Imagine you’re faced with a wiring project, and you’re standing in the hardware store aisle, staring at rolls of copper wire. But wait—there are two types: stranded and solid. What’s the difference? Which should you choose? This decision isn’t just about grabbing the nearest roll; it can significantly impact the efficiency, safety, and cost of your electrical work. In this article, we’ll delve into the world of copper wiring, comparing stranded and solid options. You’ll discover their unique characteristics, understand where each excels, and learn how to make an informed choice for your specific needs. Ready to untangle the intricacies of copper wire? Let’s dive in!

Understanding Copper Wire Types

Definition of Stranded Copper Wire

Stranded copper wire is made up of multiple small copper strands twisted together to form a single, flexible wire. This design increases the wire’s flexibility and resistance to metal fatigue, making it particularly useful in applications where the wire needs to be routed through tight spaces or is subject to constant movement and vibration.

Definition of Solid Copper Wire

Solid copper wire consists of a single, continuous copper conductor, making it more rigid and less flexible than stranded wire. This type of wire is generally used in applications where the wire remains stationary and does not require frequent bending or movement.

Importance in Electrical Applications

Copper wire is widely used in electrical and industrial applications. Its excellent electrical conductivity, durability, and versatility make copper wire a popular choice in electrical and industrial applications. The choice between stranded and solid copper wire depends on the specific requirements of the application, including factors such as flexibility, current capacity, and installation conditions.

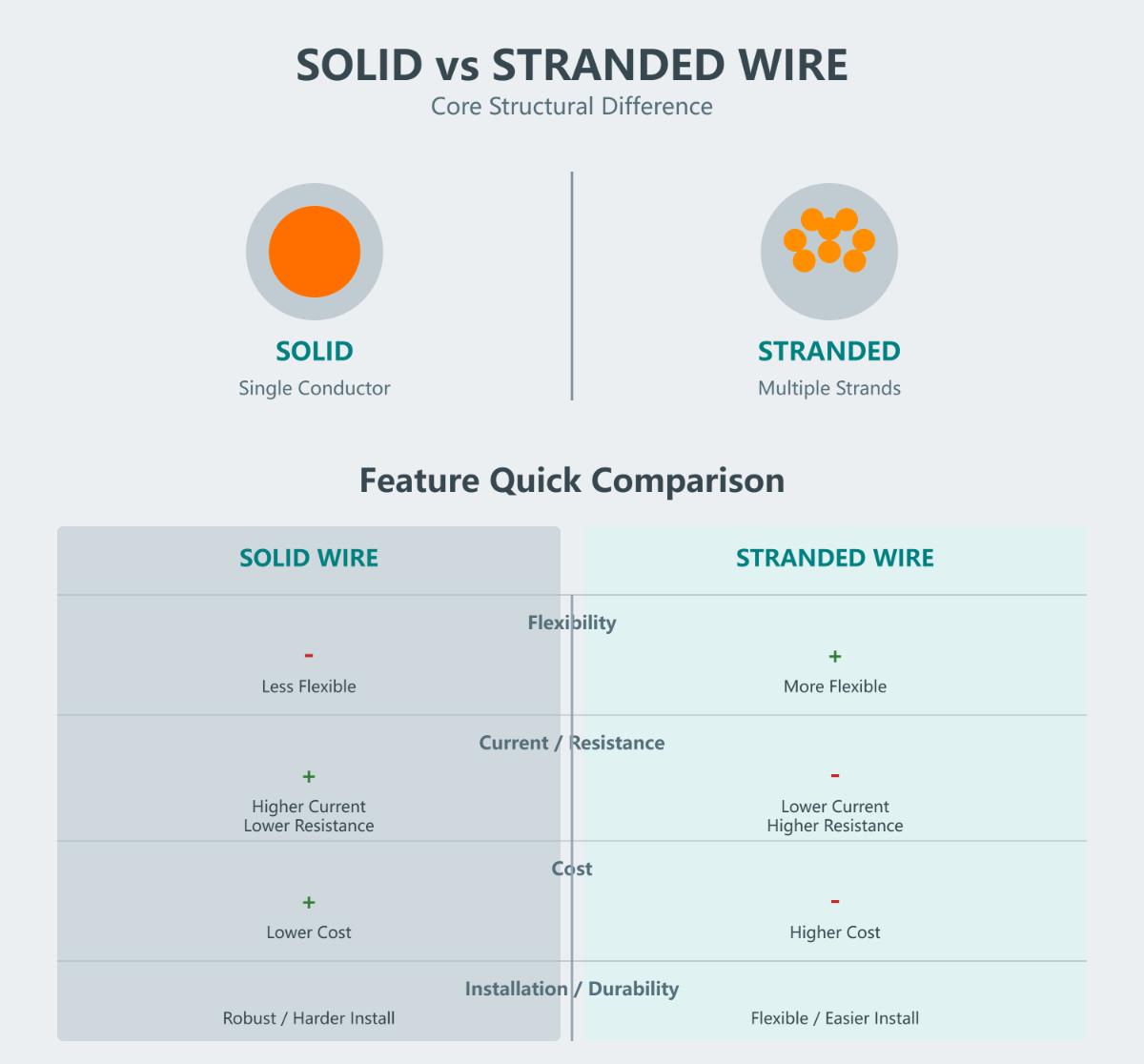

Flexibility

Flexibility is a crucial factor in selecting the appropriate type of copper wire. Stranded copper wire’s multiple strands allow it to bend and flex more easily without breaking, making it ideal for dynamic environments. Solid copper wire, being less flexible, is more suited for fixed installations where the wire does not need to move or bend frequently.

Current Capacity

Current capacity, or the amount of electrical current a wire can carry, is another important consideration. Both stranded and solid copper wires offer excellent conductivity. However, solid copper wire typically has a slightly higher current capacity due to its single conductor, which minimizes resistance. Stranded copper wire, while still highly conductive, may have slightly higher resistance due to the small air gaps between the strands.

Key Differences Between Stranded and Solid Copper Wire

Flexibility

Stranded copper wire is highly flexible, ideal for dynamic environments, while solid copper wire is more rigid, suited for stationary applications.

Current Capacity

- Stranded Copper Wire: While it offers excellent conductivity, the small gaps between the strands can slightly increase resistance. This difference is generally negligible in most practical applications.

- Solid Copper Wire: Offers slightly higher current capacity due to the continuous copper conductor, providing minimal resistance. It is preferred for applications where maximum current capacity is essential.

Practical Application Scenarios

When to Use Stranded Copper Wire

Stranded copper wire is preferred in automotive wiring, robotics, and portable devices due to its flexibility and ability to withstand movement and vibration.

When to Use Solid Copper Wire

Solid copper wire is ideal for applications where the wire remains stationary. Examples include:

- Residential Wiring: In walls and ceilings where wires remain fixed.

- Circuit Boards: Where precise and stable connections are necessary.

- Permanent Installations: Where wires do not need to bend or move after installation.

Key Differences Between Stranded and Solid Copper Wire

Flexibility

Flexibility is a critical factor when selecting copper wire for various applications. It shows how easily the wire can bend, twist, or move without breaking. This attribute significantly influences the choice between stranded and solid copper wire.

Stranded Copper Wire

Stranded copper wire is composed of multiple smaller strands of copper twisted together. This construction provides exceptional flexibility, allowing the wire to bend and move without breaking. Such flexibility makes stranded copper wire ideal for applications where the wire must navigate through tight spaces, endure constant motion, or be subject to vibration. Common uses include automotive wiring, robotics, and portable electronic devices.

Solid Copper Wire

Solid copper wire consists of a single, continuous strand of copper. This design makes it less flexible and more rigid compared to its stranded counterpart. Solid copper wire is best suited for stationary applications where the wire does not need to bend or move frequently. Its rigidity provides stability and durability in installations such as residential wiring, circuit boards, and permanent infrastructure.

Current Capacity

Current capacity, or the amount of electrical current a wire can carry, is another essential consideration. It affects the efficiency and safety of electrical systems.

Stranded Copper Wire

While stranded copper wire offers excellent conductivity, its construction introduces small air gaps between the strands, which can increase resistance slightly. This slight increase in resistance can slightly reduce the wire’s current capacity. However, in most practical applications, this difference is minimal and does not significantly impact performance.

Solid Copper Wire

Solid copper wire, with its single, unbroken conductor, provides a lower resistance path for electrical current. This results in a higher current capacity compared to stranded wire. The lack of air gaps means that solid copper wire can carry larger current loads more efficiently, making it a preferred choice for applications where maximum current capacity is essential, such as power distribution systems and long-distance cabling.

Mechanical Properties

Mechanical properties such as corrosion resistance and durability under physical stress also play a role in wire selection.

Stranded Copper Wire

Stranded wire’s increased surface area and gaps between strands make it more prone to corrosion and moisture. This characteristic can reduce its lifespan in harsh or outdoor environments unless adequately protected. Additionally, while flexible, stranded wire can suffer from strand fatigue over time, particularly in dynamic applications where it is continuously bent or moved.

Solid Copper Wire

Solid copper wire’s monolithic design reduces surface exposure, minimizing oxidation risks and enhancing durability, especially in fixed installations. Its rigid structure withstands physical stress better, making it suitable for direct burial, conduit use, and environments requiring vibration resistance. However, its lack of flexibility makes it prone to metal fatigue and cracking under repeated bending, limiting its use in dynamic applications.

Application-Specific Recommendations

Choosing between stranded and solid copper wire depends on the specific needs of your application.

Best Uses for Stranded Copper Wire

- Automotive Wiring: Ideal for use in vehicles where wires must navigate through tight spaces and endure constant movement and vibration.

- Robotics and Portable Devices: Suitable for applications requiring frequent flexing and maneuverability.

Best Uses for Solid Copper Wire

- Residential Wiring: Ideal for fixed installations within walls and ceilings.

- Circuit Boards: Provides stable and precise connections necessary for electronic components.

- Permanent Installations: Suitable for environments where wires do not need to bend or move after installation.

Understanding these key differences helps in selecting the appropriate type of copper wire for various electrical applications, ensuring optimal performance and longevity.

Practical Application Scenarios

Flexibility and Durability

- Stranded Wire: Stranded copper wire is highly flexible. It is composed of multiple small strands of copper twisted together, allowing it to bend and flex without breaking. This makes it ideal for applications where the wire needs to move frequently, such as in electronic devices, robotics, and automotive wiring. Its malleability ensures that it can withstand constant motion and vibration without suffering from metal fatigue.

- Solid Wire: Solid copper wire, on the other hand, is less flexible due to its single, continuous conductor. This rigidity makes it more suitable for stationary applications where the wire does not need to be bent or moved frequently. It holds its shape well and is more resistant to physical stress, making it ideal for fixed installations like residential wiring, circuit boards, and permanent infrastructure.

Current Capacity and Electrical Conductivity

- Solid Wire: Solid copper wire typically has a higher current capacity and better electrical conductivity compared to stranded wire. This is because the single conductor offers a lower resistance path for the electrical current. As a result, solid wire is often used in applications that require high power transmission and efficiency, such as power distribution systems and long-distance cabling.

- Stranded Wire: Although stranded wire is also highly conductive, the tiny spaces between the strands can slightly raise resistance. This can reduce the wire’s current capacity compared to solid wire. However, stranded wire can still handle significant current loads, making it suitable for applications where flexibility is more critical than maximum current capacity.

Corrosion Resistance and Environmental Conditions

- Solid Wire: Solid copper wire’s single-core design exposes less surface area to the environment. This makes it more resistant to corrosion. This characteristic is advantageous for outdoor applications, such as direct burial or use in harsh weather conditions, where environmental exposure can be a concern.

- Stranded Wire: The multiple strands in stranded wire increase its surface area, making it more susceptible to corrosion. However, stranded wire can be treated with tinning or other protective coatings to enhance its resistance to environmental factors. Despite this, it is generally better suited for indoor applications where corrosion is less of a concern.

Cost and Installation Ease

- Solid Wire: Solid copper wire is generally less expensive to produce and install compared to stranded wire. Its simpler manufacturing process and ease of installation in fixed applications contribute to its lower cost. This makes solid wire a cost-effective choice for residential and commercial wiring projects where the wire does not need to be flexible.

- Stranded Wire: While stranded wire is more costly, it offers easier handling and installation in flexible applications. Installers often prefer stranded wire for its ability to navigate through tight spaces and around obstacles. This flexibility can save time and effort during installation, particularly in complex or dynamic environments.

Signal Integrity and Attenuation

- Solid Wire: Solid copper wire provides superior signal integrity over a broader frequency range with less attenuation. This makes it an excellent choice for telecommunications and data transmission applications, where stable electrical characteristics and minimal signal loss are crucial.

- Stranded Wire: Stranded wire exhibits higher attenuation, especially in higher-gauge (thinner) conductors. This can result in increased signal loss, making it less suitable for applications requiring high signal integrity. However, stranded wire is still widely used in many electronic devices where flexibility and durability are more important than minimal signal attenuation.

Advantages and Disadvantages

Stranded copper wire and solid copper wire each have distinct advantages and disadvantages that make them suitable for different applications.

Stranded Copper Wire

Pros

- Flexibility: Stranded copper wire is highly flexible due to its construction of multiple smaller strands twisted together. This flexibility makes it ideal for applications that require frequent bending or movement, such as in automotive wiring and portable devices.

- Heat Dissipation: Stranded copper wire’s air gaps facilitate better heat dissipation, reducing overheating risks. This can help in dynamic environments where the wire may be subject to varying temperatures.

- Vibration Resistance: Stranded wire is more resistant to vibrations and can endure more flexing without breaking. This makes it suitable for environments with constant motion, such as machinery and robotics.

- Ease of Installation: The flexibility of stranded wire makes it easier to handle and install, especially in tight spaces or when routing around obstacles. This can save time and effort during installation.

Cons

- Higher Attenuation and Resistance: Stranded wire has small air gaps between strands that increase resistance and signal loss. This can be problematic in high signal integrity applications.

- Corrosion Susceptibility: The increased surface area and air gaps in stranded wire make it more susceptible to corrosion. While protective coatings such as tinning can mitigate this issue, it still remains a concern, especially in harsh or outdoor environments.

- Higher Production Costs: The manufacturing process for stranded wire is more complex and labor-intensive, leading to higher production costs. This can be a drawback for budget-sensitive applications.

Solid Copper Wire

Pros

- Electrical Conductivity: Solid copper wire has a single, continuous conductor. This provides superior electrical conductivity and stable performance across a wide range of frequencies. It’s an excellent choice for high-performance electrical applications.

- Current Capacity: Due to its solid core, solid copper wire has a higher current capacity compared to stranded wire of the same gauge. This makes it suitable for applications requiring substantial power transmission.

- Ruggedness and Corrosion Resistance: Solid wire is more resistant to corrosion and vibration, as it has less surface area exposed to environmental factors. This enhances its durability in various conditions.

- Lower Voltage Drop: Over long distances, solid wire experiences less voltage drop compared to stranded wire. This makes it ideal for longer cable runs where maintaining voltage levels is crucial.

- Cost-Effectiveness: The production costs for solid wire are generally lower than for stranded wire, making it a more economical choice for many applications.

Cons

- Rigidity: Solid wire is rigid and less flexible, which can make it more prone to breaking if bent excessively. This rigidity can be a limitation in applications that require frequent movement or bending.

- Heat Dissipation: Solid copper wire heats up faster due to its solid core and lack of air gaps. This can be a disadvantage in applications requiring effective heat management.

- Installation Difficulty: The rigidity of solid wire can make it more challenging to install in tight spaces or where frequent bending is required. This can complicate the installation process and require more effort to maneuver the wire into place.

Understanding these advantages and disadvantages helps in making an informed decision when selecting between stranded and solid copper wire for specific electrical applications.

Cost Considerations

Production Costs

Producing solid copper wire is usually more economical than making stranded copper wire. The manufacturing process for solid wire is simpler, involving the creation of a single continuous conductor. This simplicity reduces labor and material costs, making solid wire a cost-effective choice for many applications. In contrast, stranded wire requires twisting multiple thin strands of copper together, which adds complexity and increases production costs.

Flexibility and Routing

The flexibility of stranded copper wire provides significant advantages in applications where the wire must navigate through tight spaces or endure frequent movement. This flexibility can reduce installation time and costs, as it is easier to route around obstacles and requires less effort to handle. Although solid copper wire is less flexible, it holds its shape well over time, making it ideal for fixed installations where bending is infrequent.

Solid copper wire is generally preferred for fixed installations due to its robustness and higher current capacity. It is well-suited for applications that require stable electrical performance over a wide frequency range. Conversely, stranded wire thrives in settings with frequent flexing or significant movement. While stranded wire may have a slightly higher resistance due to air gaps between strands, this difference is usually negligible in most practical applications.

Maintenance and Replacement

Stranded copper wire might need more upkeep because its individual strands can break, particularly at the ends. This can increase long-term costs if frequent replacements are needed. However, stranded wire’s ability to withstand vibrations better than solid wire can reduce the need for replacements in dynamic environments. Solid copper wire, being more rigid, is less prone to strand breakage but may need more frequent replacement in applications with significant flexing or movement.

Long-Term Cost Efficiency

To decide which type of copper wire is more cost-efficient in the long run, consider the specific needs of your application. Solid copper wire, with its lower production costs and higher durability in fixed installations, can be more cost-effective for stationary applications. Stranded wire, despite its higher initial cost, offers advantages in terms of flexibility and durability in dynamic environments, potentially reducing long-term maintenance and replacement costs.

Electrical Applications

Household Wiring

In residential settings, the decision between using stranded or solid copper wire depends on the specific requirements of the installation.

Stranded Copper Wire

Stranded wire is ideal for connecting appliances that may be moved or repositioned and for light fixtures where its flexibility reduces the risk of breakage and can navigate tight spaces and bends more easily. Additionally, stranded wire is crucial for portable devices like vacuum cleaners and small kitchen appliances, where frequent movement requires durable, flexible wiring.

Solid Copper Wire

Solid wire is used extensively in walls and ceilings where the wiring stays in place, maintaining the integrity of the electrical path over time. It is also preferred for electrical outlets and switches, providing reliable connections that ensure consistent performance in a home’s electrical system.

Industrial Wiring

In industrial environments, the choice between stranded and solid copper wire depends on the demands of the application, including flexibility, current capacity, and environmental conditions.

Stranded Copper Wire

Stranded wire is favored in industrial settings where wires are subject to frequent movement or vibration, such as in machinery and temporary setups. This includes wiring within machines that operate continuously and experience constant movement, and temporary installations like those on construction sites or events. Stranded wire is also used in control panels where wires need to be routed through complex pathways.

Solid Copper Wire

Solid copper wire is chosen for fixed installations that require high current capacity and minimal maintenance. It is ideal for power distribution systems in industrial settings due to its higher current capacity and lower voltage drop. Fixed installations such as conduit wiring benefit from the stability and durability of solid wire.

Automotive Wiring

In the automotive industry, wires need to handle constant motion and vibration, making stranded copper wire the standard choice. Stranded wire is suitable for routing through the cramped and dynamic environment of an engine compartment, and for wiring dashboards, seats, and other internal components where flexibility and durability are essential.

Telecommunications

Telecommunications applications require wires that offer reliable signal transmission and minimal attenuation.

Solid Copper Wire

Solid wire is often used in telecommunications for its superior signal integrity, making it preferred for long-distance cabling due to its lower attenuation and better performance over extended lengths. In data centers, the stable and consistent electrical characteristics of solid wire ensure high-quality data transmission.

Stranded Copper Wire

Stranded wire is used in telecommunications where flexibility is required. For connecting equipment within a network, stranded wire patch cables are favored for their ease of handling and flexibility. In scenarios where equipment may be frequently repositioned, stranded wire’s flexibility helps maintain reliable connections.

Wire Selection Guide

Factors to Consider

When selecting the appropriate copper wire for your electrical project, several factors must be considered to ensure optimal performance, safety, and cost-effectiveness. Understanding these factors will help you make an informed decision between stranded and solid copper wire.

Flexibility

Flexibility is crucial for wires that need to bend or move frequently.

- Stranded Copper Wire: Known for its superior flexibility, stranded wire is ideal for dynamic environments where the wire must navigate through tight spaces or endure constant movement and vibration. This flexibility is due to its construction of multiple thin strands twisted together, allowing it to bend without breaking.

- Solid Copper Wire: Conversely, solid wire is more rigid and less flexible. It is best suited for stationary applications where the wire remains fixed and does not need to bend frequently. Its rigidity provides stability and durability in installations.

Current Capacity

This factor is crucial for ensuring the efficiency and safety of your electrical system, as it refers to the amount of electrical current a wire can carry safely without overheating.

- Stranded Copper Wire: While stranded wire has excellent conductivity, the small air gaps between strands can slightly increase resistance, leading to a marginally lower current capacity compared to solid wire. However, this difference is generally negligible in most practical applications.

- Solid Copper Wire: With its single, continuous conductor, solid wire offers higher current capacity and lower resistance. This makes it suitable for applications requiring substantial power transmission and high efficiency.

Cost

Cost is an important factor in choosing a wire, including both initial expenses and long-term efficiency.

- Stranded Copper Wire: Generally more expensive to produce due to the complexity of manufacturing multiple strands. However, its flexibility can reduce installation time and effort, potentially offsetting the higher initial cost in dynamic applications.

- Solid Copper Wire: Less expensive to produce because of the simpler manufacturing process. It is a cost-effective choice for fixed installations where flexibility is not a primary concern.

Specific Electrical Project Needs

The specific needs of your electrical project will significantly influence your wire choice. Consider the following scenarios:

- Indoor vs. Outdoor Applications: Stranded wire is typically preferred for indoor applications due to its flexibility, while solid wire is more suitable for outdoor or direct burial applications because of its higher resistance to environmental factors.

- Dynamic vs. Static Environments: For dynamic environments where wires are subject to constant movement, such as in automotive wiring or robotics, stranded wire is the preferred choice. For static environments, like residential or industrial wiring where the wire remains stationary, solid wire is more appropriate.

Standards Compliance

Ensuring that your wires comply with relevant standards is essential for safety and reliability.

- NEC (National Electrical Code): The NEC provides guidelines for safe electrical design, installation, and inspection to protect people and property from electrical hazards. Both stranded and solid copper wires must meet NEC requirements for their respective applications.

- IEC (International Electrotechnical Commission): The IEC sets international standards for electrical and electronic technologies. Compliance with IEC standards ensures that the wire meets global safety and performance criteria.

By carefully considering these factors—flexibility, current capacity, cost, specific project needs, and standards compliance—you can select the most suitable type of copper wire for your electrical application, ensuring optimal performance, safety, and cost-effectiveness.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the differences between stranded and solid copper wire?

Stranded and solid copper wires differ primarily in their structure and application suitability. Solid copper wire consists of a single, thick conductor, offering higher current capacity and lower resistance, making it ideal for high-current applications and long-distance transmissions. It is robust but less flexible, which can make installation in complex environments more challenging.

On the other hand, stranded copper wire is composed of multiple thinner strands twisted together, providing greater flexibility and resistance to breakage from bending or vibration. This flexibility makes it suitable for applications requiring frequent movement or adjustments, such as in automotive wiring or electronics.

While solid wire is generally more cost-effective and less prone to corrosion due to fewer exposed surfaces, stranded wire’s complex manufacturing process makes it more expensive. However, its durability and ease of routing can justify the higher cost in specific scenarios.

When should I use stranded vs solid copper wire?

Choosing between stranded and solid copper wire depends on the specific requirements of your application. Solid copper wire is ideal for fixed installations where the wire will remain static, such as in household wiring, telecommunications, or outdoor environments. It provides excellent electrical conductivity and stability, making it suitable for high current applications and scenarios where minimal movement is expected.

On the other hand, stranded copper wire is better suited for situations requiring flexibility and resistance to vibration. Its multiple strands allow it to bend and twist without breaking, making it perfect for indoor wiring, electronic devices, and automotive applications where frequent movement or manipulation is necessary.

How does flexibility affect wire selection?

Flexibility significantly impacts wire selection, particularly when choosing between stranded and solid copper wires. Stranded copper wire, composed of multiple thin strands, is highly flexible, making it ideal for applications where the wire must bend frequently or navigate tight spaces. This flexibility allows stranded wire to absorb stress more effectively, reducing the risk of breakage during movement.

In contrast, solid copper wire, consisting of a single, solid conductor, is much less flexible. While this rigidity can simplify installation in fixed positions, solid wire is prone to breakage when bent repeatedly, making it less suitable for dynamic environments. Therefore, the decision between stranded and solid copper wire should consider the specific application’s need for flexibility to ensure optimal performance and durability.

What impact does current capacity have on wire choice?

Current capacity significantly influences the choice between stranded and solid copper wires. This factor is crucial because it determines the wire’s ability to safely carry electrical current without overheating. Solid copper wires generally offer higher current capacity due to their lower resistance and fewer internal connections compared to stranded wires. This makes them suitable for applications requiring stable, high current flow, such as fixed installations in residential or commercial settings.

On the other hand, stranded copper wires, while slightly less efficient in terms of current capacity due to the increased resistance from multiple strands, offer superior flexibility. This flexibility makes them ideal for scenarios involving frequent movement or bending, such as in automotive or robotic applications. Therefore, the decision hinges on balancing the need for current capacity with the specific requirements of the electrical project, such as flexibility and installation conditions. Understanding these distinctions ensures optimal performance and safety in electrical systems.

What are the cost differences between stranded and solid copper wire?

When comparing stranded and solid copper wire, cost differences are notable and can influence the choice between the two. Solid copper wire is generally more cost-effective due to its simpler production process, involving a single-core wire that is easier and cheaper to manufacture. This results in lower upfront purchase costs. Stranded copper wire, however, consists of multiple thin wires twisted together, requiring more complex and expensive production techniques, making it more expensive initially.

Despite the higher initial cost, stranded wire’s flexibility can reduce installation expenses, particularly in environments with numerous obstacles. Additionally, stranded wire’s durability in applications with vibration or movement can extend its lifespan and reduce replacement costs over time.

Therefore, while solid copper wire offers short-term savings due to its lower production and purchase price, stranded copper wire may provide long-term cost benefits in dynamic environments. The choice between these wires should consider both immediate costs and long-term operational requirements.