When it comes to securing components in mechanical and structural applications, the choice of fasteners can significantly impact both performance and safety. Among the myriad of options, shear nuts and tension nuts stand out for their specific design purposes and load-bearing capabilities. But what exactly sets these two apart, and why does it matter?

Understanding the differences between shear nuts and tension nuts is crucial for making informed decisions in engineering and construction. While shear nuts are designed to handle lateral forces, making them ideal for anti-tamper applications, tension nuts are built to withstand axial loads, ensuring robust structural integrity. Each type serves a unique purpose, and their applications vary accordingly.

In this article, we will delve into the core differences between shear nuts and tension nuts, explore their design and functional attributes, and provide insights into their respective applications. By the end, you’ll have a clearer understanding of which nut to choose for your specific needs. So, what makes one nut better than the other in certain scenarios? Let’s find out.

Understanding Shear and Tensile Loads

Definition of Shear Load

A shear load is a force acting perpendicular to the axis of a fastener, causing parts of the material to slide past each other. This type of load can lead to shear failure if the material cannot withstand the applied force. In the context of nuts and bolts, shear loads are critical in applications where the primary forces are lateral, such as in certain structural joints and mechanical assemblies. The shear strength of a fastener is its ability to resist these perpendicular forces without breaking or deforming.

Definition of Tensile Load

A tensile load acts along the axis of a fastener, pulling it apart and testing the material’s capacity to withstand axial stretching forces. Tensile loads are common in applications where fasteners are used to clamp components together, ensuring they do not separate under tension. The tensile strength of a fastener is crucial for maintaining the integrity of bolted connections in structures, machinery, and various mechanical systems.

Impact of Load Types on Nut Selection

The type of load a fastener will encounter significantly influences the selection of the appropriate nut. Shear nuts and tension nuts are designed to handle different types of loads, and choosing the correct type is essential for the safety and performance of the application.

Shear Nuts

Shear nuts are designed to resist shear forces. They are often used in applications where security and tamper resistance are paramount, such as public infrastructure and automotive components. Shear nuts are designed to be difficult to remove once installed, enhancing security. However, they generally have lower tensile strength compared to tension nuts, making them less suitable for applications where axial forces are predominant.

Tension Nuts

Tension nuts, conversely, are designed to maintain clamping pressure and resist tensile forces. They are commonly used in applications that require precise bolt tensioning, such as in structural bolting and heavy industry. Typically made from corrosion-resistant materials like stainless steel, these nuts offer both strength and longevity. These nuts are also designed for easy removal and adjustment, making them ideal for applications that require regular maintenance.

Key Differences in Function and Design

The primary differences between shear nuts and tension nuts lie in their design and functionality tailored to their respective load types.

- Shear Nuts: Designed with a focus on resisting shear forces, often featuring a larger bottom diameter to prevent easy removal. They are typically made from hardened steel to enhance their strength and durability under lateral forces.

- Tension Nuts: Engineered to withstand tensile loads, ensuring consistent clamping force along the fastener’s axis. These nuts are usually made from corrosion-resistant materials like stainless steel, providing both strength and longevity.

Specific Use Cases for Each Nut Type

Understanding the use cases for each type of nut helps in making informed decisions; for instance, shear nuts are ideal for high-security applications such as public infrastructure, automotive components, and industrial machinery where tamper resistance is critical.

- Shear Nuts: Ideal for high-security applications where tamper resistance is critical, providing visible evidence of tampering and enhancing security in public infrastructure, automotive components, and industrial machinery.

- Tension Nuts: Suitable for applications requiring precise bolt tensioning, such as structural bolting, construction projects, and heavy industry. They are essential in environments where maintaining clamping pressure and withstanding axial stretching forces are crucial for structural integrity and safety.

Design and Functional Differences

Overview of Shear Nut Design

Shear nuts are designed to withstand forces that push sideways, known as shear forces. These nuts typically feature a lower profile and a thinner body compared to standard nuts, often including fewer threads. This intentional design makes them difficult to remove once installed, providing tamper resistance. Shear nuts are commonly made from hardened steel or similarly robust materials that can withstand high shear forces without deforming or breaking.

Shape, Dimensions, and Material Composition

Shear nuts usually have a larger base diameter that narrows towards the top. This shape makes them particularly challenging to remove without destroying the nut, enhancing security. The reduced thread engagement means these nuts are optimized for shear resistance rather than tensile strength. They are typically made from hardened steel or other strong materials that can endure significant shear forces. This ensures that the nuts can hold up under lateral loads without failing, making them suitable for applications where shear loads predominate.

Overview of Tension Nut Design

Tension nuts are designed to maintain clamping pressure and resist tensile loads. They feature a uniform diameter throughout and securely fit onto the bolt using all available threads. These nuts are often made from corrosion-resistant materials like stainless steel to provide durability under tensile loads and environmental exposure.

Shape, Dimensions, and Material Composition

Tension nuts have a consistent diameter along their entire length, which allows for full thread engagement with the bolt. This design helps in achieving the necessary preload to resist tensile forces effectively. The uniform shape also makes tension nuts easier to remove and reuse, which is beneficial in applications requiring frequent maintenance. Tension nuts are commonly made from corrosion-resistant materials such as stainless steel, ensuring they can withstand tensile loads over time without succumbing to environmental factors like rust or corrosion.

Comparative Analysis: Shear Nut vs Tension Nut Functionality

Shear nuts and tension nuts are built to handle different types of forces: shear nuts for sideways pressure and tension nuts for pulling forces.

Load Resistance

- Shear Nuts: Designed to resist shear loads, which act perpendicular to the bolt’s axis. Shear nuts are optimized for applications where the bolt experiences lateral forces, and their reduced thread engagement enhances shear resistance at the expense of tensile strength.

- Tension Nuts: Engineered to resist tensile loads, which act along the bolt axis. Tension nuts maintain clamping pressure, ensuring joint integrity and preventing separation under axial loads. They require precise preload to avoid fatigue and loosening.

Key Differences in Function and Design

Torque and Installation

Shear nuts require lower torque during installation due to their fewer threads and reduced tensile strength. In contrast, tension nuts need higher torque to achieve the correct preload necessary for tension resistance. Using the wrong torque can cause the nuts to fail early. Therefore, it’s crucial to apply the correct torque specifications for each type of nut.

Tamper Resistance and Reusability

Shear nuts offer high tamper resistance; once installed, they are difficult to remove without destruction, making them ideal for security-sensitive applications. However, this limits their reusability. Tension nuts, on the other hand, are designed for easy removal and reuse, making them suitable for applications that require frequent adjustments or maintenance.

Specific Use Cases for Each Nut Type

Understanding the distinct use cases for shear nuts and tension nuts is crucial for selecting the appropriate fastener for a given application.

- Shear Nuts: Suitable for public infrastructure, automotive components, and industrial machinery where shear loads predominate and tamper resistance is critical. Examples include bridges, street furniture, and certain automotive assemblies.

- Tension Nuts: Ideal for heavy industry, construction projects, and high-tension structural joints where precise bolt tensioning is essential. They are used in environments that demand high clamp load without additional torsional stresses, such as high-temperature settings and structural bolting applications.

Visual Comparisons

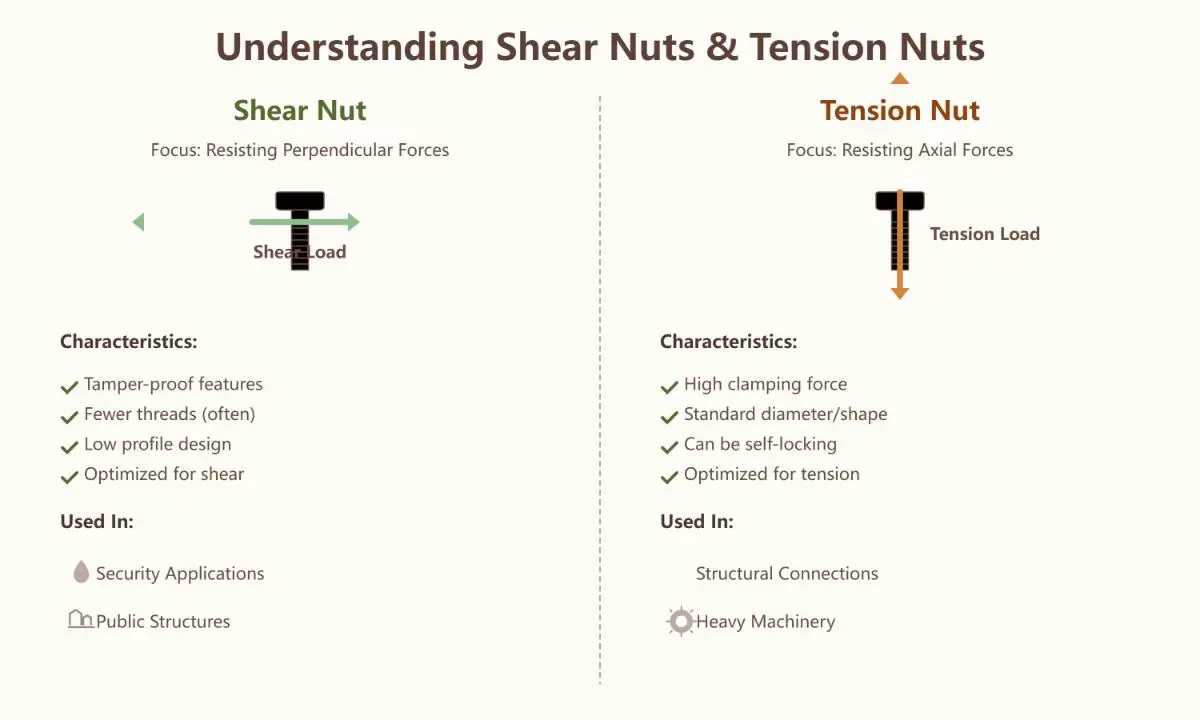

Diagrams Showing Load Directions

Visual representations are crucial for understanding the differences between shear and tension loads. Diagrams can effectively illustrate how each type of load impacts the fastener and the materials it connects.

Shear Load Diagram

A shear load diagram typically shows forces acting perpendicular to the fastener’s axis. This diagram highlights how shear forces cause joint members to slide sideways. It should include arrows indicating the direction of the shear forces and the resulting movement of the materials.

Tensile Load Diagram

A tensile load diagram illustrates forces acting along the fastener’s axis, pulling the joint members apart. This helps to understand how tensile loads maintain clamping pressure and ensure structural integrity. The diagram uses arrows to show the direction of the tensile forces and the stretching effect on the fastener.

Visual Differences in Nut Design

Examining the physical design differences between shear nuts and tension nuts through visuals can enhance comprehension.

Shear Nut Design

Shear nuts typically have a distinctive shape, with a larger base diameter tapering towards the top. This design makes them difficult to remove and provides tamper resistance. A visual comparison can show:

- Base Diameter: Larger at the bottom for enhanced security.

- Thread Engagement: Fewer threads engaged with the bolt, optimized for shear resistance.

- Material Composition: Typically made from hardened steel, emphasizing strength and durability against shear forces.

Tension Nut Design

Tension nuts feature a uniform diameter throughout their length, facilitating full thread engagement and ease of removal or adjustment. A visual comparison can highlight:

- Uniform Diameter: Consistent along the length for full thread engagement.

- Material Composition: Often made from corrosion-resistant materials like stainless steel, suitable for various environments.

- Ease of Adjustment: Design allows for easy removal and reinstallation, ideal for applications requiring frequent maintenance.

Comparative Analysis Through Visuals

Using side-by-side diagrams of shear nuts and tension nuts can effectively convey their differences in design and functionality.

Shear Nut vs Tension Nut: Design Comparison

A comparative visual can juxtapose the two nut types, emphasizing their distinctive features:

- Shape and Dimensions: Contrast the tapered design of shear nuts with the uniform shape of tension nuts.

- Thread Engagement: Show fewer threads in shear nuts versus full engagement in tension nuts.

- Material Choice: Highlight hardened steel for shear nuts and stainless steel for tension nuts.

Functional Performance Visuals

Illustrations can compare how each nut type performs under respective loads:

- Shear Resistance: Visualize shear nuts resisting lateral forces, preventing sliding of joint members.

- Tensile Strength: Show tension nuts maintaining clamping pressure under axial loads, ensuring joint integrity.

Real-World Application Visuals

Real-world examples can help contextualize the use of shear and tension nuts in various industries.

Shear Nuts in Public Infrastructure

Visuals depicting shear nuts used in bridges, street furniture, and automotive assemblies can illustrate their tamper-resistant properties and ability to withstand shear loads.

Tension Nuts in Structural Engineering

Images of tension nuts used in construction projects and heavy industry applications illustrate their ability to maintain clamping pressure and resist tensile forces.

Material and Strength Characteristics

Common Materials Used in Shear and Tension Nuts

Shear nuts are often made from hardened steel, a material valued for its strength and resistance to deformation. Hardened steel undergoes processes like quenching and tempering to boost its strength, making it ideal for applications needing high shear strength. This material ensures that shear nuts can handle significant lateral forces without failing, which is essential for maintaining the integrity of joints under shear loads.

Tension nuts are commonly made from corrosion-resistant materials such as stainless steel or high-performance alloys like A286. These materials offer excellent resistance to environmental factors such as moisture, chemicals, and extreme temperatures, ensuring the longevity and reliability of the fasteners. This corrosion resistance is particularly important in maintaining the clamping force under tensile loads, as it prevents degradation that could compromise the structural integrity of the joint.

Shear Strength vs Tensile Strength

Shear Strength

Shear strength is the capacity of a material to resist forces that cause its internal structure to slide against itself. Shear nuts are designed to optimize shear strength, enabling them to handle lateral loads effectively. The use of hardened steel, with its superior shear resistance, ensures that these nuts can maintain their integrity even when subjected to high shear forces.

Tensile Strength

Tensile strength is the ability of a material to withstand axial loads that pull it apart, and tension nuts are designed to maximize this property. The full thread engagement and the use of corrosion-resistant materials like stainless steel enhance the tensile strength of these nuts, making them ideal for applications where axial loads are predominant.

Impact of Material Properties on Nut Performance

Shear Nuts

Hardened steel gives shear nuts the necessary strength to resist lateral forces, though they usually have lower tensile strength compared to tension nuts. Shear nuts are designed to prioritize shear strength, which means they may have reduced corrosion resistance. This trade-off is acceptable in environments where lateral forces are the primary concern.

Tension Nuts

For tension nuts, the material properties are critical in ensuring they can withstand tensile loads while maintaining their integrity over time. The use of corrosion-resistant materials such as stainless steel or high-performance alloys ensures that tension nuts can endure harsh environmental conditions without degrading. This corrosion resistance is essential in preserving the clamping force and preventing joint failure. Moreover, the full thread engagement design of tension nuts distributes the load more evenly, enhancing their ability to resist axial forces.

Key Functional Differences

| Feature | Shear Nut | Tension Nut |

|---|---|---|

| Primary Load | Perpendicular (shear) | Axial (tension) |

| Material | Hardened steel | Stainless steel or corrosion-resistant alloys |

| Strength Focus | Shear strength | Tensile strength |

| Corrosion Resistance | Lower (sacrificed for shear strength) | High (critical for tensile performance) |

| Reusability | Limited (often single-use) | High (reusable unless corroded) |

Applications

Shear Nuts

Shear nuts are used in applications where lateral forces are predominant, and tamper resistance is critical. Typical uses include:

- Public Infrastructure: Bridges, rail tracks, and other structures where high shear strength is essential for safety and security.

- High-Security Systems: Electrical enclosures, tamper-evident assemblies, and other applications requiring tamper-resistant fasteners.

- Aerospace: Components where space and weight constraints necessitate thin-profile fasteners with high shear strength.

Tension Nuts

Tension nuts are perfect for applications where maintaining clamping force and resisting axial loads is crucial. Common uses include:

- Structural Engineering: Bolted joints in buildings and steel frameworks where structural integrity under tensile loads is critical.

- High-Temperature Systems: Exhaust manifolds, industrial boilers, and other environments where temperature resistance and tensile strength are essential.

- Vibration-Prone Environments: Machinery and equipment that require sustained clamp force and resistance to loosening due to vibrations.

Torque and Installation Considerations

Key Differences Between Shear Nuts and Tension Nuts

Purpose and Load Type

Shear nuts are designed to withstand forces that push sideways against the fastener, preventing parts from sliding apart. These forces can cause two joined parts to slide relative to each other, potentially leading to the shearing of the bolt or nut across its shaft. Tension nuts, on the other hand, are built to withstand tensile forces that act along the axis of the fastener, pulling the joined parts apart. This ensures that the nut and bolt clamp the parts together under tension, maintaining structural integrity.

Material and Construction

Shear nuts are commonly made from hardened steel to endure high shear stresses and provide durability as well as tamper resistance. Tension nuts often utilize corrosion-resistant materials such as stainless steel, which prioritize longevity in harsh environments and ease of removal or adjustment.

Design and Reusability

Shear nuts have a distinctive shape with a larger bottom diameter and shorter thread engagement, making them tamper-resistant but less effective in tensile strength. Tension nuts, however, have a uniform diameter and full thread engagement, allowing for repeated installation and removal, which is ideal for applications requiring maintenance or adjustments.

Torque Considerations in Installation

Torque Values Differ by Nut Type

Shear nuts require lower installation torque compared to tension nuts. This lower torque is due to the fewer threads engaged in shear nuts, which are designed for shear loading. Over-torquing shear nuts can cause pre-load issues or damage the nut. Tension nuts need higher torque to secure the joint, focusing on tension and bolt elongation, ensuring the bolt is stretched properly without additional torsional stress.

Torque Application Based on Nut, Not Load Alone

The torque specification should be based on the type of nut (shear vs. tension) rather than solely on whether the joint is under shear or tension. Misapplication of torque values, such as using tension nut torque for shear nuts, can lead to overloading or premature failure.

Preload and Load Distribution

Proper preload is critical for tension nuts to prevent loosening and fatigue. Torque values ensure the bolt is stretched properly. For shear nuts, preload is less crucial because the joint primarily resists shear forces. The bolt retains full shear capacity, but the nut’s tensile engagement is reduced, so torque must be controlled to avoid stripping.

Installation Practices and Applications

Shear Nut Installation

Shear nuts are installed with lower torque. When tightened, the exposed part shears off, preventing tampering. They are common in applications requiring security, tamper resistance, and durability, such as public infrastructure, automotive parts, industrial machinery, and high-security environments. Due to their design and material hardness, shear nuts have limited reusability.

Tension Nut Installation

Tension nuts require higher torque to achieve proper clamp load. They are designed for joints where tension and bolt elongation are primary concerns. Tension nuts are suitable for applications needing frequent maintenance or adjustments, such as heavy industry, construction, and high-temperature environments. These nuts are easy to remove and reuse.

| Aspect | Shear Nut | Tension Nut |

|---|---|---|

| Primary Load Resisted | Shear (perpendicular to bolt axis) | Tension (axial pull) |

| Material | Hardened steel (high strength) | Corrosion-resistant materials |

| Design | Tapered, low-profile, tamper-resistant | Uniform diameter, standard threads |

| Torque Requirement | Lower torque to avoid stripping | Higher torque for preload |

| Reusability | Limited, often single-use | Reusable |

| Applications | Security-sensitive, infrastructure, automotive | Structural joints, maintenance-intensive |

Selecting the correct nut type and applying the appropriate torque based on nut design—rather than just load type—is essential for ensuring joint integrity, safety, and longevity.

Applications and Industry Use Cases

Typical Applications for Shear Nuts

Public Infrastructure

Shear nuts are frequently used in public infrastructure projects to enhance tamper resistance and security. They are commonly found in bridges, railings, and street furniture. Their design makes them extremely difficult to remove without causing visible damage, providing a strong deterrent against tampering and vandalism.

Automotive Assembly

In the automotive industry, shear nuts are used in components like suspension systems and engine mounts to ensure parts remain securely fastened under stress. Their robust construction guarantees that critical components stay intact even under the high demands of vehicle operation.

Industrial Machinery

Industrial machinery often operates under conditions that generate significant shear forces. Shear nuts are ideal for securing parts in these environments due to their ability to resist lateral loads. They are used in heavy equipment and manufacturing machinery where stability and security are essential.

Marine Environments

Marine applications benefit from the durability and tamper-resistant properties of shear nuts. These nuts are used in docks, piers, and boats, where exposure to harsh conditions and potential tampering are concerns. The high shear strength ensures the integrity of fastened joints even in corrosive environments.

Typical Applications for Tension Nuts

Structural Bolting

Tension nuts are crucial in structural bolting applications to maintain clamping pressure and resist axial loads. They are used in steel frameworks, bridges, and buildings, ensuring that joints remain secure and structurally sound.

Manufacturing

In manufacturing settings, tension nuts are essential for machinery and equipment that require precise bolt tensioning. Their design allows for easy removal and adjustment, facilitating regular maintenance and ensuring efficient operation. Tension nuts are particularly useful in high-temperature environments where material stability under tensile loads is critical.

Engineering Projects

Engineering projects often involve complex assemblies that demand reliable fasteners capable of maintaining clamping force. Tension nuts provide consistent tensioning, ensuring the safety and stability of structures. Their corrosion-resistant materials make them suitable for various environmental conditions.

High-Temperature Systems

Applications involving high temperatures, such as exhaust systems and industrial boilers, require fasteners that can withstand thermal expansion and contraction. Tension nuts are ideal for these environments because they maintain clamping pressure under fluctuating temperatures. Their corrosion-resistant properties also prevent degradation over time.

Security and Tamper Resistance Considerations

Shear Nuts

Shear nuts offer excellent security features due to their tamper-resistant design. Once installed, they are extremely difficult to remove without destroying them, making them ideal for high-security applications. Their use in public infrastructure, automotive components, and other secure systems ensures that fastened joints remain tamper-evident.

Tension Nuts

While tension nuts are not inherently tamper-resistant like shear nuts, their ease of removal and adjustment makes them suitable for applications requiring frequent maintenance. They are used in environments where precise tensioning and regular adjustments are necessary, such as construction and engineering projects. Their corrosion-resistant materials contribute to their longevity and reliability in various settings.

Real-World Case Studies

Automotive Industry

In the automotive industry, shear nuts are commonly used in suspension systems and engine mounts. These components are subject to significant lateral forces due to the dynamic nature of vehicle operation. Shear nuts provide the necessary resistance to these forces, ensuring that critical parts remain securely fastened. For instance, in high-performance vehicles, the suspension system experiences extreme shear loads during rapid acceleration and deceleration. The tamper-resistant design of shear nuts also enhances security by preventing unauthorized removal or tampering with essential components.

Conversely, tension nuts are typically employed in areas where maintaining a consistent clamping force is crucial. For example, in the assembly of automotive frames, tension nuts ensure structural integrity under tensile loads. Their ability to withstand axial forces makes them ideal for securing parts that require precise tensioning, such as engine block assemblies where bolts must remain tight to prevent leaks and ensure optimal performance.

Public Infrastructure

In public infrastructure, shear nuts are often used in the construction of bridges and rail systems. These structures are subject to constant vibration and lateral forces, particularly from traffic and environmental conditions, making shear nuts ideal for resisting these loads and ensuring safety and stability. Additionally, their tamper-resistant design helps prevent vandalism and unauthorized removal, which is critical for maintaining public safety.

While less common in shear-dominated environments, tension nuts play a crucial role in applications where axial loads are prevalent. For instance, in pre-stressed concrete anchors used in large infrastructure projects, tension nuts maintain the necessary clamping force to ensure structural components remain in place. This application highlights the importance of precise preload torque to achieve uniform clamping pressure, which is vital for the long-term durability and stability of the structure.

Aerospace Industry

In the aerospace sector, tension nuts are mainly used because they can keep a consistent axial preload. Aircraft engines require bolted joints that can withstand thermal cycling and vibration. Tension nuts are used to secure these joints, ensuring that the clamp load remains consistent even under extreme conditions. The precise torque-to-yield methods employed in aerospace applications help achieve the necessary preload, although variability in friction can pose challenges.

Shear nuts, on the other hand, are limited to non-critical components within the aerospace industry. Their lower tensile strength and single-use nature make them less suitable for primary structural applications. However, they are still valuable in areas where lateral forces are significant but not critical to the overall structural integrity, such as certain interior fittings and secondary assemblies.

Industrial Machinery

In industrial machinery, shear nuts are favored in high-vibration environments. Equipment such as crushers and presses generate significant lateral forces that can cause bolts to shear if not properly secured. Shear nuts are used to secure these components, offering enhanced resistance to shear loads and reducing maintenance costs. Case studies have shown that using shear nuts in conveyor systems leads to fewer instances of bolt failure and decreased downtime.

Tension nuts are essential for applications where uniform sealing pressure is critical, such as flanged pipe connections in chemical plants. These environments often involve high temperatures and pressures, requiring fasteners that can maintain consistent clamping force. Tension nuts made from creep-resistant alloys like A286 or Inconel are used to prevent leaks and ensure the reliability of the connections under thermal stress.

Lessons from Failure Analysis

Failure analysis of shear nuts often reveals that inadequate thread engagement or improper installation torque are common causes of failure. Ensuring adequate thread engagement and following the recommended torque specifications can help prevent these issues. For tension nuts, failures are frequently due to inaccurate preload calculations or inconsistencies in lubrication during tightening. Employing finite element analysis (FEA) and experimental testing can help optimize custom nut designs, particularly when dealing with exotic materials and critical applications.

Understanding the distinct advantages and limitations of shear and tension nuts allows engineers to select the appropriate fastener type for specific industrial needs, ensuring both safety and performance.

Advantages and Disadvantages

Advantages

Shear Nuts

Security

Shear nuts are extremely difficult to remove once installed, making them a strong deterrent against tampering. This feature is particularly beneficial in security-critical applications where unauthorized removal must be prevented.

Load Resistance

Shear nuts are designed to withstand lateral forces perpendicular to the fastener’s axis, making them highly effective in applications dominated by shear forces. This ensures the joint remains secure under such stresses.

Durability

Made from hardened steel, shear nuts offer exceptional strength and longevity under shear stress. This material choice ensures they can endure high lateral loads without failing.

Cost

Shear nuts provide a cost-effective solution for applications where shear resistance and security are priorities. Their specialized design and material make them a reliable choice without significantly increasing costs.

Tension Nuts

Ease of Removal and Adjustment

Tension nuts are designed for easy installation and removal, making them suitable for applications that require regular maintenance and inspection. This feature is particularly beneficial in environments where components need to be frequently adjusted or replaced.

Load Resistance

Optimized for tensile loads, tension nuts provide high preload and clamping force. This ensures the joint maintains its integrity under tension, which is crucial for many structural applications.

Durability

Often made from corrosion-resistant materials such as stainless steel, tension nuts are suitable for use in harsh environments where durability and longevity are essential.

Versatility

Due to their design and material properties, tension nuts are versatile and can be used in a wide range of applications, from heavy industry to construction projects.

Disadvantages

Shear Nuts

Reusability

Shear nuts have limited or no reusability. Once installed, they are typically destroyed upon removal, making them a single-use fastener. This limits their application in environments where components need to be frequently adjusted or replaced.

Tensile Strength

Shear nuts have fewer threads engaged with the bolt, resulting in lower tensile strength. This makes them unsuitable for applications where axial forces are significant.

Maintenance

The tamper-resistant design of shear nuts makes them difficult to remove and replace, which is a disadvantage in applications requiring regular maintenance or inspection.

Application Limitation

Shear nuts are best used in environments where shear forces are predominant and security is a priority. They are less effective in applications where tensile forces are significant or where easy adjustability is required.

Tension Nuts

Tamper Resistance

Tension nuts are not designed to be tamper-resistant, making them less suitable for security-critical applications where unauthorized removal needs to be prevented.

Potential for Loosening

Without proper maintenance, tension nuts can loosen over time, especially in environments with constant vibration. This necessitates regular checking and retightening to ensure joint integrity.

Maintenance Requirements

Tension nuts need periodic checking and tightening to maintain their clamping force. This adds to the maintenance requirements of the application, especially in high-stress environments.

Cost Consideration

The use of corrosion-resistant materials and the need for precise installation can make tension nuts more expensive, which is important to consider in cost-sensitive projects.

Selection Criteria

Key Mechanical Differences

When selecting between shear nuts and tension nuts, it is crucial to understand the mechanical differences that influence their performance under various loads.

Shear Strength vs. Tensile Strength

- Shear Nuts: Designed to resist shear forces that act perpendicular to the fastener’s axis, shear nuts prevent parts from sliding relative to each other. These forces commonly occur in applications that require lateral stability.

- Tension Nuts: Designed to withstand axial tensile forces, tension nuts keep connected parts securely clamped together. This is essential for maintaining structural integrity under axial loads.

Design and Material Considerations

The design and material composition of shear and tension nuts significantly impact their functionality and suitability for specific applications.

Shear Nuts

- Material: Typically made from hardened steel to maximize shear strength and durability.

- Design: Feature a larger diameter at the bottom and a smaller top, making them difficult to remove once tightened. This design enhances tamper resistance but limits reusability.

Tension Nuts

- Material: Often constructed from corrosion-resistant materials like stainless steel, which provide durability and ease of maintenance.

- Design: Their uniform diameter makes removal and adjustment easy, ideal for applications needing frequent maintenance.

Functional Performance

The functional performance of shear and tension nuts differs based on the type of load they are designed to resist.

Shear Nuts

- Functionality: Primarily resist lateral forces, providing high tamper resistance and security. Commonly used in public infrastructure, automotive, and industrial applications where permanent fastening is necessary.

- Performance: Cost-effective and durable with limited reusability and reduced tensile strength compared to tension nuts.

Tension Nuts

- Functionality: Designed to resist tensile forces and maintain clamping pressure. Essential for applications requiring precise bolt tensioning, such as in heavy industry and construction.

- Performance: Allow for easy removal and adjustment, making them suitable for environments requiring regular maintenance. However, they lack the tamper resistance of shear nuts.

Specific Use Cases

Selecting the appropriate nut type depends on the specific requirements of the application.

Shear Nuts

- Applications: Public infrastructure, automotive components, electrical equipment, and industrial machinery where tamper resistance and security are critical.

- Advantages: High shear strength and tamper resistance.

- Disadvantages: Limited reusability and reduced tensile strength.

Tension Nuts

- Applications: Heavy industry, construction projects, and high-temperature environments where precise tensioning and maintenance are necessary.

- Advantages: High tensile strength, corrosion resistance, and ease of maintenance.

- Disadvantages: Less tamper resistance compared to shear nuts.

Practical Selection Criteria

When choosing between shear nuts and tension nuts, consider the following aspects:

- Load Type: Identify if the main forces acting on the joint are shear or tensile.

- Material Requirements: Assess the need for corrosion resistance or maximum shear strength.

- Security Needs: Evaluate the importance of tamper resistance.

- Maintenance Frequency: Consider the necessity for frequent adjustments or maintenance.

- Application Environment: Match the nut type to the environmental conditions and specific application requirements.

| Aspect | Shear Nut | Tension Nut |

|---|---|---|

| Primary Load Resistance | Shear forces (perpendicular) | Tensile forces (axial) |

| Material | Hardened steel (high strength) | Corrosion-resistant (stainless steel) |

| Design | Tapered, non-removable | Uniform diameter, removable |

| Security & Tamper Resistance | High; used where tamper evidence needed | Low; designed for adjustability |

| Reusability | Limited | High |

| Typical Applications | Public infrastructure, automotive, electrical equipment, industrial machinery, marine, high-security areas | Heavy industry, construction, bolted connections requiring regular maintenance, high-temperature environments |

| Clamping Capability | Moderate (reduced tensile strength) | High (precise preload control) |

Understanding these criteria ensures that the correct nut type is selected, optimizing joint integrity and longevity based on the specific demands of the application.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is the difference between a shear nut and a tension nut?

The primary difference between a shear nut and a tension nut lies in their design and functional priorities.

A shear nut is designed to resist forces perpendicular to the fastener’s axis, known as shear loads. This type of nut often features tamper-resistant characteristics, such as reduced thread count and low-profile shapes, making it suitable for applications where security is a concern, such as public infrastructure and high-security systems. The fewer threads reduce its tensile strength but enhance its shear performance.

On the other hand, a tension nut is optimized to withstand axial forces, known as tensile loads. It maintains clamping pressure in bolted joints and typically includes features like uniform diameter and self-locking variants to prevent loosening under vibration. Tension nuts are used in applications requiring high load capacity and durability, such as structural bolting and heavy industry.

In what applications should I use a shear nut versus a tension nut?

Shear nuts and tension nuts serve different purposes based on the type of load and application requirements.

Shear nuts are designed for security and tamper resistance. They are typically used in situations where preventing unauthorized removal is crucial. Common applications include securing public infrastructure like street signs and park benches, automotive components that must remain fixed under vibration, and industrial equipment where tamper-proofing is essential. These nuts have a hexagonal head that shears off upon reaching a specified torque, leaving a smooth, conical base that is difficult to remove without specialized tools.

In contrast, tension nuts are designed to handle tensile loads, providing strong, reusable fastening where maintaining clamping force is necessary. They are ideal for structural applications such as building frameworks, bridges, and heavy machinery, as well as mechanical and aerospace assemblies. Unlike shear nuts, tension nuts can be tightened and loosened multiple times without damage, making them suitable for situations where disassembly and maintenance are expected.

Why do shear nuts have less tensile strength than tension nuts?

Shear nuts have less tensile strength than tension nuts primarily due to their design and intended functional application. Shear nuts are designed to resist shear forces, which are loads applied perpendicular to the bolt axis, causing parts to slide sideways relative to each other. This design necessitates a thinner nut with fewer threads engaging the bolt, reducing the area available to withstand axial loads, thereby lowering their tensile strength.

In contrast, tension nuts are designed to maximize tensile strength and clamp load, which hold joint members tightly together against axial forces pulling them apart. They feature a thicker body and more threads engaging the bolt, allowing them to sustain higher axial loads and be torqued to higher values without stripping. The increased thread engagement and larger body of tension nuts enable a higher tensile capacity, making them suitable for applications where strong axial clamping force is critical.

How does torque differ between shear nuts and tension nuts during installation?

The torque applied during the installation of shear nuts and tension nuts differs due to their distinct designs and applications. Shear nuts are designed to resist shear forces and provide tamper resistance. They typically require lower torque values during installation because they often engage fewer threads with the bolt, reducing the twisting force needed to secure them. The primary focus for shear nuts is on resisting lateral forces rather than achieving high tensile strength.

In contrast, tension nuts are designed to maintain clamping pressure and are suitable for applications requiring precise bolt tensioning. These nuts generally require higher torque values to ensure the necessary clamping force, which stretches the bolt axially without additional torsional stress. This higher torque is crucial for maintaining structural integrity in applications subjected to tensile loads.

Are shear nuts reusable and how does their tamper resistance compare to tension nuts?

Shear nuts are non-reusable. They are designed for one-time use, where the hexagonal end breaks off upon tightening, leaving the nut securely fastened and difficult to remove. This breakaway feature makes them ideal for permanent security applications, as any attempt to tamper with them will be evident and likely result in damage.

In contrast, tension nuts are reusable. They can be installed and removed multiple times using a specialized tool, making them suitable for applications where the fastener may need to be accessed and reinstalled periodically. While tension nuts provide high security by requiring a specific tool for removal, they do not offer the same level of tamper resistance as shear nuts since they can be intentionally removed without damage.

What are the selection criteria for choosing between shear nuts and tension nuts in industrial applications?

When choosing between shear nuts and tension nuts for industrial applications, the selection criteria primarily depend on the type of load the joint will encounter, security needs, maintenance considerations, and mechanical properties required. Shear nuts are designed to resist shear forces, which act perpendicular to the bolt axis and can cause components to slide relative to each other. These nuts are suitable for applications where the bolt is loaded mainly in shear, such as in structural applications. They offer high tamper resistance but are typically single-use due to their design, which shears off upon installation.

On the other hand, tension nuts are intended to maintain clamping pressure and resist tensile forces acting parallel to the bolt axis. They are used in applications requiring precise bolt tensioning and high tensile strength, such as in construction, heavy industry, and environments where frequent adjustments are necessary. Tension nuts are more versatile and easier to remove or adjust, making them suitable for maintenance-heavy applications.