In the world of metalworking, welding techniques are pivotal in determining the strength and durability of a structure. But when it comes to spot welding versus tack welding, choosing the right method can make all the difference in the outcome of your project. While both techniques serve as vital components in joining metals, understanding their distinct processes, applications, and benefits is crucial for any intermediate enthusiast or professional in the field. Spot welding, known for its speed and efficiency in creating strong, permanent bonds, contrasts sharply with tack welding’s role as a temporary fixture meant to hold components in place until a more permanent solution is applied. Dive into this comparative analysis to unravel the key differences and discover which welding technique best suits your project’s needs. Are you ready to determine which welding method reigns supreme in your metalworking endeavors?

Understanding Spot Welding

Spot welding is a resistance welding technique commonly used to join thin sheets of metal. This process involves applying pressure and electrical current to metal surfaces at localized points, causing them to heat and fuse together. The welds are formed at the interface of the overlapping sheets where the current is concentrated. Known for its rapid execution, spot welding efficiently creates strong, permanent joints.

Spot welding is widely used in industries such as automotive for assembling car bodies, aerospace for constructing aircraft, electronics for fabricating enclosures, and appliances for building durable household items.

Spot welding offers high efficiency, producing multiple welds quickly, making it perfect for mass production environments. The resulting welds are typically very strong and durable, suitable for applications requiring long-lasting performance. Additionally, due to its high speed and minimal material usage, spot welding is a cost-effective method for joining metal sheets. It can be easily integrated into automated production lines, enhancing productivity and consistency in manufacturing processes.

However, there are limitations to consider:

- Best for thin metal sheets, usually up to 3 mm thick.

- Electrodes wear out over time, needing maintenance.

- Limited to accessible areas, unsuitable for complex shapes.

- Requires clean, prepared surfaces to ensure the welds are of high quality, as contaminants can affect the outcome.

Exploring Tack Welding

Definition and Process Overview

Tack welding is a technique used to temporarily join metal parts, acting as an initial step before the final welding process. It involves creating small, intermittent welds to hold parts in alignment, allowing for precise positioning and adjustments in complex structures. Tack welds are typically performed manually using standard welding equipment like MIG or TIG welders. They are designed to be easily removable, enabling adjustments in the assembly of complex structures.

Common Applications in Metalworking

Tack welding plays a crucial role in various metalworking applications. It is commonly employed in the fabrication of large assemblies, such as pipelines and structural frameworks, where precise alignment is essential. Tack welding is invaluable during testing designs, facilitating the checking of joint fit-up and design feasibility without committing to permanent welds. Moreover, it is ideal for holding irregularly shaped parts in place, ensuring stability before proceeding to the final welding phase.

Key Benefits

Tack welding offers several advantages in metalworking:

- Alignment Precision: Tack welds ensure that components are held in the correct position, reducing errors during the final welding process.

- Flexibility: The technique is adaptable to various joint configurations, accommodating diverse shapes and sizes of metal parts.

- Cost-Effectiveness: Utilizing standard welding equipment makes tack welding an economical choice for temporary joint fixation.

- Error Correction: Tack welds allow for adjustments and repositioning before permanent welding, minimizing costly rework.

Limitations

While tack welding is beneficial, it is not intended for structural strength and requires follow-up welding for permanence. The manual nature of tack welding demands skilled labor to ensure consistency and avoid defects. Proper cleaning and preparation of surfaces are essential to prevent contamination and ensure effective tack welds.

Tack welding is essential in metalworking because it allows flexibility and precision during assembly, but remember it’s just a temporary fix until the final welding is done.

Welding Techniques: A Broader Perspective

Overview of Welding Techniques in Metalworking

Welding is a crucial metalworking technique for joining metal parts, either permanently or temporarily. Different methods cater to varying needs for strength, precision, and application, with spot welding and tack welding standing out for their distinct purposes and functionalities.

Temporary vs Permanent Welding Methods

Spot Welding

Spot welding is a permanent technique that uses electric current to create welds at specific points. It’s highly efficient for mass production, providing strong, durable joints quickly. This method is automated and involves specialized equipment like water-cooled electrodes, making it ideal for industries such as automotive manufacturing where speed and consistency are essential.

Tack Welding

Tack welding serves as a temporary method to hold metal parts in position before final welding. Performed manually using standard arc welding equipment like MIG or TIG welders, tack welds are intermittent and easily removable, allowing for adjustments and alignment in complex assemblies. This technique is crucial when precision and flexibility are needed before permanent joints are made.

Choosing the Right Technique Based on Metal Thickness

Choosing the right welding technique depends on the metal’s thickness. Spot welding is ideal for thin sheet metals up to 3 mm, providing strong, permanent bonds needed for durable applications. Tack welding, however, is versatile and works well with thicker metals, allowing for initial positioning and alignment before final welding.

Key Considerations for Welding Technique Selection

Consider these factors when choosing between spot welding and tack welding:

- Project Needs: Determine if you need permanent or temporary joints. Spot welding is best for permanent bonds, while tack welding is ideal for temporary fixes.

- Material and Thickness: Check if the welding technique matches the material and thickness. Spot welding suits thin metals, while tack welding is adaptable for various thicknesses.

- Production Setting: Think about the production environment. Spot welding is great for high-volume automation, whereas tack welding allows for manual adjustments in complex assemblies.

Practical Applications

Spot Welding

Spot welding is widely used for creating strong, permanent joints in various industries:

- Automotive: Assembling car bodies and structural components.

- Aerospace: Building aircraft parts that need high strength and durability.

- Electronics: Fabricating precise and durable enclosures and components.

- Appliances: Producing household items with robust joints.

Tack Welding

Tack welding is essential for temporary positioning in various applications:

- Structural Frameworks: Aligning and holding parts during large assembly construction.

- Pipeline Fabrication: Ensuring precise alignment of sections before final welding.

- Design Testing: Allowing adjustments and testing of joints without permanent welds.

- Complex Assemblies: Holding irregularly shaped parts in place before final welding.

Comparative Analysis: Spot Welding vs Tack Welding

Detailed Comparison of Processes

Spot Welding Process

Spot welding creates permanent joints by fusing two metal sheets together using electrical resistance. Electrodes are placed on both sides of the metal sheets, and a high current is passed through them. The resistance of the metal to the electrical current generates heat, which melts and fuses the metal at the contact points. This method is characterized by its rapid execution and strong, durable welds, making it ideal for high-volume production environments.

Tack Welding Process

Tack welding creates temporary joints used to hold metal parts in alignment before the final welding process. Tack welding, performed manually using standard arc welding equipment like MIG or TIG welders, creates temporary welds that can be easily broken or removed, allowing for adjustments before making permanent welds.

Differences in Applications and Use Cases

Spot Welding Applications

Spot welding is commonly used in industries that require durable and permanent joints, particularly in high-volume production settings. Key applications include:

- Automotive Manufacturing: Extensively used in assembling car bodies, ensuring strong and permanent joints in the vehicle’s structure.

- Consumer Goods: Employed in the production of appliances and electronics, where strong, reliable welds are necessary.

- Aerospace: Used in the construction of aircraft components, providing the necessary strength and durability.

Tack Welding Applications

Tack welding is essential in applications where temporary alignment and positioning are required before final welding. Typical use cases include:

- Structural Fabrication: Used to hold parts in place during the assembly of large structures, such as pipelines and frameworks.

- Design Testing: Allows for the testing and adjustment of joint fit-up and design feasibility without committing to permanent welds.

- Complex Assemblies: Ideal for holding irregularly shaped parts in place, ensuring stability before final welding.

Advantages and Disadvantages of Each Technique

Spot Welding Advantages

- Efficiency: Can produce multiple welds quickly, making it suitable for mass production.

- Strength: The welds created are strong and durable, suitable for applications requiring long-lasting performance.

- Automation: Easily integrated into automated production lines, enhancing productivity and consistency.

Spot Welding Disadvantages

- Metal Thickness Limitation: Works best with thin metal sheets, usually up to 3 mm thick.

- Equipment Cost: The specialized machines required can be expensive.

- Accessibility: Limited to accessible areas and may not be suitable for complex shapes.

Tack Welding Advantages

- Flexibility: Adaptable to various joint configurations and metal thicknesses.

- Cost-Effectiveness: Utilizing standard welding equipment makes it an economical choice for temporary joints.

- Error Correction: Allows for adjustments and repositioning before permanent welding, minimizing costly rework.

Tack Welding Disadvantages

- Temporary Nature: Tack welds are not intended for structural strength and require follow-up welding for permanence.

- Skilled Labor: The manual nature demands skilled labor to ensure consistency and avoid defects.

- Surface Preparation: Properly cleaning and preparing surfaces prevents contamination and ensures effective tack welds.

Visual Comparison: Table of Key Differences

| Aspect | Spot Welding | Tack Welding |

|---|---|---|

| Purpose | Permanent joints | Temporary joints |

| Durability | Strong, durable welds | Easily removable for adjustments |

| Equipment | Specialized machines with water-cooled electrodes | Standard arc welding equipment (MIG or TIG) |

| Metal Thickness | Best for thin sheets (up to 3 mm) | Suitable for various thicknesses |

| Weld Size | Small, less than 1 cm in diameter | Longer, 1 to 2.5 cm, not fully penetrating |

| Production Rate | High, hundreds of welds per minute | Slower, manual application |

| Applications | Automotive, aerospace, consumer goods | Structural frameworks, pipeline fabrication |

Understanding the processes, applications, and benefits of spot and tack welding helps professionals choose the right technique for each task. Each method offers unique benefits tailored to different industrial requirements and project specifications.

Choosing the Right Welding Technique for Your Project

Choosing the right welding technique can make or break your project, so it’s essential to weigh several factors to ensure the best results. Understanding your project requirements and the materials involved is crucial in selecting the appropriate welding method.

Project Requirements and Material Considerations

When deciding between spot welding and tack welding, consider whether the welds need to be permanent or temporary. Spot welding is ideal for projects demanding durable, permanent joints, such as those found in automotive manufacturing and appliance production. Tack welding, however, excels in temporary alignment and positioning, making it perfect for assembling complex structures and frameworks.

The type and thickness of materials also play a pivotal role. Spot welding is best for thin metal sheets, up to 3 mm thick, providing strong bonds for high-volume production. Conversely, tack welding is more versatile, accommodating various metal thicknesses, and is often used for initial positioning before final welding.

Selecting Appropriate Welding Equipment

The choice of equipment can significantly impact your project. Spot welding requires machines with water-cooled electrodes, crucial for fast-paced production lines but can be costly. Tack welding utilizes standard arc welding equipment like MIG or TIG welders, which are more cost-effective and suitable for manual applications.

Case Studies: When to Use Spot Welding vs Tack Welding

In automotive manufacturing, spot welding is the go-to for assembling car bodies. These joints are strong and durable, perfect for the demands of vehicle use. Tack welding, however, is often employed during the fabrication of structural components, allowing precise alignment and adjustments before the final welding.

For construction projects involving large structural frameworks, tack welding proves invaluable. It allows for the temporary positioning of beams and columns, ensuring accurate alignment before final welding. Spot welding may also be utilized in specific construction applications where permanent joints are required, such as in prefabricated metal components.

Tips for Selecting Appropriate Welding Equipment

- For large-scale production, invest in spot welding equipment for efficiency.

- Tack welding with MIG/TIG tools suits smaller projects or prototypes.

- Choose spot welding for thin, homogeneous sheets, and tack welding for mixed thicknesses and alloys.

- Allocate funds for specialized spot welding machines if high-speed production is essential, while opting for tack welding if budget constraints and flexibility are priorities.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the main differences between spot welding and tack welding?

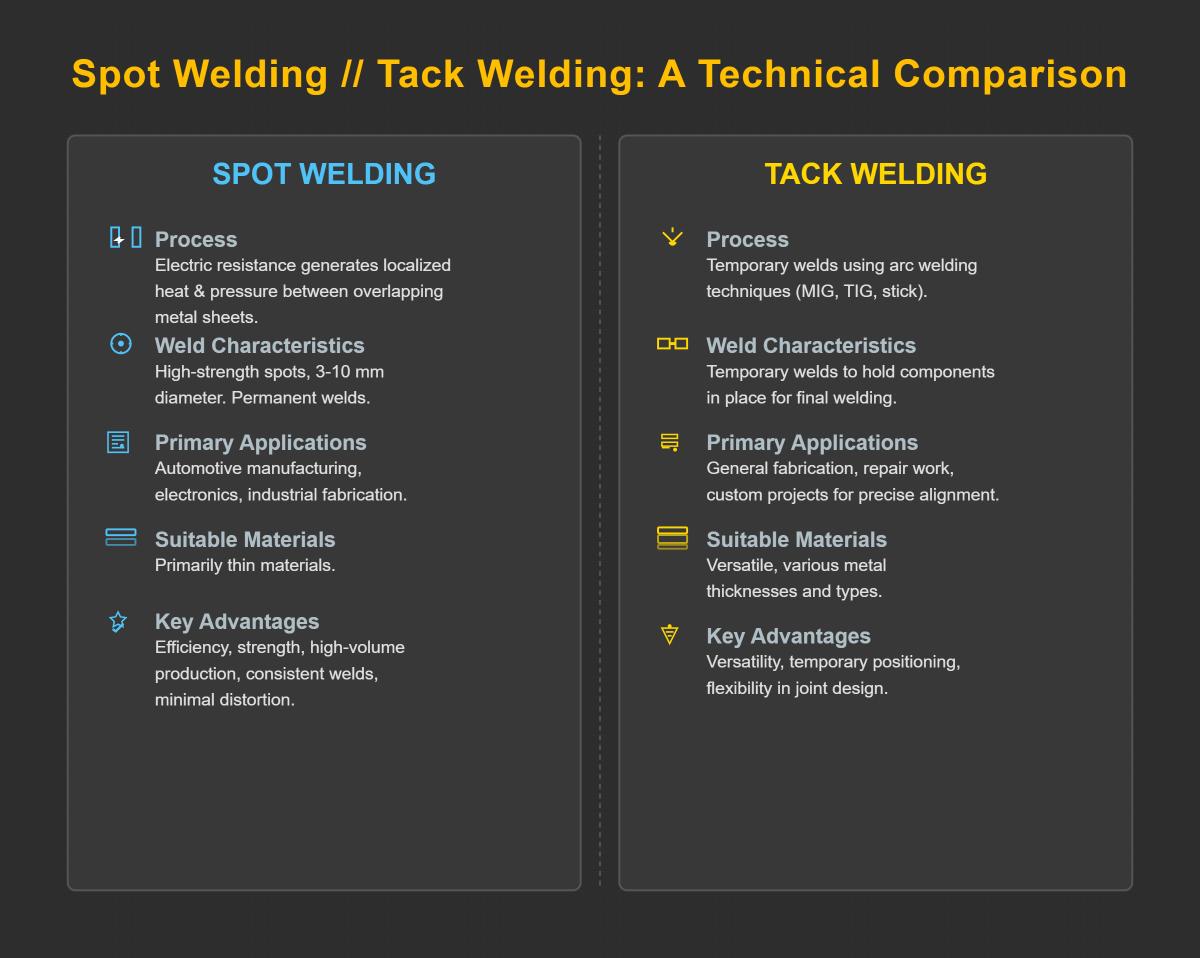

Spot welding and tack welding differ primarily in their processes and applications. Spot welding uses electric resistance to generate localized heat and pressure between overlapping metal sheets, creating high-strength weld spots typically 3–10 mm in diameter. It is commonly used in automotive manufacturing, electronics, and industrial fabrication for its efficiency and strength in thin materials. Conversely, tack welding involves temporary welds made using arc welding techniques such as MIG, TIG, or stick welding to hold components in place before final welding. It is versatile, accommodating various metal thicknesses and types, and is essential in general fabrication, repair work, and custom projects for precise alignment. Spot welding is favored for high-volume, consistent welds with minimal distortion, while tack welding is crucial for temporary positioning and flexibility in joint design.

When should I use spot welding versus tack welding?

Spot welding should be used when creating permanent, high-strength joints in high-volume manufacturing environments, such as automotive body assembly or electronics. It is ideal for thin metal sheets (≤3 mm) and provides consistent joint quality, making it suitable for applications requiring precise and durable connections. This method involves specialized machines and can be automated for efficiency.

Conversely, tack welding is preferable for temporary alignment of components in complex assemblies, like pipeline joints, where precise positioning is crucial before final welding. It is adaptable to thicker metals and versatile across various material types. Tack welding is beneficial for prototyping, testing fit-ups, and scenarios where the ability to rework or adjust is necessary. It uses standard MIG/TIG welders, which are more cost-effective for smaller-scale or custom projects.

How do spot welding and tack welding affect metalworking efficiency?

Spot welding and tack welding affect metalworking efficiency in distinct ways due to their differing processes and applications. Spot welding is a highly automated technique that uses copper electrodes to create strong, permanent joints quickly, making it highly efficient for high-volume production environments like automotive manufacturing. Its ability to rapidly produce hundreds of welds per minute on thin sheet metals significantly enhances productivity and reduces labor costs, although it requires a substantial initial investment in specialized equipment.

In contrast, tack welding is a manual process using standard arc welding equipment, such as MIG or TIG machines, to create temporary joints. This method is more labor-intensive and time-consuming, as it requires precise manual positioning and welding, which can slow down production in mass manufacturing settings. However, tack welding is versatile and can handle various metal thicknesses, providing flexibility in projects requiring precise alignment before final welding.

What welding equipment is essential for spot and tack welding?

For spot welding, essential equipment includes a spot welding machine, which features water-cooled copper electrodes, a high-current power supply, and automated control systems. These machines are specialized for welding thin metal sheets, typically up to 3 mm thick, and are often integrated into robotic systems for high-volume production, such as automotive panels. Copper alloy electrodes are crucial for conductivity and heat resistance, while cooling systems prevent electrode overheating during high-current operations.

Tack welding requires arc welding machines, commonly MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welders, which offer adjustable settings suitable for various materials like carbon steel, stainless steel, and aluminum. Accessories like clamps or vice grips are needed to secure workpieces, while tools such as chipping hammers and anti-spatter spray facilitate post-weld cleanup. Safety gear, including helmets, glasses, and heat-resistant gloves, is essential to protect against UV radiation, debris, and hot materials.

Can both spot and tack welding be used in automotive applications?

Both spot welding and tack welding are integral to automotive applications, each serving distinct purposes. Spot welding is a permanent joining technique, primarily used for assembling structural components like body panels and frames due to its ability to efficiently produce strong, consistent welds at high speed. This process is typically automated, making it ideal for mass production environments.

On the other hand, tack welding is a temporary method used to align and hold parts in place during the fabrication process before final welding. It is particularly useful in repair work and prototyping, where flexibility and the ability to manually adjust components are crucial.

In automotive contexts, spot welding excels in high-volume production due to its speed and automation capabilities, whereas tack welding is favored for its versatility and low heat input, which minimizes distortion. Both techniques can be used synergistically in scenarios like body repair and prototyping, where tack welding provides preliminary alignment and spot welding ensures long-term structural integrity.