Are you struggling to accurately calculate the weight of GI wire for your construction or engineering project? Intermediate users often face this challenge, as it’s crucial for ensuring the right amount of material is used. GI wire, composed of galvanized iron, has specific properties that affect its weight. To calculate it, a standard formula is used, but different factors can impact the result. In this step-by-step guide, you’ll learn how to use a GI wire weight calculator effectively. But how can you make your calculations even more precise? Let’s find out.

Introduction to GI Wire

What is GI Wire?

GI wire, or Galvanized Iron wire, is a type of metal wire coated with a protective layer of zinc through galvanization. This zinc coating provides enhanced durability and resistance to corrosion, making GI wire an ideal choice for various applications, especially those exposed to outdoor or harsh environments.

Composition and Manufacturing Process

The base material for GI wire is typically low-carbon steel, chosen for its good balance of strength and flexibility. The manufacturing process involves several steps:

- Wire Drawing: This process involves pulling the steel through a series of dies to create thin wires. Each die reduces the diameter of the wire, gradually bringing it to the desired thickness.

- Annealing: The drawn wires are heat-treated to relieve internal stresses and improve ductility. This process involves heating the wires to a specific temperature and then allowing them to cool slowly.

- Pickling: The wires are cleaned using an acid solution to remove any surface impurities such as rust or scale that may have formed during the drawing and annealing processes.

- Galvanizing: This step involves coating the cleaned steel wires with a layer of zinc to protect them from corrosion.

Key Properties Relevant to Weight Calculation

Durability and Corrosion Resistance

The zinc coating on GI wire acts as a powerful shield, greatly boosting its ability to resist rust and corrosion. This property is crucial for applications where the wire is exposed to moisture or chemicals, ensuring a longer lifespan and reducing the need for frequent replacements.

Tensile Strength

GI wire boasts high tensile strength, making it suitable for demanding applications that require robust and reliable materials. Tensile strength is a critical factor in weight calculations, as it determines the load the wire can handle without breaking.

Flexibility and Ductility

The flexibility and ductility of GI wire make it easy to work with, allowing it to be bent and twisted without breaking. These properties are especially important for applications that involve intricate designs or require the wire to conform to specific shapes.

Gauge and Diameter

GI wire is available in various gauges, which correspond to different diameters. The gauge of the wire is a key parameter in weight calculations, as it directly affects the wire’s cross-sectional area and, consequently, its weight. Common gauges range from 8 to 24, with lower numbers indicating thicker wires. For example, thicker gauges like 8 and 10 are often used in heavy-duty construction and fencing, while thinner gauges like 20 and 22 are used in lightweight applications such as crafting and small-scale agricultural projects.

Common Uses of GI Wire

Construction

In the construction industry, GI wire is widely used for binding materials, reinforcing concrete, and creating wire meshes. Its durability and strength make it an essential component in building structures that require long-lasting performance. Compared to other materials, GI wire’s resistance to corrosion ensures that it can withstand the test of time even in challenging environments.

Fencing and Security

GI wire is often used in the production of barbed wire, chain-link fences, and other security barriers. Its corrosion resistance ensures that these structures remain effective and intact over time, even in harsh environmental conditions. This makes GI wire a preferred choice over other materials that may degrade or rust quickly.

Agriculture

In agricultural settings, GI wire is used for creating trellises, supporting plant growth, and constructing animal enclosures. Its flexibility allows it to be adapted to various farming needs, while its durability ensures it can withstand outdoor conditions. The protective zinc coating helps it resist weather-related wear and tear, providing a reliable solution for farmers.

Telecommunications

GI wire is utilized in the telecommunications industry for suspending cables and providing structural support. Its high tensile strength and resistance to corrosion make it a reliable choice for these critical applications. The wire’s ability to maintain integrity under different weather conditions ensures uninterrupted service and support for communication networks.

The Significance of Accurate GI Wire Weight Calculation

Importance in Construction and Engineering

Accurate weight calculations for GI wire are crucial in construction and engineering for several reasons.

Efficient Material Management and Optimized Transportation

Accurate weight calculations facilitate efficient material management and optimized transportation. By knowing the exact weight, project managers can estimate the right quantity of wire needed, avoiding both shortages and excesses. This optimization helps in managing storage space effectively and ensures that inventory levels are maintained properly, reducing the risk of project delays. Additionally, knowing the exact weight helps in loading trucks to their maximum capacity without exceeding weight limits, which reduces transportation costs and prevents fines.

Cost Planning and Budgeting

Precise weight calculations are vital for cost planning and budgeting. They enable accurate estimation of material costs, helping to prepare detailed and realistic project budgets. This is particularly important in large-scale projects where even small inaccuracies can lead to significant cost overruns.

Factors Affecting GI Wire Weight

Several factors influence the weight of GI wire, and understanding these is crucial for accurate calculations:

Wire Diameter

The diameter of the GI wire is a primary determinant of its weight. Larger diameters result in heavier wires. The diameter is typically measured in millimeters and is a key input in weight calculation formulas.

Wire Length

The total length of the wire required for a project directly impacts the overall cost and feasibility of the project. A longer length of wire means higher material costs and potentially more labor for installation.

Material Density

The density of the material from which the GI wire is made also affects its weight. GI wire generally has a density of around 7.9 g/cm³, and this value is used in weight calculation formulas to provide more precise results.

Zinc Coating Thickness

The thickness of the zinc coating on GI wire can slightly alter its weight. While this effect is often minimal, in applications requiring high precision, it might be necessary to account for the coating’s contribution to the overall weight. This is particularly important in engineering projects where exact specifications are crucial for performance and safety.

Key Benefits of Accurate Weight Calculation

Enhanced Safety and Compliance

In construction and engineering, safety and compliance with building codes and standards are paramount. Accurate weight calculations ensure that the structures and components are designed to handle the intended loads safely. This reduces the risk of structural failures and enhances the longevity and reliability of the building.

Improved Project Efficiency

Accurate weight calculations improve project efficiency by ensuring optimal use of materials. This helps in streamlining various project phases, from procurement and storage to transportation and installation, longevity and reliability of the building.

Environmental Sustainability

Efficient use of materials, facilitated by accurate weight calculations, also supports environmental sustainability. By reducing material waste and optimizing resource usage, projects can minimize their environmental footprint, contributing to more sustainable construction practices.

Accurate calculation of GI wire weight is indispensable for effective project management, cost control, and compliance with safety standards. Understanding the factors that influence wire weight and the benefits of precise calculations can significantly enhance project outcomes.

Formulas for GI Wire Weight Calculation

To calculate the weight of GI wire, you need to understand the basic formula that relates volume to density.

To use this formula, you first need to calculate the volume of the GI wire. The volume of a wire, which has a cylindrical shape, can be determined using the formula:

In this formula, the diameter is the thickness of the wire, measured in meters, and the length is the total length of the wire, also in meters. The density of GI wire is approximately (7850kg/m3).

Steps to use the basic formula:

- Measure the wire’s diameter and length in meters.

- Calculate the volume using the formula.

- Multiply the volume by the density (7850kg/m3) to get the weight in kilograms.

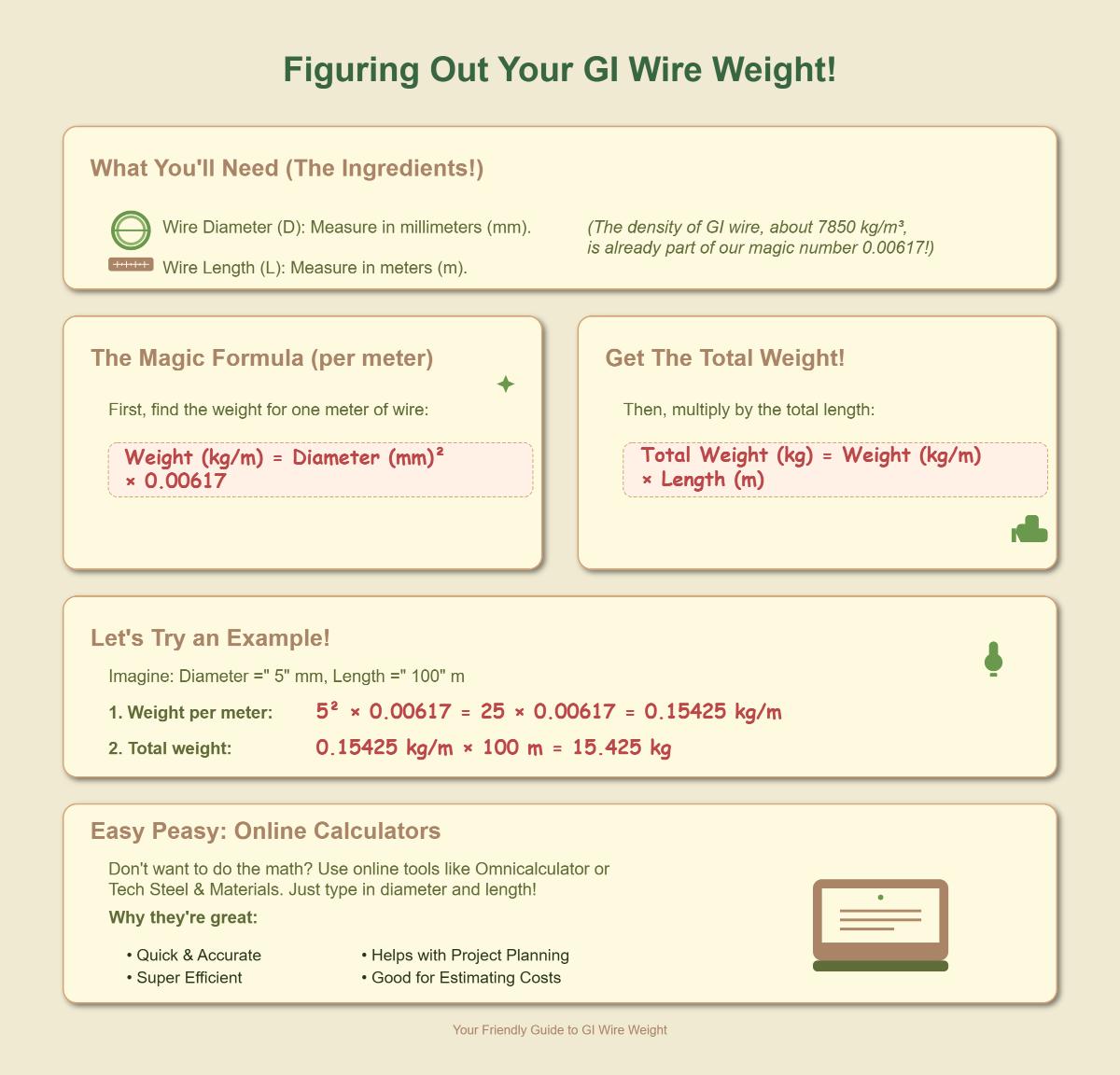

For quick estimates, you can use a simplified formula. This formula allows you to estimate the weight per meter of the wire without having to calculate the volume explicitly.

The simplified formula is:

In this formula, the diameter is measured in millimeters.

Steps to use the simplified formula:

- Measure the wire’s diameter in millimeters.

- Square the diameter.

- Multiply by (0.00617) to get the weight per meter in kilograms.

- For total weight, multiply this by the wire’s length in meters.

The diameter of the GI wire has a significant impact on its weight. In both formulas, a larger diameter leads to a heavier wire. In the basic formula, the diameter is squared when calculating the volume, which means that even a small increase in diameter can result in a substantial increase in weight. In the simplified formula, the diameter is also squared, directly affecting the weight per meter.

The length of the wire is directly proportional to its weight. In the basic formula, the length is a multiplier in the volume calculation, so a longer wire will have a greater volume and, consequently, a higher weight. In the simplified formula, the length is used to calculate the total weight after determining the weight per meter.

The density of the GI wire is a constant value in the formulas. Using the correct density of approximately (7850kg/m3) is crucial for accurate weight calculations. Any deviation from this value can lead to inaccurate results.

Although the zinc coating on GI wire isn’t usually included in weight calculations, it does add to the total weight. For precise applications, estimate the zinc coating’s volume, multiply by zinc’s density, and add this to the wire’s base weight.

Practical Guide to Using a GI Wire Weight Calculator

Introduction

A GI wire weight calculator is an invaluable tool for determining the precise weight of galvanized iron wire. This accuracy is essential for various industries, including construction, civil engineering, and manufacturing. This guide provides a step-by-step approach to effectively using a GI wire weight calculator and offers insights into manual calculation methods.

Understanding the Basics of GI Wire Weight Calculation

To calculate the weight of GI wire, the primary formula used is:

GI wire typically has a density of about 7850 kg/m³.

Simplified Formula for Quick Estimation

A quick estimation formula for GI wire weight per meter is:

This formula allows for rough weight estimations based on the wire diameter in millimeters.

Step-by-Step Guide to Using a GI Wire Weight Calculator

Step 1: Locating a Reliable Calculator

Start by finding a trustworthy GI wire weight calculator. Many online tools are available, offering a user-friendly interface for quick and accurate calculations. Make sure the calculator is tailored for GI wire to accurately consider its material properties.

Step 2: Inputting Necessary Parameters

Once you have located a reliable calculator, follow these steps:

- Select Metal Type: Choose galvanized steel as the metal type. This ensures the calculator uses the correct density for GI wire.

- Input Wire Diameter: Enter the wire diameter in millimeters. Accurate measurement of the diameter is crucial for precise weight calculation.

- Enter Total Length: Specify the total length of the wire required in meters. This value is necessary to calculate the total weight of the wire.

Step 3: Interpreting the Calculator Results

After inputting the necessary parameters, perform the calculation. The calculator will use the provided data to determine the volume of the wire and multiply it by the material’s density to give you the weight instantly. Review the results to ensure they align with your project requirements.

Manual Calculation Process

For those who prefer manual calculations or wish to verify the results provided by the calculator, follow these steps:

- Measure Total Length: Determine the total length of the GI wire needed in meters.

- Calculate Weight per Meter: Apply the simplified formula:

- Multiply by Total Length: Finally, multiply the calculated weight per meter by the total length of the wire.

Applications and Importance

Construction and Civil Engineering

Precise weight calculations are crucial for construction and civil engineering projects like gabion boxes and fencing. Ensuring accurate weight estimations helps maintain structural stability and compliance with safety standards.

Manufacturing

In manufacturing processes like barbed wire production, accurate weight calculations ensure consistent product quality and efficient inventory management. This precision is critical for maintaining production schedules and minimizing material waste.

Additional Considerations for Complex Applications

For more complex applications, such as welded wire mesh or gabions, additional factors need to be considered:

- Mesh Dimensions: Calculate the area and perimeter of the mesh to determine the total length of wire used.

- Specialized Calculators: Use tools designed to account for mesh area, perimeter, and wire diameter for more accurate estimates.

Benefits of Using GI Wire Weight Calculators

- Efficiency: Automated calculations save time and minimize manual effort.

- Precision: Ensures accurate material management and cost estimation, critical for project planning.

- Convenience: Offers pre-calculated values for standard projects, making it easier to estimate material needs.

By following these steps and understanding the principles behind GI wire weight calculators, you can ensure precise material planning and management for your projects.

Advanced Calculation Techniques

Techniques for More Precise Calculations

Accounting for Zinc Coating Thickness

For high-precision applications, the zinc coating on GI wire can affect the weight. First, measure the average thickness of the zinc coating. Then, calculate the volume of the zinc layer by considering the wire as a cylinder with the coating. Subtract the volume of the inner steel core. Multiply the volume of the zinc layer by the density of zinc (approximately 7140 kg/m³). Add this weight to the weight of the steel core, which can be calculated using the standard wire weight formula.

Adjusting for Temperature and Environmental Effects

Temperature changes can cause the wire to expand or contract, slightly altering its volume and weight. Use the coefficient of thermal expansion for steel (about 1.2×10⁻⁵ /°C). Measure the initial length and diameter of the wire at a reference temperature. Calculate the change in length and diameter based on the expected temperature change. Then, recalculate the volume and weight using the adjusted dimensions.

Tools and Software for Advanced Users

Specialized Online Calculators

There are many online calculators designed for advanced GI wire weight calculations. These tools can account for factors such as zinc coating thickness, temperature effects, and complex geometries. Examples of reliable calculators include those available on engineeringtoolbox.com and omnicalculator.com. Input all relevant parameters, including the wire’s diameter, length, zinc coating thickness, and expected temperature. The calculator will then provide a more accurate weight calculation.

CAD and Engineering Software

For complex projects, computer-aided design (CAD) and engineering software can be invaluable. Import the wire’s geometry into the software and define the material properties, including the densities of steel and zinc. The software can perform detailed calculations, considering the wire’s shape, any bends or curves, and other factors. This approach is particularly beneficial for projects involving custom-shaped GI wire components, providing precise and comprehensive analysis.

Real-World Applications and Case Studies

Practical Applications

Construction Projects

In building projects, accurate weight calculations of GI wire are vital for ensuring structural integrity and compliance with safety regulations. For example, in reinforced concrete structures, the weight of GI wire mesh can significantly impact the overall load-bearing capacity and stability of the construction.

1. First, engineers determine the project’s structural requirements, including the load it must support.

- Based on these requirements, they select the appropriate wire diameter and mesh size.

- Next, they use a GI wire weight calculator to estimate the total weight of the wire mesh needed.

Logistics and Transportation

Proper weight planning helps in optimizing shipment loads, reducing logistics expenses, and avoiding fines related to overloading vehicles. This is particularly important for large-scale construction projects where materials are transported over long distances. The steps to achieve this are:

- Calculate the weight of all the GI wire required for the project using a reliable calculator.

- Plan the number of shipments based on the vehicle’s load capacity.

- Ensure that the total weight of each shipment does not exceed the legal limits.

Material Procurement

By accurately estimating the weight of GI wire needed for a project, businesses can avoid unnecessary material waste and reduce procurement costs. The process is as follows:

- Analyze the project plan to determine the GI wire specifications (diameter, length, quantity) and use a weight calculator for an accurate estimate.

- Place an order for the required amount of wire, taking into account a small buffer for unforeseen circumstances.

Case Studies

Example 1: Gabion Construction

- Project Overview: A construction company is building a gabion wall to prevent soil erosion in a rural area. The gabion requires a specific amount of GI wire mesh.

- Challenge: Accurately calculating the weight of GI wire needed for the mesh to ensure sufficient material supply without excess.

- Solution Steps:

- The company measures the dimensions of the gabion wall, including its length, height, and the size of the mesh openings.

- They input the wire diameter and the measured dimensions into a GI wire weight calculator.

- Based on the calculator’s output, the company purchases the exact amount of GI wire mesh, optimizing costs and reducing waste.

Example 2: Wire Mesh Reinforcement

- Project Overview: A manufacturing facility is producing reinforced concrete slabs using GI wire mesh for reinforcement.

- Challenge: Determining the precise weight of GI wire mesh to meet the structural requirements of the slabs while minimizing excess material.

- Solution Steps:

- The facility’s engineers analyze the structural design of the concrete slabs to determine the required wire diameter, mesh size, and 2. They use a specialized calculator that accounts for the mesh dimensions, wire diameter, and material density.

- After getting the accurate weight calculation, the facility produces the wire mesh according to the specifications, ensuring that the structural requirements are met without unnecessary waste.

Solution-Oriented Approach

Calculation Methods

- Basic Formula: Calculate GI wire weight with the formula (Weight (kg/m)=Wire Diameter2×0.00617 ). To get the 1. Measure the total length of the wire in meters.

- Calculate the weight per meter using the formula.

- Multiply the weight per meter by the total length of the wire.

- Mesh Calculations: For wire mesh, the calculation involves the mesh dimensions and wire diameter. A simplified formula is (Weight (kg)=(Wire Diameter2×Mesh Number×Width×Length)/2 ). The steps are:

- Determine the wire diameter, mesh number (number of openings per unit length), width, and length of the mesh.

- Input these values into the formula to calculate the weight.

Technology Integration

- Online Calculators: Utilizing online GI wire weight calculators can streamline the process, providing quick and accurate results.

- Find a reliable online calculator, such as those provided by MachineMFG and MG Demir.

- Input parameters like wire diameter, length, and mesh dimensions.

- Obtain the weight calculation instantly.

- Software Solutions: For complex projects involving multiple wire mesh configurations, software solutions can automatically calculate wire lengths and multiply by width, ensuring accuracy across various material types.

- Select appropriate software based on the project’s complexity.

- Input all the relevant information about the wire and mesh configurations.

- Let the software perform the calculations and generate accurate weight estimates.

Industry Benefits

- Cost Efficiency: Accurate weight calculations help reduce material waste and procurement costs. By following the above-mentioned steps for calculation and procurement, companies can order the right amount of GI wire, saving money on excess materials.

- Compliance: Ensuring compliance with weight regulations during transportation is crucial. By accurately calculating the weight of GI wire for each shipment, companies can avoid potential fines related to overloading vehicles.

Frequently Asked Questions

Below are answers to some frequently asked questions:

How do I calculate the weight of GI wire for my project?

To calculate the weight of GI wire for your project, you need to follow a straightforward process. First, gather the necessary parameters: the wire’s diameter, length, and the density of the GI wire (typically around 7850 kg/m³). The basic formula to calculate the weight per meter of GI wire is:

This formula provides the weight per meter based on the diameter. To find the total weight, multiply this result by the total length of the wire in meters.

For example, if you have a wire with a diameter of 5 mm and a length of 100 meters:

Weight (kg/m)=52×0.00617=0.15425 kg/m

Total Weight=0.15425 kg/m×100 m=15.425 kg

Alternatively, you can use reliable online GI wire weight calculators, such as those from Omnicalculator or Tech Steel & Materials, which simplify the process by requiring you to input the diameter and length. These tools ensure accuracy and efficiency in your calculations, aiding in project planning and cost estimation.

What formula should I use to estimate the weight of GI wire?

To estimate the weight of GI (Galvanized Iron) wire, you can use the following simplified formula, which is suitable for most practical purposes:

In this formula:

- Wire Diameter should be measured in millimeters (mm).

- The result will give you the weight per meter in kilograms (kg).

To find the total weight of the GI wire, multiply the weight per meter by the total length of the wire in meters:

This approach ensures you can quickly and accurately estimate the weight of GI wire, which is crucial for material management and cost estimation in construction and engineering projects. For more precise calculations, consider using a reliable GI wire weight calculator available online.

Are there any advanced techniques to improve the accuracy of my calculations?

To improve the accuracy of your GI wire weight calculations, consider implementing the following advanced techniques:

Precision in Input Values: Ensure that all measurements and inputs are as precise as possible. Small errors in diameter or length can significantly impact the final weight calculation.

Verification of Formulas: Familiarize yourself with the standard formulas used in GI wire weight calculations. Understanding these formulas helps in verifying the results generated by calculators.

Double-Check Calculations: Manually double-check critical calculations to confirm the accuracy of the automated results. This verification step can catch potential errors.

Use of Advanced Software: Employ specialized software tools that offer enhanced accuracy and additional features for weight calculations. These tools often include error-checking mechanisms and advanced algorithms.

Environmental Factors: Consider factors such as temperature and humidity, which can affect the weight of GI wire. Adjust calculations accordingly if these variables are significant in your application.

Regular Calibration: Ensure that any measuring instruments used are regularly calibrated to maintain accuracy.

Practice Estimation Techniques: Develop a habit of estimating weights using mental math to quickly identify any discrepancies in calculator results.

By integrating these techniques, you can achieve more precise and reliable GI wire weight calculations, enhancing the accuracy and effectiveness of your engineering projects.

How does accurate GI wire weight calculation benefit construction projects?

Accurate GI wire weight calculation offers several benefits to construction projects. In terms of cost management, it helps order the right quantity of wire, preventing shortages and excess inventory, and allows for precise material cost estimation. For safety and structural integrity, precise calculations ensure that the GI wire meets strength and load requirements, adhering to building codes. Regarding logistics and transportation, it aids in planning shipping and optimizing storage space, ensuring compliance with regulations and preventing vehicle overloading.

What are some common mistakes to avoid when using a GI wire weight calculator?

When using a GI wire weight calculator, several common mistakes can impact the accuracy of your results. First, ensure consistency in units; all measurements should be in the same unit system (e.g., meters and kilograms). Incorrectly measuring or converting the wire’s diameter or gauge is another frequent error; verify the gauge and convert it accurately using systems like the American Wire Gauge (AWG).

Additionally, use the correct material density for GI wire, typically around 7850 kg/m³. Miscalculating the total wire length needed for your project can lead to errors, so measure accurately. If working with welded wire mesh, include mesh dimensions and the total wire length in your calculations. Lastly, while simplified formulas can provide estimates, for complex scenarios, use comprehensive formulas and reliable online calculators to ensure precision.

Where can I find reliable GI wire weight calculators?

To find reliable GI wire weight calculators, you can explore several reputable sources online. Websites such as Steel Tubes India offer comprehensive wire weight calculators for various metal types, including GI wire. Additionally, MFG Shop discusses the use of GI wire weight calculators and suggests tools like Omnicalculator and Vincent Metals for detailed calculations. Online Metals provides a general metal weight calculator that can be adapted for GI wire by inputting the appropriate material and dimensions. Another option is 247Calculator, which supports different materials and allows you to input wire thickness and length. These calculators typically require you to select the material (GI wire), enter the wire diameter and length, and then calculate the weight based on the density of GI wire, which is approximately 7.9 g/cm³.