Are you ready to take your automation projects to the next level by mastering the setup of a servo driver? Whether you’re an intermediate hobbyist or a professional looking to fine-tune your skills, this comprehensive step-by-step tutorial will guide you through the entire process. From understanding the essential components and preparing your workspace, to wiring your servo motor and integrating it with a PLC, we’ve got you covered. We’ll delve into the nitty-gritty of configuration, ensuring your servo driver operates smoothly and efficiently. By the end of this guide, you’ll not only know how to connect a servo motor to a servo driver but also how to troubleshoot common setup issues. Ready to dive in and unlock the full potential of your servo systems? Let’s get started!

Introduction

Introduction to Servo Driver Setup

Servo drivers play a vital role in controlling servo motors, which are essential in applications like robotics, automation, and CNC machines. They convert low-power control signals into high-power signals necessary for precise motor operation. This section provides an overview of the components involved and the initial steps required for setting up a servo driver.

Key Components Overview

Servo Motor

A servo motor typically has three wires: power, ground, and a signal wire, which receives command pulses to control the motor’s position, speed, and direction.

Servo Driver

The servo driver converts control signals from a controller, such as a PLC or microcontroller, into the high-power signals needed to drive the servo motor, ensuring precise positioning and movement.

PLC (Programmable Logic Controller)

In automation systems, a PLC is commonly used to control servo drivers by sending precise command signals based on its programmed logic.

Power Supply

A reliable power supply is essential for both the servo driver and the motor. The power supply must match the voltage and current requirements specified by the servo driver and motor.

Analog Servo Drive

In some setups, an analog servo drive may be used, which operates with analog signals for control. This type of drive is suitable for applications requiring smooth and continuous control.

Preparing for Installation

Before beginning the installation, gather all necessary tools and materials, such as wiring diagrams, connectors, and safety equipment. Adhere to all safety precautions to avoid electrical hazards and ensure a successful setup.

By understanding these components and preparing adequately, you can proceed with confidence to wire and configure your servo driver system.

Understanding the Components

Servo Driver

A servo driver is a key component in servo motor systems that converts low-power control signals into high-power signals to drive the motor. It ensures precise control over the motor’s position, speed, and torque by receiving commands from a controller, such as a PLC (Programmable Logic Controller) or a microcontroller, and translating these commands into actions by adjusting the power supplied to the servo motor.

Servo Motor

The servo motor is an actuator that converts electrical signals into precise mechanical movements, typically consisting of a rotor, stator, and an encoder or resolver for feedback. The motor operates based on the control signals received from the servo driver, allowing for accurate control of angular or linear position, velocity, and acceleration. Servo motors are commonly used in applications requiring high precision, such as robotics, CNC machinery, and automation systems.

PLC (Programmable Logic Controller)

A PLC is a specialized computing device used in industrial control systems to automate processes. In servo systems, a PLC sends control signals to the servo driver and can be programmed to perform tasks like coordinating multiple motors and responding to sensor inputs. It acts as the brain of the automation system, ensuring that the servo motors operate in a synchronized and efficient manner.

Power Supply

The power supply is a crucial component that provides the necessary electrical power to the servo driver and motor. It must match the voltage and current requirements specified by the servo driver and motor to ensure stable and reliable operation. Power supplies can be either DC (like 24V or 48V) or AC, depending on the servo system’s requirements. Proper selection and installation of the power supply are essential to prevent issues such as voltage drops, overheating, and electrical noise.

Analog Servo Drive

An analog servo drive is a type of servo driver that operates using analog signals for control. Unlike digital servo drives, which use digital communication protocols, analog servo drives receive continuous voltage or current signals to control the motor’s operation. This type of drive is suitable for applications requiring smooth and continuous control, such as certain types of machining and process control. Analog servo drives are often used in older systems or specific industrial applications where smooth, continuous control is preferred.

Preparing for Installation

Tools and Materials Needed

Before starting the installation, gather all the necessary tools and materials to ensure a smooth and efficient setup. Here is a checklist of essential items:

- Screwdrivers and Wrenches: Various types and sizes for securing connections and mounting components.

- Wire Strippers and Cutters: For preparing and cutting wires to the required lengths.

- Multimeter: To measure voltage, current, and resistance, ensuring proper connections.

- Crimping Tools: For attaching connectors to wires securely.

- Cable Ties and Labels: To organize and identify wiring.

- Servo Drive Manual: For reference on specifications and connection details.

- Wiring Diagrams: Specific to your servo drive and motor setup.

- Personal Protective Equipment (PPE): Such as safety glasses and gloves.

Safety Precautions

Ensuring safety during the installation process is paramount. Follow these guidelines to prevent accidents and protect both personnel and equipment:

Electrical Safety

- Disconnect Power: Always turn off and disconnect power sources before working on electrical connections to prevent electric shock.

- Proper Grounding: Ensure all components are properly grounded to prevent electrical hazards and interference.

- Insulated Tools: Use insulated tools to minimize the risk of electrical contact.

Workspace Safety

- Clean Workspace: Maintain a clean and organized workspace to avoid tripping hazards and ensure easy access to tools and components.

- Adequate Lighting: Ensure the workspace is well-lit to clearly see connections and wiring.

Handling Components

- Static Discharge: Use anti-static wristbands or mats to prevent static discharge, which can damage electronic components.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s guidelines for handling and installing components to avoid damage and ensure proper operation.

Reviewing Specifications

Understanding the specifications of your servo drive, motor, and associated components is crucial for a successful installation, so follow these steps:

Servo Drive Specifications

- Voltage Ratings: Check the input voltage requirements and ensure your power supply matches these ratings.

- Current Requirements: Determine the current requirements to ensure your power supply can handle the load.

- Communication Protocols: Identify the communication protocols (e.g., RS232, RS485, Ethernet) used by the servo drive for integration with controllers.

Motor Specifications

- Voltage and Current: Verify the motor’s voltage and current ratings to match them with the servo drive.

- Feedback Devices: Identify the type of feedback device (e.g., encoder, resolver) used for accurate control and ensure compatibility with the servo drive.

Ensuring Compatibility

Ensuring the servo drive, motor, and controller are compatible is essential for seamless operation. Here are the key aspects to verify:

Electrical Compatibility

- Voltage and Current Match: Ensure the voltage and current ratings of the servo drive and motor align with the power supply.

- Control Signal Levels: Confirm that the control signal levels from the controller are compatible with the servo drive inputs.

Mechanical Compatibility

- Mounting Interfaces: Ensure the mounting interfaces of the servo drive and motor fit your setup.

- Connector Types: Ensure that the connectors used for wiring the servo drive, motor, and controller are compatible and securely fit.

Wiring the Servo Motor

Servo motors are crucial for automation systems, offering precise control of mechanical movements. A typical servo motor used in hobbyist and industrial applications features three primary connectors:

- Power (Red Wire): Supplies power to the motor, usually 5V for hobby servos, but may vary in industrial applications.

- Ground (Black or Brown Wire): Connects to the ground terminal to complete the circuit.

- Signal (Yellow or Orange Wire): Receives control signals to dictate the motor’s position, speed, and direction.

Wiring Steps

Step 1: Identify the Connectors

- Locate the three wires coming from your servo motor.

- Confirm the color coding: red for power, black/brown for ground, and yellow/orange for the signal.

Step 2: Connect the Power and Ground

- Power Connection: Connect the red wire to the positive terminal of your power source. For hobby applications, this is typically 5V, but for industrial servos, check the manufacturer’s specifications.

- Ground Connection: Connect the black or brown wire to the ground (GND) terminal of your power source or control board.

Step 3: Connect the Signal Wire

- Signal Connection: Connect the yellow or orange wire to the control pin on your microcontroller or servo driver. This pin should be capable of generating Pulse Width Modulation (PWM) signals if required.

Step 4: Verify Connections

- Double-check that all connections are secure and correctly aligned.

- Check that no metal parts of the wires are exposed or touching each other to avoid short circuits.

Power Considerations

Voltage Needs

- Most hobby servos operate within a 4.8–6V DC range. Industrial servos might require higher voltages, so always refer to the servo’s datasheet.

- Ensure your power supply matches the required voltage to avoid damaging the servo.

Current Needs

- Verify that your power supply can deliver sufficient current for the servo motor. Multiple servos connected in parallel will require a power supply capable of handling the combined current draw.

Separate Power Supply

- For systems using several servos, consider using an external power supply to prevent overloading the microcontroller or driver board.

Advanced Wiring Tips for Industrial Servos

Cable Separation

- Keep power cables and signal cables at least 300 mm apart to reduce electrical noise and interference.

Shielding

- Use twisted pair shielded cables for signal and encoder feedback lines to enhance signal integrity and reduce noise.

Controller Setup

- Follow the manufacturer’s wiring diagram to connect the servo motor to a dedicated servo driver or controller. Ensure proper connections for power, ground, and signal/encoder feedback.

Testing and Troubleshooting

Initial Test

- Turn on the system and use your microcontroller code to run a basic servo sweep or position test, ensuring the servo responds correctly.

Troubleshooting Common Issues

- No Movement: Check power and ground connections. Ensure the signal pin is correctly mapped in your code.

- Erratic Movement: Verify that all wires are securely connected and that the power supply is stable.

- Inconsistent Performance: Check for electrical noise and ensure proper separation and shielding of cables.

Connecting the Servo Driver to the PLC

PLC Integration Process

Connecting a servo driver to a PLC involves several critical steps to ensure seamless communication and control. Follow these steps to properly integrate your servo driver with a PLC.

Step 1: Power Off Devices

Make sure both the servo driver and the PLC are powered off before making any connections. This precaution helps prevent electrical hazards and protects the devices from potential damage.

Step 2: Gather Required Components

Collect all necessary cables, connectors, and software. Commonly required items include communication cables (e.g., Ethernet, RS-232, or RS-485), power cables, control signal cables, and the manufacturer’s manuals and wiring diagrams.

Step 3: Establish Power Connections

- Connect Power to PLC and Servo Driver:

- Connect the power supply to both the PLC and the servo driver.

- Properly ground the devices to reduce electrical noise and interference.

- For three-phase power requirements, connect the L1, L2, and L3 lines to the servo driver appropriately.

Step 4: Connect Communication Cables

- Determine Communication Protocol:

- Determine whether your PLC and servo driver use Ethernet, RS-232, or RS-485 for communication.

- Connect Communication Ports:

- Connect the communication cable from the PLC’s communication port to the servo driver’s corresponding port.

- Ensure the connectors are securely attached to avoid loose connections that can cause communication errors.

Step 5: Wire Control Inputs

- Identify Control Inputs on Servo Driver:

- Refer to the servo driver’s manual to identify the control input terminals.

- Connect to PLC Output Module:

- Wire the control inputs of the servo driver to the output module of the PLC.

- Ensure compatibility in terms of voltage levels to avoid damage to the devices.

Step 6: Configure PLC Software

- Power On Devices:

- After completing the physical connections, power on the PLC and the servo driver.

- Set Communication Parameters:

- Configure the PLC software to recognize the servo driver by setting the appropriate communication parameters (e.g., baud rate, data bits, parity).

- Refer to the manuals for specific settings required by your devices.

Step 7: Program the PLC

- Develop Control Program:

- Write a control program in the PLC to send commands to the servo driver.

- This program should include commands for positioning, speed, and torque control using Pulse Width Modulation (PWM) signals if necessary.

- Define Operational Parameters:

- Set key parameters such as speed, acceleration, and deceleration profiles to match your application requirements.

Step 8: Use Pre-built Function Blocks

- Utilize PLC Libraries:

- Many PLCs come with pre-built function blocks or libraries that simplify the programming process.

- Use these blocks for common tasks like positioning and torque control to expedite the setup.

Connection Diagram

Refer to the specific connection diagram provided by the manufacturer of your PLC and servo driver. This diagram will illustrate the exact wiring scheme needed for your setup, ensuring all connections are correctly made.

Final Steps

- Verify Connections:

- Double-check all physical connections to ensure they are secure and correctly aligned.

- Test the System:

- Test the system by sending simple commands from the PLC to the servo driver to ensure they communicate and function correctly.

- Troubleshoot:

- If issues arise, revisit the connection and configuration steps to identify and resolve any errors.

Configuration and Setup

Initial Configuration

Configuring a servo driver requires setting up various parameters to ensure the servo motor operates correctly and efficiently.

Control Mode Selection

- Position Control: Ideal for applications where precise positioning is required, such as in CNC machines and robotics.

- Velocity Control: Used when speed regulation is the primary concern, such as in conveyor systems.

- Torque Control: Suitable for applications needing precise control of torque, like in tension control systems.

Select the control mode using the servo drive’s interface, software, or keypad. Check the manual for specific instructions.

Motor Type Configuration

- Brushless DC (BLDC) Motors: Common in many industrial applications for their efficiency and durability.

- AC Servo Motors: Preferred for high-performance applications due to their ability to handle higher power and provide better control.

Configure the motor type by accessing the servo drive’s settings and selecting the appropriate motor type from the available options.

Power Supply Requirements

A stable and adequate power supply is crucial for the reliable operation of the servo system. Ensure that the power supply matches the voltage and current requirements specified by the servo driver and motor.

DC Servo Drives typically operate at 24V, 48V, or higher, depending on the application. AC Servo Drives require AC input, commonly 220V or 380V, depending on the region and application. Ensure the power supply can provide sufficient current to handle the peak and continuous current demands of the servo motor. Check the servo drive and motor specifications to determine the exact requirements.

Parameter Setting

Properly setting parameters is vital for the optimal performance of the servo system. Key parameters include:

Gain Settings

Gain settings include Proportional Gain (P) for response speed, Integral Gain (I) for eliminating steady-state errors, and Derivative Gain (D) for stability. Start with the manufacturer’s recommended values and adjust as necessary during testing.

Speed and Acceleration

- Maximum Speed: Set the maximum allowable speed for the servo motor.

- Acceleration/Deceleration Rates: Define how quickly the motor should ramp up to speed or slow down.

These settings help in protecting the motor and ensuring smooth operation.

Software Configuration

Many servo drives come with software tools for advanced configuration and tuning. Follow the manufacturer’s instructions to install the software and connect your computer to the servo drive using the appropriate interface (e.g., USB, Ethernet). Use the software to adjust parameters, monitor performance data, and diagnose issues.

Testing the Configuration

Testing ensures that the servo system operates correctly under actual working conditions.

Initial Tests

- Basic Movement Test: Command the servo motor to move to a specific position and observe its response.

- Speed and Torque Tests: Verify that the motor reaches the desired speed and torque levels without issues.

Validation

- System Integration Test: Ensure the servo drive correctly responds to commands from the PLC or control system.

- Performance Testing: Run the servo motor through typical operational cycles to validate its performance and stability.

Make adjustments to the configuration as necessary based on the test results. Always refer to the manufacturer’s guidelines for specific testing procedures and recommended adjustments.

Startup and Activation

Power Supply Connection

Identify Power Terminals

First, locate the power terminals on your servo driver. These terminals are typically marked for easy identification, such as terminal 35 providing 24 volts and another terminal serving as an activation signal.

Connect Power Supply

Ensure the power supply matches the voltage and current requirements specified by the servo driver, then connect the positive and negative terminals of the power supply accordingly. Secure all connections to prevent any loose wires, which could cause electrical faults.

Activation Signal

Understanding Activation Requirements

Some servo drivers require a specific activation signal to start the motor. This could be a positive or negative signal, depending on the model. Refer to the servo driver’s manual for detailed information on the required activation signal.

Sending the Activation Signal

Once the power connections are secure, send the activation signal to the correct terminal. This signal can be generated by a PLC or another control device. Ensure that the signal voltage matches the servo driver’s specifications to avoid any damage.

Initial Testing

Jog Mode Activation

Use the jog mode on the servo driver to manually test the servo motor’s movement. Jog mode allows you to move the motor incrementally to verify if it responds correctly to control signals. This is an essential step to ensure that the motor is functioning properly before running automated sequences.

Monitoring Indicators

Check for indicators like green lights or status displays on the servo driver. These indicators will confirm whether the servo driver is ready and operational. Any error indicators should be addressed immediately by checking the connections and configurations.

Control Signal Connection

Pulse Control

Use output signals from your controller to send pulse signals to the servo driver. These pulses determine the motor’s position or speed. Ensure that the control signals are properly configured and match the servo driver’s requirements.

Voltage Options

Some servo drivers offer options for 5V or 24V control signals. Choose the appropriate voltage based on your setup, and use necessary resistors for protection. Incorrect voltage levels can damage the servo driver or motor.

Configuring the Servo Driver

Mode Selection

Choose the mode that best suits your application, such as position, velocity, or torque mode, and set the drive accordingly. For example, if using EtherCAT communication, ensure the drive is set to the correct mode.

Position Tables

If your application requires position tables, configure the servo driver with the correct lookup table settings. This can typically be done using software tools provided by the servo driver manufacturer.

Safety Precautions

Power-Up Safety

Before powering up the servo system, ensure that all components are securely fastened. Loose components can lead to mechanical failures or electrical short circuits.

Voltage Checks

Double-check that all voltage levels match the specifications of your equipment. Incorrect voltage levels can cause significant damage to the servo driver and motor.

Troubleshooting

Verify Connections

If the servo motor does not respond as expected, verify all connections. Ensure that power, ground, and control signal connections are secure and correctly aligned.

Consult Documentation

Refer to the servo driver’s manual for troubleshooting guides specific to your model. The manual will provide detailed steps for diagnosing and resolving common issues.

Final Steps

Confirm Operation

After completing the setup and activation steps, confirm that the servo driver and motor operate as intended. Run a series of tests to ensure that all parameters are correctly set and the system performs reliably under expected conditions.

Regular Maintenance

Implement a regular maintenance schedule to check the servo driver and motor for any signs of wear or damage. Regular maintenance helps in prolonging the life of the equipment and maintaining optimal performance.

Troubleshooting Common Issues

Power Supply Issues

Symptoms

- Inconsistent motor performance

- Overheating

- Failure to start or sudden stops

Solutions

- Ensure the motor receives the correct voltage and current as specified in the manufacturer’s documentation.

- Use a multimeter to measure the voltage at the motor’s terminals.

- Check for any power supply fluctuations and stabilize the voltage if necessary.

Loose or Corroded Connections

Symptoms

- Signal loss

- Reduced power transfer

Solutions

- Inspect all wiring connections, including power, feedback, and control signals.

- Tighten any loose connections and clean any corroded terminals.

- Check for broken wires or connectors and replace as needed.

Thermal Overload Error

Symptoms

- Drive overheats, triggering a thermal fault code

Solutions

- Inspect and clean cooling fans and heat sinks to ensure proper ventilation.

- Ensure the surrounding temperature meets the servo drive’s recommended limits.

- Reduce motor load or duty cycle if it exceeds drive capacity.

Software Configuration Errors

Symptoms

- Erratic or non-functional drive behavior due to improper settings

Solutions

- Restore factory settings and reconfigure parameters as per application requirements.

- Update the firmware to the latest version provided by the manufacturer.

- Use diagnostic tools to identify misconfigured parameters.

Servo Motor Overload

Symptoms

- Failure to start or sudden stops

Solutions

- Check if the motor is overloaded and reduce the load if necessary.

- Ensure proper heat dissipation and consider strengthening it if needed.

Encoder Issues

Symptoms

- Servo motor positioning issues

Solutions

- Inspect the encoder for proper functioning and replace it if found defective.

- Verify parameter settings of the servo driver, including gain and integration time.

Noise During Operation

Symptoms

- Unusual noise while the motor is running

Solutions

- Check the installation of the servo motor and mechanical parts.

- Inspect the motor’s bearings for damage and replace if necessary.

Preventative Maintenance

Regular Cleaning

Periodically inspect and clean the servo drive to remove dust and debris.

Firmware Updates

Keep the firmware updated to ensure compatibility and optimal performance.

Operator Training

Provide training for operators and technicians to ensure correct handling and operation of servo systems, minimizing errors.

When to Seek Professional Help

If troubleshooting steps fail to resolve the issue, it may indicate a deeper hardware or software problem. Contacting the servo drive manufacturer or a professional technician is recommended. Provide detailed fault information, including error codes and operating conditions, to expedite the resolution process.

Frequently Asked Questions

Below are answers to some frequently asked questions:

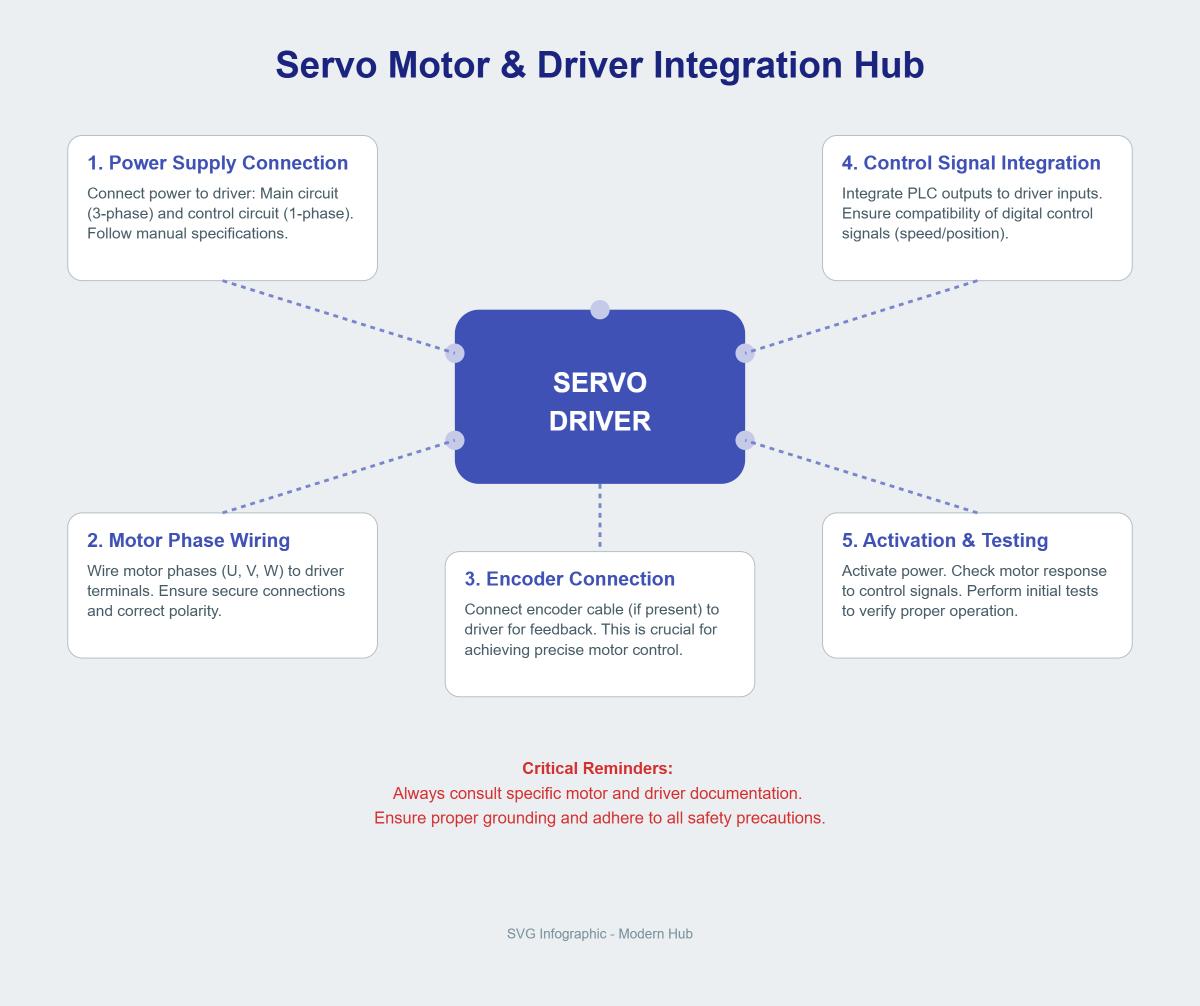

How do I connect a servo motor to a servo driver?

To connect a servo motor to a servo driver, follow these steps:

- Power Supply Connection: Connect the power supply to the servo driver. Ensure the correct connections for both the main circuit (typically three-phase) and the control circuit (usually single-phase), as specified by the servo driver’s manual.

- Motor Phase Wiring: Connect the motor phase wires (U, V, W) from the servo motor to the corresponding terminals on the servo driver. Make sure the connections are secure and match the polarity specified by the manufacturers.

- Encoder Connection: If your servo motor has an encoder, connect the encoder cable to the appropriate terminal on the servo driver. This is crucial for providing feedback for precise control.

- Control Signal Integration: If using a PLC for control, connect the PLC outputs to the servo driver’s control inputs. Ensure the digital control signals for speed and position are compatible with the servo driver’s requirements.

- Activation and Testing: Once all connections are made, activate the power supply to the servo driver. Check that the servo motor powers on correctly and responds to control signals. Perform initial tests to verify proper operation.

Always consult the specific documentation for your servo motor and servo driver to ensure compatibility and correct procedures. Proper grounding and adherence to safety precautions are essential.

What is the step-by-step process to set up a servo driver?

To set up a servo driver, follow these steps:

- Understand Your Components: Identify the servo driver, servo motor, controller (like a PLC), and power supply. The servo driver amplifies and controls signals sent to the servo motor.

- Wiring the Hardware:

- Power Connections: Connect the power supply to the servo driver’s power terminals, ensuring the voltage matches the specifications of the servo driver and motor.

- Signal Connections: Connect the controller’s output to the servo driver’s signal input. For PLCs, use specific outputs for pulse and direction signals as per the servo driver manual. For Arduino, use PWM-capable pins.

- Grounding: Connect all grounds (controller, driver, and power supply) to avoid signal noise.

- Driver Configuration:

- Set the voltage level for signal inputs.

- Select the control mode (position, speed, or torque) using dip switches or software.

- Configure pulse and direction settings according to your application.

- Controller Programming:

- For Arduino, use the Servo library and write code to control the servo position.

- For PLCs, program it to send pulse and direction signals to the driver and activate the correct output terminals.

- Power Up and Test:

- Power up the system and check the servo driver’s status LED for readiness.

- Manually trigger signals to verify motor movement.

- Adjust parameters like pulse width and frequency as needed.

- Troubleshooting:

- If the motor does not move, check all wiring and power supply.

- For erratic behavior, verify ground connections and signal integrity.

- Ensure the driver and motor are not overloaded to prevent overheating.

By following these steps, you can successfully set up a servo driver for your project. Always refer to the specific documentation for detailed instructions and safety precautions.

How do I integrate a servo driver with a PLC?

To integrate a servo driver with a PLC, follow these steps:

First, ensure that both the PLC and the servo drive are powered off to prevent electrical hazards. Gather all necessary components, including the PLC, servo drive, appropriate communication cables, and software. Verify that the servo drive and PLC are compatible, particularly regarding communication protocols like Ethernet, RS-232, or RS-485.

Next, connect the power supply to both devices, ensuring proper grounding to minimize electrical noise. Use the appropriate communication cable to connect the PLC’s communication port to the servo drive’s corresponding port. Then, connect the PLC’s output signals to the servo drive’s input terminals, typically for control commands such as speed and position.

Once all connections are made, power on both the PLC and servo drive. Configure the PLC software with the correct communication parameters, including baud rate, data bits, and parity. Write a control program in the PLC to send commands to the servo drive, which may involve setting up position control or velocity control modes. Test the connection by sending simple commands to verify proper communication and control.

If issues arise, check that all cables are secure and correct, and review the communication settings on both devices. Refer to the manuals of the PLC and servo drive for specific troubleshooting instructions. Ensure the servo motor is properly connected to the servo drive, and verify that the PLC outputs are compatible with the servo drive’s input requirements.

By following these steps, you can successfully integrate a servo driver with a PLC, ensuring precise and reliable control of the servo motor.

What are common issues when setting up a servo driver and how can I troubleshoot them?

Common issues when setting up a servo driver often stem from wiring errors, incorrect configuration, and power supply problems. Loose or incorrect wiring can lead to the servo motor not turning or generating abnormal noises. Ensure all connections are secure and follow the motor phasing correctly, particularly for three-phase motors. Overheating issues can arise from overloads or improper settings; check the load and review controller parameters to ensure they are set correctly. Communication errors between the servo driver and PLC can result from faulty wiring or incompatible settings, requiring inspection of connections and software updates. Overcurrent, overvoltage, or undervoltage errors typically indicate power supply issues or incorrect settings; measure voltage and current at the motor terminals and review the configuration. Regular maintenance and documentation of any changes in settings or wiring can help prevent and quickly resolve these common issues.