When it comes to choosing the right stainless steel for your project, the decision between Stainless Steel 309 and 304 can be a game-changer. These two grades may look similar at first glance, but their differences in corrosion resistance, mechanical properties, and suitability for high – temperature applications are significant. For intermediate users seeking in – depth knowledge, understanding these disparities is crucial. Whether you’re wondering about which grade offers better corrosion protection in harsh environments or which is more suitable for high – heat equipment, this guide has you covered. So, are you ready to discover which stainless steel grade is the ideal fit for your needs?

Chemical Composition Comparison

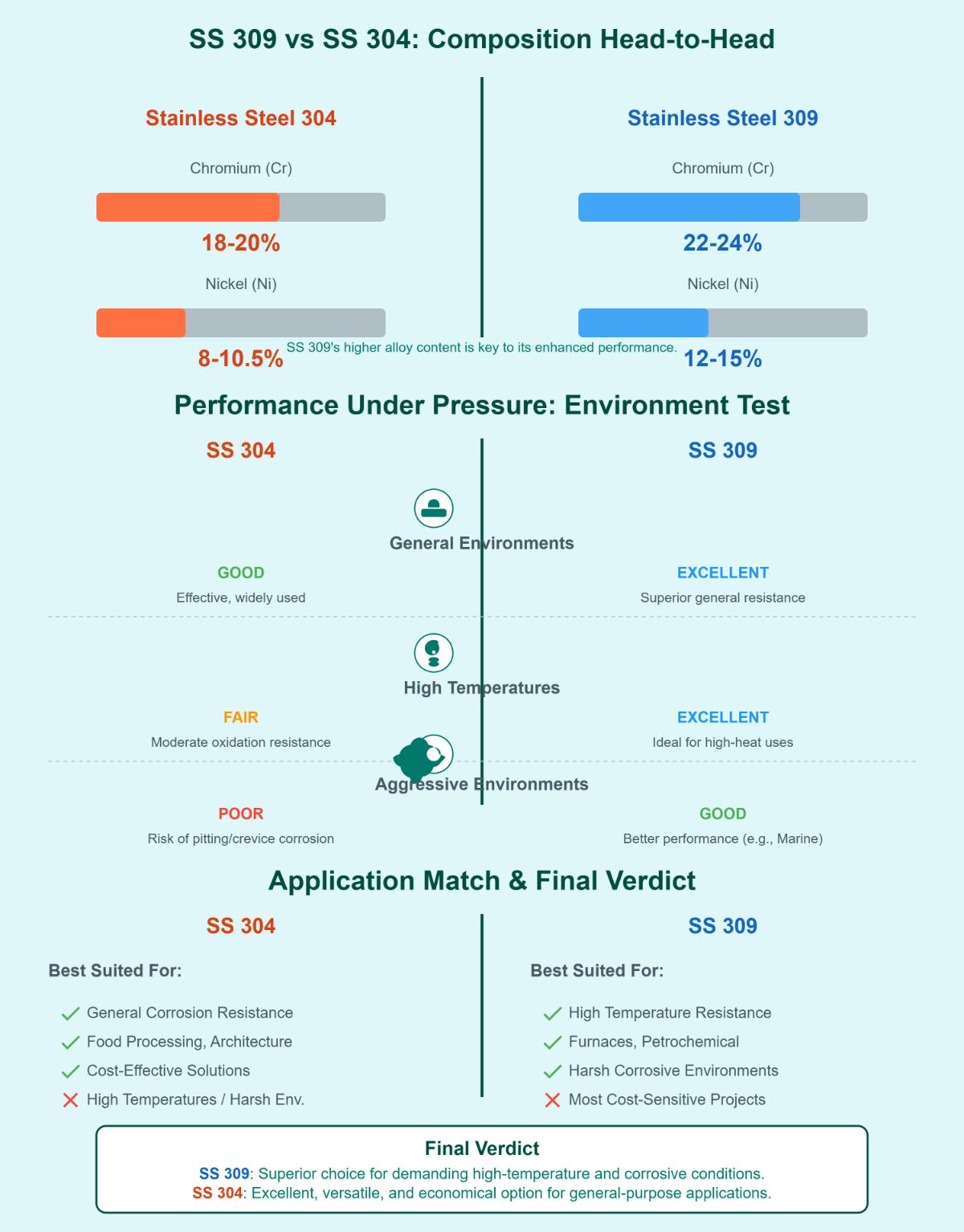

Chemical Composition Overview

Stainless Steel 309

Stainless Steel 309, a type of austenitic stainless steel, contains the following elements:

- Chromium (Cr): 22% to 24%

- Nickel (Ni): 12% to 15%

- Carbon (C): Up to 0.20%

- Manganese (Mn): Up to 2.00%

- Silicon (Si): Up to 1.00%

- Sulfur (S): Up to 0.030%

- Phosphorus (P): Up to 0.045%

Stainless Steel 304

Stainless Steel 304, also an austenitic stainless steel, has the following chemical composition:

- Chromium (Cr): 18% to 20%

- Nickel (Ni): 8% to 10.5%

- Carbon (C): Up to 0.08% (with 304L variant having reduced carbon)

- Manganese (Mn): Up to 2.00%

- Silicon (Si): Up to 0.75%

- Sulfur (S): Up to 0.030%

- Phosphorus (P): Up to 0.045%

Key Differences and Implications

Chromium and Nickel Content

The higher chromium (22% to 24%) and nickel (12% to 15%) content in Stainless Steel 309 significantly enhances its resistance to oxidation and heat. This makes 309 more suitable for high – temperature applications compared to 304, which has lower chromium (18% to 20%) and nickel (8% to 10.5%) content.

Carbon Content

Stainless Steel 309’s higher carbon content (up to 0.20%) compared to 304 (up to 0.08%) can lead to increased strength and hardness, but it can also cause carbide precipitation during welding, which may reduce corrosion resistance in the heat – affected zones. The 309S variant, with lower carbon content, is available to mitigate this issue.

Impact on Mechanical Properties

Due to its composition, 309 typically has higher tensile strength (600 to 710 MPa) and yield strength (260 to 350 MPa) than 304, which has a wider range of tensile (580 to 1180 MPa) and yield strength (230 to 860 MPa).

Applications Based on Composition

The high chromium and nickel content of Stainless Steel 309 makes it ideal for high – temperature applications like furnace components and boiler baffles.

Stainless Steel 304, with its balanced chemical composition, is widely used in food processing equipment, kitchen appliances, and architectural applications. Its cost – effectiveness and versatile properties make it a preferred choice for a broad range of industries, especially where high – temperature resistance is not a primary requirement.

Cost Implications

Due to its higher chromium and nickel content, Stainless Steel 309 is generally more expensive than 304. However, its superior heat and corrosion resistance can justify the higher cost in demanding applications.

Mechanical Properties Comparison

Tensile Strength

Stainless Steel 309 showcases a tensile strength ranging from 600 to 710 MPa, with a minimum specified tensile strength around 620 MPa. This makes it ideal for applications requiring high load-bearing capacity and resistance to stress-induced deformation. Stainless Steel 304, with a tensile strength range of 515 to 1180 MPa (typically 580 to 700 MPa), is versatile and commonly used for general applications.

Yield Strength

Stainless Steel 309 has a yield strength between 260 and 350 MPa, with a minimum of approximately 310 MPa. This higher yield strength shows its ability to resist permanent deformation under load, making it ideal for high-stress applications. On the other hand, Stainless Steel 304 has a yield strength ranging from 230 to 860 MPa, with a minimum of about 205 MPa, and is more appropriate for applications with moderate stress levels.

Elongation at Break

Stainless Steel 309 generally has an elongation at break between 34% and 47%, with a minimum of about 45%. This high value suggests better ductility, enabling it to endure greater deformation before failure, which is beneficial in applications involving thermal expansion and contraction. Stainless Steel 304 has an elongation at break ranging from 8% to 43%, with a minimum of about 40%. While ductile, it may not perform as well as Grade 309 in high – temperature and high – stress scenarios.

Hardness

Stainless Steel 309 has a Rockwell B hardness of up to 85, indicating its resistance to deformation, but it is not as hard as Grade 304. Stainless Steel 304 can reach up to 92 on the Rockwell B hardness scale, making it slightly harder and more resistant to surface deformation.

Fatigue and Shear Strength

Stainless Steel 309 has a slightly higher fatigue strength, ranging from 250 to 280 MPa, and a shear strength between 420 and 470 MPa. These properties make it more suitable for components exposed to repetitive stress and high shear loads. Stainless Steel 304 exhibits a fatigue strength range of 210 to 440 MPa and a shear strength range of 400 to 690 MPa, which is versatile for general applications but may fall short compared to Grade 309 in high – temperature conditions.

Thermal Properties

Stainless Steel 309 can maintain its mechanical properties at temperatures up to 980°C, making it ideal for high – temperature environments such as furnace components and heat exchangers. In contrast, Stainless Steel 304 can only withstand temperatures up to about 710°C, which limits its use in high – temperature applications.

Corrosion Resistance

Stainless Steel 309 and 304 are both known for their corrosion resistance, but they differ due to their unique chemical compositions.

Composition and Performance

Chromium and Nickel Content

- 304 Stainless Steel: Contains approximately 18-20% chromium and 8-10.5% nickel, which provides good – 309 Stainless Steel: With 22-24% chromium and 12-15% nickel, 309 offers superior corrosion resistance, particularly in high-temperature environments and in conditions with high chloride concentrations.

Performance in Different Environments

- 304 Stainless Steel: Performs well in atmospheric conditions and is commonly used in applications such as food processing and architectural components. It is effective in general corrosive environments but may not be ideal for more aggressive conditions.

- 309 Stainless Steel: Excels in high-temperature applications due to its enhanced resistance to oxidation and scaling. It is suitable for furnace parts, heat exchangers, and other high-temperature equipment, providing better performance in harsher environments.

Pitting and Crevice Corrosion Resistance

- 304 Stainless Steel: Can be susceptible to pitting and crevice corrosion in environments with high chloride concentrations. Its Pitting Resistance Equivalent Number (PREN) is lower compared to 309.

- 309 Stainless Steel: Offers better resistance to pitting and crevice corrosion due to its higher chromium and nickel content, making it more suitable for environments exposed to chlorides.

High-Temperature Corrosion Resistance

- 304 Stainless Steel: Not designed for extreme temperatures and may lose effectiveness above certain thresholds.

- 309 Stainless Steel: Can withstand temperatures up to 1100°C (2012°F), making it ideal for applications requiring high-temperature stability and corrosion resistance.

Applications in Corrosive Environments

- 304 Stainless Steel: Used in environments where moderate corrosion resistance is needed, such as food processing, kitchen appliances, and architectural applications.

- 309 Stainless Steel: Ideal for high-temperature and highly corrosive settings like furnace parts and boiler baffles.

High-Temperature Application Considerations

Suitability for High-Temperature Applications

When selecting materials for high-temperature applications, comparing their performance characteristics is crucial. Stainless Steel 309 and 304 offer distinct advantages depending on specific requirements.

Maximum Service Temperature

Stainless Steel 309 withstands continuous temperatures up to 2000°F (1093°C). This makes it highly suitable for extreme heat environments, such as industrial furnaces and heat exchangers, where maintaining mechanical properties at elevated temperatures is essential.

Stainless Steel 304, however, has a maximum continuous service temperature of 1700°F (925°C). While it remains suitable for many high-temperature applications, it is limited compared to 309. Therefore, 304 is better suited for environments where temperatures do not exceed this threshold.

Intermittent Service Temperature

For applications involving intermittent exposure to high temperatures, Stainless Steel 309 can handle up to 2000°F (1093°C). This is particularly beneficial in processes where temperatures fluctuate, such as thermal cycling operations.

Stainless Steel 304 manages intermittent temperatures up to 1600°F (870°C). Although lower than 309, it suffices for many applications, including those in the food processing and chemical industries where occasional high temperatures are encountered.

Resistance to Oxidation

A critical factor for high-temperature applications is oxidation resistance. Stainless Steel 309, with its higher chromium (22-24%) and nickel (12-15%) content, offers superior resistance to oxidation and scaling at elevated temperatures. This makes it a preferred choice for components exposed to air at high temperatures, such as furnace parts and boiler baffles.

Stainless Steel 304, with 18-20% chromium and 8-10.5% nickel, also provides good oxidation resistance, but not to the same extent as 309. In less demanding high-temperature environments, 304 performs well, but it is less suited for applications where oxidation is a significant concern.

Examples of High-Temperature Equipment

Moving on to the examples of high-temperature equipment, several types benefit from the high-temperature capabilities of Stainless Steel 309 and 304.

Industrial furnaces often utilize Stainless Steel 309 due to its excellent resistance to high temperatures and thermal cycling. Its ability to maintain structural integrity and resist oxidation makes it ideal for furnace linings, heating elements, and components exposed to extreme heat.

Heat exchangers also benefit from Stainless Steel 309. Efficient heat transfer and resistance to thermal stress are critical, and 309’s high-temperature strength and corrosion resistance ensure reliability in demanding conditions.

Boilers operating at high temperatures use Stainless Steel 309 for boiler tubes and other components. Its resistance to oxidation and scaling at elevated temperatures maintains performance over extended periods.

In food processing equipment, Stainless Steel 304 is widely used where temperatures may occasionally reach high levels. Its excellent corrosion resistance and adequate high-temperature performance make it ideal for ovens, grills, and other cooking appliances.

The chemical industry employs both Stainless Steel 309 and 304, depending on the temperature requirements. 309 is chosen for high-temperature reactors and heat exchangers, while 304 is used in applications with moderate temperature exposure, where corrosion resistance is paramount.

Choosing between Stainless Steel 309 and 304 for high-temperature applications depends on specific temperature requirements and environmental conditions. Stainless Steel 309 offers superior performance in extreme heat and oxidative environments, making it suitable for the most demanding applications. Stainless Steel 304 provides a cost-effective solution for moderate high-temperature applications with excellent corrosion resistance and versatility.

Environmental and Sustainability Impacts

Recyclability and Environmental Footprint

Stainless Steel 309

Stainless Steel 309 is highly recyclable, which significantly reduces its environmental footprint. Although its production requires more resources due to its higher alloy content, including substantial amounts of chromium and nickel, the extended service life of 309 offsets the initial resource investment by reducing the need for frequent replacements, thereby lowering overall material consumption and associated environmental impacts.

Stainless Steel 304

Similarly, Stainless Steel 304 is highly recyclable and recognized for its minimal environmental impact. The lower alloy content in 304 means its production requires fewer resources, making it more environmentally efficient when high-temperature resistance is not essential. This efficiency in resource usage, combined with its recyclability, makes 304 a sustainable choice for various applications.

Sustainability Benefits

Stainless Steel 309

The durability and resistance of Stainless Steel 309 make it an excellent choice for critical applications where longevity is essential. Its ability to withstand extreme conditions, such as high temperatures and corrosive environments, reduces the frequency of replacements. This not only extends the material’s lifecycle but also minimizes the environmental impact associated with production and disposal processes. The superior durability and resistance to harsh conditions mean that 309 can maintain performance over extended periods, contributing to

Stainless Steel 304

Stainless Steel 304 also offers significant sustainability benefits due to its long service life and versatility. Its durability helps reduce the need for frequent replacements, thereby conserving resources and minimizing waste. The widespread use of 304 in various industries ensures consistent quality and performance, while its adaptability to different applications helps maintain sustainability standards. The material’s ability to be recycled and reused further enhances its environmental credentials.

Production and Resource Usage

Stainless Steel 309

The production of Stainless Steel 309 requires more resources due to its higher alloy content, especially chromium and nickel. This higher resource usage can initially seem less environmentally friendly. However, the extended service life of 309 compensates for this by reducing the need for frequent replacements. Over time, the reduced frequency of manufacturing new components offsets the initial higher resource consumption, resulting in a more sustainable lifecycle for the material.

Stainless Steel 304

In contrast, Stainless Steel 304’s production involves a lower alloy content, making it more resource-efficient. The reduced need for chromium and nickel in its composition means that fewer natural resources are consumed during production. This efficiency makes 304 an attractive option for applications where high-temperature resistance is not a critical requirement. The lower resource usage during production, combined with the material’s recyclability, underscores its environmental benefits.

Cost and Availability

The higher alloy content in Stainless Steel 309 generally makes it more expensive than 304, but its performance in extreme conditions can lead to long-term cost savings. However, 309 is less commonly available compared to 304, which can impact its accessibility for certain projects. Stainless Steel 304 is more cost-effective and widely available, making it suitable for a broader range of applications. Its lower cost and high availability make it an appealing choice for many industries, particularly where corrosion resistance and aesthetic appeal are important.

Applications and Performance

Stainless Steel 309

Stainless Steel 309 is ideal for high-temperature and corrosive environments. Its superior oxidation resistance at elevated temperatures makes it a preferred choice for demanding industrial settings, such as furnace components, heat exchangers, and petrochemical equipment. The material’s ability to maintain structural integrity and resist corrosion under extreme conditions ensures reliable performance in critical applications.

Stainless Steel 304

Stainless Steel 304 is widely used in general corrosion-resistant applications, including food processing equipment, kitchen appliances, and architectural features. It is favored for its formability, weldability, and aesthetic appeal. The versatility of 304 allows it to perform well in a variety of environments, making it a reliable choice for numerous applications where high-temperature resistance is not the primary concern.

Cost and Availability Analysis

When comparing the costs of Stainless Steel 309 and 304, several key factors contribute to the differences.

Material Composition Impact

Stainless Steel 309 contains a higher percentage of chromium (22-24%) and nickel (12-15%) compared to 304, which has 18-20% chromium and 8-10.5% nickel. The higher amounts of these elements in 309 contribute to its superior heat and oxidation resistance but also increase its cost, as chromium and nickel are relatively expensive materials.

Production Costs

The manufacturing process for Stainless Steel 309 is more complex and energy-intensive due to its higher alloy content, leading to increased production costs. On the other hand, the production of Stainless Steel 304 benefits from economies of scale, as it is more widely used and produced in larger quantities. This widespread production helps to lower the

Market Price

In the market, Stainless Steel 309 is generally more expensive than 304 because of the higher cost of raw materials and additional manufacturing expenses. This makes 304 the more cost-effective option for applications where its properties are sufficient.

Availability in the Market

General Availability

Both Stainless Steel 309 and 304 are widely available in various forms such as sheets, plates, bars, and pipes. However, 304 is more commonly found due to its broad range of applications. Its extensive use in industries such as food processing, kitchen appliances, and construction ensures a high production volume, which in turn enhances its availability.

Regional Availability

The availability of both grades can vary regionally. Stainless Steel 304, being more commonly used, is readily available in most markets around the world. Stainless Steel 309, while also available globally, might be less accessible in certain regions due to its specialized application areas. This can affect lead times and availability for specific projects requiring 309.

Supplier Networks

A well-established network of suppliers and distributors for Stainless Steel 304 ensures that it is easily accessible for most projects. The extensive supplier network helps maintain a steady supply, which contributes to its lower cost and higher availability. In contrast, Stainless Steel 309 may require sourcing from specialized suppliers, which can affect its availability and increase procurement costs.

Applications Influencing Demand

Due to its excellent corrosion resistance and formability, Stainless Steel 304 is extensively used in food processing equipment, kitchen appliances, architectural trim, and automotive components. This high demand across diverse sectors contributes to its widespread production and availability. Conversely, Stainless Steel 309 is used primarily in high-temperature environments like furnace parts, heat exchangers, boiler baffles, and high-temperature reactors. These specialized applications result in lower

ASTM Standards Compliance

The American Society for Testing and Materials (ASTM) standards provide a detailed framework for specifying, testing, and ensuring the quality of materials like stainless steel grades 309 and 304. These standards ensure that materials meet specific criteria for chemical composition, mechanical properties, and performance in various applications.

Compliance Requirements for Stainless Steel 309

Stainless Steel 309 is subject to several ASTM standards, which outline its chemical composition, mechanical properties, and suitable applications. Key standards include:

ASTM A240

This standard specifies chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications, ensuring that Stainless Steel 309 meets the required chemical composition and mechanical properties for high-temperature applications.

ASTM A167

This standard covers stainless and heat-resisting chromium-nickel steel plate, sheet, and strip, ensuring the material is suitable for high-temperature and corrosive environments, often used in furnace components and heat exchangers.

ASTM A276

This standard covers stainless steel bars and shapes, outlining the mechanical properties needed for structural applications in high-temperature environments.

Compliance Requirements for Stainless Steel 304

Stainless Steel 304 is widely used and must comply with various ASTM standards that define its chemical composition, mechanical properties, and applications. Key standards include:

ASTM A240

Similar to Stainless Steel 309, this standard specifies chromium and chromium-nickel stainless steel plate, sheet, and strip, ensuring that 304 meets the specifications for general applications like kitchen appliances and architectural components.

ASTM A312

This standard specifies seamless, welded, and heavily cold worked austenitic stainless steel pipes, ensuring the material’s suitability for piping applications in industries such as chemical and food processing.

ASTM A167

This standard covers stainless and heat-resisting chromium-nickel steel plate, sheet, and strip, ensuring 304 meets the necessary criteria for general corrosion resistance and moderate high-temperature applications.

Comparative Analysis of ASTM Standards Compliance

Chemical Composition Standards

Both Stainless Steel 309 and 304 must adhere to specific chemical composition standards outlined by ASTM. The differences in chromium and nickel content are critical for their respective applications:

- 309: Higher chromium (22-24%) and nickel (12-15%) content for enhanced high-temperature resistance.

- 304: Balanced chromium (18-20%) and nickel (8-10.5%) content for general corrosion resistance.

Mechanical Properties Standards

ASTM standards ensure that both grades exhibit the necessary mechanical properties for their applications:

- 309: Higher tensile and yield strength to withstand high-stress environments.

- 304: Adequate strength for general applications, with good formability and weldability.

Application-Specific Standards

The ASTM standards guide the use of these stainless steel grades in various industries:

- 309: Ideal for high-temperature applications such as furnace parts and heat exchangers.

- 304: Widely used in food processing, kitchen appliances, and architectural components.

Compliance with ASTM standards ensures that both Stainless Steel 309 and 304 meet the stringent requirements for their respective applications. This compliance guarantees consistent quality and performance, allowing engineers and material scientists to select the appropriate grade for specific needs confidently.

Case Studies of Successful Applications

High-Temperature Industrial Applications

Stainless Steel 309 is widely used in high-temperature industrial settings due to its exceptional heat resistance and mechanical stability. For instance, it is ideal for furnace components, such as linings and heating elements, where it withstands extreme temperatures. This steel type resists oxidation and scaling up to 2000°F. Similarly, in heat exchangers that endure high thermal stress, Stainless Steel 309 ensures long-term reliability, as it effectively manages thermal cycling and corrosion in hot environments.

In contrast, Stainless Steel 304 is suitable for applications where temperatures do not exceed 1700°F. It is commonly used in general engineering, including architectural features, where moderate heat resistance suffices.

Food and Beverage Industry

Stainless Steel 304 is the material of choice in the food and beverage industry, thanks to its outstanding corrosion resistance and ease of cleaning. Its widespread application in hygienic processing equipment, such as tanks, piping, and utensils, is due to its ability to endure various cleaning processes and resist contamination. The material is also highly formable and weldable, allowing for the creation of complex shapes needed in food processing machinery. Furthermore, its aesthetic appeal makes it ideal for visible kitchen equipment and appliances.

Stainless Steel 309 is not typically utilized in this sector. However, when high-temperature sterilization processes are involved, it may be selected for specific components requiring enhanced heat resistance.

Architectural and Construction Applications

Stainless Steel 304 is frequently chosen for architectural and construction projects due to its visual appeal and corrosion resistance. It is often used for architectural trim, cladding, and structural elements where durability and aesthetics are crucial. The material’s bright, shiny finish adds elegance and sophistication to design elements like handrails, facades, and decorative features, making it a favorite for architects and designers.

Stainless Steel 309, although less common in standard architectural applications, may be used in specialized construction projects. It provides structural integrity and longevity in components exposed to extreme heat or corrosive environments.

Petrochemical and Chemical Industry

In the petrochemical and chemical industries, Stainless Steel 309 is preferred for high-temperature reactors, boiler baffles, and other components exposed to harsh chemical environments. The high chromium and nickel content in 309 provides superior durability and corrosion resistance, essential for reliable performance in critical applications. For example, in catalytic converters and reformers, these elements ensure efficient operation under demanding conditions.

While Stainless Steel 304 is also employed in the chemical industry, it is better suited for less demanding temperature requirements. It is commonly used in storage tanks, piping systems, and equipment handling less aggressive chemicals, offering good corrosion resistance and cost-effectiveness.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the differences in corrosion resistance between Stainless Steel 309 and 304?

Stainless Steel 309 and 304 both offer notable corrosion resistance, but there are significant differences based on their chemical composition and performance in various environments. Stainless Steel 309 contains higher levels of chromium (22-24%) and nickel (12-15%) compared to 304 (18-20% chromium and 8-10.5% nickel). This composition gives 309 superior corrosion resistance, particularly in high-temperature environments where oxidation resistance is crucial.

In general corrosive environments, 304 is highly effective and widely used in applications like food processing and architectural features. However, it is less resistant in aggressive environments, such as marine conditions, where pitting and crevice corrosion can occur. On the other hand, 309 performs better in harsher environments due to its enhanced composition and can withstand higher temperatures, making it ideal for furnace components and petrochemical equipment.

Thus, while both grades offer good corrosion resistance, 309 is superior in high-temperature and highly corrosive environments, whereas 304 is preferred for its versatility and cost-effectiveness in general applications.

Which stainless steel grade is better suited for high-temperature applications?

For high-temperature applications, Stainless Steel 309 is better suited than 304. With a higher percentage of chromium (22 – 24%) and nickel (12 – 15%), 309 offers enhanced oxidation resistance and mechanical strength at elevated temperatures. It can withstand continuous service up to 2,000°F (1,095°C) and intermittent up to 1,800°F (980°C), and retains mechanical integrity better than 304. While both offer good corrosion resistance, 309’s higher alloy content gives it superior oxidation resistance at high temperatures. It’s used in industrial furnaces, boiler components, and petrochemical equipment.

How do the mechanical properties of Stainless Steel 309 compare to those of 304?

Stainless Steel 309 and 304 exhibit distinct differences in their mechanical properties, influencing their suitability for various applications. Stainless Steel 309 typically has a higher tensile strength, ranging from 600 to 710 MPa, compared to Stainless Steel 304, which ranges from 580 to 1180 MPa but with a lower minimum of around 515 MPa. This makes 309 better suited for load-bearing applications.

In terms of yield strength, Stainless Steel 309 also performs better with a range of 260 to 350 MPa and a minimum of 310 MPa, whereas Stainless Steel 304 ranges from 230 to 860 MPa, with a lower minimum of 205 MPa. This higher yield strength of 309 indicates better resistance to permanent deformation.

Elongation at break for Stainless Steel 309 is generally higher (34% to 47%, minimum 45%), compared to 304 (8% to 43%, minimum 40%), indicating greater ductility in 309. However, Stainless Steel 304 has a higher Rockwell B hardness up to 92, compared to 85 for 309.

Additionally, 309 maintains its mechanical properties at higher temperatures (up to 980°C) than 304 (up to 710°C), making 309 ideal for high-temperature environments. These differences underline the suitability of Stainless Steel 309 for more demanding applications requiring higher strength and temperature resistance, despite its higher cost compared to the more versatile and widely used Stainless Steel 304.

What are the cost differences between Stainless Steel 309 and 304?

Stainless Steel 309 generally costs more than Stainless Steel 304 due to its higher alloy content and specialized applications. The main factors driving this cost difference are the increased levels of chromium (22-24%) and nickel (12-15%) in 309 compared to 304, which contains 18-20% chromium and 8-10.5% nickel. These elements are more expensive, contributing to the higher production costs of 309. Additionally, the manufacturing process for 309 is more complex, necessitating precise handling and additional steps, further increasing its cost.

Stainless Steel 304 benefits from economies of scale due to its widespread use in various industries, leading to lower per-unit costs. In contrast, the specialized applications of 309, such as in high-temperature environments, result in lower production volumes and higher costs per unit. While 309’s initial cost is higher, its superior performance and durability in demanding conditions can offer long-term cost savings by reducing maintenance and replacement expenses.

How does the availability of Stainless Steel 309 compare to 304 in the market?

Stainless Steel 304 is more widely available in the market compared to Stainless Steel 309. This is primarily due to its versatility and cost-effectiveness, making it a preferred choice for a broad range of applications, from kitchen appliances to architectural components. As a result, 304 is mass-produced and stocked by most major suppliers globally.

In contrast, Stainless Steel 309 is designed for specialized high-temperature applications, such as in the petrochemical and furnace manufacturing industries. This specialized use means that 309 is produced in smaller quantities and is less commonly stocked. Therefore, sourcing 309 may require more specific suppliers and could be less readily available in some regions compared to 304.

What are the long-term benefits of using Stainless Steel 309 over 304?

Stainless Steel 309 offers several long-term benefits over 304, particularly in high-temperature applications and environments requiring superior corrosion resistance. Due to its higher chromium (23%) and nickel (12-14%) content, 309 provides enhanced resistance to corrosion and oxidation, especially at elevated temperatures. This makes it ideal for applications such as furnace parts and heat exchangers.

Mechanically, 309 exhibits higher tensile strength (620 MPa) and yield strength (310 MPa) compared to 304, which has tensile and yield strengths of 515 MPa and 205 MPa, respectively. Additionally, 309 maintains its mechanical properties up to 980°C, significantly higher than 304’s limit of approximately 710°C. This allows 309 to perform reliably in high-temperature settings, reducing the need for frequent maintenance and replacements.

While 309 is generally more expensive than 304 due to its composition, its durability and resistance to extreme conditions can lead to lower long-term costs. Reduced downtime and extended lifespan of components made from 309 contribute to significant savings over time, making it a cost-effective choice in demanding environments.