Imagine a world where precision meets efficiency, transforming raw materials into intricate designs with seamless ease. Welcome to the realm of fiber laser cutting—a revolutionary technology reshaping modern manufacturing. But what exactly is fiber laser cutting, and how does it work? In essence, fiber laser cutting involves using a high-powered laser to cut through various materials with astounding accuracy and speed. This guide will walk you through each step, from understanding the basics of fiber laser cutting to exploring its numerous applications and advantages. Whether you’re a novice eager to learn or a professional seeking to refine your skills, this step-by-step guide will illuminate the path to mastering fiber laser cutting. Ready to dive in and discover the power behind this cutting-edge technology?

Introduction to Fiber Laser Cutting

Fiber laser cutting uses a high-intensity laser beam to precisely cut various materials, especially metals. This process involves the laser beam melting, burning, or vaporizing the material to achieve precise and intricate cuts, and it is known for its speed, accuracy, and efficiency, making it a popular choice in modern manufacturing.

Laser cutting began in the 1960s with the development of the first lasers. Initially, laser technology was used for scientific and medical applications. However, as the technology evolved, its potential for industrial use became apparent. The first industrial laser cutting machines were introduced in the 1970s, primarily using CO2 lasers. Over the years, advancements in laser technology led to the development of fiber lasers, which offered significant improvements in performance and versatility.

Fiber laser cutting has revolutionized the manufacturing industry due to its numerous advantages:

- Precision: Fiber lasers create a highly focused beam, enabling precise cuts and reducing material waste.

- Speed: The high power and efficiency of fiber lasers enable faster cutting speeds compared to traditional methods, increasing productivity.

- Versatility: Fiber lasers can cut a wide range of materials, including various metals and some non-metals, making them suitable for diverse applications.

- Efficiency: Fiber lasers convert electrical energy into laser light more efficiently than other laser types, reducing operational costs and energy consumption.

- Low Maintenance: Fiber lasers have fewer moving parts and a more robust design, resulting in lower maintenance requirements and longer service life.

These advantages have made fiber laser cutting crucial in industries like automotive, aerospace, electronics, and metal fabrication. The ability to produce complex and precise components quickly and cost-effectively has driven widespread adoption of this technology in modern manufacturing.

How Fiber Laser Cutting Works

Overview of the Fiber Laser Cutting Process

Fiber laser cutting is an advanced technique that uses a high-intensity laser beam to cut through various materials with precision and efficiency. The process involves several key steps and components to achieve accurate and clean cuts.

Key Components of a Fiber Laser Cutting Machine

A fiber laser cutting machine consists of several critical parts that work together to produce the desired cuts:

- Laser Generator: This component generates the laser beam.

- Optical Fiber: Transmits the laser beam from the generator to the cutting head.

- Cutting Head: Contains lenses to focus the laser beam.

- CNC System: Controls the movement and operation of the cutting head.

- Assist Gas System: Provides gas to aid in material removal.

Detailed Explanation of How the Laser Beam Interacts with Materials

Generation of the Laser Beam

The laser generator is the core of the fiber laser cutting machine, producing a high-intensity laser beam by passing pump light, typically from laser diodes, through an optical fiber doped with rare-earth elements like ytterbium. This fiber acts as the gain medium, amplifying the light to produce a coherent laser beam with a specific wavelength, generally around 1 micron.

Transmission Through Optical Fiber

The laser light travels through an optical fiber made of a silica glass core surrounded by cladding, which reflects the light back into the core to minimize power loss and ensure efficient delivery of the laser beam to the cutting head.

Focusing the Laser Beam

Upon exiting the optical fiber, the laser beam passes through a series of lenses within the cutting head. These lenses focus the beam to a very small, precise spot on the workpiece surface. The focused beam has an extremely high energy density, which is essential for achieving clean and accurate cuts.

Heating and Melting the Material

When the focused laser beam strikes the material’s surface, it rapidly heats the targeted area to its melting or vaporization temperature. The intense heat causes the material to melt or vaporize almost instantly at the focal point of the beam.

Material Removal via Assist Gas

At the same time, an assist gas (such as nitrogen, oxygen, or air) is blown through a nozzle aligned with the laser beam onto the heated spot, helping to remove molten material or vaporized particles from the cut area, clearing the path for the laser to continue cutting and preventing the cut from being contaminated or obstructed.

Controlled Movement for Cutting

The cutting head moves according to a programmed path controlled by a CNC (computer numerical control) system. This system precisely regulates both the laser power and the cutting head’s movement to produce intricate shapes and clean edges in the material.

Cooling and Heat Dissipation

The optical fiber’s design allows for efficient heat dissipation, reducing wear on the machine and maintaining consistent cutting performance, which ensures the equipment’s longevity and reliability.

Applications and Advantages of Fiber Laser Cutting

Industrial Applications

Fiber laser cutting is widely used across various industries due to its precision, speed, and versatility. Here are some of the key sectors that benefit from this technology:

Metal Fabrication

In metal fabrication, fiber laser cutting is essential for creating precise and intricate parts. It is used to cut sheet metal, tubes, and various metal components with high accuracy, ensuring parts fit together perfectly and maintain structural integrity. This precision is crucial for producing parts that meet high standards of quality and functionality.

Automotive Industry

The automotive industry relies heavily on fiber laser cutting for manufacturing parts such as body panels, engine components, and intricate chassis parts. This technology’s quick and consistent high-quality cuts help manufacturers adhere to tight schedules and uphold safety and performance standards.

Aerospace and Electronics

In aerospace and electronics, the need for precision and minimal heat-affected zones is critical. Fiber laser cutting meets these requirements by providing accurate cuts with minimal thermal distortion, which is essential for components that must maintain tight tolerances and high reliability.

Benefits of Fiber Laser Cutting

Fiber laser cutting offers several advantages that make it a preferred choice in modern manufacturing processes:

Precision

Fiber lasers provide exceptional precision, allowing for intricate and detailed cuts with minimal tolerances. This precision is vital in industries where even minor deviations can lead to product failure.

Speed and Productivity

Fiber lasers operate at higher cutting speeds compared to traditional methods, resulting in faster production cycles and improved throughput. This increased speed enables manufacturers to meet tight deadlines and increase overall productivity.

Material Versatility

Fiber lasers can cut various materials like metals (stainless steel, mild steel, titanium), plastics, wood, ceramics, and composites. This versatility makes fiber laser cutting suitable for diverse applications across various industries.

Lower Operating Costs

Fiber lasers are more energy-efficient and require less maintenance than CO2 lasers. They do not need mirror alignments or frequent replacements, which reduces overall operating costs and maintenance requirements.

Minimal Heat-Affected Zone (HAZ)

The focused beam of fiber lasers minimizes the heat-affected zone, which reduces material distortion, warping, and discoloration. This is particularly important when working with sensitive materials that must maintain their structural properties.

Minimal Material Waste

The precision of fiber laser cutting results in very little waste material. This efficiency allows for tighter nesting of parts and maximum material utilization, leading to cost savings and reduced environmental impact.

Automation Capabilities

Fiber laser cutting machines can be easily integrated with automated systems, enhancing productivity and reducing manual labor requirements. Automation enhances consistency and quality since machines perform repetitive tasks with high accuracy.

Fiber laser cutting is a versatile and efficient technology that offers numerous benefits for various industries. Its precision, speed, and cost-effectiveness make it an indispensable tool in modern manufacturing.

Materials Suitable for Fiber Laser Cutting

Metals Suitable for Fiber Laser Cutting

Stainless Steel

Stainless steel is a favored material for fiber laser cutting because of its durability and resistance to corrosion. Fiber lasers can cut stainless steel with high precision, typically achieving cutting speeds between 10 to 20 mm/s and frequencies around 1000 Hz. This makes it ideal for applications requiring clean and precise cuts.

Aluminum and Carbon Steel

Aluminum and carbon steel are both metals that fiber lasers handle well. By adjusting power and speed settings based on the material’s thickness, fiber lasers can efficiently cut these metals, making them suitable for various industrial applications.

Copper and Brass

Copper and brass are challenging to cut due to their high thermal conductivity, but fiber lasers can handle them effectively with the right settings and cooling systems. This capability is particularly useful in industries requiring precise and intricate cuts in conductive materials.

Other Materials Suitable for Fiber Laser Cutting

Plastics and PVC

While not as common as metals, some fiber lasers can cut plastics and PVC. However, this process is generally less efficient compared to CO2 lasers, which are typically preferred for cutting non-metal materials.

Wood and Fabric

Fiber lasers are generally not used for cutting wood and fabric, as CO2 lasers are more suitable for these materials. CO2 lasers provide better efficiency and quality when working with organic materials.

Key Considerations for Fiber Laser Cutting

Several factors need to be considered to achieve optimal results with fiber laser cutting.

Laser Power

The power required for cutting varies depending on the material’s thickness and type. For instance, cutting thick metal sheets (20mm or more) may require higher power, such as a 1500W fiber laser cutter. Proper power settings ensure clean and precise cuts.

Cooling Systems

Cooling systems are essential for preventing overheating and material deformation during the cutting process. Efficient cooling helps maintain the integrity of the cut and prolongs the lifespan of the laser cutting machine.

Cutting Speed and Frequency

Adjusting cutting speed and frequency is crucial for achieving optimal cut quality and efficiency. These parameters must be tailored to the specific material being cut to ensure smooth and precise results.

Benefits of Fiber Laser Cutting

Fiber laser cutting offers numerous advantages, including high precision and minimal burrs, resulting in smooth surfaces. This precision is vital in industries where accuracy is paramount.

Versatility

Fiber lasers can handle a variety of metals and some other materials, making them versatile tools in manufacturing and fabrication processes.

Efficiency

The fast cutting speeds of fiber lasers make them ideal for high-volume production, enhancing overall productivity and reducing operational costs.

Comparing Fiber Laser Cutting to Other Laser Cutting Methods

Fiber Laser vs. CO2 Laser Cutting

Mechanism and Function

Fiber lasers and CO2 lasers generate and transmit laser beams in fundamentally different ways. Fiber lasers use a solid-state gain medium, typically an optical fiber doped with rare-earth elements like ytterbium. This setup results in a highly efficient and compact laser source. In contrast, CO2 lasers use a gas mixture (carbon dioxide, nitrogen, and helium) excited by an electrical discharge to produce the laser beam.

Wavelength and Cutting Efficiency

One key difference is the wavelength of the laser beam, with fiber lasers emitting around 1 micron and CO2 lasers at 10.6 microns. Fiber lasers’ wavelength is more readily absorbed by metals, leading to faster and more efficient cutting. CO2 lasers’ wavelength is better suited for cutting non-metallic materials like wood, acrylic, and plastics but is less efficient for metals.

Applications

Fiber lasers are excellent for cutting thin to medium metal sheets, including reflective metals like aluminum, brass, and copper, which can be challenging for CO2 lasers. They are widely used in industries such as automotive, aerospace, and electronics for precise and high-speed metal cutting. CO2 lasers are preferred for applications involving thicker materials and non-metals, such as signage, woodworking, and plastic fabrication.

Fiber Laser vs. Traditional Cutting Methods

Precision and Accuracy

Fiber lasers offer greater precision and accuracy than traditional methods like plasma cutting and punching. The highly focused laser beam allows for intricate designs and smooth edges, often requiring no additional finishing.

Speed and Productivity

Fiber lasers operate at higher speeds, especially when cutting thin to medium-thickness materials. This speed advantage leads to increased productivity and shorter production cycles, making fiber lasers ideal for high-volume manufacturing environments.

Material Handling and Versatility

Fiber lasers are versatile in handling a wide range of materials, including reflective metals that traditional methods struggle with. They produce cleaner cuts with less material distortion and minimal heat-affected zones, which is crucial for maintaining the integrity of the workpiece.

Pros and Cons of Different Laser Technologies

Fiber Lasers

Fiber lasers are highly efficient, lower operating costs, and require less maintenance due to their compact design. However, they have a higher initial investment and are less effective for thicker non-metal materials.

CO2 Lasers

CO2 lasers excel at cutting a wide range of non-metallic materials and are generally more cost-effective for applications involving thicker materials. However, they have lower efficiency and higher operating costs due to the need for gas mixtures and more complex maintenance. Additionally, CO2 lasers are less effective for cutting reflective metals, which can reflect the laser beam back into the machine and cause damage.

Use Case Scenarios for Each Method

Fiber Laser Cutting:

- Ideal for industries requiring precise and high-speed cutting of thin to medium-thickness metals.

- Suitable for producing intricate parts for automotive, aerospace, and electronics applications.

CO2 Laser Cutting:

- Preferred for cutting thicker materials and non-metals in applications like signage, woodworking, and plastic fabrication.

- Useful in environments where cutting a diverse range of materials is necessary, including both metals and non-metals.

Choosing the Right Fiber Laser Cutting Machine

Choosing the right fiber laser cutting machine involves considering several important factors to ensure it meets your specific needs.

Laser Power and Cutting Area

The laser’s power determines its cutting capabilities, with higher power enabling the cutting of thicker materials. Machines with 1 to 3 kW power are suitable for thin to medium-thickness materials, while 4 kW or higher power is ideal for thicker metals. Additionally, consider the cutting area size to match the dimensions of your materials, as a larger area offers more flexibility for handling bigger workpieces.

Software Compatibility

Make sure the fiber laser cutting machine works with your design software. This compatibility makes file transfer and editing easier, simplifying the cutting process. Choose machines that support common file formats used in design programs like CAD.

Automation and Support

Modern fiber laser cutting machines include automation features like automatic parameter setting, intelligent cutting matching, and user-friendly interfaces, making them easier to use, especially for beginners. Additionally, reliable after-sales support is essential for maintaining performance and longevity. Opt for providers offering comprehensive support, including on-site technician help for setup, training, and optimization, to quickly resolve issues and ensure smooth operation.

Evaluating Machine Specifications

When comparing different fiber laser cutting machines, evaluate the following specifications to make an informed decision:

- Laser Source Type: Ensure the machine uses a high-quality fiber laser source, known for efficiency and durability.

- Cooling System: A robust cooling system is essential to prevent overheating and ensure consistent performance.

- Cutting Speed: Higher cutting speeds translate to increased productivity, so consider machines with faster cutting capabilities.

- Precision and Accuracy: Check the machine’s tolerance levels to ensure it can achieve the precision required for your projects.

- Maintenance Requirements: Opt for machines with low maintenance needs to minimize downtime and operational costs.

Recommendations Based on Common Needs

For SMEs needing flexibility and cost-efficiency, choose a fiber laser cutting machine with 1 to 3 kW power, a moderate cutting area, and user-friendly software. For high-volume production, opt for machines with 4 kW or more power and larger cutting areas for speed and efficiency. For specialized applications, like cutting reflective metals or intricate designs, select machines with advanced features like adaptive optics and high-precision control systems for accuracy.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What is fiber laser cutting and how does it work?

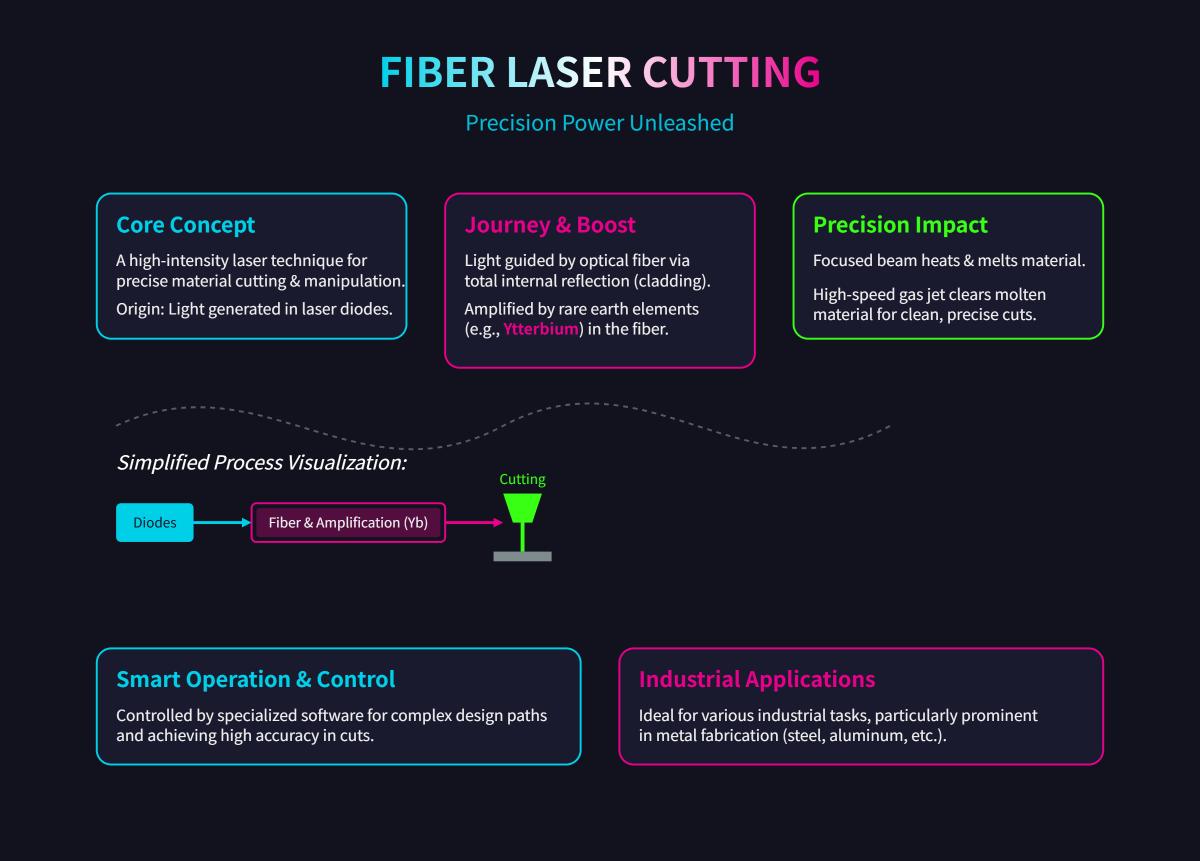

Fiber laser cutting is a modern industrial technique that uses a high-intensity laser to cut and manipulate materials with precision and efficiency. The laser is generated in laser diodes and transmitted through an optical fiber, which contains rare earth elements like Ytterbium to amplify the light. This amplified light is then directed at the material to be cut.

The process involves several steps: First, the laser light is created and guided into a fiber optic cable. The cladding within the cable ensures efficient light transmission through total internal reflection. As the light interacts with the rare earth materials, it is amplified into a powerful laser beam. This beam is then focused on the material, where it heats and melts the surface. A high-speed airflow removes the molten material, allowing for precise cutting.

Controlled by specialized software, fiber laser cutting machines can follow complex design paths with high accuracy, making them ideal for various industrial applications, particularly in metal fabrication.

What materials can be cut with a fiber laser cutter?

Fiber laser cutters are versatile tools capable of cutting various materials, with a primary focus on metals. Common materials that can be efficiently cut using a fiber laser cutter include:

- Stainless Steel: Known for its clean, precise cuts, typically up to 0.75 inches thick.

- Carbon Steels: Provides smooth edges, with a maximum cutting thickness around 0.5 inches.

- Mild Steel: Widely used in industry, can be cut up to 0.6 inches thick.

- Aluminum and Alloys: Lightweight and strong, these can be cut up to 0.4 inches thick, though their reflectivity can pose challenges.

- Copper and Alloys: Reflectivity makes these materials more challenging to cut, with a maximum thickness of about 0.2 inches.

- Titanium: Used in aerospace applications, can be cut up to 0.3 inches thick.

- Nickel Alloys: Known for their heat and corrosion resistance, cuttable up to 0.4 inches thick.

- Foam (EVA, PE, PU, etc.): These materials can be cut with high precision, up to 2 inches thick.

Materials like ABS plastic, HDPE, and PVC are not recommended for fiber laser cutting due to the risk of melting, fire, or toxic fumes. Fiber lasers offer high efficiency and precision, making them ideal for many industrial applications.

How does fiber laser cutting compare to other laser cutting methods?

Fiber laser cutting is a modern and efficient method that offers several advantages over other laser cutting methods, such as CO2 laser cutting. Fiber lasers use solid-state technology and produce a shorter wavelength (around 1 μm), which allows for better absorption and faster cutting speeds, especially for metals. This makes fiber laser cutting highly precise and ideal for detailed and intricate designs.

Compared to CO2 lasers, which use gas mixtures to generate longer wavelengths (10.6 μm), fiber lasers are more versatile in cutting thinner materials quickly. While CO2 lasers are traditionally better suited for cutting thicker materials and non-metallic materials like plastics and stone, fiber lasers have improved to handle thicker metals efficiently.

Additionally, fiber lasers are known for their reliability, lower maintenance requirements, and energy efficiency. They can cut a variety of materials, including metals like steel, aluminum, and copper, and some non-metals, although CO2 lasers may still be preferable for certain non-metallic applications.

What are the advantages of using fiber laser cutting in manufacturing?

Fiber laser cutting offers several advantages in manufacturing, making it a preferred method for many applications. Firstly, it provides high precision and accuracy, allowing for complex cuts with minimal error. This ensures that parts fit together perfectly, often eliminating the need for additional machining. Secondly, fiber laser cutting is highly efficient and fast, particularly when cutting thin metals, which boosts productivity and reduces lead times.

Additionally, fiber lasers are energy-efficient, consuming less power compared to traditional cutting methods, thus lowering operating costs and environmental impact. They also require less maintenance since they lack mirrors and multiple moving parts commonly found in other laser systems. Fiber lasers are particularly effective for cutting reflective metals like stainless steel, copper, and aluminum due to their reduced risk of energy reflection.

Furthermore, fiber laser cutting is a non-contact method, preserving the quality of the material by minimizing thermal distortion and mechanical stress. This leads to consistent, high-quality results across all pieces, reducing the likelihood of errors and rework. Overall, the precision, efficiency, and cost-effectiveness of fiber laser cutting make it a valuable technology in modern manufacturing.

Are there any limitations to using fiber laser cutting?

Fiber laser cutting is an advanced and efficient method for precision cutting, particularly in metal fabrication. However, it has some limitations that users should be aware of. Firstly, fiber lasers are less effective on transparent materials like glass or clear acrylic because the laser beam passes through these materials without being absorbed. Additionally, cutting highly flammable materials such as wood can be hazardous due to the risk of ignition. While fiber lasers can cut metals like copper, brass, and aluminum, the process may not be as efficient or precise and often requires specialized settings.

Another limitation is the thickness of the material. Fiber lasers are best suited for cutting thin to medium-thickness metals. Thicker materials may require multiple passes or alternative cutting methods. Safety considerations are also crucial; cutting certain materials can produce toxic fumes, necessitating proper ventilation and protective gear. Finally, the initial cost of fiber laser cutting machines is high, and they require regular maintenance and specialized training, which can increase operational costs. Understanding these limitations is essential for making informed decisions about using fiber laser cutting technology in various applications.

How can I choose the right fiber laser cutting machine for my needs?

Choosing the right fiber laser cutting machine involves several key considerations to ensure it meets your specific needs. Start by assessing the types of materials you will be cutting, as fiber laser cutters are particularly effective for metals such as steel, aluminum, and copper, and less so for non-metals like wood or acrylic. Next, consider the thickness of the materials, as this will determine the necessary laser power. For example, thin metals may only require a 1kW machine, while thicker materials could need up to 10kW or more.

Evaluate your production needs in terms of volume and speed. High-throughput environments may benefit from machines with faster cutting speeds and automated features. Additionally, consider the machine’s specifications, such as laser power, cutting quality, and the reputation of the brand. Higher power allows for cutting thicker materials but also increases cost, so balance power with your typical material thickness for efficiency.

Budget is another crucial factor. Fiber laser cutters are more expensive than other types but offer superior performance for metal cutting. Consider both the initial investment and ongoing operating costs, including energy consumption and maintenance.