Imagine assembling a critical stainless steel structure, only to find that the fasteners are seizing up, rendering your project stuck in its tracks. This frustrating phenomenon, known as galling, is a common issue with stainless steel threads that can cause significant delays and damage. But what exactly causes galling, and more importantly, how can you prevent it?

In this article, we’ll explore the science behind galling and provide a comprehensive guide on how to mitigate this troublesome problem. You’ll learn about the best materials to use, effective methods for prevention, and real-world case studies that demonstrate successful strategies. Whether you’re a seasoned engineer or someone who frequently works with stainless steel fasteners, this overview will equip you with the knowledge to tackle galling head-on. Ready to ensure your projects run smoothly? Let’s dive in.

Understanding Galling

What is Galling?

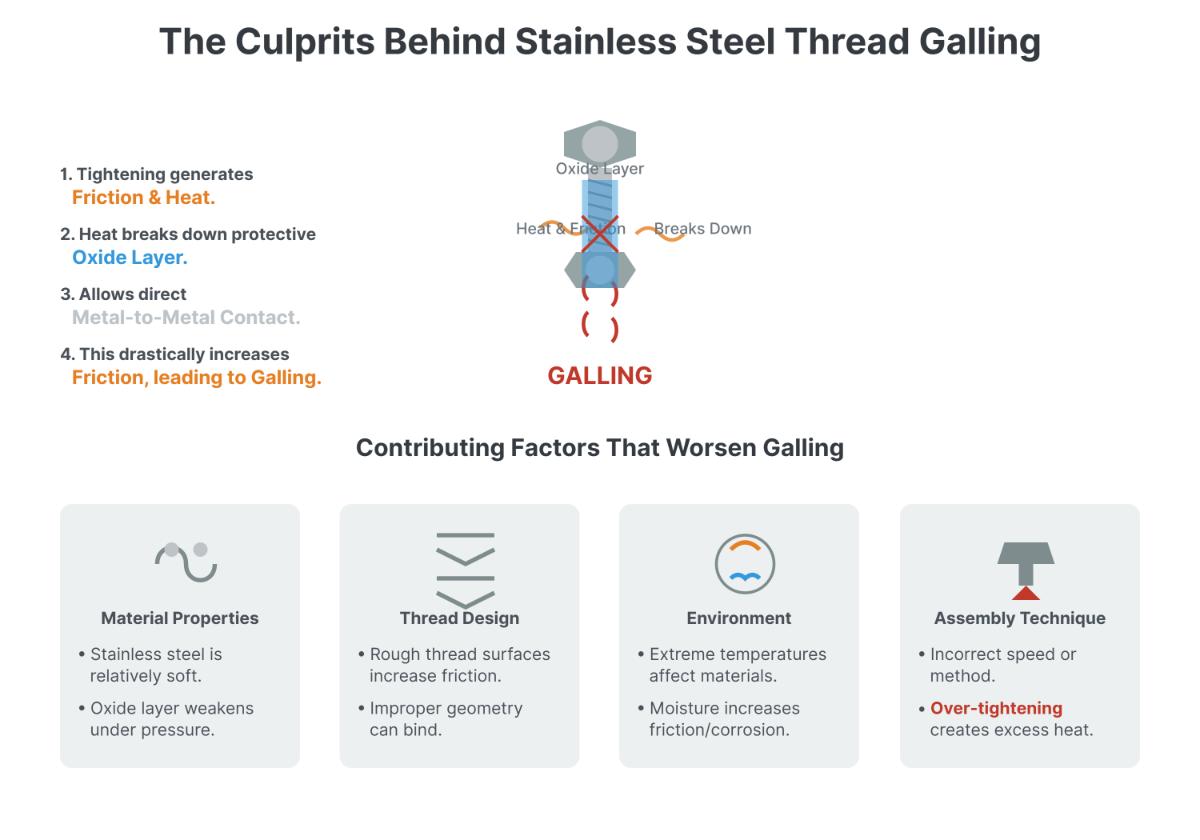

Galling is a severe form of adhesive wear that happens when two metal surfaces slide against each other under pressure. It is particularly prevalent in stainless steel components, where the material’s tendency to form a thin oxide layer can lead to increased friction and heat. When the protective oxide layer is compromised, the exposed base metal can weld together under pressure, causing the surfaces to seize or adhere to each other.

Causes of Galling

Friction and Heat

During the tightening or assembly of threaded components, high friction and heat can wear away the oxide layer on stainless steel. This exposes the base metal, which then undergoes solid – phase welding between the threads, causing them to seize.

Material Properties

Stainless steel, especially austenitic grades like type 304, is highly susceptible to galling due to its modest heat dissipation and high coefficient of friction, which can exacerbate adhesion between similar hardness materials.

Thread Smoothness and Cleanliness

Even threads that appear smooth may have tiny imperfections that increase friction, and debris or contaminants can act as abrasives, raising the likelihood of galling.

Identifying Galling

Visual Inspection

Galling can often be identified through visual inspection. Look for signs of material transfer between the mating surfaces or significant wear on the threads. Damaged or roughened thread surfaces are indicative of galling.

Changes in Torque

If the torque needed to tighten a fastener continues to increase disproportionately, it may be a sign that galling is happening.

Consequences of Galling

Galling can lead to several critical issues in mechanical assemblies:

- Seized Bolts: Once galling occurs, the threads can seize, making it difficult or impossible to further tighten or loosen the fastener.

- Thread Damage: The welding and subsequent tearing of the material can cause significant damage to the threads, rendering the fastener unusable.

- Broken Fasteners: In severe cases, galling can lead to the breakage of fasteners during the assembly process, leading to costly repairs and downtime.

Material Selection for Galling Prevention

Material Selection Criteria

Choosing the right materials is crucial to prevent galling in stainless steel threads, ensuring durability and reliability in fasteners. Several factors should be considered when selecting materials to ensure the longevity and reliability of fasteners.

Dissimilar Materials

Using materials with different hardness levels can significantly reduce galling, as they prevent surfaces from sticking together. For example, combining austenitic stainless steel bolts with nuts made from duplex stainless steel, brass, or bronze can effectively minimize galling. This approach leverages the differences in mechanical properties to reduce friction and wear.

Austenitic Stainless Steels and Surface Treatments

Standard austenitic stainless steels, such as type 304 and 316, are commonly used due to their excellent corrosion resistance. However, these materials are prone to galling when used together. To mitigate this, manufacturers often turn to proprietary stainless steels specifically designed to resist galling.

Certain stainless steel alloys are engineered to provide enhanced resistance to galling while maintaining high corrosion resistance. Notable examples include:

- Nitronic 60: This alloy is renowned for its superior galling resistance. It contains additions of silicon and manganese, which enhance its wear resistance and reduce the likelihood of adhesive wear.

- Gall-Tough Stainless: Similar to Nitronic 60, Gall-Tough Stainless is designed to prevent galling through its unique composition, which includes elements that promote a hard, wear-resistant surface.

Applying surface treatments and coatings can further enhance the galling resistance of stainless steel threads. These treatments reduce friction and provide a protective barrier between mating surfaces.

- PTFE Coatings: Polytetrafluoroethylene (PTFE) coatings, commonly known as Teflon, are highly effective in reducing friction. PTFE is a low-friction material that prevents direct metal-to-metal contact, thereby reducing the risk of galling.

- Molybdenum Disulfide: Molybdenum disulfide (MoS2) provides excellent lubrication properties, reducing friction and wear between threaded components. MoS2 coatings are particularly beneficial in high-temperature applications where other lubricants may degrade.

Thread Design and Manufacturing

The design and manufacturing of threads play a crucial role in preventing galling. Certain thread types and manufacturing processes can reduce the likelihood of adhesive wear.

Rolled threads are smoother and more uniform compared to cut threads. The rolling process hardens the thread surface, enhancing its resistance to galling. Additionally, rolled threads have fewer imperfections that can contribute to friction, making them a preferred choice for applications prone to galling.

Coarse threads have fewer threads per inch compared to fine threads, which reduces the contact area between mating surfaces. This design lowers the friction and heat generated during tightening, thus decreasing the risk of galling. Coarse threads are particularly useful in applications requiring frequent assembly and disassembly.

Material Compatibility

Ensuring compatibility between materials used in fasteners and their mating components is vital. Incompatible materials can exacerbate galling, so it is essential to consider the entire system when selecting materials. Think of it like pairing dance partners: if they don’t move well together, they can trip each other up. Using compatible, high-quality materials in combination with appropriate surface treatments and thread designs can significantly enhance the performance and reliability of stainless steel fasteners.

Methods to Prevent Galling

Material Selection

Dissimilar Materials

Choosing materials with different hardness levels can significantly reduce the risk of galling. For instance, pairing a hard nut with a softer bolt can prevent the surfaces from sticking together. This approach exploits the differences in mechanical properties to minimize friction and wear during the tightening process.

Alternative Materials

Materials like brass or bronze inherently resist galling due to their unique characteristics, making them less prone to adhesive wear. These materials offer a viable alternative to stainless steel in applications where galling is a concern.

Thread Design and Finish

Coarse Threads

Choosing coarse threads over fine ones is advisable. Coarse threads have a larger thread allowance and are more forgiving of handling abuse. They reduce the contact area between mating surfaces, which in turn lowers the friction and heat generated during tightening, decreasing the likelihood of galling.

Thread Rolling

Thread rolling provides a smoother finish compared to thread cutting. This process hardens the thread surface and reduces imperfections that can contribute to friction. As a result, the risk of galling is significantly reduced.

Lubrication

Anti-Seize Compounds

Applying anti-seize compounds, such as copper-based or calcium oxide greases, effectively prevents galling by significantly reducing friction between mating threads.

Dry Film Lubricants

Dry film lubricants can be applied to one of the mating threads. They are particularly useful for locknuts. By creating a low-friction barrier between the threads, they prevent direct metal-to-metal contact and reduce the risk of galling.

Assembly Techniques

Slow Installation

Reducing the installation speed is crucial. Slower installation minimizes the heat generated from friction during the tightening process. Less heat means less likelihood of the protective oxide layer on stainless steel being worn away, thereby reducing the risk of galling.

Avoid Using Bolts for Alignment

Aligning components with bolts can cause excessive force, increasing the risk of galling. Proper alignment ensures that the bolts are tightened evenly and without unnecessary stress.

Surface Preparation

Cleanliness

Ensuring that threads are clean and free from debris is fundamental. Debris or contaminants can act as abrasives, increasing friction and raising the likelihood of galling. Regular cleaning of the threads before assembly can prevent these issues.

Electropolishing

Electropolishing smooths the surface roughness of the threads. A smoother surface reduces the contact points between the mating threads, which in turn decreases friction and the risk of galling.

Plating and Coatings

Hard Chrome and Zinc Plating

Hard chrome and zinc plating are effective in preventing galling. These platings create a protective layer on the threads, reducing friction and preventing direct metal-to-metal contact. However, the plating thickness must be carefully considered to maintain the proper thread fit.

Case Studies and Examples

Industrial Applications

In industrial settings where frequent assembly and disassembly of components are common, galling can be a significant issue. One effective approach to mitigating this is the use of Nitronic – 60 stainless steel. This specific alloy, designed to resist galling due to its unique composition of silicon and manganese, significantly reduces the occurrence of galling when used in fasteners compared to standard stainless steels.

For instance, a large manufacturing plant’s maintenance team frequently encountered galling issues with their stainless steel fasteners during routine machinery maintenance. By switching to Nitronic – 60 bolts and nuts, the team observed a dramatic decrease in galling incidents, leading to smoother maintenance operations and reduced downtime.

Structural Steel Projects

Structural steel applications often involve heavy – duty fasteners that must endure significant loads. In such projects, the use of coarse threads combined with anti – seize compounds has proven effective in preventing galling. Coarse threads reduce the contact area between surfaces, decreasing friction and the risk of galling.

A notable example is a bridge construction project where galling of stainless steel bolts was initially a major concern. Engineers decided to use bolts with coarse threads and applied a molybdenum disulfide (MoS2) anti – seize compound to the threads. This combination not only prevented galling but also facilitated easier assembly and disassembly of the structural components, ensuring the project’s timely completion.

High – Temperature Environments

High temperatures can worsen galling due to increased thermal expansion and friction. In such cases, the application of high – temperature lubricants and the use of materials resistant to thermal expansion are critical.

A power plant operating in a high – temperature environment faced severe galling issues with its stainless steel fasteners. The solution involved applying high – temperature lubricants specifically designed to withstand the plant’s extreme conditions. Additionally, they switched to using a combination of austenitic and duplex stainless steels. These materials provided better thermal stability and reduced the risk of galling, ensuring the reliability and longevity of the fasteners.

Aerospace and Aviation

In the aerospace industry, where the integrity of fasteners is paramount, preventing galling is crucial. One successful approach has been the use of PTFE (polytetrafluoroethylene) coatings on fasteners. PTFE provides a low – friction barrier that prevents metal – to – metal contact, thus reducing the likelihood of galling.

A case study from an aerospace manufacturer demonstrated the effectiveness of this approach. The company experienced galling problems with stainless steel fasteners used in aircraft assembly. By applying PTFE coatings to the fasteners, they significantly reduced friction during tightening and eliminated galling issues. This improvement not only enhanced the reliability of the fasteners but also streamlined the assembly process.

Marine Applications

Marine environments pose unique challenges due to the presence of saltwater, which can accelerate corrosion and galling. In a marine engineering project involving the assembly of offshore platforms, engineers faced persistent galling issues with stainless steel fasteners.

To address this, they implemented a combination of surface treatments and proper lubrication. The fasteners were electropolished to smooth the thread surfaces and reduce friction points. Additionally, a marine – grade anti – seize compound was applied to the threads. This comprehensive approach effectively prevented galling and ensured the durability and reliability of the fasteners in the harsh marine environment.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What causes galling in stainless steel threads?

Galling in stainless steel threads is primarily caused by friction and heat generated during the tightening process. This heat can break down the protective oxide layer on stainless steel, leading to direct metal-to-metal contact, which increases friction and results in galling. Stainless steel’s relatively soft nature and the tendency of its oxide layer to degrade under pressure further contribute to this issue. Additionally, rough thread surfaces and improper thread design can exacerbate galling. Environmental factors like extreme temperatures and moisture can also increase friction, while incorrect assembly techniques, such as over-tightening, can significantly elevate the risk of galling.

How can I prevent galling in stainless steel fasteners?

To prevent galling in stainless steel fasteners, several effective strategies can be employed:

- Lubrication: Applying anti-galling lubricants, such as anti-seize compounds or commercial waxes, to the threads significantly reduces friction, allowing smoother interaction between surfaces.

- Material Selection: Using dissimilar materials, such as pairing a harder nut with a softer bolt, can help reduce the tendency for galling. Strain-hardened stainless steels, which have improved strength and reduced ductility, are also less prone to galling.

- Thread Design and Quality: Opt for coarse threads (e.g., 2A-2B fit) and rolled threads, which have smoother surfaces compared to cut threads, minimizing friction and the risk of galling.

- Installation Procedures: Install fasteners slowly and avoid high-speed tools to reduce heat buildup. Ensure proper alignment and adhere to recommended torque specifications to prevent excessive pressure on the threads.

- Environmental and Maintenance Considerations: Keep fasteners clean and store them in environments that protect their coatings from heat and sunlight.

Implementing these strategies will help minimize the occurrence of galling, ensuring reliable and durable assemblies.

What materials are best for preventing galling?

To prevent galling in stainless steel threads, selecting the appropriate materials is crucial. Premium stainless steels, such as strain-hardened or cold-formed varieties like BUMAX 88, offer high resistance due to their increased strength and reduced ductility. Duplex and martensitic stainless steels are also effective, as their higher hardness and work-hardening rates make them less susceptible to galling. Additionally, Nitronic-60 stainless steel is renowned for its superior galling resistance, making it suitable for critical applications. Non-ferrous materials like brass and bronze are inherently resistant to galling and are often used in sliding applications. By choosing these materials, manufacturers can significantly reduce the risk of galling in stainless steel fasteners.

Are there specific coatings that help in preventing galling?

Yes, specific coatings can help in preventing galling in stainless steel threads. PTFE (Teflon) coatings are particularly effective due to their low friction and corrosion-resistant properties, which help to reduce the heat and friction that cause galling. Anti-seize compounds, which contain solids like molybdenum disulfide, silver, aluminum, or copper, create a barrier between metal surfaces, effectively preventing direct metal-to-metal contact and reducing galling risks. Additionally, other wear-resistant coatings can be applied to one of the mating surfaces to further minimize the chances of galling by reducing friction and wear during tightening. These coatings play a crucial role in enhancing the reliability and longevity of threaded connections in stainless steel fasteners.

How does lubrication help in reducing galling in stainless steel threads?

Lubrication helps in reducing galling in stainless steel threads by creating a barrier between the metal surfaces, which minimizes direct metal-to-metal contact. This reduction in contact lowers the friction and heat generated during the tightening process, both of which are primary contributors to galling. By applying lubricants or anti-seize compounds, the threads are protected from shearing and locking together, which prevents the adhesive wear characteristic of galling. Additionally, lubrication helps to dispel moisture that can exacerbate galling and corrosion, particularly in harsh environments like saltwater. This protective layer ensures smoother interaction between the threads, thus significantly reducing the risk of galling.