Copper’s flexibility and durability further enhance its suitability for these applications.

Comparative Applications

Nichrome’s high resistivity makes it suitable for heating elements in appliances like toasters and hair dryers, as it can handle temperatures up to about 1150°C (2100°F). Meanwhile, copper’s low resistivity and high conductivity make it perfect for electrical wiring, ensuring efficient current flow with minimal energy loss. Copper’s flexibility and durability also contribute to its widespread use in these applications.

Material Composition and Crystal Structure Impact on Resistance

Nichrome Alloy Composition

Nichrome is an alloy made from approximately 80% nickel and 20% chromium, sometimes with small amounts of other elements like iron to enhance certain properties. The combination of these metals results in a unique set of characteristics, particularly in terms of electrical resistance.

- Nickel (Ni): Nickel is a transition metal known for its high electrical resistivity and good corrosion resistance. It contributes significantly to the overall stability and durability of nichrome at high temperatures.

- Chromium (Cr): Chromium enhances the alloy’s resistance to oxidation and corrosion, making it suitable for high-temperature applications. It also plays a crucial role in increasing the electrical resistivity of the alloy.

The combination of these metals in nichrome results in atomic-scale irregularities within the crystal structure. These irregularities impede the flow of electrons, significantly increasing the material’s resistivity.

Copper as a Pure Metal

Copper is typically refined to a purity of 99.9% or higher, which minimizes impurities and results in low electrical resistivity and high conductivity. Its uniform composition and crystal structure are key to its excellent electrical properties.

- Purity: The high purity of copper minimizes the presence of impurities that could disrupt the flow of electrons. This results in low electrical resistivity and high conductivity.

- Crystal Structure: Copper’s face-centered cubic (FCC) crystal lattice is highly ordered and consistent, providing a smooth path for electron movement. This uniformity is essential for its superior electrical conductivity.

Crystal Lattice Structure

The crystal lattice structure of a material significantly influences its electrical properties. The arrangement of atoms within the lattice affects how easily electrons can move through the material.

Copper’s Crystal Structure

Copper has a face-centered cubic (FCC) crystal structure, characterized by a highly ordered and uniform arrangement of atoms. This structure allows electrons to move with minimal scattering, leading to low resistivity and high conductivity. The regularity of the lattice ensures that there are fewer obstacles for electron flow, which is why copper is such an efficient conductor.

Nichrome’s Alloy Structure

Nichrome, on the other hand, has a more complex crystal structure due to the presence of multiple elements. The nickel and chromium atoms create a less uniform lattice with more imperfections and distortions. These atomic-scale irregularities increase the scattering of electrons, which raises the resistivity of the material. This structure is beneficial in applications where high resistance is needed, such as in heating elements.

Impact on Electrical Resistance

The crystal lattice structure and material composition of both nichrome and copper directly impact their electrical resistance.

Electrical resistance (R) is calculated using the formula (R=ρ×L/A), where (ρ) is resistivity, (L) is length, and (A) is cross-sectional area. Because nichrome has higher resistivity than copper, a wire made of nichrome will have more resistance than a copper wire of the same size.

Nichrome’s mixed atomic structure causes more electron scattering, increasing resistance. Copper’s uniform structure allows electrons to flow smoothly, resulting in low resistance.

Thermal and Chemical Stability

The composition and structure of nichrome and copper also affect their thermal and chemical stability.

Nichrome’s alloy composition provides excellent resistance to oxidation and maintains its structure at high temperatures (~1150°C), making it ideal for heating elements. Copper, while great at heat dissipation due to its thermal conductivity, oxidizes more easily at high temperatures, which can affect its performance.

Applications: Why Nichrome is Used for Heating Elements and Copper for Electrical Wiring

Nichrome in Heating Elements

Nichrome, an alloy of nickel and chromium, is commonly used in heating elements because of its unique and suitable properties.

High Electrical Resistance

Nichrome’s high electrical resistance is crucial for heating elements. When electrical current passes through nichrome wire, the high resistivity converts electrical energy into heat rather than merely conducting it. This efficient conversion is essential for devices designed to generate heat, such as toasters, ovens, and industrial furnaces.

Excellent Heat Tolerance

Nichrome can withstand temperatures up to 1150°C (2100°F) without melting or losing integrity, thanks to the chromium content that forms a protective oxide layer. This heat resistance ensures the longevity and reliability of nichrome heating elements by preventing oxidation and corrosion.

Mechanical Stability

Nichrome remains stable at high temperatures without creeping or sagging. This stability ensures consistent heating performance over time, which is vital for applications where precise temperature control is necessary. The durability and reliability of nichrome make it a preferred choice for heating elements in various appliances and industrial equipment.

Copper in Electrical Wiring

Copper is extensively used in electrical wiring due to its exceptional electrical properties and suitability for efficient current transmission.

Superior Electrical Conductivity

Copper’s low electrical resistivity allows it to conduct electrical current with minimal energy loss. This high conductivity is essential for wiring applications where power must be transmitted over distances with minimal voltage drop. The efficiency of copper in conducting electricity ensures reliable performance in power distribution, building wiring, and electronic circuits.

Flexibility and Durability

Copper is very flexible, allowing it to bend and shape without breaking, which is essential for wiring in tight spaces. Additionally, copper’s durability ensures that it can withstand environmental exposure and mechanical stress without failing, making it ideal for long-term use in electrical systems.

Corrosion Resistance

Copper resists corrosion well enough for most wiring applications, but in corrosive environments, it can be coated or insulated to improve longevity and performance.

Comparative Analysis

The fundamental differences in resistivity and thermal properties between nichrome and copper directly dictate their respective applications.

Heating Elements vs. Electrical Wiring

- Nichrome: The high resistivity and heat tolerance make nichrome ideal for heating elements, where the primary function is to generate heat. Its ability to withstand high temperatures and maintain mechanical stability ensures reliable performance in devices designed to produce heat.

- Copper: The low resistivity and high conductivity of copper make it perfect for electrical wiring, where efficient current flow is critical. Copper’s flexibility, durability, and adequate corrosion resistance further enhance its suitability for transmitting electrical power over distances.

Visual Comparisons

Visual representations of crystal lattice structures can help clarify the differences in electrical properties between nichrome and copper.

Copper has a face-centered cubic (FCC) structure, which is highly ordered and consistent, allowing electrons to flow smoothly with minimal scattering due to each copper atom being surrounded by 12 nearest neighbors. This uniform arrangement contributes to copper’s low resistivity and high conductivity.

Nichrome, an alloy of nickel and chromium, has a more complex crystal structure with atomic-scale irregularities that increase electron scattering and resistivity. The presence of different atoms introduces distortions and imperfections in the lattice, resulting in higher resistivity compared to copper.

Tables highlight the key differences in electrical properties between nichrome and copper.

| Property | Nichrome | Copper |

|---|---|---|

| Resistivity | ~1.10 × 10⁻⁶ Ω·m | ~1.68 × 10⁻⁸ Ω·m |

| Conductivity | ~1.03 × 10⁶ S/m | ~5.96 × 10⁷ S/m |

| Heat Tolerance | Up to 1150°C | ~200°C |

| Primary Use | Heating elements | Electrical wiring |

In copper, the uniform FCC crystal lattice provides smooth pathways for electrons, resulting in efficient current flow crucial for high conductivity applications. The smooth pathways enable efficient current flow, which is critical for applications requiring high conductivity.

Nichrome’s irregular lattice structure causes more scattering of electrons, leading to higher resistivity. This scattering is beneficial for generating heat in heating elements, as the resistance converts electrical energy into thermal energy.

Heating elements made from nichrome wire emphasize its high resistivity and excellent heat tolerance. Diagrams can depict how the wire heats up and maintains stability at high temperatures.

Copper wiring diagrams highlight its superior conductivity and flexibility. Visuals can show how copper wiring efficiently transmits electrical power with minimal energy loss.

By using these visual comparisons, readers can better understand the distinct properties and applications of nichrome and copper, enhancing their grasp of why each material is chosen for specific functions.

Practical Guides to Material Properties

Knowing the basic properties of nichrome and copper helps in choosing the right material for your needs. This guide simplifies the key attributes of each material and links them to practical uses.

Nichrome

Electrical and Thermal Properties:

- Resistivity: Nichrome has a resistivity of approximately 1.10–1.12 µΩ·m, making it highly resistant to electrical flow.

- Conductivity: Its conductivity is relatively low at around 1.03×10⁶ S/m.

- Melting Point: Nichrome melts at around 1400°C.

- Heat Stability: It stays stable and resists oxidation at temperatures up to 1150°C.

- Application: Its high resistivity efficiently converts electrical energy into heat, and it withstands high temperatures without oxidizing, making it reliable for long-term use. These properties make nichrome suitable for high-temperature applications, such as industrial furnaces and heating elements.

Copper

Electrical and Thermal Properties:

- Resistivity: Copper boasts a low resistivity of about 16.78 nΩ·m.

- Conductivity: It has excellent conductivity, measured at approximately 5.96×10⁷ S/m.

- Melting Point: Copper melts at approximately 1083°C.

- Heat Stability: Copper is stable up to about 300°C but can degrade at higher temperatures.

- Application: Low resistivity and high conductivity make copper perfect for efficient electrical wiring and power transmission. High thermal conductivity also makes copper ideal for heat dissipation in electrical systems and cooling applications.

Practical Examples

Nichrome in Heating Elements

Nichrome is extensively used in devices that require heat generation, such as toasters, hair dryers, and industrial heating systems. Its high resistivity ensures efficient conversion of electrical energy into heat, and its ability to withstand high temperatures without oxidizing makes it reliable for continuous use.

Copper in Electrical Wiring

Copper is the material of choice for electrical wiring due to its low resistivity and high conductivity, ensuring minimal energy loss during transmission. Its flexibility and durability allow it to be used in various environments, including residential, commercial, and industrial settings.

Decision Making Based on Application

When choosing between nichrome and copper, consider the following criteria:

- Heat Generation: For applications requiring heat, such as heating elements, nichrome is preferred due to its high resistivity and heat stability.

- Electrical Transmission: For efficient electrical wiring, copper is ideal because of its low resistivity and high conductivity.

- Environmental Conditions: Copper may need protective coatings in corrosive environments, but nichrome naturally resists oxidation at high temperatures.

Material Properties in Everyday Use

Nichrome:

- Heating Elements: Its high resistance is crucial for generating heat in appliances.

- High-Temperature Use: Suitable for applications needing stable performance at elevated temperatures.

Copper:

- Electrical Wiring: Provides efficient power transmission with minimal energy loss.

- Heat Dissipation: Excellent for use in cooling systems and heat sinks due to its thermal conductivity.

| Property | Nichrome | Copper |

|---|---|---|

| Resistivity | ~1.10–1.12 µΩ·m | ~16.78 nΩ·m |

| Conductivity | ~1.03×10⁶ S/m | ~5.96×10⁷ S/m |

| Melting Point | ~1400°C | ~1083°C |

| Heat Stability | Excellent above 1000°C | Degrades above 300°C |

| Primary Use | Heating elements | Electrical wiring |

This guide provides a clear comparison of nichrome and copper properties, helping you choose the right material for your specific application needs.

Physical and Chemical Properties Influencing Durability and Performance

Composition and Impact on Durability

The composition of a material significantly affects its durability. Nichrome is an alloy composed mainly of nickel (60%-85%) and chromium (10%-25%), with possible additions of iron and other elements, providing excellent resistance to oxidation and corrosion, especially at high temperatures. The nickel component provides stability and durability, while chromium enhances resistance to oxidation, maintaining the alloy’s integrity even under prolonged heating.

In contrast, copper is a pure metal, often refined to a purity exceeding 99.9%. Its high purity ensures minimal impurities that could cause degradation. Copper’s natural properties make it resistant to corrosion under normal conditions, although it is susceptible to oxidation and the formation of a patina over time. This patina, however, can act as a protective layer, preventing further corrosion.

Thermal Stability and Performance

Heat resistance is crucial for materials used in environments subjected to high temperatures. Nichrome excels in heat resistance with a melting point of around 1400°C. It maintains structural integrity and resists oxidation even at elevated temperatures, making it ideal for applications like heating elements. The alloy’s ability to withstand high temperatures without significant degradation ensures long-term performance and reliability.

Copper has a lower melting point of approximately 1083°C and excellent thermal conductivity. While it is highly effective in applications requiring heat dissipation, such as heat sinks and electrical wiring, it does not perform as well as nichrome in high-temperature environments. Prolonged exposure to high temperatures can lead to oxidation and reduced performance in copper.

Electrical Properties and Performance

The electrical properties of materials greatly influence their performance and durability in electrical applications. Nichrome’s high resistivity (around 1.12 μΩ·m) makes it suitable for resistance heating applications, where it converts electrical energy into heat efficiently. This property, combined with its thermal stability, ensures that nichrome heating elements remain durable and effective over time.

Copper, known for its outstanding electrical conductivity (about 5.96 x 10^7 S/m), is ideal for applications requiring efficient current flow, such as electrical wiring. Its low resistivity (approximately 16.78 nΩ·m) minimizes energy loss, ensuring that electrical systems perform reliably and efficiently. Copper’s conductivity also contributes to its ability to dissipate heat, enhancing its performance in thermal management systems.

Corrosion Resistance

Corrosion resistance is another critical factor affecting the durability and performance of materials. Nichrome’s composition, particularly the presence of chromium, provides excellent resistance to oxidation and corrosion, even in high-temperature environments. This makes nichrome a durable choice for applications exposed to harsh conditions, such as industrial furnaces and heating elements.

Copper, while generally resistant to corrosion, can react with certain chemicals, such as strong oxidizing acids like nitric acid. In typical environments, copper forms a protective oxide layer that prevents further corrosion, contributing to its durability in electrical wiring and other applications. However, in highly corrosive environments, additional protective measures, such as coatings or insulation, may be necessary to maintain copper’s performance.

Mechanical Stability

Mechanical stability under thermal and electrical stress is essential for long-term performance, and nichrome maintains excellent stability at high temperatures, preserving its shape and integrity without significant deformation. This property ensures consistent performance in heating elements, where precise control over temperature is necessary.

Copper, on the other hand, is highly ductile and flexible, which makes it easy to work with in electrical wiring applications. Its mechanical properties allow it to withstand bending and shaping without breaking, contributing to its durability in various installations. However, copper’s mechanical stability may decrease at elevated temperatures, where it can become more susceptible to deformation.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is the difference in electrical resistance between nichrome and copper?

The primary difference in electrical resistance between nichrome and copper is that nichrome has a significantly higher resistivity compared to copper. Nichrome, an alloy primarily composed of nickel and chromium, has a resistivity of approximately (1.1×10−6Ω)-m. This high resistivity is due to its complex alloy structure, which includes grain boundaries and dislocations that increase electron scattering. In contrast, copper, a pure metal, has a much lower resistivity of about (1.7 1.1×10−8Ω)-m, which translates to excellent electrical conductivity. Copper’s high conductivity makes it ideal for applications requiring efficient current flow, such as electrical wiring and circuits. On the other hand, nichrome’s high resistivity makes it suitable for heating elements, where it efficiently converts electrical energy into heat. Understanding these differences is crucial for selecting the appropriate material for specific applications based on their electrical properties.

Why does nichrome have higher resistance than copper?

Nichrome has higher resistance than copper primarily due to differences in their material composition and atomic structure. Nichrome is an alloy typically composed of about 80% nickel and 20% chromium, which results in a more complex and irregular crystal lattice. This alloyed structure contains grain boundaries, dislocations, and voids, creating numerous obstacles for electron flow and increasing electron scattering. Consequently, nichrome has a high resistivity of approximately (1.1×10−6Ω⋅m).

In contrast, copper is a pure elemental metal with a highly uniform face-centered cubic (FCC) crystal lattice, allowing electrons to move through with minimal scattering. This orderly atomic arrangement results in low resistivity, around (1.7 ×10−8Ω⋅m), making copper an excellent conductor of electricity. The significant difference in resistivity between these materials explains why nichrome is preferred for applications requiring high resistance and heat generation, such as heating elements, while copper is ideal for electrical wiring due to its superior conductivity.

What makes nichrome suitable for heating elements compared to copper?

Nichrome is particularly suitable for heating elements compared to copper due to its high electrical resistivity, thermal stability, and oxidation resistance. Nichrome, an alloy typically composed of nickel, chromium, and sometimes iron, has a high resistivity (~1.10 × 10⁻⁶ Ω·m), which generates substantial heat when an electric current passes through it. This property is crucial for heating applications as it ensures that most of the electrical energy is converted into heat. Additionally, nichrome’s melting point is around 1,400°C, and it remains stable up to 1,250°C, thanks to a protective chromium oxide layer that prevents oxidation and degradation at high temperatures. This stability is essential for maintaining performance and longevity in high-temperature environments. In contrast, copper, despite its excellent electrical conductivity (~5.96 × 10⁷ S/m), has low resistivity (~1.68 × 10⁻⁸ Ω·m), making it inefficient for heat generation. Copper also has a lower melting point (~1,083°C) and poor oxidation resistance, which limits its effectiveness in high-temperature applications. Consequently, nichrome’s properties make it ideal for use in heating elements found in appliances like toasters, hair dryers, and industrial furnaces.

How do the material compositions of nichrome and copper affect their electrical properties?

The material compositions of nichrome and copper significantly affect their electrical properties. Nichrome is an alloy primarily composed of 80% nickel and 20% chromium, with possible trace elements like iron. This alloy structure introduces atomic irregularities that scatter electrons, resulting in higher electrical resistivity (~1.10 μΩ·m) and lower conductivity (~1.03 × 10⁶ S/m). These properties make nichrome suitable for applications where high resistance is desired, such as in heating elements, because it efficiently converts electrical energy into heat.

In contrast, copper is a nearly pure metal, characterized by its uniform crystal lattice structure that allows electrons to move freely with minimal scattering. This results in extremely low resistivity (~16.78 nΩ·m) and high conductivity (~5.96 × 10⁷ S/m). The high conductivity of copper makes it ideal for electrical wiring and components where minimal energy loss and efficient electron flow are crucial. Thus, the distinct compositions and resulting electrical properties of nichrome and copper dictate their specific applications in various electrical and thermal contexts.

How do the crystal lattice structures of nichrome and copper impact their resistivity?

The crystal lattice structures of nichrome and copper significantly impact their resistivity, determining their suitability for different applications. Copper, a pure elemental metal, has a face-centered cubic (FCC) crystal lattice structure. This highly ordered and uniform arrangement allows conduction electrons to flow with minimal scattering, resulting in very low electrical resistivity (approximately (1.7 ×10−8Ω⋅m). This low resistivity makes copper an excellent conductor, ideal for electrical wiring where efficient current flow is essential.

In contrast, nichrome is an alloy composed mainly of nickel and chromium, sometimes with iron, leading to a complex and irregular crystal lattice structure. This mixed atomic composition introduces numerous lattice irregularities such as grain boundaries and dislocations, which act as scattering centers for conduction electrons. These imperfections significantly impede electron flow, resulting in much higher resistivity (ranging from (1.1 ×10−6) to (1.5 ×10−6Ω⋅m). The high resistivity of nichrome makes it suitable for applications requiring resistance heating, such as in heating elements and toasters. Thus, the differences in crystal lattice structures between copper and nichrome directly influence their resistivity and appropriate applications.

What are the safety considerations when using nichrome and copper in electrical systems?

When considering the safety of using nichrome and copper in electrical systems, it is crucial to understand their distinct properties and associated risks.

Nichrome, an alloy of nickel and chromium, is known for its high electrical resistivity and heat resistance, making it ideal for heating elements. However, its high operating temperatures (up to 1,250°C to 1,400°C) pose significant burn and fire hazards. Proper insulation and physical barriers are essential to prevent accidental contact and ignition of nearby materials. Additionally, secure wiring and protective gear during installation are necessary to mitigate electrical shorts and shocks. Nichrome’s resistance to oxidation and corrosion at high temperatures ensures durability and safety in prolonged use.

Copper, a pure metal with very low electrical resistivity, is preferred for electrical wiring due to its efficient current conduction and minimal heat generation under normal loads. This reduces the risk of burns and fires. However, copper’s high conductivity means that faults can result in large currents, necessitating proper circuit protection (e.g., breakers, fuses) to prevent overheating and electrical fires. Copper wiring must also be properly insulated to avoid electrical shocks, and its oxidation, while forming a stable layer, requires maintenance in harsh environments to ensure safe connections.