Imagine you’re starting a new project in CAD, but you’re unsure how to set up your drawing frames and borders correctly. This step-by-step guide is designed to help you navigate the world of CAD drawing frame sizes and standards with ease. Whether you’re wondering about the standard sizes for CAD drawing frames, the appropriate line thickness for borders, or the common sheet sizes used in architectural and engineering drawings, this guide has got you covered. We’ll break down each concept, from understanding the BS EN ISO 5457 standard to setting up title blocks and sheet margins. By the end, you’ll have practical tips and insights to ensure your CAD drawings are up to industry standards. Ready to dive in and master the essentials of CAD drawing frames? Let’s get started!

Introduction to CAD Drawing Frame Sizes and Borders

Overview of CAD Drawing Frames

CAD drawing frames are standardized boundaries surrounding the main content of technical drawings. These frames help to organize information, provide space for annotations, and ensure that all necessary details are included in a consistent format.

Importance of Drawing Borders

Borders are essential in CAD drawings as they delineate the working area, maintain a clean and professional look, and ensure all relevant information is contained within the defined space. Borders also include important information like the project name, date, and drawing number.

Standard Sheet Sizes

The dimensions of CAD drawing frames are typically based on standard sheet sizes. These sizes are compatible with printers and facilitate easy handling and storage. Here are some common standard sizes:

| Size | Dimensions (mm) | Common Use |

|---|---|---|

| A4 | 210 x 297 | General documents and drafts |

| A3 | 297 x 420 | Larger technical drawings |

| A2 | 420 x 594 | Detailed architectural plans |

| A1 | 594 x 841 | Large-scale architectural plans |

| B4 | 250 x 353 | Specialized technical drawings |

Creating Full-Scale Drawings

In CAD software, drawings are typically created at full scale (1:1) in model space. This practice allows for precise representation of dimensions and features without scaling issues. When printing, the drawings can be scaled down to fit standard sheet sizes while maintaining their original proportions.

Elements of a CAD Drawing Frame

Borders

Borders define the edges of the drawing area and typically include space for notes, titles, and other relevant information. Standardized border templates are available in most CAD software, ensuring that all drawings adhere to a consistent format.

Title Block

The title block is a critical component of the drawing frame, usually located at the bottom or side of the sheet. It contains essential information such as the project name, drawing number, date, and the name of the drafter. This information helps in identifying and managing drawings efficiently.

Best Practices for CAD Drawing Frames

- Use Standard Sizes: Adhering to ISO or ANSI standards for sheet sizes ensures compatibility with printing systems and consistency across projects.

- Maintain Full-Scale Models: Creating drawings at a full scale in model space helps to avoid scaling errors and ensures precision.

- Organize Layouts Clearly: Ensure that the layout is well-organized to facilitate easy interpretation. Proper placement of views, sections, and details is crucial.

Understanding and implementing CAD drawing frames and borders effectively is essential for producing professional and standardized technical drawings.

Understanding the BS EN ISO 5457 Standard for Drawing Borders

Overview of BS EN ISO 5457

BS EN ISO 5457 is a guideline that outlines the size and layout of preprinted sheets for technical drawings, ensuring consistency and clarity across engineering fields. Understanding this standard is essential for producing professional and compliant technical drawings.

Key Elements of BS EN ISO 5457

Border Specifications

The standard specifies a 20mm wide border on the left side for filing, and 10mm wide borders on the top, right, and bottom sides. These borders help in organizing the drawing and provide space for filing and annotations.

Frame and Drawing Space

The frame around the drawing space should have continuous lines that are 0.7mm thick, ensuring all technical details are contained within this area.

Centring Marks

To ensure accurate positioning during reproduction or microfilming, four centring marks are recommended at the ends of the two symmetry axes of the sheet. These marks aid in precise alignment.

Grid Reference System

Although not directly specified in the 1999 version of the standard, earlier versions suggest the use of a grid reference system. This system includes grid lines that should be at least 0.5mm thick, with reference labels using capital letters along one edge and numerals along the other edge for easy referencing.

Applying BS EN ISO 5457 in CAD Drawings

When creating CAD drawings, adhering to BS EN ISO 5457 ensures standardization and clarity. Here are some best practices:

- Ensure frame lines are consistently 0.7mm thick. If your CAD software doesn’t have this specific thickness, use the thickest available line weight.

- Always use the specified border dimensions (20mm on the left, 10mm on the other sides) to ensure drawings fit within standard templates and can be easily filed or shared.

- Incorporate grid references to organize complex drawings. This practice helps in identifying specific parts or sections, making the drawings easier to read and interpret.

By following these guidelines, you can create clear, organized, and compliant technical drawings that adhere to the BS EN ISO 5457 standard.

Standard Line Thickness (Lineweight) for Drawing Borders

Introduction to Line Weights

Line weights, also known as line thicknesses, are crucial in CAD drawings for distinguishing various elements and ensuring clarity.

Common Line Thickness Standards

Using the correct line thickness for drawing borders helps frame and highlight the design effectively, with heavy line weights like 0.50 mm or thicker typically used for prominent elements such as exterior walls and architectural features. In landscape drawings, 0.6 mm is often chosen for building outlines and borders to create a clear boundary.

Medium line weights, ranging from 0.35 mm to 0.50 mm, are used for walls, floors, and structural elements in section views, providing a balance between visibility and detail without overwhelming the drawing.

Plotting and Scaling Considerations

When plotting drawings at half size, avoid using very fine lines to maintain readability. Use pen tables to adjust line weights for different scales, ensuring clarity.

Standards and Guidelines

USA Standards

In the USA, standards like ASME Y14.5 and Y14.5M offer guidelines for line weights in technical drawings, ensuring consistency and clarity across various types of drawings.

UK Standards

In the UK, BS 8888 and BS 1192 provide similar guidance to maintain uniformity in technical drawings.

Best Practices

Consistency in line weights throughout a drawing is crucial for maintaining visual clarity, helping viewers quickly understand the drawing and locate key elements. Adjust line weights according to the plot scale to ensure readability, using thicker lines for smaller scale drawings if necessary. Utilize established pen tables to manage line weights when plotting at different scales, maintaining consistency and clarity regardless of the drawing size.

Tools and Software

Software like gCADPlus allows for precise control over line thicknesses for different elements in a drawing, essential for creating clear and detailed designs that adhere to established standards.

Overview of Common Standard Sheet Sizes (Arch A, B, C, ANSI Sizes)

ANSI Sizes

ANSI sizes are crucial for anyone working with technical and engineering drawings. ANSI, the American National Standards Institute, provides widely used standard sheet sizes in the United States, especially important for technical and engineering drawings.

- ANSI A: 8.5 x 11 inches (216 x 279 mm)

- This is the same size as a standard letter sheet, commonly used for small technical drawings, reports, and documents.

- ANSI B: 11 x 17 inches (279 x 432 mm)

- Often used for larger drawings requiring more detail than an ANSI A sheet can accommodate, it is also frequently used for creating booklets or folded documents.

- ANSI C: 17 x 22 inches (432 x 559 mm)

- Typically used for detailed architectural or engineering drawings, providing ample space for intricate designs and multiple views.

- ANSI D: 22 x 34 inches (559 x 864 mm)

- Commonly used for large-scale technical drawings and blueprints, ideal for detailed plans and schematics.

- ANSI E: 34 x 44 inches (864 x 1118 mm)

- Used for the largest and most complex drawings, offering a vast area for comprehensive plans and detailed views.

Arch Sizes

Arch sizes are primarily used in architectural drawings, providing larger formats ideal for building plans and construction details.

- Arch A: 9 x 12 inches (229 x 305 mm)

- Slightly larger than ANSI A, suitable for small-scale architectural drawings and preliminary sketches.

- Arch B: 12 x 18 inches (305 x 457 mm)

- Offers more space than Arch A, allowing for more detailed architectural plans and design layouts.

- Arch C: 18 x 24 inches (457 x 610 mm)

- Commonly used for detailed architectural plans, providing a larger canvas for comprehensive building designs and detailed sections.

- Arch D: 24 x 36 inches (610 x 914 mm)

- Often used for full-scale building plans and construction drawings, offering sufficient space for detailed floor plans, elevations, and sections.

- Arch E: 36 x 48 inches (914 x 1219 mm)

- Used for the most extensive architectural drawings, offering a large format for detailed site plans and extensive building layouts.

Comparison and Usage

Although both ANSI and Arch sizes are used for technical drawings, they serve different purposes. ANSI sizes are more standardized for engineering and technical purposes, whereas Arch sizes are tailored for architectural and construction drawings.

Best Practices for Choosing Sheet Sizes

- Consider the Purpose: Select sheet sizes based on the type of drawing (engineering vs. architectural) and the level of detail required. Engineering drawings may benefit from ANSI sizes, while architectural drawings often use Arch sizes.

- Software Compatibility: Choose a sheet size that matches your CAD software’s default settings to simplify the drawing process and avoid compatibility issues.

- Scalability: Choose sheet sizes that can be easily scaled down for printing on smaller paper sizes if needed. This flexibility ensures that drawings remain readable and accessible regardless of the output size.

Detailed Guide to Setting Up Title Blocks and Sheet Margins in CAD Drawings

Title Blocks in CAD Drawings

Title blocks in CAD drawings provide essential information about the project, including the drawing title, author, date, and scale. Setting up title blocks correctly ensures that all necessary details are easily accessible and the drawing maintains a professional appearance.

Purpose of Title Blocks

Title blocks serve multiple purposes:

- Identification: They help identify the drawing by providing key details like the project name, drawing number, and author.

- Metadata: They include metadata such as the date of creation, revision history, and scale of the drawing.

- Consistency: They ensure consistency across different drawings within the same project, making it easier to manage and reference them.

Creating a Title Block

There are two main methods for creating a title block in CAD software:

From Scratch

- Open a new drawing file in your CAD software and switch to the layout tab to design your title block.

- Draw the Boundary: Use the drawing tools to create a rectangle at the bottom or side of the layout to serve as the boundary for the title block.

- Add Text Fields: Insert text fields for the necessary information such as project name, author, date, and scale. Use the text tool to create these fields and place them within the boundary.

- Use dynamic text fields for changing information, such as the date or filename, to keep the title block updated automatically.

Using Templates

- Access Templates: Many CAD programs, like AutoCAD, offer pre-existing title block templates. These can be found in the template library or downloaded from online resources.

- Select a Template: Choose a template that matches your requirements and insert it into your drawing layout.

- Customize Fields: Modify the placeholders in the template to fit your project specifics. Adjust text fields and add any additional information required.

Best Practices for Title Blocks

- Placement: Always place title blocks in the paper space rather than the model space. This allows for easier management and scaling across different paper sizes.

- Consistency: Use standardized title block templates for consistency across all drawings in a project.

- Readability: Ensure that the text size and font are readable. Avoid overly decorative fonts that may hinder readability.

- Information: Include all necessary information such as project name, drawing title, author, date, scale, and any relevant notes or revisions.

Setting Up Sheet Margins

Margins ensure the drawing content isn’t cut off during printing and provide a clean boundary around the drawing area.

Importance of Margins

- Protection: Margins protect important details from being trimmed off during printing.

- Clarity: They provide a clear boundary, making the drawing look neat and professional.

- Space for Notes: Margins offer space for notes, annotations, and other supplementary information.

Configuring Margins in CAD Software

- Open Layout Tab: Open the layout tab of your drawing.

- Page Setup Manager: Right-click on the layout and select the Page Setup Manager.

- Adjust Plot Settings: In the Page Setup Manager, adjust the plot settings to configure the margins. Set the desired margin sizes for the top, bottom, left, and right sides.

Best Practices for Margins

- Standard Sizes: Use standardized margin sizes to maintain consistency across different drawings. Common sizes include 20mm for the left margin and 10mm for the other sides.

- Project Requirements: Adjust margins based on specific project requirements. Some projects may need more space for annotations or additional details.

- Clear Boundaries: Ensure that the margins create clear boundaries around the drawing content, enhancing readability and professionalism.

Following these steps and best practices will help you set up title blocks and sheet margins in CAD drawings, ensuring clarity, consistency, and a professional look for your projects.

Practical Tips for Ensuring CAD Drawing Layouts Comply with Standards

Understanding the Importance of CAD Standards

CAD standards are a set of predefined rules that organize drawings, covering aspects like layer naming, dimension styles, text fonts, line types, and drawing frame sizes. Adhering to these standards ensures uniformity across all drawings in a project, which facilitates efficient collaboration and review.

Choosing the Correct Drawing Frame Size

Select a drawing frame size that matches common paper sizes like A0, A1, A2, A3, and A4, based on your geographical standard (ISO, ANSI, etc.). Ensure the frame size comfortably fits your drawing details without overcrowding or leaving too much whitespace. The physical size of the detail should be proportionate to the sheet size to fit the border and title block appropriately.

Using Standardized Title Blocks and Borders

Title blocks should include essential information such as the project name, drawing title, scale, date, and revision number. To avoid clutter, maintain a separate title block with a detail grid system. Each detail should fit into one or more grid spaces without overlapping to keep the layout organized. Consistent title blocks help in quick identification and referencing of drawings.

Layout Setup: Paper Space vs. Model Space

Draw your design in Model Space at a real-world scale, and use Paper Space to set up the drawing frame and viewports. Set viewports to the appropriate scale that matches your dimensioning and detail requirements. Place all elements like title blocks, borders, and annotations in Paper Space to prevent scaling issues when printing.

Maintaining Correct Drawing Order and Layer Usage

Follow a strict layering convention where each type of object, such as dimensions, text, lines, and hatches, is placed on a specific layer with predefined color, linetype, and lineweight settings. Arrange drawing elements in the correct order, such as placing dimension lines on top of geometry lines, to avoid confusion during reading. Use BYLAYER properties for color, linetype, and lineweight to maintain consistency and ease of changes.

Setting Dimension and Text Styles According to Standards

Use standardized dimension settings such as arrow size, extension line length, text height, and alignment. For example, an arrow size might be set to 1/8 inch, text height to 3/32 inch, with text placed above and centered to the dimension line. Dimension units, precision, and zero suppression should conform to project or regional standards (e.g., architectural units with 1/16” precision). Text styles should be clear and consistent, using a standard font and size, with text colors set to BYLAYER.

Verifying Scale and Fit of Details

Before finalizing the layout, make sure all details and annotations fit within the designated frame and grid spaces without overlap or excessive blank areas. Adjust sizes and scales as necessary to ensure legibility and proper alignment with the title block and border.

Developing and Deploying a CAD Standards Manual

Document your CAD standards in a clear, accessible manual covering frame sizes, title block design, layer naming, dimension styles, and plotting instructions. Train users and integrate these standards into CAD templates to ensure consistent application across all projects.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the standard sizes for CAD drawing frames and borders?

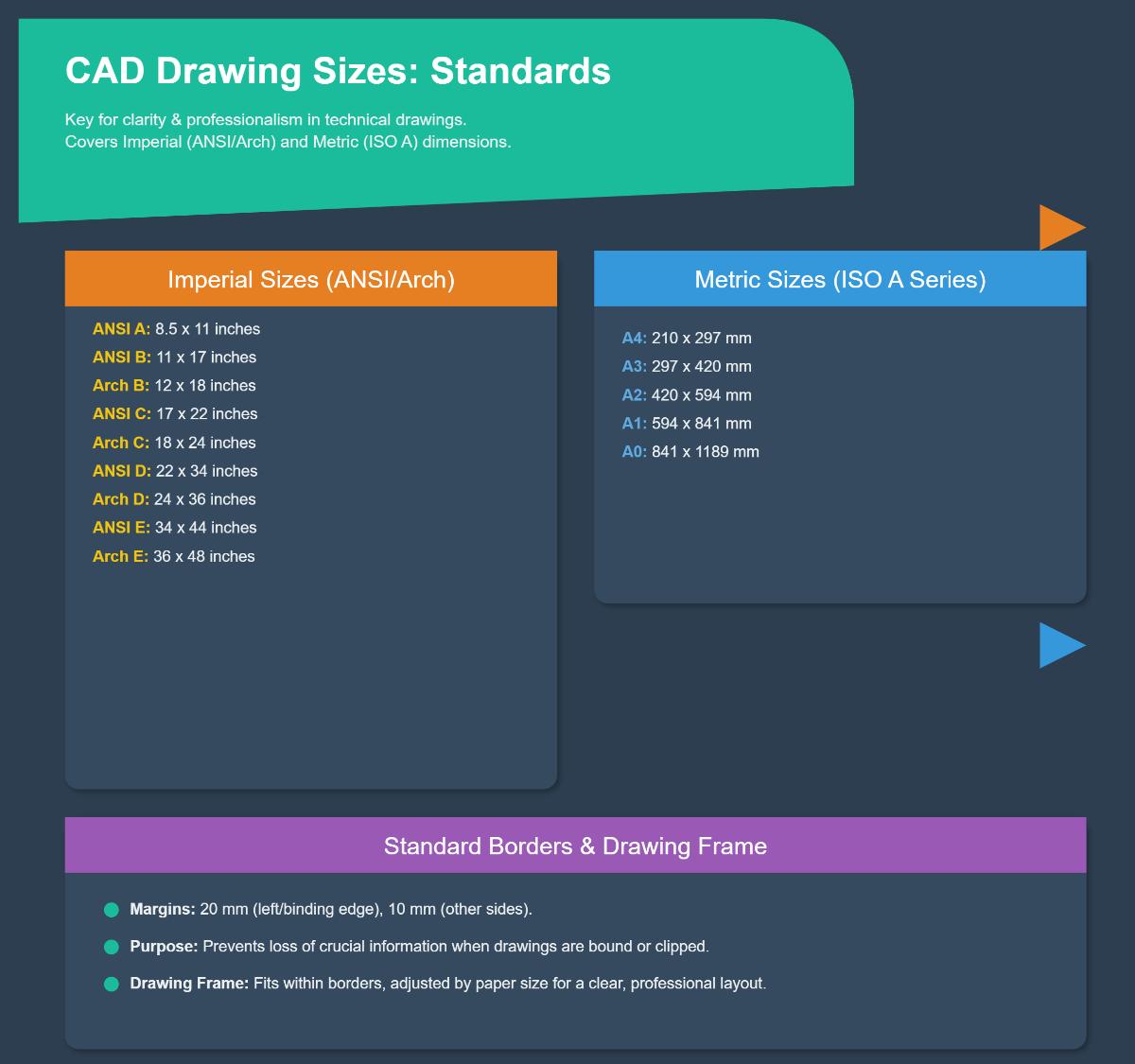

Standard sizes for CAD drawing frames and borders are essential for ensuring clarity, consistency, and professionalism in engineering and architectural drawings. These sizes typically correspond to standard paper dimensions, which are divided into Imperial (ANSI/Architectural sizes) and Metric (ISO A series).

For Imperial sizes, common dimensions include:

- ANSI A: 8.5 x 11 inches

- ANSI B / Arch B: 11 x 17 / 12 x 18 inches

- ANSI C / Arch C: 17 x 22 / 18 x 24 inches

- ANSI D / Arch D: 22 x 34 / 24 x 36 inches

- ANSI E / Arch E: 34 x 44 / 36 x 48 inches

For Metric sizes, commonly used dimensions are:

- A4: 210 x 297 mm

- A3: 297 x 420 mm

- A2: 420 x 594 mm

- A1: 594 x 841 mm

- A0: 841 x 1189 mm

Standard borders typically have a 20 mm margin on the left (binding edge) and 10 mm margins on the other three sides. This setup ensures no essential information is lost when drawings are bound or clipped. The drawing frame, where the actual content is placed, fits within these borders, adjusted according to the paper size to maintain a clear and professional layout.

What line thickness should be used for drawing borders in CAD?

For drawing borders in CAD, the recommended line thickness is generally 0.7 mm. This thickness is considered the thickest lineweight and is typically used for borders and title blocks in technical drawings. Using a 0.7 mm line ensures clarity and emphasis, differentiating the border lines from other elements in the drawing. This standard aligns with guidelines such as the BS EN ISO 5457, which is commonly followed in engineering and architectural documentation. Adopting this line thickness helps define the drawing sheet clearly, making it easier to read and file, thus ensuring your CAD drawings maintain a professional and standardized appearance.

Where should the title block and other information be placed on a CAD drawing sheet?

The title block, which contains essential project information such as the project title, location, project number, date issued, and organization details, should be placed in the lower right corner of the CAD drawing sheet. This placement is a standard practice to ensure consistency and easy reference across various drawings. The specific size and arrangement of the title block may vary depending on the CAD standards being followed. Consistency in using the same title block format and placement across all drawings is crucial for maintaining a standardized process.

What are common standard sheet sizes used in architectural and engineering drawings?

Common standard sheet sizes used in architectural and engineering drawings are crucial for ensuring clarity and consistency across projects. In architectural drawings, the most frequently used sizes in the U.S. include ARCH A (9 x 12 inches), ARCH B (12 x 18 inches), ARCH C (18 x 24 inches), ARCH D (24 x 36 inches), and ARCH E (36 x 48 inches). These sizes are well-suited for construction plans and large format documents.

For engineering drawings, the ISO A series is widely used internationally, including sizes such as A0, A1, A2, and A3. These sizes are based on the ISO 216 standard, ensuring global consistency. In the U.S., ANSI sizes may also be used, though they are more common for general office documents.

Using these standardized sizes helps maintain organization, consistency, and facilitates better communication and collaboration among architects, engineers, and contractors.

How can I ensure my CAD drawing layout complies with industry standards?

To ensure your CAD drawing layout complies with industry standards, start by familiarizing yourself with common guidelines like the United States National CAD Standard (NCS), which provides comprehensive rules on drawing orientation, layout, symbols, and line types. Follow these key steps:

- Consistent Drawing Orientation and Layout: Ensure your drawings are consistently oriented and laid out, with standard title blocks and borders.

- Standard Line Types and Dimensions: Use standardized line types and ensure dimensions are formatted and scaled correctly as per NCS guidelines.

- Layer Management: Organize CAD elements into appropriate layers based on disciplines, such as architectural or civil, to maintain clarity and facilitate team collaboration.

- Scale and Coordinates: Create drawings at true scale and coordinates in model space to ensure accuracy.

- Unit Systems: Use a consistent unit system throughout the project, either architectural (feet and inches) or engineering (decimal).

- Precision Input: Use precision input techniques to accurately place all elements and ensure intersections are precise.

Additionally, developing a comprehensive guide for your organization’s CAD standards, providing regular training, and periodically updating the standards to reflect industry changes will help maintain compliance. Resources like Autodesk University and the National CAD Standard (NCS) offer valuable guidance and examples.

Are there any tools or software recommendations for setting up CAD drawings according to standards?

When setting up CAD drawings according to standards, there are several tools and software options available that can help ensure compliance. AutoCAD is the most widely recognized CAD software, offering extensive tools for both 2D and 3D drafting, and it supports common file formats like DWG and DXF, facilitating standard adherence. DraftSight Professional is another versatile option, providing a familiar interface and advanced features such as layer management and dimensioning to maintain drawing standards. SmartDraw is user-friendly, with built-in templates and symbols for various engineering and architectural standards. Creo, developed by PTC, is robust for complex designs and ensures engineering standards compliance, particularly in the automotive and mechanical sectors. Lastly, Alibre Atom3D is a beginner-friendly software that supports 3D modeling and design, making it suitable for newcomers to CAD drafting. These tools help streamline the process of creating CAD drawings that meet industry standards, improving efficiency and collaboration.