The common rule for operating in various welding positions is to maintain the correct electrode angle, master the three actions of electrode movement, control the shape and temperature of the weld pool, ensure the metallurgical reactions in the weld metal are complete, thoroughly eliminate gases and impurities, and achieve good fusion with the base material.

The temperature of the weld pool is related to its shape and size. By carefully observing its changes and continuously adjusting the electrode angle and movement, the temperature of the weld pool can be controlled to ensure the quality of the welding.

1. Flat position welding

(1) Characteristics of flat position welding

The metal droplets from the electrode mainly transition to the weld pool by gravity, making it easy to maintain the shape and metal of the weld pool. When welding workpieces of the same thickness, the welding current in the flat position is higher than in other positions, resulting in higher welding productivity. Slag and weld metal can easily mix, especially during fillet welds, where slag can get ahead and form slag inclusions.

Incorrect welding parameters and operations can lead to defects such as incomplete penetration, undercut, or excessive reinforcement. During flat butt welding, if the welding parameters or sequence are improperly chosen, welding distortion can easily occur. When performing single-sided welding with double-sided formation, the first weld may result in uneven penetration and poor backside formation.

(2) Electrode angle in flat position

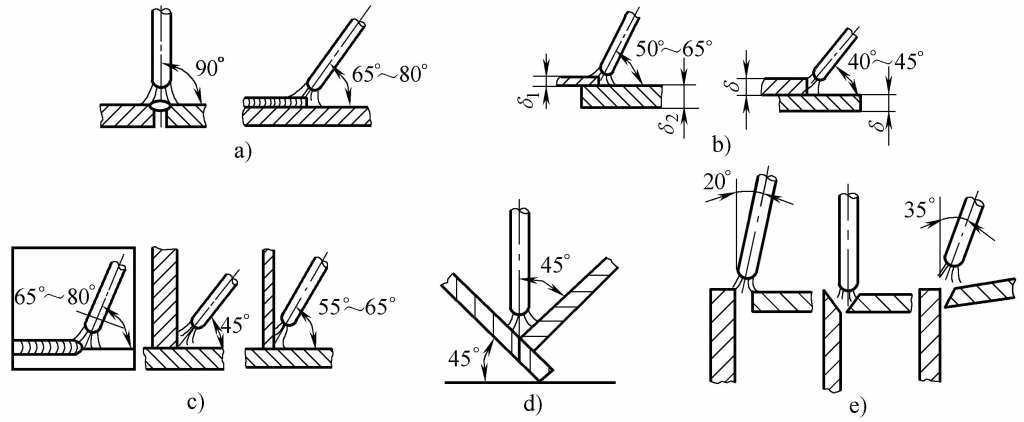

Flat position welding can be divided into butt joint flat welding, lap joint fillet welding, T-joint fillet welding, boat-shaped welding, and corner joint flat welding based on the form of the welding joint. The electrode angle for flat position welding is shown in Figure 5-26.

a) Butt joint flat welding

b) Lap joint fillet weld

c) T-joint fillet weld

d) Boat weld

e) Corner joint flat weld

(3) Key points of welding in the flat position

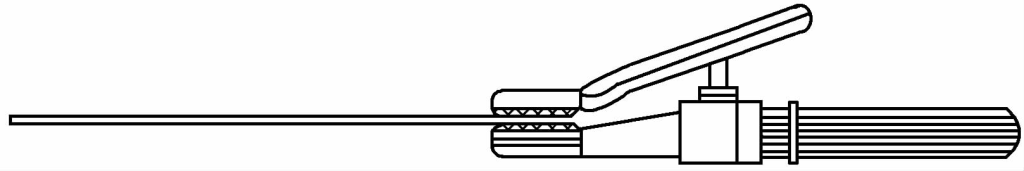

Place the workpiece in the flat welding position, the welder holds the welding tongs with the welding rod clamped on it, the face is protected by a face shield (helmet-style or hand-held), strike an arc on the workpiece, use the high temperature of the electric arc (6000~8000K) to melt the metal of the welding rod and the base metal, the melted parts of the metals fuse together to form a molten pool. After moving the welding rod away, the welding molten pool cools to form a weld seam, which firmly combines the two separate base materials together, achieving welding in the flat position.

1) Depending on the plate thickness, a thicker welding rod can be used, welded with a larger welding current. Under the same plate thickness conditions, the welding current in the flat position is greater than that in the vertical, horizontal, and overhead positions.

2) It is best to use short arc welding, which can reduce the heat loss of the high temperature arc and increase the depth of the molten pool. It prevents harmful gases around the arc from entering the molten pool, reducing the oxidation of the weld metal elements and the possibility of porosity in the weld.

3) During welding, the welding rod and the workpiece form a 40°~90° angle, control the separation of slag and molten metal well, and prevent the slag from leading.

4) When the plate thickness is ≤6mm, butt flat welding generally uses an I-shaped groove, and the front weld should use a short arc welding with a welding rod diameter of ф3.2~ф4mm, the depth of penetration should reach 2/3 of the thickness of the workpiece. Before back chipping weld, it is not necessary to remove the weld root (except for important components), but the slag must be cleaned up, and the welding current can be higher.

5) When there is a phenomenon of slag and molten pool metal not mixing clearly during butt flat welding, the arc can be lengthened, the welding rod tilted forward, and actions to push the slag towards the back of the molten pool can be taken to prevent slag inclusion.

6) When welding horizontal inclined seams, uphill welding should be used to prevent slag from flowing to the front of the molten pool and to avoid slag inclusion defects in the weld.

7) When using multi-layer and multi-pass welding, attention should be paid to selecting the number and sequence of weld passes.

8) For T-joint, corner joint, and lap joint fillet welds, if the thickness of the two plates is different, adjust the angle of the welding rod to bias the arc towards the thicker plate to ensure even heating of both plates.

(4) Correctly choose the method of moving the rod

1) For plate thickness <6mm, I-groove butt flat welding, using double-sided welding, the front weld should use a straight rod movement, slightly slow, the back weld should also use a straight rod movement, the welding current should be slightly higher than that used for the front weld, and the rod movement should be fast.

2) For plate thickness ≥6mm, according to design requirements, other types of grooves (V-shape, double V-shape, Y-shape, etc.) besides I-groove can be used for butt flat welding, and multi-layer welding or multi-layer multi-pass welding can be adopted.

The first layer (root pass) should use a small diameter welding rod, low welding current, straight or sawtooth rod movement for welding. For subsequent layers, larger diameter welding rods and higher welding currents with short arc welding can be used. Sawtooth rod movement must pause on both sides of the groove, and the welding direction of adjacent layers should be opposite, with staggered joints.

3) For T-joint fillet welds with a weld leg size <6mm, single-layer welding can be used with straight, oblique ring, or sawtooth rod movements; for larger weld leg sizes, multi-layer welding or multi-layer multi-pass welding should be used. Root pass always uses straight rod movement, subsequent layers can use oblique sawtooth or oblique ring rod movements. Multi-layer multi-pass welding should preferably use straight rod movement for welding.

4) For lap joint and corner joint fillet welds, the rod movement operation is similar to that of T-joint fillet welds.

5) The operation of ship-shaped welding is similar to flat butt welding with a groove.

2. Vertical welding position

(1) Characteristics of vertical welding position

In vertical welding, the molten metal and slag tend to separate due to gravity. When the pool temperature is too high, the molten metal tends to flow downwards, forming weld beads, undercut, and slag inclusion defects, making the weld seam uneven. The root of the T-joint weld is prone to incomplete penetration.

Penetration depth is easy to control, consumes more electrodes than flat welding, yet the productivity is lower than flat welding. As the heat from the arc in vertical angle welding is transferred in three directions to the workpiece, cooling is rapid. Therefore, under the same conditions as vertical butt welding, the welding current can be slightly higher to ensure good fusion of the two plates.

(2) Electrode angle in vertical welding position

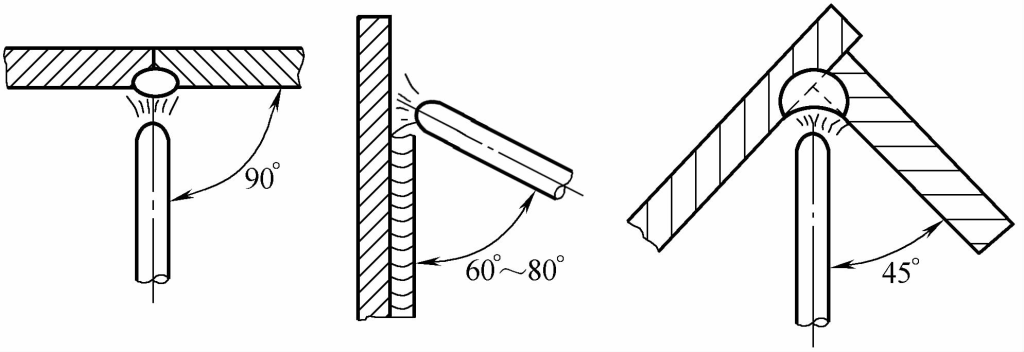

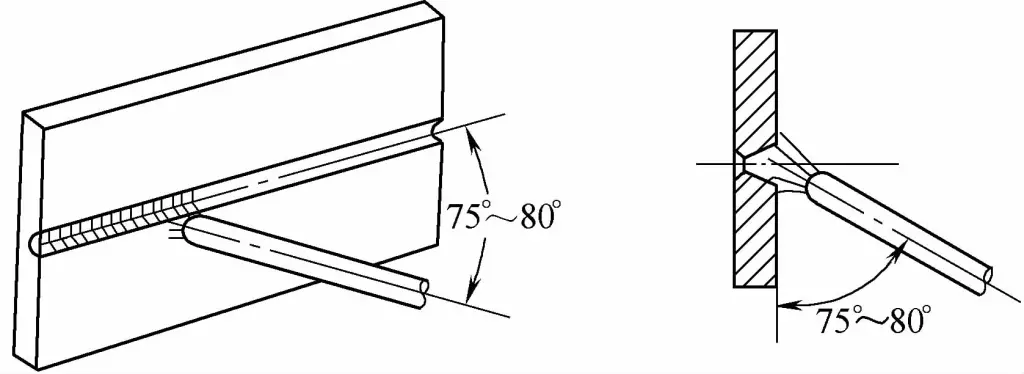

Vertical welding positions vary by the thickness of the workpiece, including thin plate butt vertical welding and thick plate butt vertical welding; by joint type, they can be divided into I-groove butt vertical welding and T-joint angle welding; by welding method, they can be divided into upward vertical welding and downward vertical welding. The electrode angle in vertical welding position is shown in Figure 5-27.

(3) Key points of vertical welding position

During vertical welding, after the electrode is clamped by the welding tongs, the tongs and the electrode should be in a straight line, as shown in Figure 5-28. The welder’s body should not face the weld directly, but should be slightly to the left or right (for left-handers), to facilitate the operation of the right hand (for left-handers) holding the welding tongs.

In production, vertical up welding is commonly used, and vertical down welding requires special electrodes to ensure weld quality. When vertical up welding, the welding current should be 10% to 15% less than that in flat welding, and a smaller electrode diameter (<4mm) should be used, maintaining the correct electrode angle. Use a short arc to reduce the distance from the droplet transition to the weld pool.

(4) Correct selection of electrode manipulation method

1) For vertical up welding of thin plate I-groove butt joints, the commonly used maximum arc length should be ≤6mm, and straight line, zigzag, crescent-shaped electrode manipulation or skip welding can be used.

2) For other forms of groove butt vertical welding, the first layer of weld is often done using skip welding or crescent-shaped, triangular electrode manipulation with small amplitude, and subsequent layers can use crescent-shaped or zigzag electrode manipulation methods.

3) For T-joint vertical welding, the electrode should have appropriate dwell time on both sides and the top corner of the weld, and the electrode swing amplitude should not exceed the width of the weld. The electrode manipulation operation is similar to that for other forms of groove butt welding.

4) When welding the cover layer, the electrode manipulation method should be selected based on the requirements for the weld surface. For slightly higher requirements on the weld surface, crescent-shaped electrode manipulation can be used, and if only a smooth weld surface is required, the zigzag method can be used.

3. Horizontal welding position

(1) Characteristics of horizontal welding position

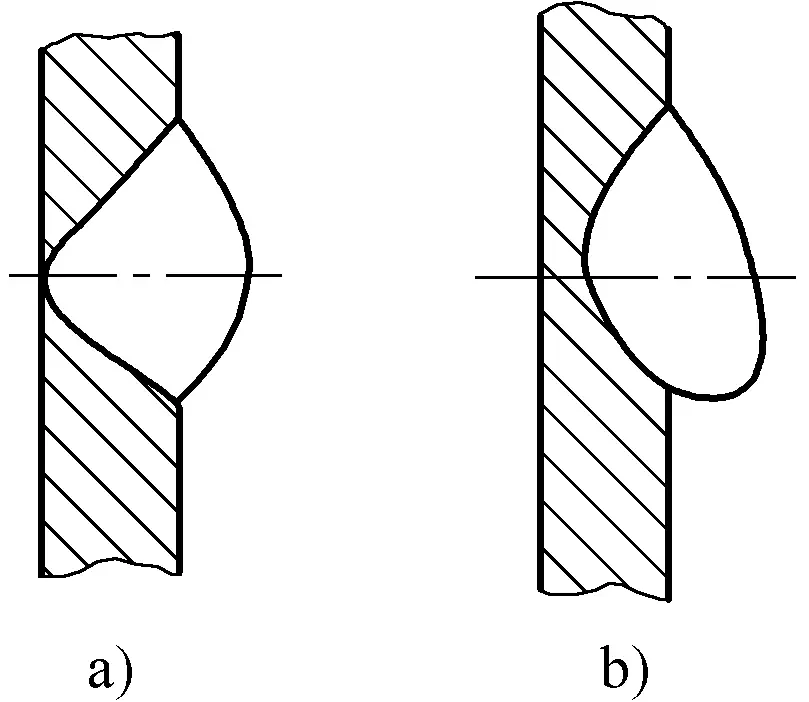

The molten metal tends to fall due to its own weight onto the groove, causing undercut defects on the upper side of the groove and forming a teardrop-shaped weld as shown in Figure 5-29b. The molten metal and slag are easy to separate.

a) Normal Horizontal Weld Seam

b) Teardrop-shaped Horizontal Weld Seam

(2) Electrode Angle in Horizontal Welding Position

During horizontal welding, it is best for the welder to operate while standing. If possible, the hand or arm holding the face shield is the best support to keep the welder’s body stable while standing and welding. The arc starting point should be directly in front of the welder.

During welding, after completing each electrode, the welder needs to move the standing position to always face the weld seam directly. The upper part of the welder’s body should move forward with the arc, but the eyes still need to maintain a certain distance from the welding arc. Also, pay attention to maintaining the angle between the electrode and the workpiece to prevent excessive dripping of molten metal. The electrode angle in the horizontal welding position is shown in Figure 5-30.

(3) Key Points of Horizontal Welding Position

1) For butt horizontal welding, generally use a V-shaped or K-shaped groove, and for butt joints with a plate thickness of 3~4mm, use an I-shaped groove for double-sided welding.

2) Use a small diameter electrode, the welding current should be smaller than in flat welding; short arc operation can better control the flow of molten metal.

3) When welding thick plates horizontally, it is advisable to use multi-layer and multi-pass welding methods for welds other than the root pass.

4) During multi-layer and multi-pass welding, special attention should be paid to the overlap distance between passes. Each pass should start at 1/3 of the previous weld to prevent unevenness in the weld.

5) Depending on the specific situation, maintain an appropriate electrode angle, and the welding speed should be slightly fast and even.

(4) Correct selection of electrode manipulation method

1) When performing horizontal butt welding with an I-groove, it is better to use a reciprocating straight line electrode manipulation method for the face weld, a straight line or slight helical form is suitable for slightly thicker pieces, and a straight line method for the back weld, with an appropriately increased welding current.

2) For butt welding with other types of grooves and multi-layer horizontal welding, a straight line electrode manipulation can be used when the gap is small; for root pass welding when the gap is large, a reciprocating straight line method should be used, and for subsequent layers in multi-layer welding, a helical form can be used, and a straight line method is advisable for multi-layer and multi-pass welding.

4. Welding in the overhead position

(1) Characteristics of welding in the overhead position

Due to gravity, molten metal tends to fall, making it difficult to control the shape and size of the weld pool. Electrode manipulation is challenging, and it is difficult to achieve a smooth surface on the weldment, leading to defects such as slag inclusion, incomplete penetration, concave weld beads, and poor weld formation. Flowing molten metal is prone to splatter and spread, and if not properly protected, it can easily cause burn accidents. Overhead welding is less efficient than welding in other spatial positions.

(2) Electrode angle in the overhead position

Depending on the distance from the welder to the workpiece, the welder can adopt standing, squatting, or sitting positions, and in some cases, a lying position, where the welder lies on the ground face up, holding the welding tongs overhead. When welding overhead, the labor intensity is high and the welding quality is unstable, usually used for emergency repairs, not suitable for mass manufacturing production.

During welding, the welder’s arms should be away from the body, the forearm erected, the upper arm and forearm naturally forming an angle for support, the center of gravity on the joint at the base of the upper arm or on the elbow, the movement of the welding rod should be accomplished by the wrist, the upper arm should gradually rise and move forward as the welding rod melts, the eyes should follow the movement of the arc to observe the welding, and the head and upper body should also tilt slightly forward as the welding rod moves.

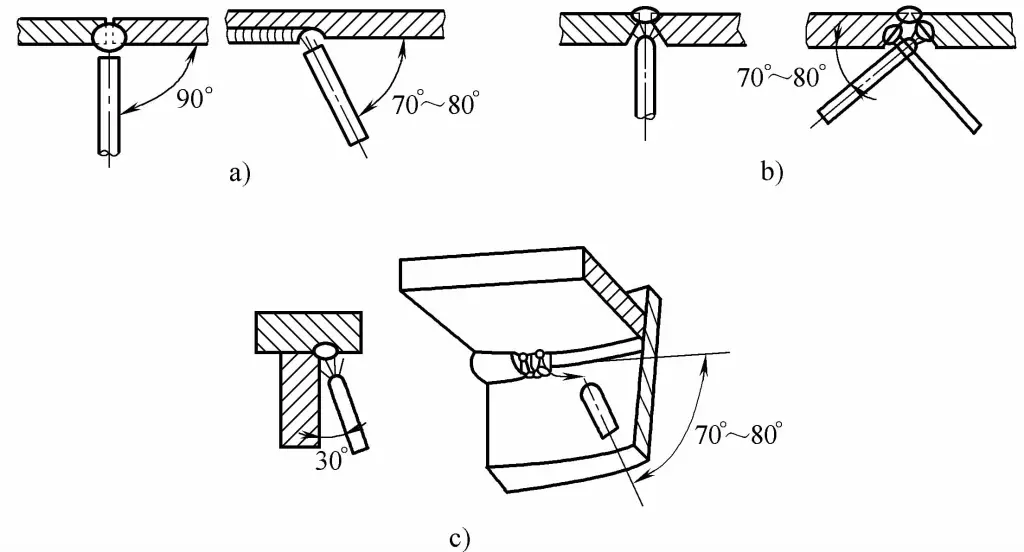

Before overhead welding, the welder must wear the necessary protective clothing for overhead welding, fasten the buttons, wrap a towel tightly around the neck, wear a shawl cap and heat-resistant shoes to prevent molten iron from falling and splashing metal from scalding the skin. The welder holds the welding tongs and changes the angle of the welding rod according to the specific situation, and can also flip the part to be welded to a flat or horizontal welding position. The angle of the welding rod in the overhead position is shown in Figure 5-31.

a) I-groove butt overhead welding

b) Other groove butt overhead welding

c) T-joint overhead angle welding

(3) Key points of welding in the overhead position

1) When the thickness of the workpiece is ≤4mm, I-groove butt welding is used for overhead welding with a 3.2mm diameter welding rod, and the welding current should be appropriate. When the thickness of the workpiece is ≥5mm, V-groove multi-layer multi-pass welding is used.

2) When the weld toe <8mm, T-joint weld overhead welding should use single-layer welding, and when the weld toe >8mm, use multi-layer multi-pass welding.

3) To facilitate droplet transition, reduce metal dripping and spattering during welding, the shortest possible arc length should be used.

4) For the root pass weld, use a small diameter electrode and low welding current to prevent undercut and slag inclusion on both sides of the weld.

(4) Correctly choose the electrode manipulation method

1) For small gaps, use a straight electrode manipulation for I-groove butt overhead welding; for larger gaps, use a straight back-and-forth electrode manipulation.

2) For other types of groove butt multi-layer overhead welding, the electrode manipulation method for the root pass should be chosen based on the size of the groove gap, using either a straight or a back-and-forth straight method. Subsequent layers can use a zigzag or crescent manipulation method. Multi-layer multi-pass welding should use a straight manipulation method, and regardless of the method used, each transition of molten metal to the pool should not be excessive.

3) For T-joint overhead welding, if the fillet size is small, a straight or back-and-forth straight electrode manipulation method can be used, completed by single-layer welding; if the fillet size is large, multi-layer or multi-pass welding can be used, with the first layer using a straight manipulation, and subsequent layers can use an oblique triangle or oblique ring manipulation method.