In the world of piping systems, choosing the right fittings can be the difference between a seamless flow and a problematic leak. Two common options are reducing inserts and reducing couplings, but what’s the difference, and when should you use each one? Whether you’re a seasoned professional or an intermediate enthusiast, understanding the nuances between these two fittings can significantly impact the efficiency and reliability of your projects. In this comprehensive comparison, we will delve into the definitions, functionalities, and applications of reducing inserts and reducing couplings. From structural differences to installation considerations, join us as we explore every aspect to help you make an informed decision. Ready to find out which fitting reigns supreme in various scenarios? Let’s dive in.

Understanding Reducing Inserts

Reducing inserts are special pipe fittings that connect pipes of different sizes in a piping system. They serve a critical role in ensuring a smooth transition from a larger diameter pipe to a smaller one, facilitating the flow of fluids or gases without compromising the integrity of the system.

Common Applications in Piping Systems

Reducing inserts are widely used across various industries that rely on precise and efficient piping systems. Some of the most common applications include:

- Chemical Processing: In environments where precise control over fluid flow is essential, reducing inserts help manage the transition between pipes of differing diameters, ensuring consistent chemical reactions.

- Oil and Gas: These inserts are critical in the oil and gas industry for handling different flow rates and pressures, contributing to safe and efficient extraction and transportation processes.

- Power Plants: Reducing inserts are used in power plants to manage the flow of steam and water through various stages of energy production, maintaining system integrity and performance.

- Water Treatment Facilities: They are essential in water treatment processes where different pipe sizes are used to manage the flow rates and pressure of water being processed and treated.

Advantages and Disadvantages

Advantages

- Precision and Control: Reducing inserts offer high precision in connecting pipes of different diameters, ensuring a secure and leak-free fit. This precision is vital in industries that need strict flow control and system reliability.

- Durability: Constructed from robust materials such as stainless steel, carbon steel, and alloy steel, reducing inserts are highly durable and resistant to corrosion and wear, making them suitable for harsh environments.

- Cost-Effectiveness: Reducing inserts allow the use of different pipe sizes within the same system. This can optimize material usage and reduce costs by minimizing the need for additional fittings and connectors.

Disadvantages

- Flow Restrictions: The step-down design of reducing inserts can cause minor flow restrictions and pressure drops. This characteristic makes them less suitable for applications where maintaining high flow rates is critical.

- Installation Complexity: Installing reducing inserts requires precise measurements and alignment to ensure a proper fit. This can make installation take longer and require more effort, especially in systems with many connections.

Understanding Reducing Couplings

Definition and Functionality

Reducing couplings are essential pipe fittings used to connect pipes of different diameters. They act as adapters, allowing for a smooth transition between varying pipe sizes without significantly altering the flow characteristics. This is important for keeping steady fluid flow in a piping system.

Design and Installation

Ease of Installation

Reducing couplings are known for their straightforward installation process. Unlike reducing inserts, which require precise alignment and measurements, reducing couplings can accommodate slight misalignments and size variations. This flexibility simplifies the installation process and reduces the potential for errors.

Flexibility

These fittings are versatile and can be used in both horizontal and vertical installations. In vertical setups, reducing couplings may need extra measures like integrated steel washers to prevent telescoping and ensure a secure connection.

Common Applications in Piping Systems

Residential Plumbing

Reducing couplings are often used in residential plumbing due to their ease of use and flexibility, making them perfect for connecting different-sized pipes in home water supply systems, ensuring a reliable and leak-free connection.

Irrigation Systems

In irrigation systems, reducing couplings help manage varying pipe sizes, facilitating efficient water distribution. They are particularly useful in agricultural setups where different sections of the irrigation network may require different pipe diameters.

Temporary Industrial Setups

For temporary industrial installations, reducing couplings offer a quick and efficient solution for connecting pipes of different sizes. They can handle pipe misalignments and size variations, making them great for quick-assembly and disassembly temporary setups.

Advantages and Disadvantages

Advantages

- Simplicity: Reducing couplings are simple to install, involving fewer parts and reducing the likelihood of installation errors.

- Cost-Effectiveness: Their use can lower – Versatility: Suitable for a wide range of applications, reducing couplings can be used in both permanent and temporary setups.

Disadvantages

- Flow Characteristics: Although reducing couplings keep the flow smooth, they may not be as precise and controllable as reducing inserts, so they’re less fit for high-precision settings.

- Structural Limitations: In vertical installations, additional measures may be needed to prevent telescoping, which can add complexity to the setup.

Design and Functionality Differences

Structural Differences

Reducing inserts and reducing couplings have distinct designs to meet different installation and functional needs.

Reducing Inserts

Reducing inserts have a step-down design. This design allows them to fit snugly inside a larger pipe while accommodating a smaller pipe. This ensures a gradual reduction in pipe diameter, creating a secure and tight connection. The step-down nature of reducing inserts means they fit inside the larger pipe and create a smaller flow area for the fluid to pass through. This can be crucial in applications where precise control over flow rate and pressure is necessary.

Reducing Couplings

In contrast, reducing couplings connect two pipes of different diameters without significantly changing the flow path. They maintain the center axis of the pipes, ensuring a smooth and direct flow. The design of reducing couplings typically involves a straight-through connection that minimizes disruptions in the flow, making them suitable for applications where maintaining a consistent flow rate is more critical than precise control.

Material Variations

The materials used for reducing inserts and reducing couplings, such as brass, plastic, or stainless steel, can vary, influencing their suitability for different applications and environments.

Reducing Inserts

Reducing inserts are commonly made from materials such as brass, plastic, or stainless steel. Brass and stainless steel inserts are preferred for their durability and resistance to corrosion, making them ideal for harsh environments such as chemical processing plants. Plastic reducing inserts are often used in applications where chemical compatibility is a concern, such as in certain water treatment processes.

Reducing Couplings

Reducing couplings are also made from materials like brass, plastic, and stainless steel. However, their design allows for more flexibility in material choice, as they do not require the same level of precision in alignment as reducing inserts. This makes them suitable for a broader range of applications, including residential plumbing and irrigation systems, where ease of installation and material compatibility are important considerations.

Compatibility with Different Piping Systems

The compatibility of reducing inserts and reducing couplings with various piping systems can significantly impact their selection for specific projects.

Reducing Inserts

Reducing inserts are highly compatible with systems that require precise control over flow and pressure. They are often used in piping systems where maintaining a specific flow rate is critical, such as in chemical processing or HVAC systems. Their ability to provide a secure and leak-free connection makes them ideal for high-precision environments.

Reducing Couplings

Reducing couplings offer greater versatility and ease of installation, making them suitable for a wide range of piping systems. They can accommodate slight misalignments and size variations, which is beneficial in applications such as residential plumbing and temporary industrial setups. Their design allows for quick and efficient connections, reducing installation time and complexity.

Key Considerations

When choosing between reducing inserts and reducing couplings, several key factors should be considered:

- Precision Requirements: Reducing inserts are better suited for applications that require precise control over flow and pressure, while reducing couplings are ideal for installations where flexibility and ease of installation are more important.

- Material Compatibility: The choice of material should be based on the specific requirements of the application, including resistance to corrosion, chemical compatibility, and durability.

- Installation Environment: The installation environment, including whether the system is permanent or temporary, and whether it involves horizontal or vertical installations, can influence the choice between reducing inserts and reducing couplings.

Understanding the design and functionality differences between reducing inserts and reducing couplings helps engineers and installers make informed decisions, enhancing the performance and reliability of piping systems.

Piping Systems

Piping systems are networks of pipes, fittings, and valves that transport fluids—either liquids or gases—from one place to another. They are fundamental in various industries, including manufacturing, power generation, and residential plumbing. The efficiency and reliability of a piping system depend on proper design, material selection, and the right choice of fittings.

Role of Reducing Inserts and Reducing Couplings in Different Piping Systems

High-Precision Piping Systems

In high-precision piping systems such as those in chemical processing plants, reducing inserts play a crucial role. These systems require strict control over flow rates, pressure, and alignment. Reducing inserts, with their step-down design, can accurately join pipes of varying sizes, ensuring a smooth transition and minimizing flow disruptions. For example, in a chemical reactor where precise mixing of fluids is essential, reducing inserts help maintain the required flow characteristics.

On the other hand, reducing couplings may not be the first choice in these high-precision environments. Their design, which focuses more on ease of connection rather than precise flow control, may not meet the strict requirements of such systems.

General Industrial and Residential Piping Systems

In general industrial and residential piping systems, reducing couplings shine. These systems often prioritize ease of installation and flexibility. Reducing couplings can quickly and easily connect pipes of different sizes, accommodating slight misalignments and size variations. For instance, in a residential plumbing system, reducing couplings can be used to connect different-sized pipes in the water supply lines without the need for precise measurements.

While still usable, reducing inserts may be overkill in these scenarios due to their complex installation process and the need for precise alignment, which can be time-consuming and unnecessary in systems where high-precision flow control is not a primary concern.

Temporary Piping Systems

Temporary piping systems, such as those used in construction sites or for emergency repairs, benefit greatly from reducing couplings. Their easy installation and ability to handle minor variations make them ideal for quick setup and removal. Reducing inserts, with their more complex installation requirements, are less suitable for temporary systems where time is of the essence.

Impact of Choosing the Right Fitting

Performance

Choosing the right fitting can significantly impact the performance of a piping system. In high-precision applications, using reducing inserts can ensure optimal flow control and system efficiency. However, using reducing couplings in such systems may lead to flow irregularities and reduced performance.

Conversely, in systems where flexibility and ease of installation are key, using reducing couplings can result in a well-functioning system. If reducing inserts are used instead, the installation process may be more difficult, and the benefits of their precise flow control may not be fully utilized.

Cost

Choosing between reducing inserts and reducing couplings also affects costs. Reducing inserts, due to their precision manufacturing and the need for accurate installation, can be more expensive in terms of both material and labor costs. Reducing couplings, on the other hand, are generally more cost-effective, especially in large-scale projects where their ease of installation can save time and labor costs.

Long-Term Reliability

Long-term reliability is another factor affected by the choice of fitting. In harsh environments or systems with high-pressure requirements, reducing inserts made from durable materials can provide a more reliable connection. Reducing couplings, while versatile, may require additional support or maintenance in certain applications to ensure long-term reliability.

Installation Considerations

Preparing the Pipes

Start by cleaning the pipes to ensure they are free from debris, as this is crucial for a proper seal and preventing leaks. Measure the outer diameter of the smaller pipe and the inner diameter of the larger pipe to select the correct size of the reducing insert.

Inserting the Fitting and Connecting the Smaller Pipe

Carefully insert the reducing insert into the larger pipe, ensuring it fits snugly and is aligned properly. Once the insert is securely in place, insert the smaller pipe into the insert, making sure it fits tightly to maintain a secure connection. Apply pipe joint compound or Teflon tape on the threads to create a tight seal and prevent leaks.

Securing the Connection

Use a pipe wrench or suitable tools to tighten the connection, ensuring there are no gaps or misalignments.

Preparing the Pipes for Reducing Couplings

Begin by thoroughly cleaning the pipes to remove any debris, just as you would for reducing inserts. Measure the outer diameters of both pipes to ensure that the reducing coupling matches the pipe sizes.

Positioning the Coupling

Slide the reducing coupling onto the smaller pipe first, then position it over the larger pipe. Ensure the pipes are properly aligned to avoid misalignment.

Securing the Coupling

Once the coupling is in place, use a pipe wrench or other suitable tools to tighten the coupling. Make sure the connection is secure and that there are no leaks. Apply pipe joint compound or Teflon tape to the threads if needed to enhance the seal.

Tools and Equipment Needed

- Pipe wrench

- Measuring tape

- Pipe joint compound or Teflon tape

- Cleaning tools (e.g., wire brush, cloth)

- Hammer (for gently tapping inserts if needed)

Common Installation Challenges and Solutions

Ensuring Proper Alignment

A common challenge with reducing inserts is ensuring proper alignment. Misalignment can lead to leaks and system inefficiencies. To address this, use a measuring tape to verify dimensions and ensure that the pipes are cut squarely.

Preventing Leaks

Leaks can occur if the fittings are not tightened properly or if there is debris in the connection. Clean all pipes thoroughly before installation and use pipe joint compound or Teflon tape to create a secure seal.

Handling High-Pressure Applications

For high-pressure applications, reducing inserts may require additional support to handle the pressure. Ensure that the inserts are made from durable materials and are installed with precision to withstand high pressures.

Managing Vertical Installations

In vertical installations, reducing couplings can sometimes telescope or misalign. To prevent this, use integrated steel washers or other support mechanisms to keep the pipes in place and maintain alignment.

Installation Advantages and Disadvantages

Reducing Inserts

- Advantages: Provide precise flow control and are ideal for high-precision environments. They offer a secure, leak-free connection when installed correctly.

- Disadvantages: Require precise alignment and can be time-consuming to install. They may cause minor pressure drops and flow restrictions.

Reducing Couplings

- Advantages: Easier to install and accommodate slight misalignments. They are versatile and suitable for various applications, including temporary installations.

- Disadvantages: May not offer the same level of flow control as reducing inserts. They can be less suitable for high-precision environments.

Choosing between reducing inserts and reducing couplings depends on the specific needs of the project, including precision requirements, installation speed, and application environment. By understanding these considerations, you can make informed decisions to optimize the performance and efficiency of your piping system.

Performance and Efficiency Comparison

Durability and Lifespan

When comparing the durability and lifespan of reducing inserts and reducing couplings, several factors need to be considered, including material composition, installation quality, and operating conditions.

Reducing Couplings

Reducing couplings are often preferred for their robust one-piece construction, which minimizes potential leak points and enhances durability. Made from materials such as stainless steel, carbon steel, and high-grade plastics, reducing couplings are designed to withstand various environmental conditions, including exposure to chemicals and high temperatures. This robust design ensures that reducing couplings can offer long-term reliability and require minimal maintenance, making them ideal for applications where longevity and low maintenance are critical.

Reducing Inserts

Reducing inserts, while also available in durable materials like stainless steel and brass, depend heavily on proper installation to ensure their long-term performance. The step-down design of reducing inserts can make them more susceptible to wear if not installed correctly, potentially leading to leaks and reduced lifespan. However, when installed properly, reducing inserts can provide a secure, leak-free connection that maintains system integrity, even in high-pressure environments.

Pressure and Temperature Tolerances

The ability of fittings to withstand pressure and temperature variations is crucial for maintaining system efficiency and safety.

Reducing Couplings

Reducing couplings can handle various pressures and temperatures, making them versatile. Their seamless design maintains structural integrity during rapid pressure changes or high temperatures. This makes reducing couplings suitable for both residential and industrial applications where consistent performance under varying conditions is necessary.

Reducing Inserts

Reducing inserts are ideal for high-pressure applications, maintaining integrity in industries like petrochemical and power generation. Their design ensures that they can maintain pressure integrity, making them ideal for use in systems where high-pressure conditions are the norm.

Energy Efficiency Considerations

Flow dynamics and fitting design significantly influence energy efficiency in piping systems.

Reducing Couplings

Reducing couplings offer a direct path between pipes of different diameters, optimizing fluid flow and reducing turbulence. This streamlined flow helps in maintaining high energy efficiency within the system, making reducing couplings a preferred choice for applications where fluid velocity and minimal energy loss are critical. The smooth transition facilitated by reducing couplings ensures that there is minimal disruption to the flow, which can significantly enhance the overall performance and longevity of the piping system.

Reducing Inserts

While reducing inserts are also designed to facilitate smooth transitions between pipes of different sizes, their insertion method can introduce slight complexities in flow dynamics. This can potentially lead to minor energy losses due to turbulence, particularly if the installation is not perfectly aligned. However, in high-pressure environments where maintaining pressure integrity is more critical than flow velocity, reducing inserts can still contribute to efficient system operation.

Cost-Effectiveness Analysis

To evaluate cost-effectiveness, consider both initial costs and long-term expenses of reducing inserts and couplings.

Reducing Couplings

Reducing couplings tend to have a higher upfront cost compared to reducing inserts, primarily due to their one-piece design and material requirements. However, their ease of installation and low maintenance needs can lead to significant long-term savings. In applications where reliability and quick installation are paramount, the higher initial investment in reducing couplings can be justified by the reduced labor costs and minimal maintenance over time.

Reducing Inserts

Reducing inserts are generally more economical in terms of initial purchase price, making them an attractive option for projects with budget constraints. However, the need for precise installation and potential for higher maintenance costs if not installed correctly can offset these initial savings. In applications where multiple size reductions are necessary, reducing inserts can be cost-effective, but the potential for increased labor and maintenance costs must be considered.

- Durability: Reducing couplings offer robust, long-term durability with minimal maintenance, while reducing inserts depend on precise installation for optimal performance.

- Pressure and Temperature Tolerances: Reducing couplings handle a wide range of conditions effectively, while reducing inserts excel in high-pressure environments.

- Energy Efficiency: Reducing couplings provide streamlined flow for high energy efficiency, whereas reducing inserts may introduce slight complexities in flow dynamics.

- Cost-Effectiveness: Reducing couplings have higher upfront costs but offer long-term savings, while reducing inserts are more economical initially but may incur higher maintenance costs.

Choosing the right fitting for a specific application depends on balancing these factors to meet the operational requirements and budget constraints of the project.

Case Studies and Best Practices

Real-World Applications in Plumbing and Industrial Piping

High-Precision Chemical Processing Plant

In a chemical processing plant, a project required connecting pipes of different sizes to manage the flow of corrosive chemicals. Reducing inserts were selected for their precise flow control capabilities. The step-down design of the reducing inserts ensured a secure and leak-free connection, which was crucial in preventing chemical leaks. In contrast, reducing couplings would not have been suitable as they do not offer the same level of precision in flow control, which could have led to inconsistent chemical reactions and potential safety hazards.

Residential Plumbing System

For a residential plumbing project, reducing couplings were the preferred choice. The ease of installation and the ability to accommodate slight misalignments made them ideal for connecting different-sized pipes in the water supply lines. The plumber quickly completed the installation, saving time and labor costs, which would have been higher if reducing inserts had been used due to their complex installation.

Temporary Industrial Setup

In a construction site, a temporary piping system was needed to supply water to different work areas. Reducing couplings were used due to their quick installation and ability to handle minor variations in pipe sizes. Their one-piece design made reducing couplings ideal for the temporary setup due to minimal maintenance needs. Reducing inserts, on the other hand, would have been less practical due to their complex installation process and the need for precise alignment.

Success Stories and Lessons Learned

Chemical Plant Success

In the chemical processing plant case, the use of reducing inserts led to a successful project. The precise flow control provided by the inserts ensured consistent chemical reactions, which improved the overall efficiency and safety of the plant operations.

Residential Plumbing Efficiency

The residential plumbing project using reducing couplings was completed efficiently, with minimal disruptions to the homeowners. The ease of installation and cost-effectiveness of the reducing couplings were key factors in the success of the project. The lesson here is that for projects where speed and simplicity are priorities, reducing couplings are the better choice.

Temporary Setup Flexibility

The construction site’s temporary piping system using reducing couplings demonstrated their flexibility and suitability for quick-assembly and disassembly setups. The ability to handle minor variations in pipe sizes made the installation process smooth and efficient. The lesson learned is that in temporary applications, reducing couplings offer a practical and cost-effective solution.

Industry Standards and Compliance

Material Compatibility

Both reducing inserts and reducing couplings must comply with industry standards regarding material compatibility. For example, in applications where the pipes carry corrosive substances, the fittings must be made of materials that are resistant to corrosion, such as stainless steel or brass. Material compatibility prevents corrosion and extends the piping system’s lifespan.

Installation Requirements

Industry standards also dictate the installation requirements for both types of fittings. Reducing inserts require precise alignment and measurements during installation to ensure a proper fit and prevent leaks. Reducing couplings, while more forgiving in terms of alignment, still need to be installed correctly to maintain the integrity of the connection.

Local Plumbing Codes

Local plumbing codes vary by region and must be followed when using reducing inserts and reducing couplings. These codes may specify the types of fittings allowed, the installation methods, and the safety requirements. Adhering to local plumbing codes is essential to ensure the safety and compliance of the piping system.

Cost-Benefit Analysis

Initial Costs

Reducing inserts usually cost less initially than reducing couplings. However, the installation of reducing inserts can be more labor-intensive, which may increase the overall project costs.

Long-Term Expenses

In terms of long-term expenses, reducing couplings often require less maintenance due to their one-piece design. This can result in significant cost savings over the lifespan of the piping system. Reducing inserts, if not installed correctly, may be more prone to wear and leaks, which can lead to higher maintenance costs.

Project-Specific Considerations

The cost-benefit analysis should also take into account the specific requirements of the project. For high-precision applications where the performance benefits of reducing inserts are critical, the higher initial and potential maintenance costs may be justified. In projects where speed and simplicity are prioritized, the long-term savings from using reducing couplings may outweigh the higher upfront cost.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the main differences between reducing inserts and reducing couplings?

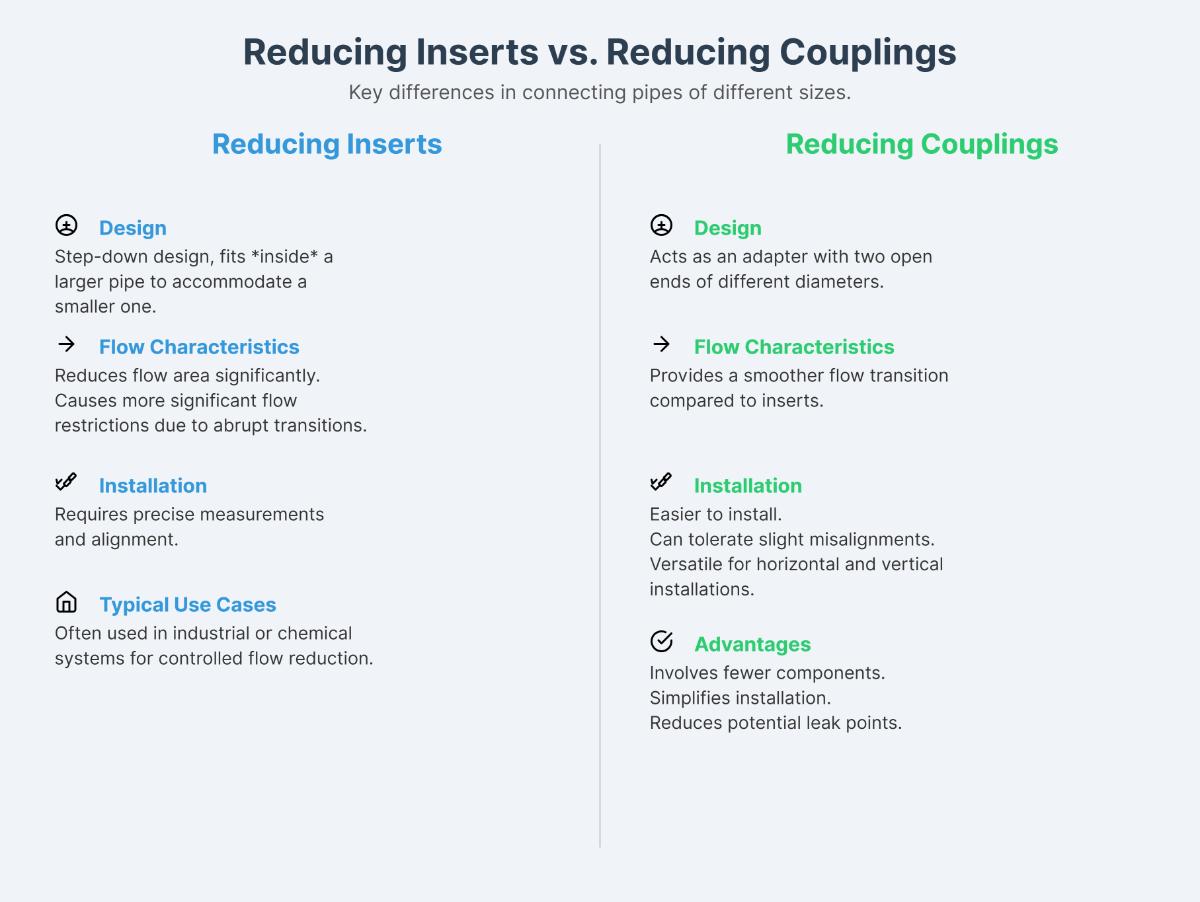

Reducing inserts and reducing couplings are both used to connect pipes of different sizes, but they have key differences. Reducing inserts feature a step – down design that fits inside a larger pipe to accommodate a smaller one, reducing the flow area. They cause more significant flow restrictions due to abrupt transitions, require precise measurements and alignment for installation, and are often used in industrial or chemical systems for controlled flow reduction. Reducing couplings, on the other hand, act as adapters with two open ends of different diameters. They provide a smoother flow transition, are easier to install and can tolerate slight misalignments. They are versatile for both horizontal and vertical installations and involve fewer components, simplifying installation and reducing potential leak points.

When should I use a reducing insert versus a reducing coupling?

When deciding between a reducing insert and a reducing coupling, consider the specific requirements of your piping system.

Use a reducing insert when precision and flow control are critical. Reducing inserts fit inside the larger pipe and accommodate a smaller one, making them ideal for high-precision environments like chemical processing, HVAC systems, and medical equipment. They are effective in maintaining exact alignment and minimizing flow disruption but require careful installation and sealing.

On the other hand, choose a reducing coupling for ease of installation and flexibility. Reducing couplings connect pipes of different sizes without significantly altering the flow area and are suitable for projects prioritizing quick and straightforward installation, such as residential plumbing repairs or irrigation systems. They accommodate slight misalignments and are effective in both horizontal and vertical installations.

How do I choose the right piping fitting for my project?

To choose the right piping fitting for your project, you need to consider several key factors. First, evaluate the compatibility of the fitting material with your pipe material and the medium it will carry. Ensure that the fitting can withstand the operational pressures and temperatures of your system.

Reducing inserts are designed for precise flow control and are ideal for high-precision environments, but they require careful alignment during installation. In contrast, reducing couplings are easier to install and more forgiving of slight misalignments, making them suitable for simpler applications or temporary fixes.

What are the cost implications of using reducing inserts versus reducing couplings?

The cost implications of using reducing inserts versus reducing couplings are influenced by their design, installation requirements, and application context.

Reducing inserts generally have a higher initial cost due to their precision engineering and the materials used, such as brass or high-quality plastic. These inserts require precise installation, which can increase labor costs but ensures long-term reliability, especially in high-value systems where precision and flow control are critical.

In contrast, reducing couplings are typically less expensive initially due to their simpler design and fewer components. They are easier to install, reducing labor costs and making them suitable for applications where precision is not as crucial. This makes them ideal for plumbing and temporary fixes where speed and cost-effectiveness are prioritized.

Are there any specific standards I need to follow when using these fittings?

Yes, specific standards must be followed when using reducing inserts and reducing couplings. For fire protection systems, the National Fire Protection Association (NFPA) offers guidelines on reducing fittings, as seen in NFPA 13 for welded fittings. Regarding material, high – pressure fittings like socket weld reducer inserts are made according to ASTM A182 and ASTM A105 standards. Compliance with these standards ensures the safety, efficiency, and reliability of piping systems.

How do reducing inserts and reducing couplings affect the

Reducing inserts and reducing couplings affect the

On the other hand, reducing couplings connect pipes directly, providing a smoother flow path and minimizing disruptions, enhancing flow efficiency. They are easier to install, requiring less precision and time, which reduces downtime during maintenance or setup. Overall, reducing couplings generally offer better flow characteristics and easier installation, while reducing inserts provide superior precision in specific environments.