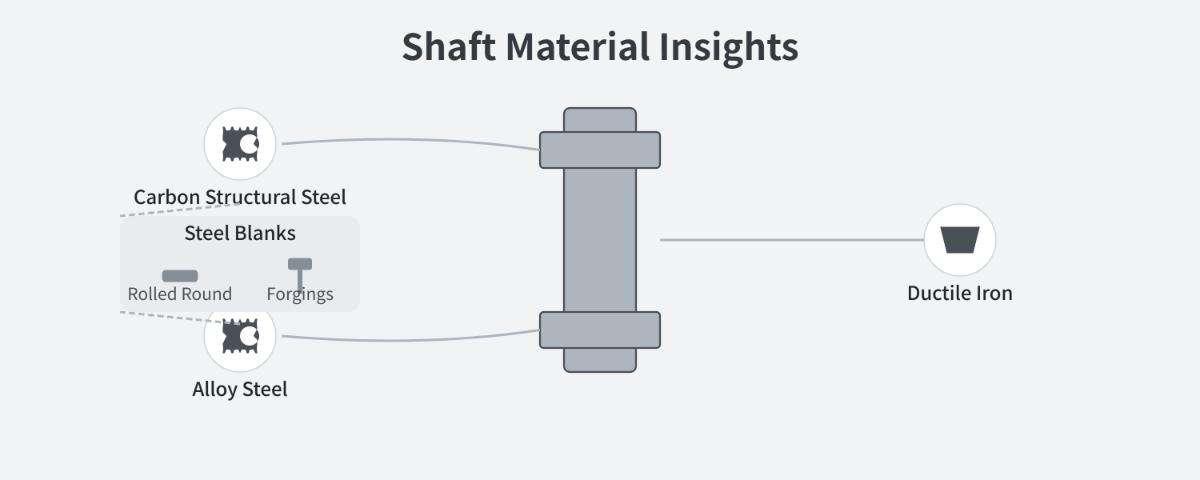

The common materials for shafts are carbon structural steel, alloy steel, and ductile iron. Steel shaft blanks are mostly rolled round steel or forgings.

I. Carbon Steel

High-quality medium carbon steel 30~50 is commonly used for relatively important or heavily loaded shafts, among which 45 steel is the most widely used. For such materials, their mechanical properties can be improved and enhanced through heat treatment methods such as quenching and tempering or normalizing.

Ordinary carbon steel Q235, Q275, etc. can be used for unimportant light load low-speed shafts or general transmission shafts.

II. Alloy Steel

Alloy steel has higher comprehensive mechanical properties and better heat treatment performance. Therefore, for important shafts that carry a large load and are limited in weight and size or have high wear resistance and corrosion resistance requirements, alloy steel can be used and subjected to certain heat treatments.

It must be noted that:

- Alloy steel is more sensitive to stress concentration and is more expensive;

- Since the elastic modulus of carbon steel and alloy steel is almost the same at normal temperatures, using alloy steel instead of carbon steel cannot achieve the purpose of improving the stiffness of the shaft;

- Various heat treatments, chemical treatments, and surface strengthening treatments (such as shot peening, rolling, etc.) can significantly improve the fatigue strength or wear resistance of the shaft, but have little effect on its stiffness.

III. Ductile Iron

Ductile iron is suitable for manufacturing shafts with complex shapes such as crankshafts, camshafts, etc., and has the advantages of being inexpensive, having relatively high strength, good wear resistance, vibration absorption, machinability, and lower sensitivity to stress concentration. However, the quality of castings is not easy to control, and reliability is relatively poor.

The common materials for shafts and their main mechanical properties are shown in the table below.

Table: Common Materials for Shafts and Their Main Mechanical Properties

| Material | Heat Treatment | Blank Diameter/mm | Hardness HBW | Mechanical Properties/MPa | Remarks | ||||

| Category | Grade | Ultimate Strength σb | Yield Point σs | Bending Fatigue Limit σ-1 | Shear Fatigue Limit τ-1 | ||||

| Carbon Structural Steel | Q235 | Air cooled after hot rolling or forging | ≤100 | — | 400~420 | 225 | 170 | 105 | Used for shafts that are not important or carry a small load |

| >100~250 | — | 375~390 | 215 | ||||||

| 45 | Normalizing | ≤100 | 170~217 | 600 | 300 | 275 | 140 | Most widely used | |

| Tempering | ≤200 | 217 ~ 255 | 650 | 360 | 300 | 155 | |||

| Alloy steel | 40Cr | Tempering | ≤100 | 241 ~ 266 | 750 | 550 | 350 | 200 | Used for important shafts carrying larger loads without significant impact |

| >100 ~ 300 | 241 ~ 266 | 700 | 550 | 340 | 185 | ||||

| 35SiMn (42SiMn) | Tempering | ≤100 | 229 ~ 286 | 800 | 520 | 400 | 205 | Performance close to 40Cr, used for medium and small shafts | |

| >100 ~ 300 | 217 ~ 269 | 750 | 450 | 350 | 185 | ||||

| 40MnB | Tempering | 25 | 1000 | 800 | 485 | 280 | Performance close to 40Cr, used for important shafts | ||

| ≤200 | 241 ~ 286 | 750 | 500 | 335 | 195 | ||||

| 20Cr | Carburizing Quenching Tempering | 15 | Surface 50 ~ 60HRC | 850 | 550 | 375 | 215 | Used for shafts requiring both high strength and toughness | |

| ≤60 | 650 | 400 | 280 | 160 | |||||

| 20CrMnTi | 15 | Surface 50 ~ 62HRC | 1100 | 850 | 525 | 300 | |||

| Ductile cast Malleable iron | QT400-15 | — | 156 ~ 197 | 400 | 300 | 145 | 125 | Used for manufacturing shafts with complex shapes | |

| QT600-3 | — | 197 ~ 269 | 600 | 420 | 215 | 185 | |||