When it comes to connecting pipes in industrial systems, the choice of flange can significantly impact both performance and cost. Slip-on flanges and raised face flanges are two of the most commonly used types, each with its unique set of advantages and applications. But how do they really compare? What are the fundamental differences in their design, material options, and pressure ratings? Moreover, which type is best suited for high-pressure environments, and how do the costs stack up? In this article, we’ll delve into these questions, offering a comprehensive comparison to help you make an informed decision. So, whether you’re an engineer, a procurement specialist, or simply curious about flange types, read on to discover which flange fits your needs best.

Introduction to Slip-On and Raised Face Flanges

Definition and Overview of Slip-On Flanges

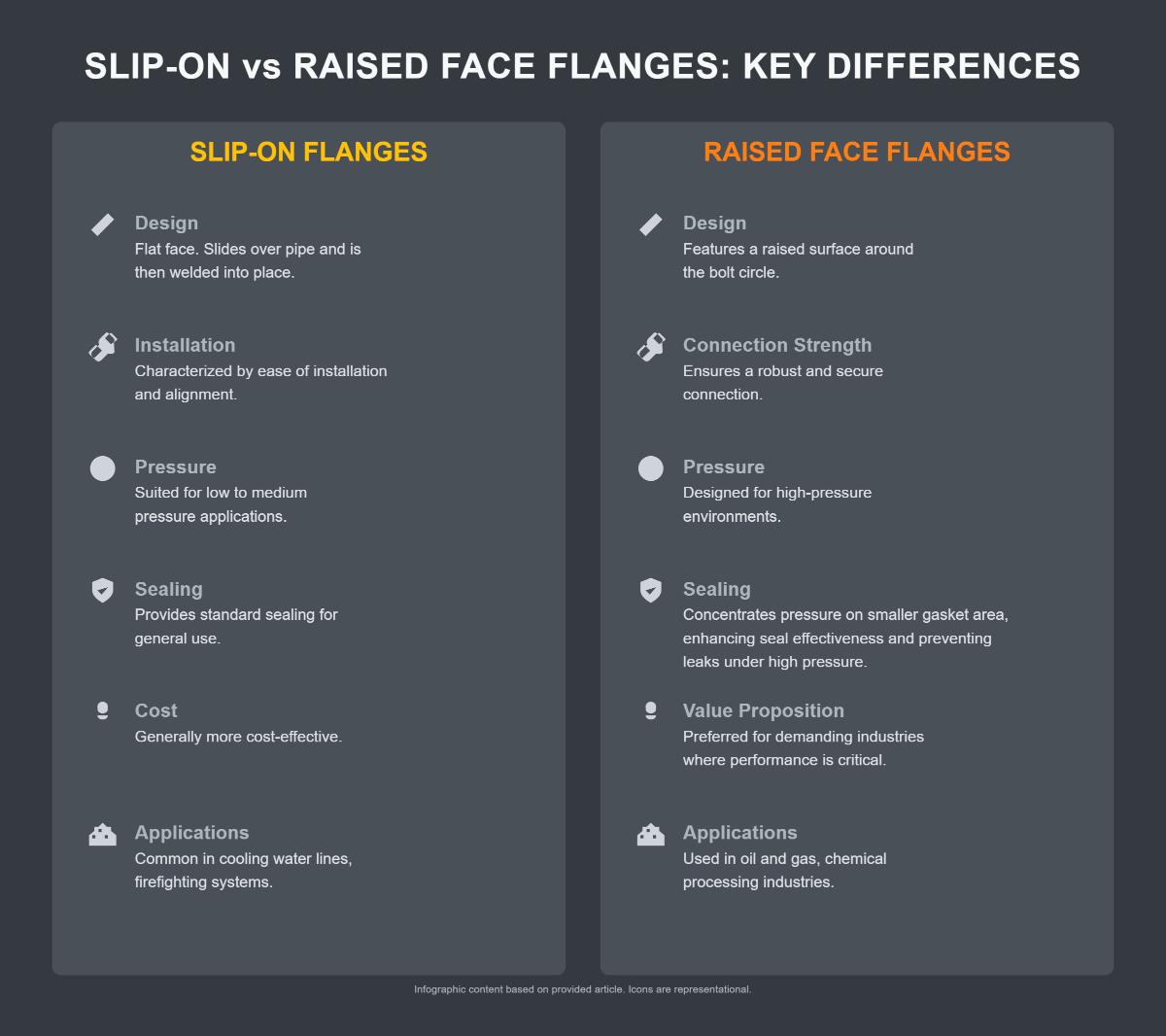

Slip-On Flanges are widely used in industrial piping systems due to their ease of installation and cost-effectiveness. These flanges are designed to slide over the end of a pipe, allowing for straightforward alignment and welding. Typically used in low to medium-pressure environments like cooling water lines and low-pressure compressed air systems, Slip-On Flanges have a flat face that, once welded, provides a secure connection. However, their flat sealing surface means they offer only moderate sealing capabilities, making them less effective for high-pressure applications.

Definition and Overview of Raised Face Flanges

In contrast, Raised Face Flanges are designed to offer superior sealing performance, particularly in high-pressure and high-temperature environments. They feature a distinctive raised area around the bolt circle, where the gasket is positioned. This raised surface concentrates pressure on the gasket, enhancing the seal’s integrity and reducing the likelihood of leaks. As a result, Raised Face Flanges are preferred in critical applications such as oil and gas pipelines, chemical processing plants, and power generation facilities. The construction of these flanges is robust, offering enhanced durability against erosion and corrosion, making them suitable for harsh and demanding conditions.

Comparative Analysis of Slip-On and Raised Face Flanges

When comparing Slip-On Flanges to Raised Face Flanges, several key differences emerge:

- Design and Installation: Slip-On Flanges are designed for ease of installation, sliding over the pipe and requiring less precise alignment, which can save time and labor costs. Raised Face Flanges, however, necessitate more meticulous alignment to ensure the gasket is correctly positioned, which can increase installation time.

- Sealing Performance: While the flat face of Slip-On Flanges limits their sealing capability, making them less ideal for high-pressure applications, Raised Face Flanges provide superior sealing with their focused gasket pressure, making them suitable for high-pressure and high-temperature environments.

- Cost Considerations: Generally, Slip-On Flanges are more cost-effective in terms of initial purchase price and installation. Raised Face Flanges, while more expensive, offer long-term reliability and leak prevention, which can justify the higher initial cost in critical applications.

- Application Suitability: Slip-On Flanges are best suited for low-pressure systems where ease of installation and cost are primary concerns. In contrast, Raised Face Flanges are selected for applications where high-pressure resistance and leak prevention are critical.

In choosing between these two types of flanges, it’s essential to consider the specific requirements of the piping system, including pressure, temperature, and environmental conditions. Each flange type has its strengths and limitations, and the decision should align with the operational demands of the application.

Comparison of Flange Designs and Materials

Slip-On Flanges and Raised Face Flanges have unique features that make them suitable for different applications.

Slip-On Flanges

Slip-On Flanges are engineered to slide over the pipe, offering a straightforward installation process. They have a flat face, making them easier to align and weld both internally and externally, which is particularly beneficial for systems requiring rapid assembly and where installation costs are a primary concern. Slip-On Flanges are typically utilized in low to medium-pressure environments, where the demands for sealing are moderate.

Raised Face Flanges

Raised Face Flanges feature a distinctive elevated surface beyond the bolt circle, which concentrates the pressure on a smaller gasket area. This design improves the seal, making them ideal for high-pressure and high-temperature applications. Industries such as oil and gas, chemical processing, and power generation often prefer Raised Face Flanges due to their superior performance in demanding conditions.

Material Options

The material choice for flanges affects their durability, resistance to corrosion, and ability to handle various pressures and temperatures.

Carbon Steel

Carbon steel is widely used for its strength and cost-effectiveness, making it suitable for high-yield applications. It provides a robust and durable option for environments where high mechanical stress is expected but where corrosion resistance is less critical.

Stainless Steel

Stainless steel flanges are chosen for their high durability and excellent corrosion resistance. This material is optimal for applications in corrosive environments or where hygiene is a concern, such as in food processing or pharmaceutical industries.

Alloy Steel

Alloy steel flanges contain higher chrome and molybdenum content, enhancing their corrosion resistance and high-temperature service capability. These flanges are suitable for applications where both high mechanical strength and resistance to harsh conditions are required.

Pressure Ratings and Standards Compliance

Flange pressure ratings and standards compliance are essential considerations for ensuring safety and reliability in piping systems.

Pressure Ratings

Slip-On Flanges are generally rated for lower pressures compared to Raised Face Flanges, which are designed to handle higher pressure environments due to their enhanced sealing capabilities. Understanding these ratings is crucial for selecting the appropriate flange for specific system requirements.

Standards Compliance

Both Slip-On and Raised Face Flanges must meet standards from organizations like ASME, ANSI, and DIN. These standards ensure that flanges meet specific dimensional and material criteria, which is vital for compatibility and performance across different industrial applications.

Application Scenarios for Each Flange Type

Best Uses for Slip-On Flanges in Piping Systems

Slip-On Flanges are especially useful when easy installation and cost savings are important. They are designed to slide over the pipe and are typically welded both internally and externally, ensuring a secure attachment. These flanges are ideal for low-pressure environments where the demands for robust sealing are minimal. They are commonly used in cooling water lines, low-pressure compressed air systems, and fire protection piping systems.

Because they are cheaper and easier to install, Slip-On Flanges are often chosen for budget-conscious projects. Industries that benefit from this include water treatment facilities, HVAC systems, and general household piping. These flanges are also suitable for systems with straightforward pipe runs, where the alignment and welding process can be completed quickly and efficiently. This includes industrial plants with extensive piping networks, temporary piping systems in construction projects, and agricultural irrigation systems.

Ideal Applications for Raised Face Flanges

Raised Face Flanges are designed to provide superior sealing performance, especially in high-pressure and high-temperature environments. Their raised face design concentrates pressure on the gasket, enhancing the seal’s integrity. Raised Face Flanges are ideal for systems that need to handle high pressures and temperatures. These environments include oil and gas pipelines, chemical processing plants, and power generation facilities.

In systems where leak prevention is critical, the enhanced sealing capability of Raised Face Flanges is indispensable. Applications requiring robust seals include aggressive chemical environments, steam systems, and high-temperature boiler connections. Raised Face Flanges are highly beneficial for industries that require long-lasting and reliable piping systems. They are often used in offshore oil rigs, high-pressure steam lines, and critical infrastructure projects.

Low-Pressure vs. High-Pressure Environments

Understanding the pressure requirements of a piping system is crucial in selecting the appropriate flange type.

Slip-On Flanges excel in low-pressure settings due to their simplicity and cost-effectiveness. They are sufficient for applications where the pressure does not exceed moderate levels, and the sealing requirements are not stringent.

Raised Face Flanges are the go-to option for high-pressure environments where the risk of leaks must be minimized. Their design ensures a tight seal under extreme conditions, making them suitable for applications involving high-pressure steam, oil, and chemicals.

Installation and Maintenance Considerations

Installation Considerations

Slip-On Flanges

Slip-on flanges are popular for their easy installation, which makes them cost-effective. These flanges are designed to slide over the pipe, allowing for straightforward alignment. This simplicity is particularly beneficial in projects where time and budget constraints are significant factors. Installation involves welding the flange inside and out to secure it to the pipe. This process is generally quicker and requires less precision compared to other flange types, making slip-on flanges an ideal choice for systems where rapid assembly is necessary.

Raised Face Flanges

The installation of raised face flanges is more complex due to their design, which requires precise alignment to ensure an effective seal. The raised face design enhances sealing but requires careful gasket positioning. This level of precision can extend installation time and increase labor costs. However, the enhanced sealing capability provided by the raised face is crucial for applications involving high pressure and temperature, where leak prevention is critical. As such, while installation may be more time-consuming, the long-term benefits in demanding environments often justify the effort.

Maintenance Considerations

Slip-On Flanges

Slip-on flanges require less maintenance due to their simple design. These flanges are well-suited for lower pressure systems, which typically require less stringent maintenance practices. The flat face design of slip-on flanges means that they are less prone to issues like gasket erosion, reducing the frequency of maintenance checks needed. This makes them a practical choice for non-critical systems where operational continuity is a priority.

Raised Face Flanges

In contrast, raised face flanges require more meticulous maintenance to maintain seal integrity. The elevated gasket surface, while offering superior sealing, is more susceptible to erosion and corrosion, particularly in harsh environments. Regular inspections and maintenance are necessary to ensure that the sealing surface remains in optimal condition. This proactive maintenance approach helps prevent leaks and extends the service life of the flange, especially in high-pressure and high-temperature applications where reliability is paramount.

Key Differences in Installation and Maintenance

- Installation Complexity: Slip-on flanges are easier and quicker to install, making them suitable for projects with tight timelines. Raised face flanges, however, require precise alignment, which can complicate installation but provides a better seal for high-stress applications.

- Maintenance Frequency: Slip-on flanges generally need less frequent maintenance due to their simple design. Raised face flanges demand regular maintenance checks to ensure the gasket remains effective, particularly in critical systems.

Cost Analysis and Real-World Applications

Understanding the cost differences between slip-on and raised face flanges is crucial for making informed decisions in piping system projects.

Initial Costs

Slip-On Flanges are generally more affordable upfront due to their simpler design and manufacturing processes, and straightforward installation further reduces initial expenses, making them a preferred choice for budget-conscious projects. In contrast, Raised Face Flanges require a higher initial investment because they need precise machining and superior materials to withstand high-pressure environments. This upfront cost is offset by their performance in demanding applications, where reliability is paramount.

Long-Term Cost Considerations

While initially cheaper, slip-on flanges might lead to increased maintenance costs over time, particularly in applications that exceed their pressure ratings. Frequent replacements can also add to long-term expenses if used in inappropriate settings. Despite higher initial costs, raised face flanges tend to be more cost-effective over time due to their durability and reduced need for maintenance. In high-pressure environments, their better sealing abilities prevent leaks, minimizing downtime and associated costs.

Real-World Applications

Looking at real-world applications of these flanges helps us understand their practical uses and benefits.

Slip-On Flanges

Slip-on flanges are widely used in low-pressure environments where ease of installation and maintenance are crucial. They are commonly found in water treatment facilities for low-pressure piping systems, in plumbing systems that require frequent modifications or expansions, and in HVAC systems with moderate pressure requirements.

Raised Face Flanges

Raised face flanges excel in high-pressure scenarios where a robust seal is essential. Common applications include oil and gas pipelines, where their design ensures safety and reliability in high-pressure transport systems. They are also used in chemical processing plants, where effective sealing is critical to prevent leaks in aggressive chemical environments. Additionally, raised face flanges are utilized in power generation facilities, particularly in high-temperature steam lines, offering long-term reliability and performance.

When choosing between slip-on and raised face flanges, it’s important to consider several factors to ensure the best performance for your application.

Design and Construction

Slip-on flanges are designed to slide over the pipe, making them easier to install and align, which is particularly advantageous in low to moderate-pressure systems. This feature is especially beneficial when installation speed and cost-effectiveness are priorities. Raised face flanges, however, feature a raised surface around the bore that enhances the sealing capability by concentrating pressure on the gasket. This design is crucial for applications requiring robust sealing under high-pressure and high-temperature conditions.

Pressure and Temperature Ratings

Slip-on flanges are generally suitable for lower pressure applications, often used in systems like water treatment and HVAC. These applications typically operate at lower pressures, making slip-on flanges an ideal choice. Raised face flanges, on the other hand, are engineered for high-pressure and high-temperature environments, making them essential for critical systems in industries such as oil and gas, chemical processing, and power generation.

Installation and Maintenance

Slip-on flanges are easier and quicker to install due to their design, which does not require precise alignment of the pipe ends. This ease of installation reduces labor costs and time, making them popular for systems that need rapid assembly. Raised face flanges, while offering superior sealing capabilities, require careful alignment and regular inspections to maintain their integrity. The installation process for raised face flanges is more complex, often necessitating specialized tools and techniques to ensure a proper seal, especially in high-pressure environments.

Choosing the right flange depends on understanding the specific requirements of your application, including pressure, temperature, and system criticality. Slip-on flanges are cost-effective and easy to install for lower pressure systems, while raised face flanges offer robust sealing for high-pressure and high-temperature environments. Evaluating the operational conditions and material compatibility is crucial for ensuring optimal performance and safety in piping systems.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the key differences between slip-on and raised face flanges?

Slip-On Flanges and Raised Face Flanges are distinct in design, application, and performance. Slip-On Flanges feature a flat face and are designed to slide over the pipe and be welded in place, making them suitable for low to medium pressure applications due to their ease of installation and alignment. Raised Face Flanges, on the other hand, have a raised surface around the bolt circle, which concentrates sealing pressure on a smaller gasket area, enhancing the seal’s effectiveness in high-pressure environments. This design is advantageous in preventing leaks under high operational pressures.

Slip-On Flanges are typically more cost-effective and are used in applications such as cooling water lines and firefighting systems, whereas Raised Face Flanges are preferred in industries like oil and gas and chemical processing due to their superior sealing capabilities and ability to withstand high pressures and temperatures.

Which type of flange is best suited for high-pressure applications?

For high-pressure applications, Raised Face Flanges are best suited due to their superior sealing capabilities and ability to withstand higher pressure ratings. Raised Face Flanges feature an elevated sealing surface that concentrates pressure on a smaller gasket area, enhancing the seal’s reliability, which is crucial in high-pressure systems to prevent leaks and ensure safety. These flanges are designed to accommodate pressure classes ranging from 150 to 2500 psi, making them ideal for demanding environments such as oil and gas pipelines, chemical processing facilities, and power generation plants. In contrast, Slip-On Flanges are more suitable for low to medium-pressure applications due to their easier installation and cost-effectiveness but do not offer the same level of pressure resistance as Raised Face Flanges.

What are the cost implications of using slip-on flanges versus raised face flanges?

When considering the cost implications of using slip-on flanges versus raised face flanges, it is essential to evaluate both initial and long-term expenses. Slip-on flanges are generally less expensive to manufacture due to their simpler design and reduced machining requirements. Their straightforward installation process, which involves sliding the flange over the pipe and welding it in place, also helps minimize labor costs and installation time, making them an economical choice for projects with tight budgets.

In contrast, raised face flanges have a more complex design that includes a raised surface, necessitating precise machining and increasing manufacturing costs. Installation of raised face flanges requires more precision to ensure proper alignment and sealing, which can elevate labor costs due to the need for skilled personnel and specialized equipment.

However, while slip-on flanges may offer initial cost savings, they can incur higher maintenance expenses over time, especially in high-pressure applications where frequent maintenance may be necessary. Raised face flanges, despite their higher initial cost, provide better sealing capabilities and durability, particularly in high-pressure and high-temperature environments. This reliability can lead to long-term cost savings by reducing the likelihood of costly repairs and downtime.

How do real-world applications influence the choice between slip-on and raised face flanges?

Real-world applications significantly influence the choice between slip-on and raised face flanges due to their distinct design features and performance under various conditions. Slip-on flanges are favored in low to medium-pressure systems, such as cooling water lines, firefighting systems, and compressed air lines, because of their ease of installation and cost-effectiveness. They slide over the pipe and require welding, making them suitable for projects with tight deadlines and limited budgets.

In contrast, raised face flanges are preferred in high-pressure and high-temperature environments, such as oil and gas pipelines, chemical processing plants, and power generation facilities. The raised face design concentrates pressure on a smaller gasket area, enhancing seal strength and durability. This makes them ideal for critical systems where robust sealing capabilities are essential.

Are there specific industries that prefer one type of flange over the other?

Yes, specific industries do prefer one type of flange over the other based on their unique operational needs. The oil and gas industry generally favors raised face flanges due to their superior sealing capabilities, which are essential for handling high-pressure and high-temperature conditions. Similarly, chemical processing plants also prefer raised face flanges for their excellent corrosion resistance and secure sealing under harsh conditions. On the other hand, slip-on flanges are commonly used in water treatment facilities because they are cost-effective and easier to install, suitable for low-pressure systems. Power generation facilities, including thermal and nuclear plants, typically use raised face flanges for their high-pressure steam and cooling water systems. Thus, the choice between slip-on and raised face flanges is driven by the specific requirements of the industry, such as pressure, temperature, and the need for reliable sealing.

What are the common maintenance practices for flanges?

Common maintenance practices for flanges, including both Slip-On and Raised Face types, are essential to ensure the reliability and safety of piping systems. Regular inspections are crucial; visual checks for wear, corrosion, leaks, and cracks should be supplemented with non-destructive testing methods like ultrasonic and magnetic particle tests. Periodic cleaning using solvent-based cleaners or mild detergents helps remove contaminants and corrosive substances, while avoiding harsh chemicals that could damage the flange surfaces.

Proper bolt tensioning is vital for maintaining flange integrity. Bolts should be tightened according to manufacturer specifications using calibrated torque wrenches to prevent leaks and ensure a secure connection. Gaskets must be inspected regularly and replaced as needed, with the gasket material chosen based on operational conditions such as temperature and fluid type.

Monitoring environmental conditions, including temperature and humidity, helps protect flange joints. If corrosion or damage is detected, appropriate repair techniques like onsite machining, welding, or applying protective coatings should be employed. For severe damage, flange replacement might be necessary.

Maintaining detailed records of all inspections, repairs, and replacements is essential for tracking the maintenance history and ensuring compliance with safety standards. These practices help extend the lifespan of flanges and prevent costly failures, ensuring the efficient and safe operation of piping systems.