Imagine a world where precision meets durability, shaping the future of manufacturing across industries. As technology advances, the quest for the perfect CNC system becomes ever more critical. Whether you’re crafting aerospace components, medical devices, or automotive parts, understanding the nuances between high-end and budget CNC systems can unlock new levels of efficiency and quality. This article dives into a comparative analysis of the top 10 CNC systems, dissecting their precision, durability, and value for money. We’ll explore leading brands like Haas Automation and DMG Mori, scrutinizing their offerings to help you make an informed choice. Are you ready to discover which CNC system stands out in the realm of cutting-edge manufacturing? Let’s delve deeper into the world of CNC technology.

CNC Systems Overview

Understanding CNC Systems

CNC systems are crucial in modern manufacturing because they automate the control of machining tools using computer programs. These systems enable the production of complex parts with high precision and efficiency, making them indispensable across various industries.

Key Components of CNC Systems

The core of any CNC system is the control unit, which interprets coded instructions to govern the operations of machine tools, such as lathes, mills, or routers. These tools perform the actual machining tasks, selected based on specific applications and desired outcomes. Integral to precise motion control is the servo mechanism, which adjusts speed and direction according to feedback. Additionally, components like ball-screws and linear guides facilitate smooth, precise linear motion, crucial for maintaining tight tolerances and repeatability.

Importance of CNC Systems in Manufacturing

CNC systems are essential in manufacturing because they boost productivity, precision, and flexibility. By automating processes, they allow for the creation of complex geometries and intricate designs with consistent quality and reduced waste, minimizing human error.

Comparative Analysis: Precision and Durability

Precision is vital in industries such as aerospace and medical device manufacturing, where exact specifications are mandatory. High-end CNC systems achieve repeatability within ±0.002–0.005mm through advanced motion control technologies. Durability is determined by structural materials like cast iron or polymer composites and the design of components such as spindles and guideways. Robust designs ensure long-term operation with minimal maintenance, offering a reliable investment.

Software Integration and Automation

The integration of CNC systems with CAD/CAM software platforms enhances their functionality and flexibility, enabling seamless design-to-production workflows and efficient production cycles. Modern CNC systems include automation features like real-time adjustments and predictive maintenance, enhancing efficiency and minimizing downtime.

Emerging Trends in CNC Technology

CNC technology continues to evolve, driven by trends such as Industry 4.0, which emphasizes connectivity and data-driven manufacturing. Innovations like AI-driven optimization and modular spindles are paving the way for smarter, more adaptive systems, contributing to sustainable manufacturing practices by reducing energy consumption and material waste.

CNC Applications in Industry

CNC systems are essential in the aerospace industry for ensuring that components meet the precise tolerances and standards critical for flight safety. Components like turbine blades, fuselage parts, and landing gear must adhere to precise specifications, and CNC machines provide the necessary accuracy for these complex geometries, ensuring each part is produced with repeatable precision. Advanced CNC systems support multi-axis machining, enabling the creation of intricate designs and features that are essential for aerodynamic performance.

In the medical field, CNC machines are indispensable for producing high-precision devices such as surgical instruments, implants, and prosthetics. CNC machines enable the use of materials like titanium and surgical-grade stainless steel, which are safe for medical applications. The ability to maintain tight tolerances ensures that each medical component meets rigorous regulatory standards, contributing to effective and safe medical treatments.

In automotive manufacturing, CNC systems are used to produce a wide range of components. These include engine parts, transmission systems, and intricate body panels. CNC machines enable high-volume production with consistent quality, vital for automotive assembly lines. The flexibility of CNC systems allows for quick adaptation to new designs and specifications, supporting the industry’s demand for innovation and customization in vehicle production.

CNC machines play a crucial role in electronics manufacturing by precisely crafting circuit boards and enclosures, ensuring each component functions reliably. The high precision of CNC systems ensures the integrity of electronic components, which is crucial for functionality and reliability. CNC machining allows for rapid prototyping and the production of complex geometries, supporting the development of advanced electronics and consumer devices.

CNC systems are vital in the energy sector, particularly in the production of components for renewable energy technologies such as wind turbines and solar panels. These machines provide the precision necessary to manufacture parts that withstand environmental stressors and enhance energy efficiency. In the oil and gas industry, CNC machines produce robust components like valves and pipelines, capable of enduring harsh conditions and ensuring safe operations.

Leading CNC Machine Brands

Precision and innovation are crucial factors that define the market leadership of CNC machine brands. Each brand offers unique features tailored to different industrial needs.

Mazak stands out with its multi-tasking machines, particularly the INTEGREX series, which integrates various machining processes into a single setup to enhance productivity. Mazak’s global presence and continuous innovation reinforce its position as a leader in automation and general manufacturing.

DMG MORI excels in 5-axis machining, essential for industries like aerospace and automotive where complex geometries are prevalent. The brand’s CELOS software offers a user-friendly interface that makes machine operation simpler and integrates well with other digital tools. These innovations make DMG MORI a preferred choice for sectors demanding precision.

Trumpf specializes in laser CNC systems, making them ideal for sheet metal processing and applications that require Industry 4.0 standards. Their machines are engineered for high precision and productivity, ensuring minimal downtime through robust design and low maintenance needs, positioning Trumpf as a leader in sectors prioritizing precision and efficiency.

Haas Automation is known for its broad range of CNC machines that balance precision and affordability, making them popular among smaller-scale manufacturers and hobbyists due to their reliability and ease of use. Haas offers an extensive lineup catering to various needs, providing versatility in general manufacturing.

Okuma’s advanced CNC solutions are designed for precision and efficiency, capable of handling complex tasks with ease. The robust designs of Okuma machines ensure continuous operation without compromising precision, making them suitable for industries like automotive and aerospace that require high reliability and performance.

FANUC is a leader in robotics and CNC systems, offering high-precision solutions that are highly customizable. The brand’s focus on robustness and reliability ensures minimal downtime, critical for maintaining productivity in manufacturing environments. FANUC’s expertise in automation makes it a formidable choice for manufacturers aiming to integrate robotic systems.

Durability is a key consideration when selecting CNC machines, as it impacts long-term performance and maintenance requirements. Both Mazak and DMG MORI machines are built with high-quality components that withstand demanding environments, ensuring they remain operational over extended periods. These brands emphasize structural integrity, making them reliable investments for industries with rigorous production schedules.

Trumpf’s machines are designed for long-term performance with a focus on reducing maintenance needs, while Haas Automation provides durable components tailored to small-scale operations. Both brands address specific market segments, ensuring their machines are well-suited to different operational demands.

Okuma machines are engineered for continuous operation, prioritizing longevity through robust designs. FANUC products similarly focus on reliability, offering solutions that minimize production downtime. These features are particularly advantageous for sectors requiring sustained high-volume production.

Each CNC brand targets specific industries, aligning their features and capabilities with sector-specific requirements. Mazak, DMG MORI, and Okuma are heavily involved in aerospace and automotive manufacturing, where precision machining of complex parts is essential. Their machines offer the precision, durability, and advanced software integration necessary for these high-tech industries.

Brands like Haas Automation and FANUC cater to general manufacturing needs, providing versatile machines suitable for a range of applications. Their focus on affordability and reliability makes them accessible to a wide array of manufacturers, from hobbyists to large-scale operations.

Trumpf is particularly focused on sheet metal processing, with machines that integrate seamlessly with Industry 4.0 applications. This specialization makes Trumpf an ideal choice for manufacturers looking to enhance productivity through advanced laser technology.

Comparative Analysis of CNC Systems

When comparing CNC systems, precision and durability are crucial because they affect manufacturing quality and efficiency. Leading brands such as Mazak, DMG MORI, and Trumpf excel in precision capabilities, which are vital for industries demanding high accuracy. Mazak’s INTEGREX series, for instance, integrates multi-tasking capabilities to enhance precision. Similarly, DMG MORI is known for its 5-axis machining, which is indispensable in aerospace applications requiring precise measurements. Trumpf’s laser CNC systems deliver exceptional cutting accuracy, ideal for sheet metal processing.

Durability is equally important, ensuring long-term operation with minimal maintenance. Okuma is renowned for its robust machining centers, designed to withstand rigorous production demands. Makino offers high-end machines known for their sturdy construction, providing reliability over extended periods. Haas Automation also manufactures CNC machines celebrated for their durability, catering to both small-scale and industrial operations.

Spindle speed and axis configuration are vital aspects that impact machining capabilities and flexibility. High spindle speeds allow for efficient material removal, enhancing productivity in high-volume manufacturing, while multi-axis configurations enable complex geometries and detailed features. DMG MORI excels in 5-axis machining, offering unmatched precision and versatility, essential for intricate tasks in sectors like medical device manufacturing and electronics.

The integration of CNC systems with software platforms like CAD/CAM enhances functionality, streamlining design-to-production workflows. Modern CNC systems from Mazak and Trumpf include automation features that offer real-time adjustments and predictive maintenance, reducing downtime and improving efficiency. Software compatibility is crucial for seamless operation across different platforms, enabling manufacturers to optimize their processes. DMG MORI’s CELOS software provides a user-friendly interface, enhancing machine operation and integration with digital tools. Automation levels vary among brands, with some systems offering advanced features that support modern manufacturing standards, promoting connectivity and data-driven production.

Choosing between automated and manual systems hinges on the unique requirements of your manufacturing operations. While manual systems might have lower upfront costs, they often demand more labor and may not achieve the same precision in complex tasks as automated systems. Automated CNC systems offer numerous advantages, including increased productivity, reduced labor costs, and enhanced precision. Brands like Mazak and FANUC provide automated solutions that integrate robotics, further boosting efficiency and minimizing human error.

Exploring CNC System Components

Key Components of CNC Systems

CNC systems are a cornerstone of modern manufacturing, providing precision and automation. Their performance and reliability depend significantly on several critical components. Understanding these components helps in choosing the right system for specific manufacturing needs.

Servo Mechanism

In CNC systems, the servo mechanism is crucial for precise motion control. It converts electrical signals into precise movements, ensuring that the machine operates with high accuracy. Servo motors are preferred for their ability to provide consistent torque and speed, which are crucial for maintaining the tight tolerances required in high-precision applications.

Ball-Screw

Ball-screws are integral to CNC systems, converting rotational motion into linear motion with high efficiency. They are preferred for their low friction and high precision, making them ideal for high-precision applications. The choice of ball-screw can significantly affect the machine’s performance, influencing factors such as repeatability and positioning accuracy.

Gantry Systems

Gantry systems in CNC machines support large work areas, enabling the machining of sizable components. They provide stability and rigidity, which are vital for maintaining precision over extended distances. Gantry systems are particularly beneficial in industries that require machining of large parts, such as aerospace and automotive sectors.

Water-Cooled Systems

Water-cooled systems are employed in CNC machines to manage the heat generated during operation. They help maintain optimal temperatures, preventing thermal deformation that could affect machining precision. They are particularly beneficial in high-speed machining, where excessive heat can cause tool wear and lower accuracy.

Comparative Analysis of CNC System Components

Understanding the strengths and weaknesses of CNC system components is crucial when making comparisons. Servo mechanisms, for example, offer superior control and precision, making them ideal for applications requiring intricate detailing. In contrast, systems with less advanced motion control may struggle to achieve the same level of detail.

Ball-screws, while more expensive than other linear motion components, provide unmatched accuracy and longevity, justifying their cost in applications where precision is non-negotiable. Comparatively, less precise alternatives might be sufficient for applications with more relaxed tolerance requirements but could compromise quality in high-precision settings.

Gantry systems offer the advantage of supporting larger workpieces without sacrificing accuracy. However, they require more space and can be more costly to implement. For industries where space is at a premium, or where large workpieces are not a factor, a different configuration might be more practical.

Water-cooled systems provide an effective solution for heat management, extending the life of the machine and tools. However, they add complexity and maintenance requirements compared to air-cooled systems, which might be preferable in less demanding applications. Selecting between these options depends on the specific heat management needs of the operation.

Technical Specifications and Standards

Technical Specifications of CNC Systems

Understanding the technical specifications of CNC systems is crucial for selecting the right equipment for specific manufacturing needs. These specifications determine the system’s capability to meet precision requirements and its durability under operational stress.

Precision Parameters

Precision in CNC systems refers to how accurately and consistently they can produce parts to specific measurements. For instance, CNC lathe systems commonly achieve tolerances within ±0.005 mm, making them suitable for creating cylindrical components like shafts and gears. Live tooling capabilities make it easier to perform multiple operations like turning and drilling, boosting precision. In contrast, 5-axis CNC machines, renowned for their complexity in aerospace and medical device manufacturing, achieve tolerances of ≤0.01 mm. This capability is enhanced by dynamic error correction systems that ensure accuracy in complex geometries.

Durability Features

Durability in CNC systems is primarily defined by the construction materials and design features that contribute to long-term performance. Brands like Mazak and DMG MORI use high-rigidity cast iron construction. This design choice ensures stability, reduces vibration, and enhances machine life during mass production. Similarly, hardened linear guides and vibration-dampening bases, typical in 5-axis CNC machines like those from Makino, further enhance durability during high-speed machining operations. Multi-tasking CNC machines, such as the Okuma MULTUS U3000, incorporate modular designs with automatic tool changers to reduce wear and facilitate high-mix production, ensuring minimal downtime and extended operational life.

Compliance with Standards

Following international standards is crucial for making sure CNC systems are reliable and safe. These standards outline how CNC systems should ensure accuracy, manage temperature changes, and maintain safety during complex operations.

Key Standards

- ISO 10791-7: Specifies the geometric accuracy requirements for CNC lathe systems, ensuring precise machining.

- ISO 230-2: Focuses on thermal compensation, which is critical for maintaining precision despite temperature fluctuations during operation.

- ASME B5.54: Provides volumetric accuracy guidelines for 5-axis CNC machines, essential for producing complex components with high precision.

- ISO 16090-1: Addresses safety requirements for multi-tasking environments, ensuring the safe integration of milling and turning operations.

- ISO 9013: Pertains to cut edge quality assessments for CNC plasma cutters, crucial for evaluating kerf accuracy in sheet metal processing.

These standards are integral to the design and function of CNC systems, ensuring they meet industry-specific requirements for precision and durability. Compliance not only enhances operational efficiency but also aligns with global manufacturing standards, promoting interoperability and quality assurance across diverse applications.

Maintenance Best Practices

Daily Maintenance Routine

A daily maintenance routine is crucial for keeping CNC machines running smoothly. This routine involves checking for wear or damage, ensuring safety guards are intact, and verifying fluid levels like lubricants and coolants. Regular cleaning of debris and inspection of air filters also help prevent potential malfunctions, maintaining the machine’s precision and efficiency.

Weekly Inspection Protocols

Focus on detailed checks during weekly inspections. Examine way covers and bellows for damage, clean and inspect the spindle and taper to maintain machining accuracy, and check electrical connections to ensure a consistent power supply.

Monthly Maintenance Tasks

Monthly maintenance involves thorough checks and adjustments. Calibrate machine axes for precision, lubricate moving parts to reduce wear, and inspect the coolant system to prevent overheating.

Quarterly System Checks

Quarterly inspections are critical for maintaining the long-term health of CNC systems:

- Inspect ball screws and linear guides for wear.

- Replace worn parts as needed to prevent disruptions.

- Update software for enhanced performance and security.

Regular Cleaning and Lubrication

Regular cleaning and lubrication are indispensable for the longevity of CNC systems. Using compressed air cautiously to clean dust and debris from interior components like guide rails and circuit boards ensures that the machine operates efficiently. Applying lubricants reduces wear on moving parts, contributing to the machine’s precision and extending its service life.

Precision and Durability Considerations

Precision and durability in CNC systems vary by brand. Haas, DMG Mori, and Okuma require regular calibration for high precision, while Fanuc and Siemens benefit from consistent maintenance to ensure long-term reliability.

Industry 4.0 Integration Benefits

Industry 4.0 has transformed CNC manufacturing by incorporating advanced technologies like IoT, AI, and predictive analytics. These innovations significantly enhance precision, durability, and efficiency across various CNC systems.

Automation and connectivity are key components of Industry 4.0, allowing IoT and sensor technologies to facilitate real-time monitoring and control. This seamless integration minimizes manual intervention, resulting in higher precision and consistency in machining processes. Additionally, predictive maintenance leverages IoT sensors and data analytics to anticipate potential machine breakdowns, reducing unplanned downtime and maintenance costs. By scheduling maintenance during less critical periods, machine lifespans are extended, and durability is enhanced.

Real-time quality checks are possible with automated systems, thanks to Industry 4.0. These systems enable immediate detection of defects, maintaining high precision and quality standards. Continuous monitoring improves product quality and reduces the need for costly post-manufacturing inspections.

Smart sensors and energy management systems help use resources efficiently, cutting down energy consumption and reducing environmental impact. Data from IIoT sensors ensures CNC machines operate at peak efficiency, decreasing waste and improving productivity.

With IoT integration, machines can easily adapt to new designs or specifications, meeting the demand for customized products without losing efficiency. This flexibility is crucial for addressing modern market demands for tailored products.

Leading CNC systems integrate Industry 4.0 technologies to enhance precision and durability:

- Haas Automation utilizes advanced sensor feedback for real-time machining adjustments, while IoT-driven predictive maintenance extends machine lifespan.

- DMG MORI offers high-speed machining with precision spindle technology, supported by integrated IoT solutions for proactive maintenance.

- Okuma Corporation employs AI-driven optimization for precise cutting conditions, with monitoring systems that detect wear to enhance durability.

- Fanuc benefits from real-time monitoring through IoT platforms, where predictive analytics improve overall machine durability.

- Mazak Corporation focuses on real-time quality assurance with automated inspection systems, ensuring consistent performance and reduced wear.

Industry 4.0 integration not only boosts machine performance but also provides economic and environmental benefits through energy efficiency and customization capabilities.

Frequently Asked Questions

Below are answers to some frequently asked questions:

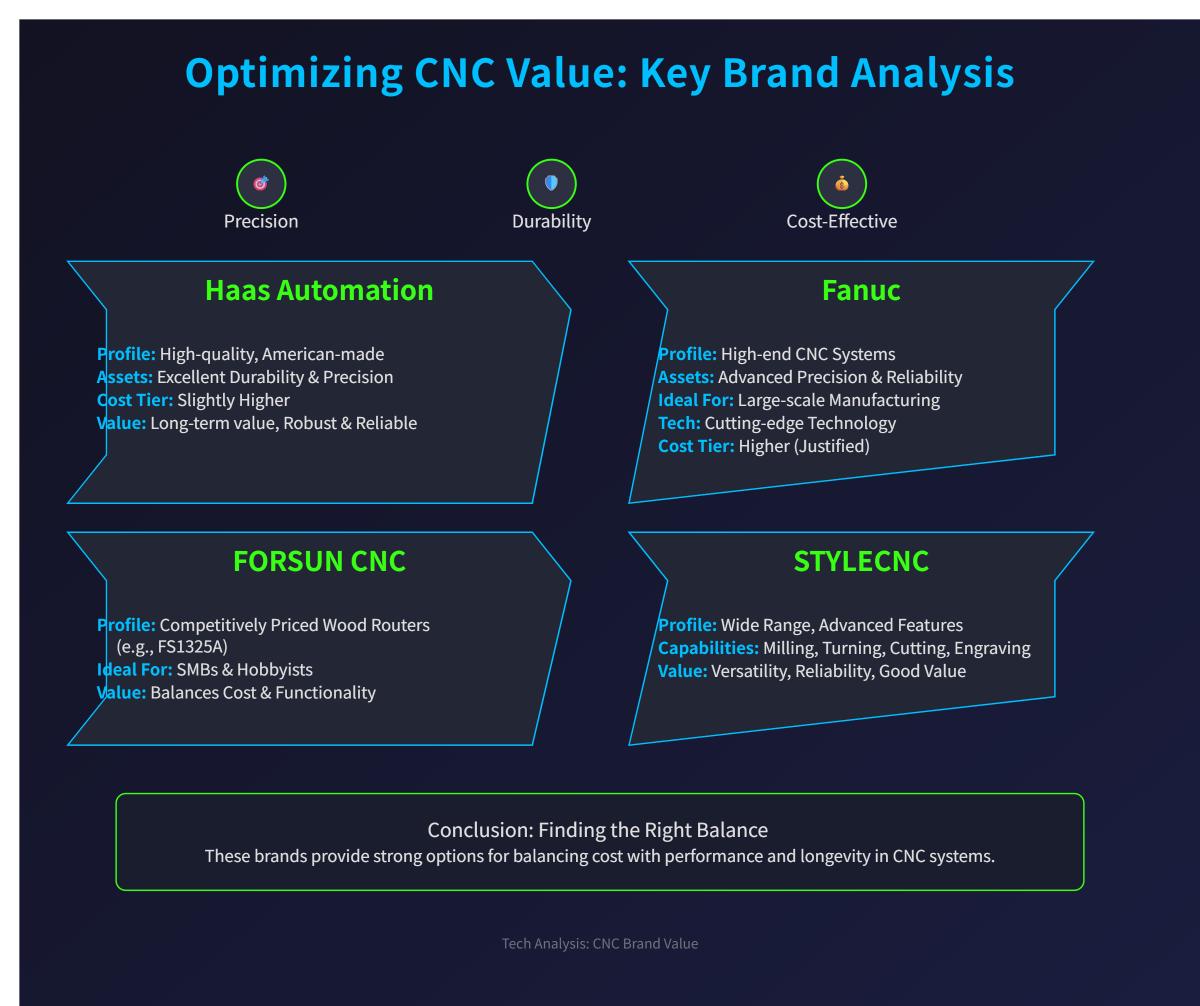

Which CNC brands offer the best value for money?

When evaluating CNC brands for the best value, it is essential to consider precision, durability, and cost-effectiveness. Haas Automation, Fanuc, FORSUN CNC, and STYLECNC stand out in this regard.

Haas Automation is renowned for its high-quality, American-made machines that provide excellent durability and precision. Although their products are slightly more expensive, they offer significant long-term value due to their robust build and reliability.

Fanuc is known for high-end CNC systems with advanced precision and reliability, making them ideal for large-scale manufacturing. Their machines provide excellent durability and cutting-edge technology, justifying their higher price point.

FORSUN CNC offers competitively priced wood CNC routers like the FS1325A, suitable for small to medium-sized businesses or hobbyists. Their machines strike a good balance between cost and functionality.

STYLECNC provides a wide range of CNC machines with advanced features for precise milling, turning, cutting, and engraving. Their machines are well-regarded for versatility and reliability, offering good value across various applications.

By focusing on these brands, businesses can find CNC systems that offer the best value, balancing cost with performance and longevity.

What are the key differences between high-end and budget CNC systems?

High-end CNC systems and budget CNC systems differ primarily in precision, durability, production speed, and cost-effectiveness. High-end systems are engineered to maintain tight tolerances and offer consistent accuracy, which is crucial in demanding environments like aerospace or medical device manufacturing. They are constructed with superior materials and robust engineering, making them more reliable and less prone to breakdowns, thereby minimizing downtime and maintenance costs. These systems also feature high-torque motors that enable faster cutting speeds without compromising precision, enhancing overall production efficiency.

In contrast, budget CNC systems may offer initial cost savings but often struggle to maintain accuracy over extended use, leading to inconsistent product quality and increased waste. Their durability is typically lower, requiring more frequent maintenance and part replacements, which can increase long-term costs. Additionally, budget systems might necessitate additional processing steps, such as sanding or finishing, thereby extending production time and labor costs. While high-end systems have higher upfront costs, they provide better long-term value through reduced waste and labor costs, consistent quality, and comprehensive manufacturer support.

How do I choose the right CNC system for medical device manufacturing?

To choose the right CNC system for medical device manufacturing, prioritize precision and compliance with industry standards. Medical devices require high accuracy due to stringent tolerances, making precision control a critical feature of any CNC system. Look for systems that offer multi-dimensional precision control to ensure components are produced with exact specifications. Compliance with ISO 13485 and ISO 9001 standards is essential, as these certifications ensure adherence to quality management systems tailored for medical devices. Additionally, material versatility is crucial; the CNC system should be capable of handling medical-grade materials such as PEEK and stainless steel. Production efficiency and flexibility are also vital, enabling quick adjustments and fast turnaround times to meet project deadlines without compromising quality. By focusing on these factors, you can ensure the CNC system chosen will meet the demanding requirements of medical device manufacturing effectively.

What are the benefits of Industry 4.0 integration in CNC systems?

Integrating Industry 4.0 technologies into CNC systems offers substantial benefits, enhancing both precision and durability. The real-time monitoring and control capabilities enable manufacturers to optimize operations, resulting in increased productivity and reduced waste. By employing predictive maintenance, CNC systems can minimize unplanned downtime, thus improving machine durability. Additionally, the use of IoT connectivity allows for smart energy management, reducing operational costs and environmental impact. Industry 4.0 integration also enhances product quality through real-time data analysis and quality assurance, ensuring compliance with strict standards. Furthermore, the flexibility provided by AI and machine learning allows CNC systems to adapt quickly to new specifications, enabling customization without sacrificing efficiency. These advancements collectively contribute to improved safety, faster response times, and better decision-making processes, offering a competitive edge in the manufacturing sector. Overall, Industry 4.0 integration transforms CNC systems into more efficient, reliable, and adaptable tools for modern manufacturing challenges.

How can I assess the total cost of ownership for CNC systems?

To assess the total cost of ownership (TCO) for CNC systems, you need to evaluate several critical factors beyond the initial purchase price. Start by considering the initial costs, including the purchase price of the CNC machine, transportation, installation, and any necessary facility modifications. Operational costs are another significant component, encompassing energy consumption, tooling, consumables like coolants, and raw material expenses.

Maintenance and repair costs are crucial, comprising both scheduled maintenance to ensure efficiency and unexpected repairs, especially post-warranty. Training and labor costs should not be overlooked; these include operator training, as well as the expenses for employing or training programmers and maintenance staff. Depreciation and resale value also play a role in TCO, reflecting the machine’s declining value over time and potential resale income.

Additionally, software upgrades and potential downtime costs must be factored in. Regular software updates are necessary to maintain efficiency and compatibility, and any machine stoppages can result in significant financial losses. By integrating these factors into your analysis, you can comprehensively compare CNC systems’ precision, durability, and overall cost-effectiveness, aiding in informed decision-making aligned with your manufacturing and financial goals.